Soft-packed battery module and assembling method thereof

A technology of soft-pack batteries and modules, which is applied to battery pack parts, batteries, secondary batteries, etc., can solve the problems of inability to install modules and pre-tighten, avoid inconvenient installation and ensure reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

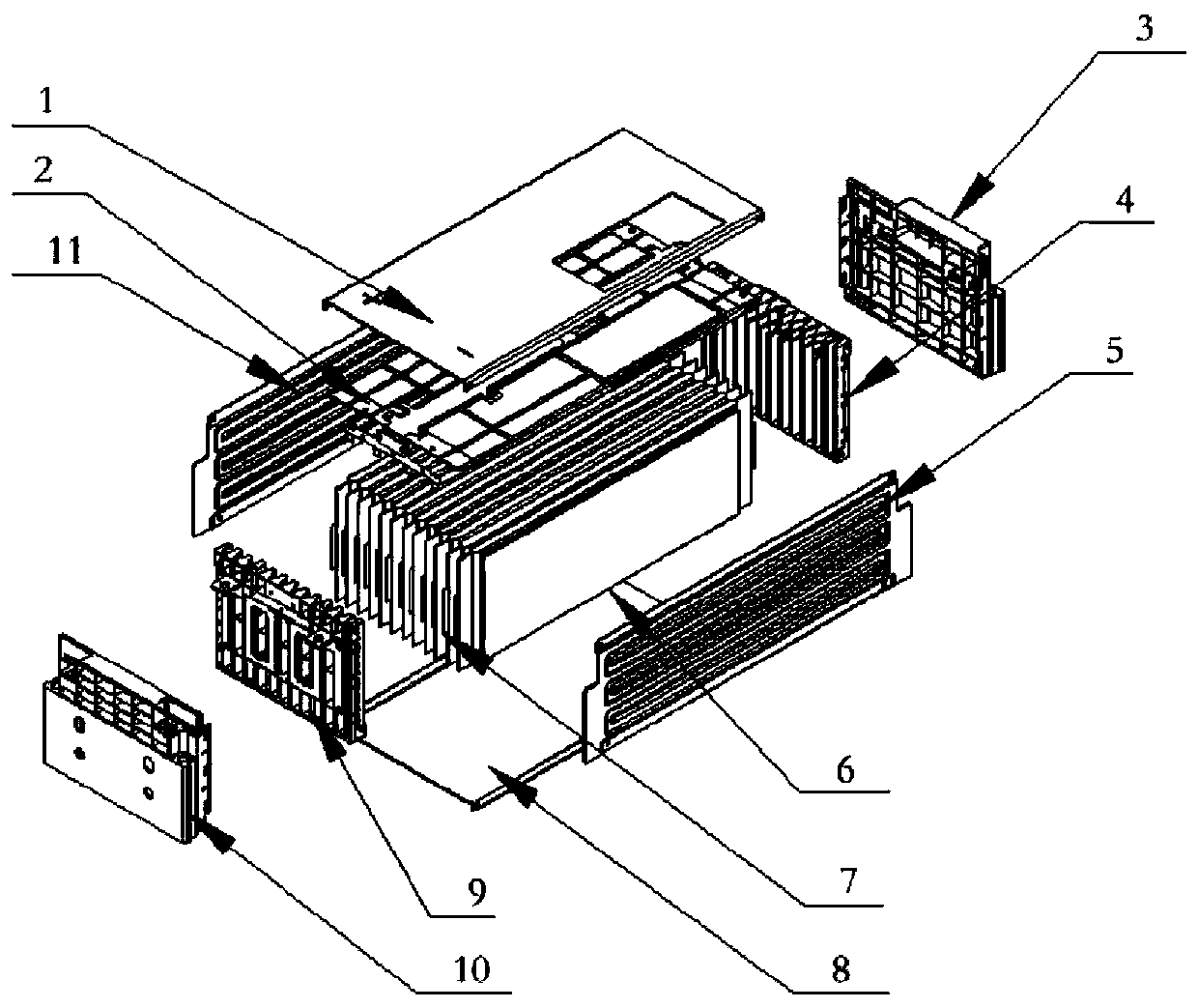

[0075] This embodiment provides a soft pack battery module, specifically a detachable module, the explosion diagram of which is shown in figure 1 As shown, the soft-pack battery module includes a cell group 7, left and right side plates, upper and lower cover plates, and front and rear side plates arranged outside the cell group 7;

