Deformable welding fixture for plate splicing welding with linear and curved weld seams

A technology for welding fixtures and straight line welds, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., and can solve problems such as inability to realize curved weld seam welding, cumbersome clamping and positioning of tailored welded blanks, and poor heat dissipation during welding. , to prevent deformation and distortion, facilitate clamping, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

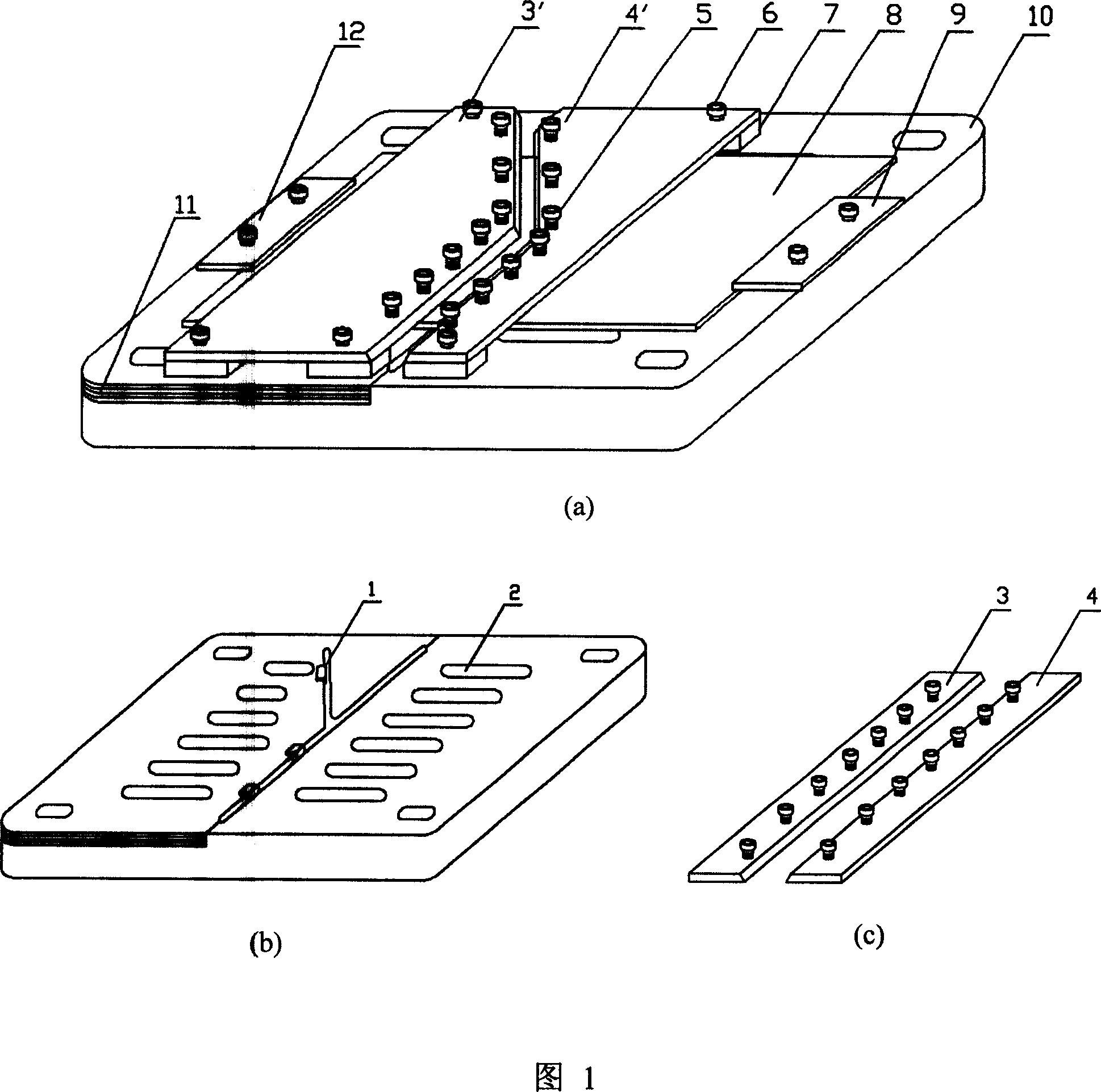

[0029] Taking the welding of curved seams as an example, the details and working conditions of the specific device proposed by the present invention will be described in detail in conjunction with FIG. 1 .

[0030] The clamp is based on the base (10), and the steps on the base (10) are used in conjunction with the base height adjustment piece (11). By changing the thickness of the base height adjustment piece (11), the height difference of the base step is adjusted, and the curve welding seam When welding, the welding of tailor-welded blanks with different thicknesses can be realized. As shown in Figure 1, the pressure plate (3') (4') is supported by the pad (7), and the hexagon socket screw B (6) passes through the pressure plate (3 ')(4') and cushion block (7) to fix it on the base (10), and the positioning block (1) is put into the weld groove to help the tailor welded blank to be positioned, as shown in Figure 1(b), so that The advantage of positioning is that no matter ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com