Packaging method of soft-packaged lithium ion battery

A technology of lithium-ion batteries and packaging methods, which is applied in the manufacture of secondary batteries, non-aqueous electrolyte batteries, electrolyte batteries, etc., can solve the problems of difficult extraction of micro-bubbles, leakage of electrolyte, and no mention of micro-bubbles, etc., to achieve improved Packaging efficiency and packaging quality, improving yield and battery quality, and improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

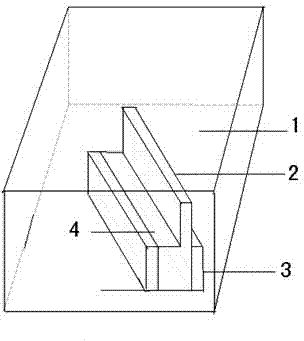

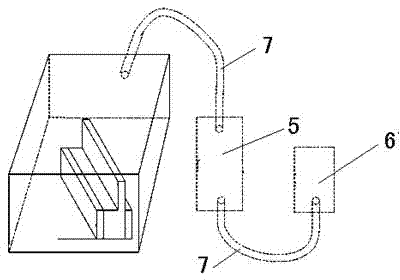

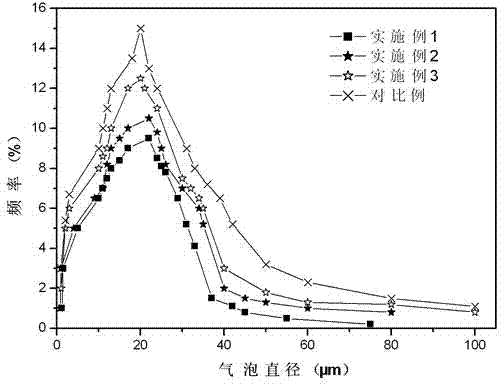

[0025] Depend on figure 1 , figure 2 Known, a kind of encapsulation method of flexible packaging lithium-ion battery comprises the following steps: first put the battery 2 to be tested into the air bag and place it on the battery fixing splint 3 in the final sealing machine with the air bag facing up. ; Heating the battery fixing splint 3 and the battery to be tested at 2 to 50°C; then, place the packaged battery 2 and the battery fixing splint 3 in the air extraction device 4, and send them together into the vacuum chamber 3, and pierce the air bag with a bayonet. And adopt vacuum pump 6 and vacuum buffer device 5 to control the degree of vacuum and the vacuum time in the vacuum chamber 1, vacuumize the vacuum chamber 1 with five times of vacuuming, wherein the vacuuming mode is: the first time of vacuuming is 30 seconds, The standing time is 60 seconds, the second vacuuming time is 28 seconds, the standing time is 56 seconds, the third vacuuming time is 26 seconds, the sta...

Embodiment 2

[0027] First put the packaged battery 2 into the air bag and clamp it on the battery fixing splint 3 in the air pump 4 with the air bag facing upward; heat the battery fixing splint 3 to 40°C; then, pack the battery 2 and the battery The fixed splint 3 is placed in the air pumping device 4, and one piece is sent into the vacuum chamber 3, the air bag is pierced with the bayonet 4, the vacuum degree and time are controlled by the vacuum pump 6 and the vacuum buffer device 5, and the vacuum chamber 1 is pumped three times. Vacuuming in vacuum mode, where the vacuuming method is: the first vacuuming time is 20 seconds, the resting time is 100 seconds, the second vacuuming time is 19 seconds, the resting time is 96 seconds, and the vacuuming time is decreased by 1 second in turn , the resting time is 5 times of the vacuuming time, and finally, the packaged battery 2 is heat-sealed with a soft-seal heat-seal jig, thereby completing the exhaust packaging process of the battery to be ...

Embodiment 3

[0029] First put the packaged battery 2 into the air bag and clamp it on the battery fixing splint 3 in the air pump 4 with the air bag facing up; heat the battery fixing splint 3 to 80°C; then, pack the battery 2 and the battery The fixed splint 3 is placed in the air pumping device 4, and one piece is sent into the vacuum chamber 3, the air bag is pierced with a bayonet, and the vacuum pump 6 and the vacuum buffer device 5 are used to control the vacuum degree and time, and the vacuum chamber 1 is vacuumed three times. Vacuuming method, wherein the vacuuming method is: the first vacuuming time is 20 seconds, the resting time is 100 seconds, the second vacuuming time is 19 seconds, the resting time is 96 seconds, and the vacuuming time is decremented by 1 second. The resting time is 5 times of the vacuuming time, and finally, the battery 2 is heat-sealed with a soft-sealing heat-sealing jig, thereby completing the exhaust packaging process of the battery to be packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com