Judgment method for cold welding defects of electrofusion joints

A technology of electrofusion joint and determination method, which is applied in the direction of analyzing solids by using sonic/ultrasonic/infrasonic waves, can solve the problem of difficulty in implementing the cold welding determination method, and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

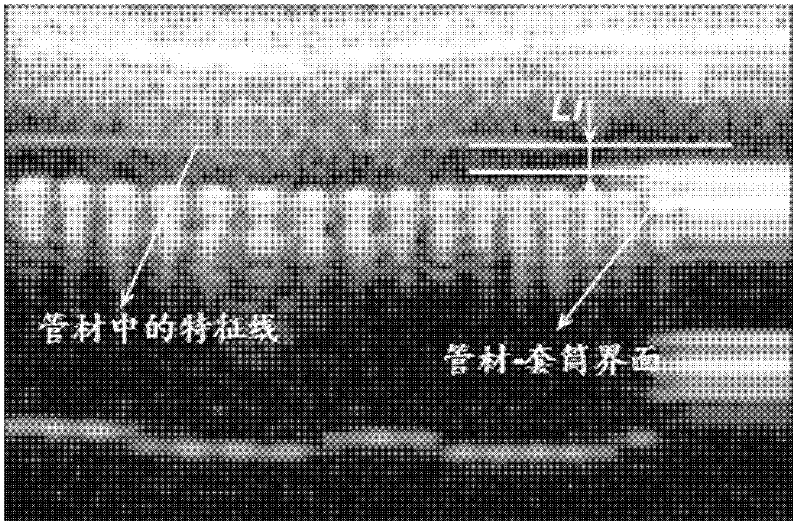

[0028] 1) Use an ultrasonic phased array detection imaging instrument to detect from the inner surface of the pipe where the electrofusion joint is welded, and adjust the gain and interface coupling conditions until the ultrasonic detection map is obtained (such as figure 1 shown);

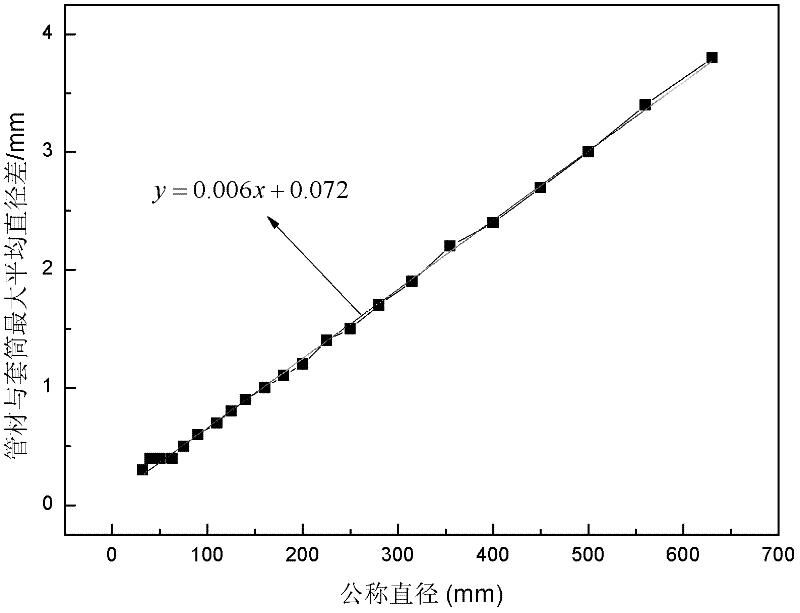

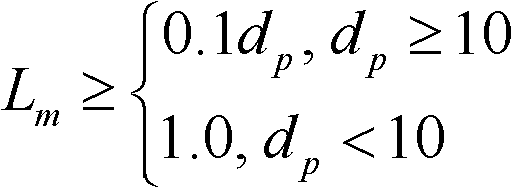

[0029] 2) The distance L between the characteristic line in the measurement diagram and the pipe-sleeve interface i (mm): The specific method is to measure the number of pixels between adjacent coils of the resistance wire in the image as N j , measure the number of pixels N between the feature line and the pipe-sleeve interface in the image L , then the distance L between the feature line and the pipe-sleeve interface i Calculate according to the following formula:

[0030] L i = N L N j · L j

[0031] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com