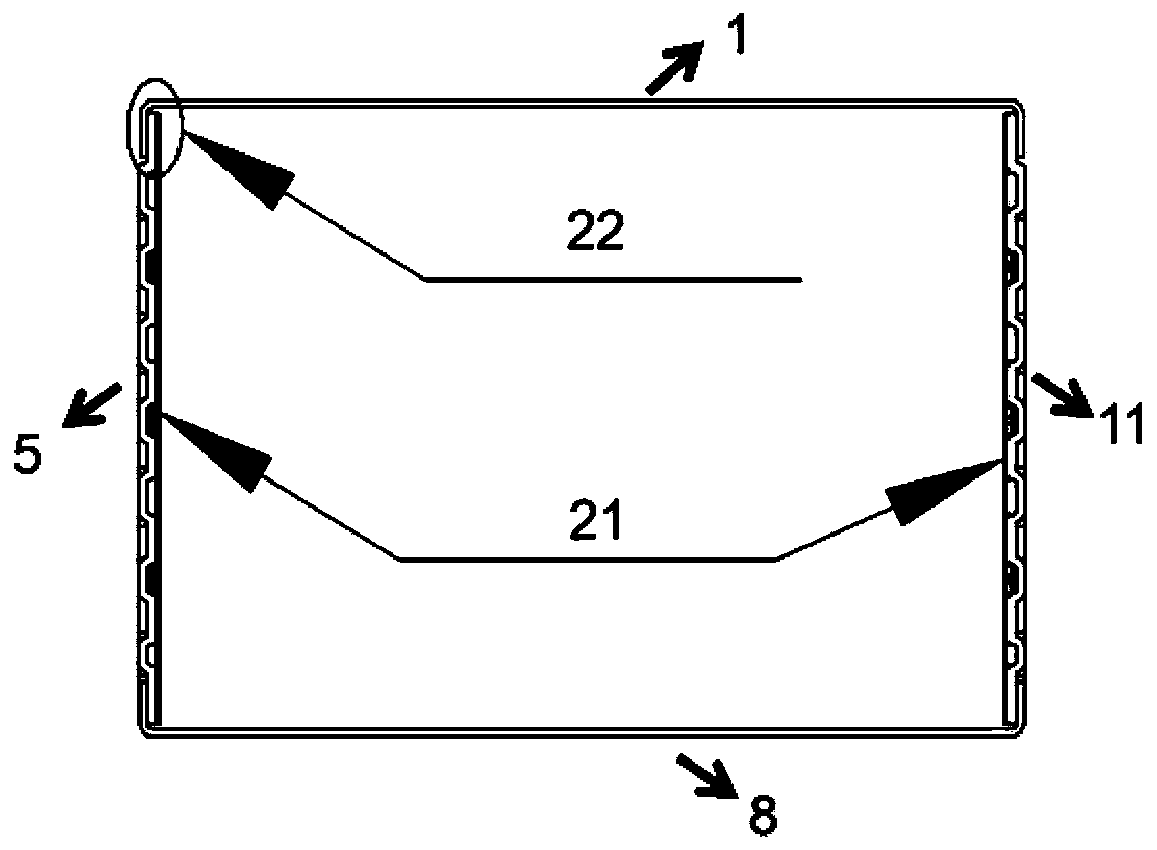

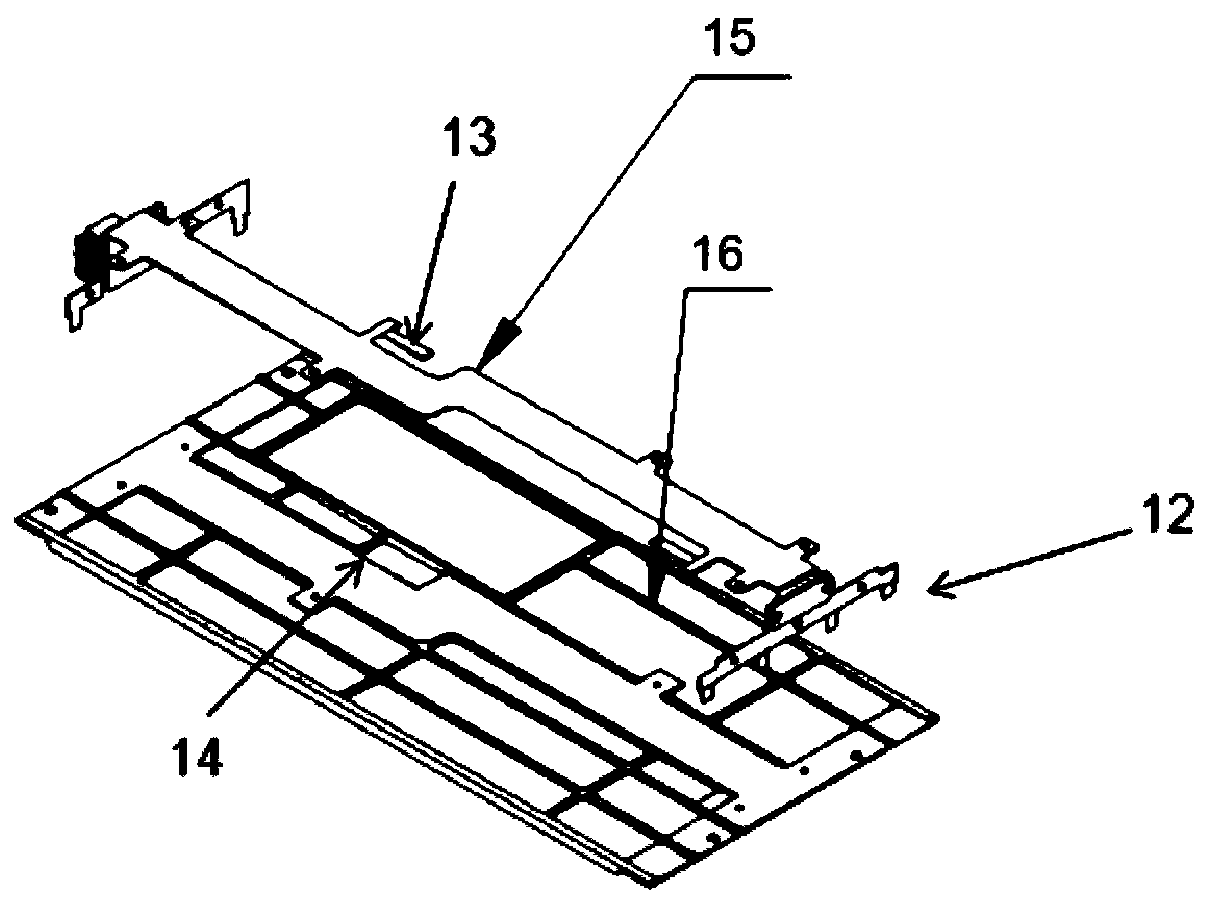

[0076] The left and right side plates include a left side plate 11 and a right side plate 5 arranged oppositely, the upper and lower cover plates include an upper cover plate 1 and a lower cover plate 8 arranged oppositely, and the front and rear side plates include: a front end cover arranged oppositely Assembling board 10 (structural schematic diagram sees Figure 5 ) and rear end cover assembly plate 3, and the front cover plate assembly plate 9 of opposite arrangement (structural schematic diagram sees Figure 4 ) and a rear cover assembly plate 4, and the front cover assembly plate 9 and the rear cover assembly plate 4 are respectively locat...

Embodiment 2

[0087] This embodiment provides a method for assembling the pouch battery module described in Embodiment 1, including the following steps:

[0088] (1) Module design

[0089] This embodiment uses the VDA355 module, the module size is: 355×151×108.5mm, the battery size is: 310×102×11mm; the thickness of all batteries: 11×12=132mm, other parts (heat shield and Glue) sum of thickness: 9mm.

[0090] (a) Use the battery cell detection device to test the cell preload F and cell expansion space The best pre-tightening force F of the measured cell is 30KPa and the expansion space of the cell is 5%.

[0091] (b) According to the pressure-strain curve curve of the selected foam material (this embodiment selects PU) as Figure 6 As shown (the ordinate is the stress, and the abscissa is the strain), it is determined that when the pressure of the foam is 30KPa, the pre-tightening compression x% of the foam is 15%, and with the use of the battery, the cell will gradually expand to T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com