Soft packed battery tab welding method

A technology for tab welding and flexible packaging of batteries, which is applied to battery pack components, circuits, electrical components, etc., and can solve problems such as low automation, increased battery volume, and foil deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution will be further described below through implementation examples and in conjunction with the accompanying drawings.

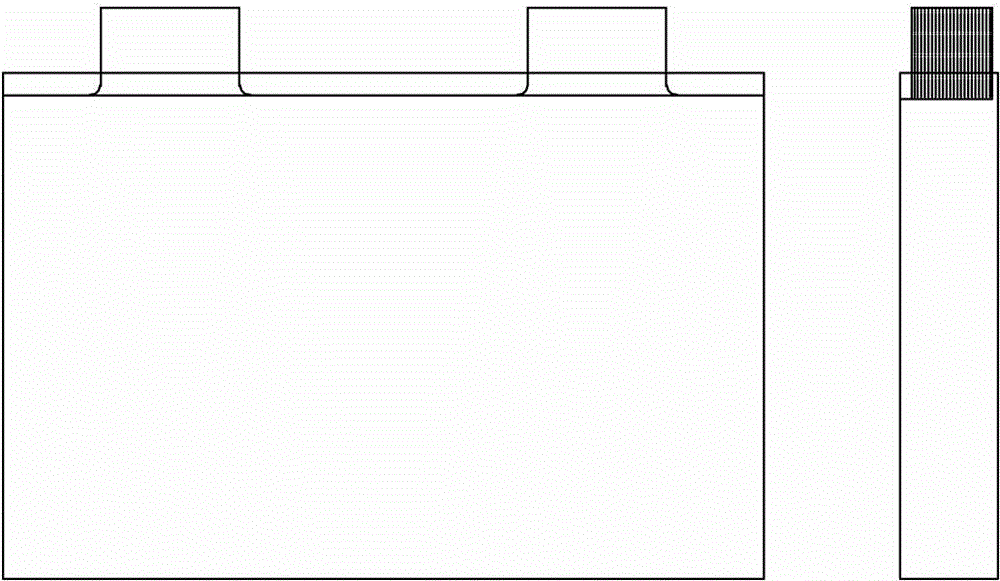

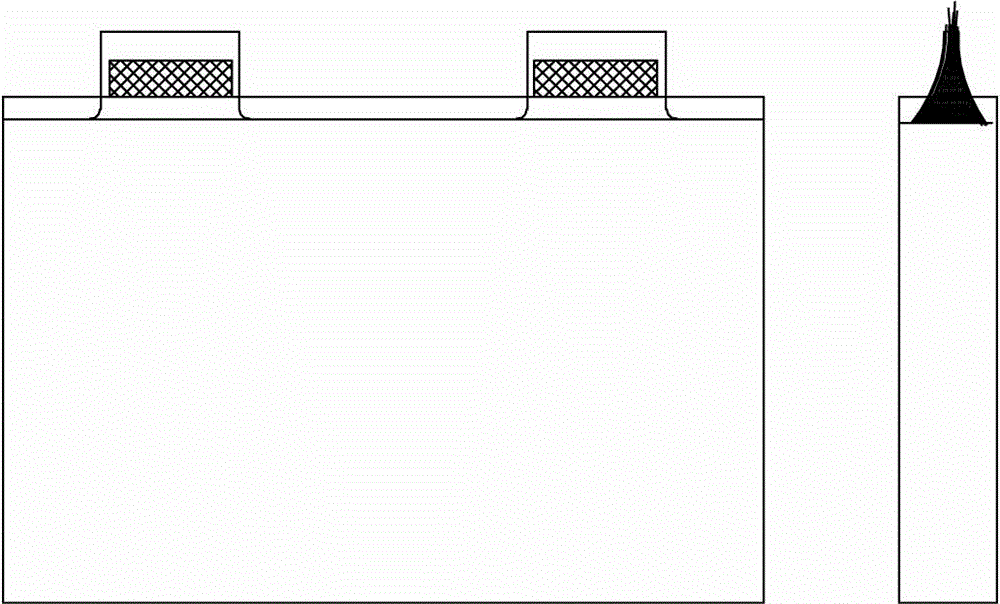

[0020] A method for welding tabs of soft-packaged batteries, first of all, the raw battery cells (structures such as figure 1 shown) for ultrasonic pre-welding. The schematic diagram of the cell structure after ultrasonic pre-welding of the cell is as follows figure 2 shown. Then, bend the soldered end of the tab with glue 90 degrees,

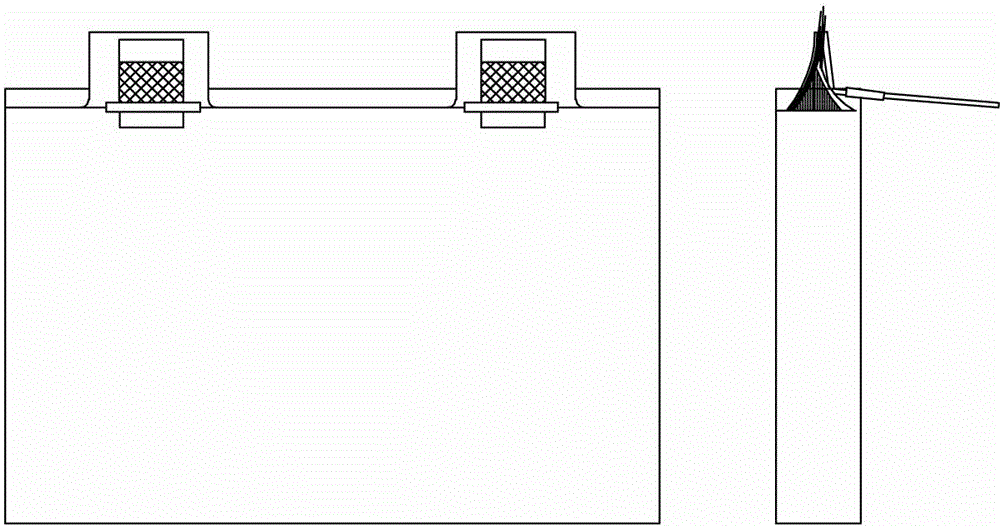

[0021] Ultrasonic welding the bent tabs with glue to the pre-welded exposed cell foil, the structure after welding is as follows image 3 shown.

[0022] Then, cut the tabs with glue and the cell foil together, and the structure of the cell after cutting is as follows Figure 4 shown. Finally, just flatten the tabs with glue, and the final cell structure is as follows Figure 5 shown.

[0023] The incoming battery cell is a laminated battery cell, and the glued tab is one of an aluminum tab ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com