Pole lug packing structure and soft-packing battery

A packaging structure and soft-pack battery technology, applied in structural parts, battery pack parts, circuits, etc., can solve problems such as leakage, hardening of the overflowing glue block, and uneven surface, so as to suppress the edge resistance from being too low and improve the stress. Effects of concentration problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present application will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings. The "front", "rear", "left", "right", "upper" and "lower" mentioned in the text are all referred to the tab package structure or wound battery core in the drawings.

[0048] The embodiment of the present application provides a pouch battery, a tab packaging structure 1 and a packaging bag 2 , of course, in order to provide electric energy, it also includes a bare cell composed of a pole piece and a separator. The tab packaging structure 1 and the packaging bag 2 together form a sealed structure, which encapsulates the bare cell and the electrolyte inside.

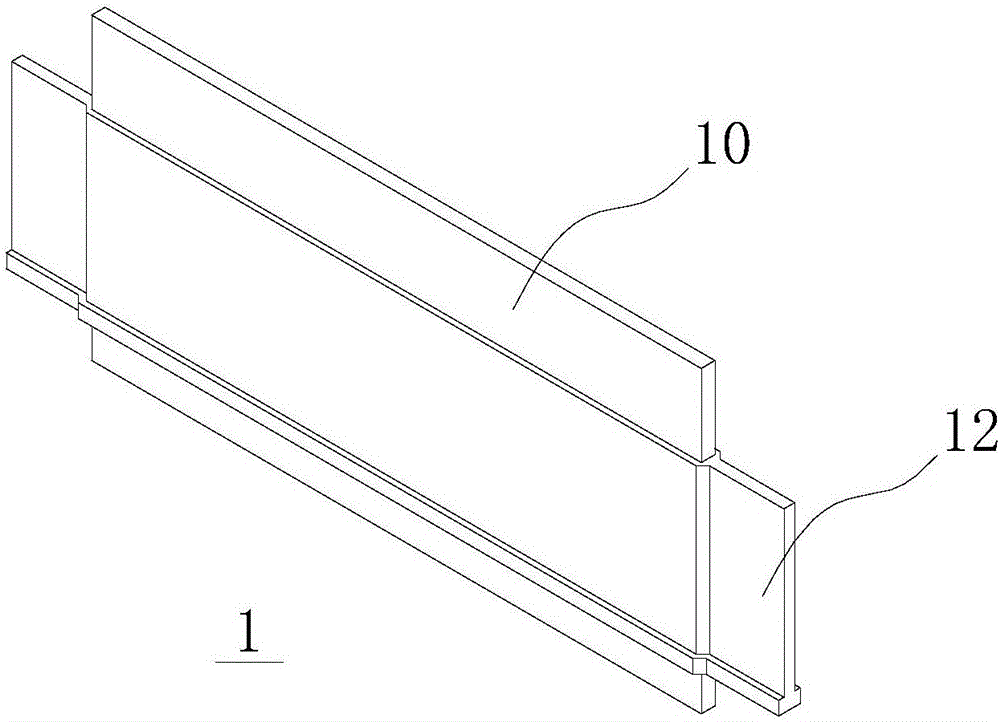

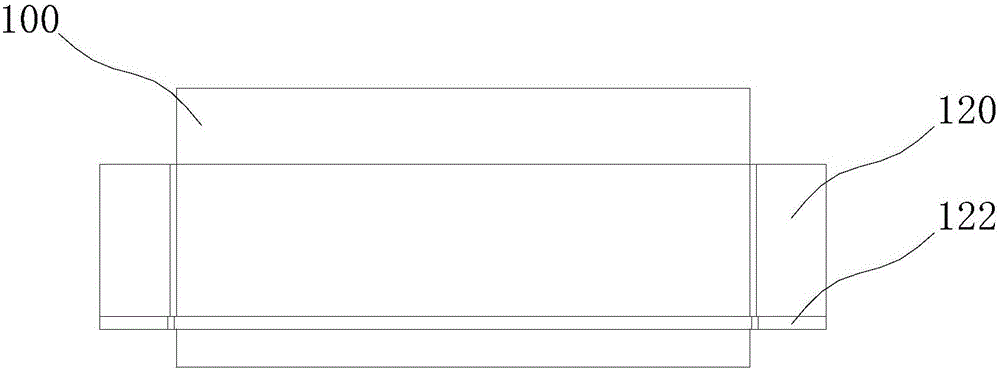

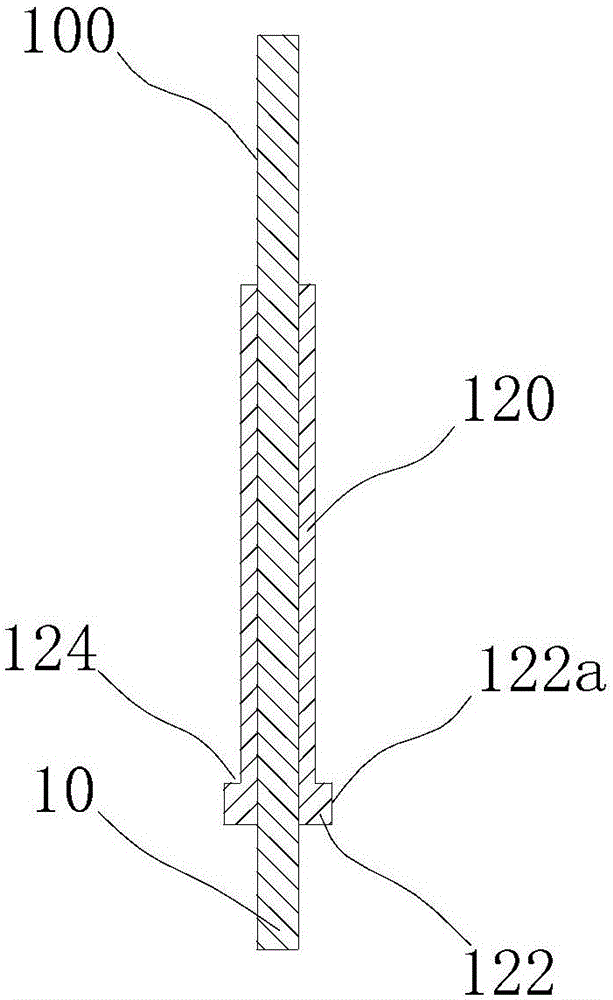

[0049] Such as figure 1 As shown, the tab packaging structure 1 includes a tab piece 10 and two tab glue layers 12 . The tab piece 10 is used to derive electrical energy from the pole piece (not shown in the figure) of the pouch battery. Therefore, in the pouch battery, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com