Abrasion resistant steel and low-carbon steel dissimilar metal consumable electrode gas shielded welding technology

A technology of melting electrode gas and welding process, which is applied in the direction of metal processing equipment, welding equipment, welding/welding/cutting items, etc., to achieve the effect of ensuring normal production, reducing production costs, and welds without cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

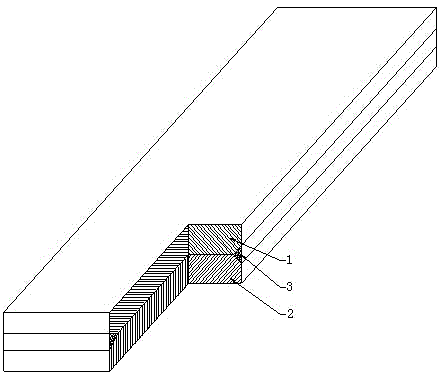

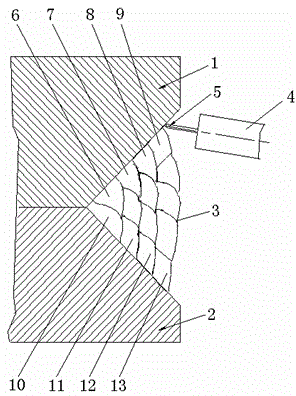

[0048] A welding process of wear-resistant steel and low-carbon steel dissimilar metal gas metal arc welding, comprising the following steps:

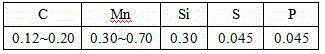

[0049] Step (1), choose dry, oil-free, rust-free ordinary carbon steel welding wire as the welding wire, and the welding wire should be dry, oil-free and rust-free before use and in the welding area to achieve the effect of hydrogen elimination treatment. For CHW-50C6, the diameter is 1.2mm;

[0050] Step (2), the wiring method during welding is direct current connection, which can heat the weldment; when the welding voltage is 20V, the welding current is 160A, the welding speed is 0.2m / min, the groove depth is 10mm, and the groove angle 90°, CO 2 The gas flow rate is 5L / min, and the interlayer temperature is 40°C, and the above wear-resistant steel and low carbon steel grooves are fully welded;

[0051] Step (3), during the first welding, perform the first welding 10 from the low-carbon steel 2 side, after the welding is completed, ...

Embodiment 2

[0058] A welding process of wear-resistant steel and low-carbon steel dissimilar metal gas metal arc welding, comprising the following steps:

[0059] Step (1), choose dry, oil-free, rust-free ordinary carbon steel welding wire as the welding wire, and the welding wire should be dry, oil-free and rust-free before use and in the welding area to achieve the effect of hydrogen elimination treatment. For CHW-50C6, the diameter is 1.2mm;

[0060] Step (2), the wiring method during welding is direct current connection, which can heat the weldment; when the welding voltage is 40V, the welding current is 300A, the welding speed is 1.5m / min, the groove depth is 15mm, and the groove angle 110°, CO 2 Under the conditions of gas flow rate of 18L / min and interlayer temperature of 120°C, full welding is carried out on the above wear-resistant steel and low carbon steel grooves;

[0061] Step (3), during the first welding, perform the first welding 10 from the low-carbon steel 2 side, afte...

Embodiment 3

[0068] A welding process of wear-resistant steel and low-carbon steel dissimilar metal gas metal arc welding, comprising the following steps:

[0069] Step (1), choose dry, oil-free, rust-free ordinary carbon steel welding wire as the welding wire, and the welding wire should be dry, oil-free and rust-free before use and in the welding area to achieve the effect of hydrogen elimination treatment. For CHW-50C6, the diameter is 1.2mm;

[0070] Step (2), the wiring method during welding is direct current connection, which can heat the weldment; when the welding voltage is 30V, the welding current is 230A, the welding speed is 1m / min, the groove depth is greater than or equal to 10mm, and the groove angle 140°, CO 2 Under the condition of gas flow rate of 10L / min and interlayer temperature of 80°C, full welding is carried out on the above wear-resistant steel and low carbon steel grooves;

[0071] Step (3), during the first welding, perform the first welding 10 from the low-carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com