Large soft pack lithium ion battery and preparation method thereof

A technology of lithium-ion batteries and ion batteries, which is applied in the manufacture of electrolyte batteries, large-sized batteries/battery packs, battery pack components, etc., can solve the problem of low stability, poor flatness, and large soft-pack lithium-ion battery production costs Advanced problems, to achieve the effect of good flatness, low cost, improved stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

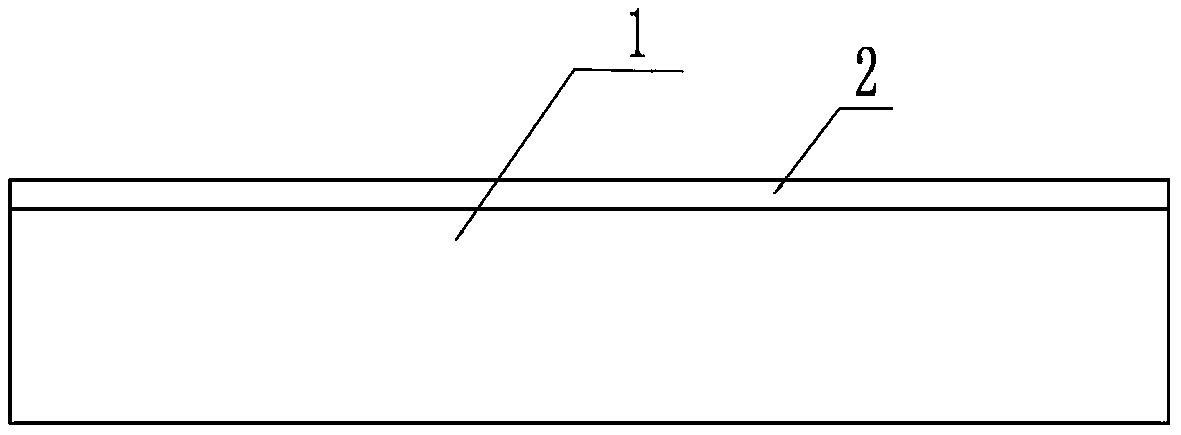

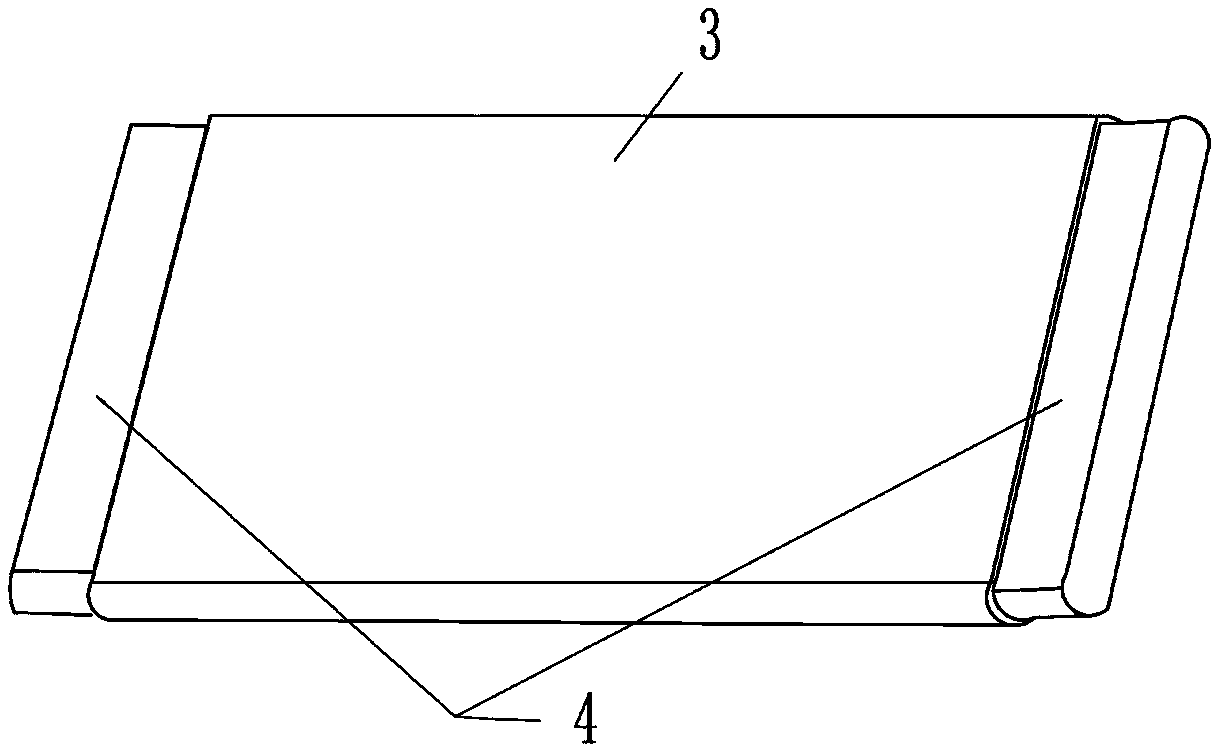

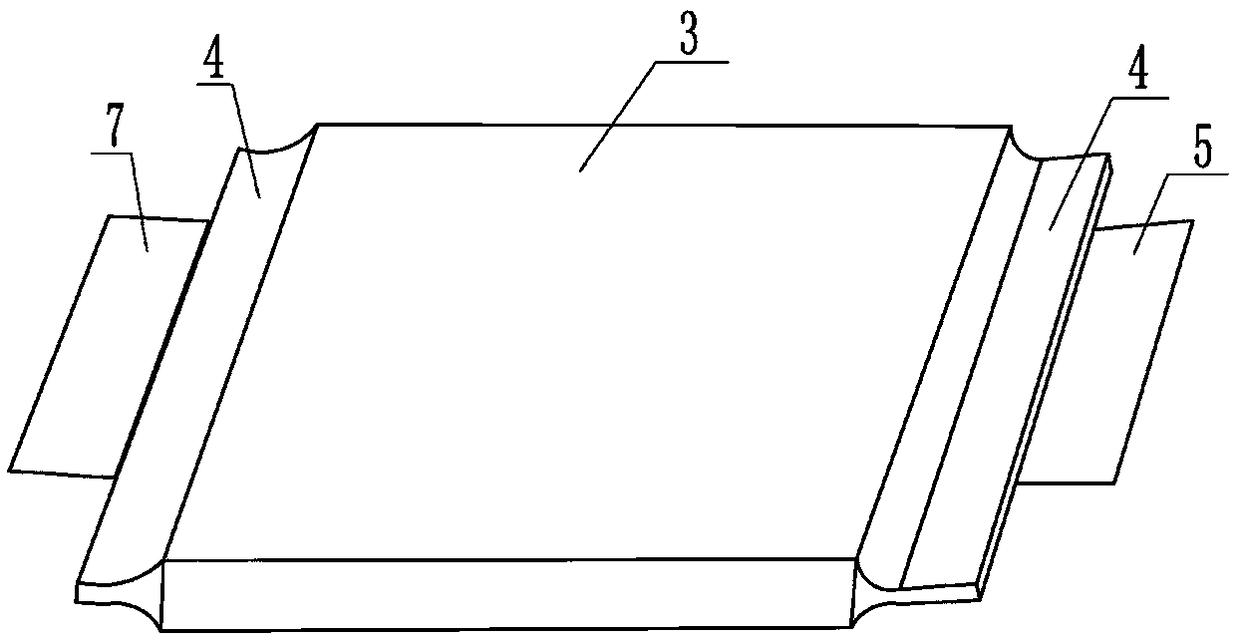

[0029] Such as Figure 5 Shown is the composition of a preferred embodiment of a large soft pack lithium-ion battery provided by the present invention. The large soft-packed lithium-ion battery includes: at least one full-tab winding core 3, and an insulating gasket 6 is correspondingly provided at the tab welding area 4 of the full-tab winding core, so that the tab welding area The overall thickness of 4 is consistent with the thickness of the main body of the full tab winding core 3 . The thickness of the large soft pack lithium-ion battery can be greater than 10.0mm. There can be two to six all-tab winding cores 3 . The insulating gasket 6 can be selected from one of polyethylene, polypropylene, polyimide, silica gel, polyvinyl alcohol or polypropylene alcohol. In this embodiment, the large soft-packed lithium-ion battery is formed by stackin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com