Automobile machining board laser welding robot

A technology for laser welding and processing plates, applied in laser welding equipment, welding equipment, metal processing equipment, etc., to achieve the effect of improving welding efficiency, high degree of automation, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

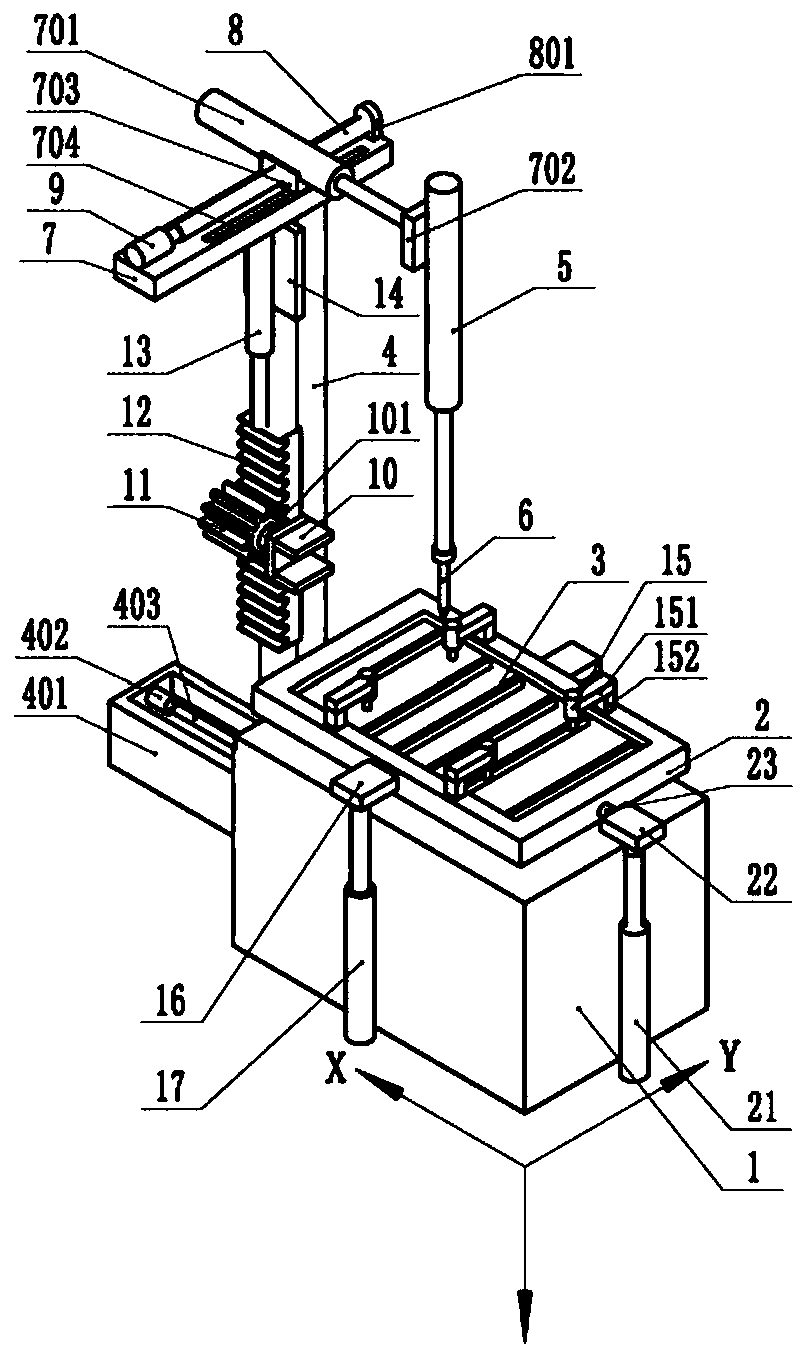

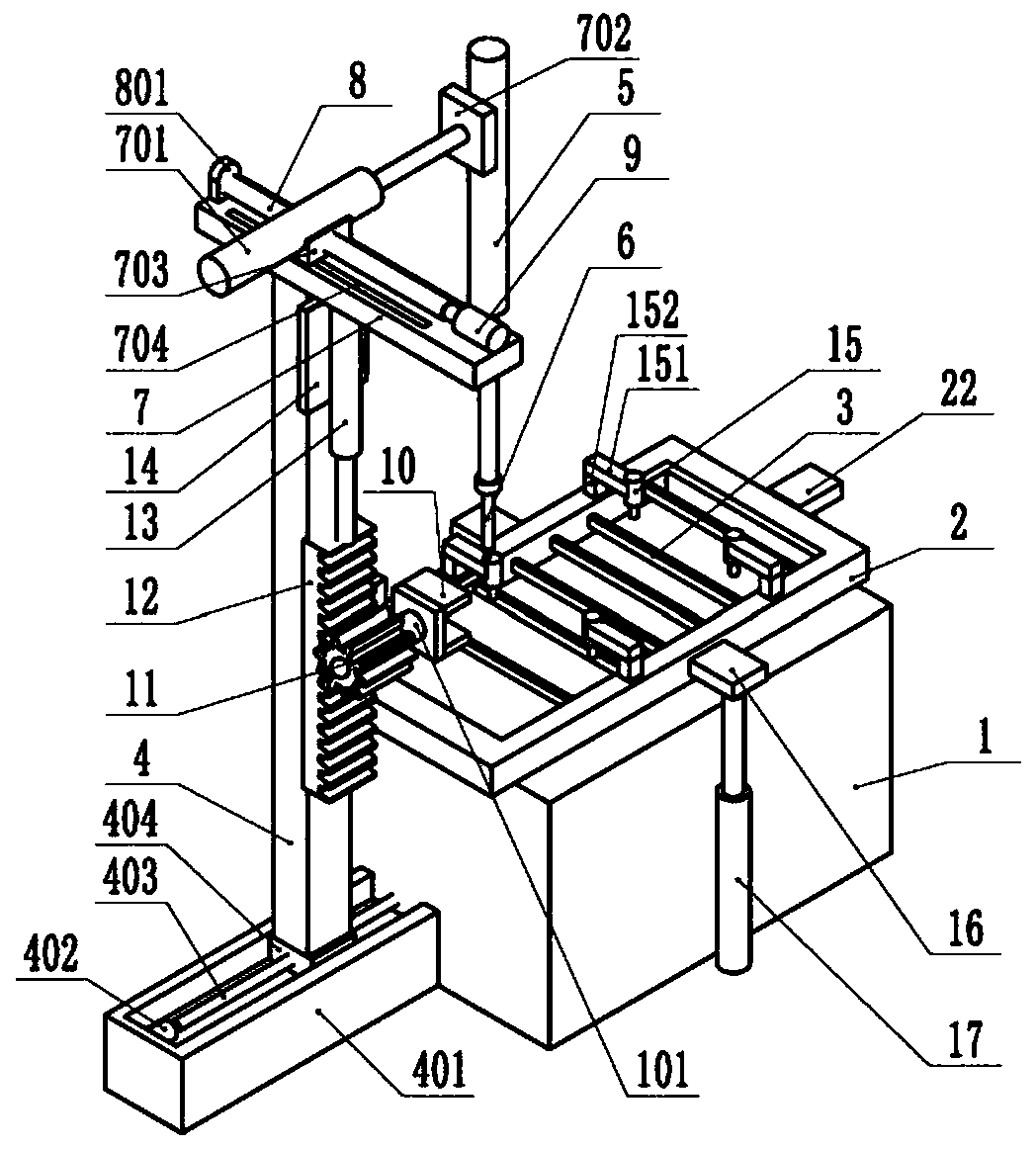

[0040] The embodiment is basically as attached figure 1 Shown: the laser welding robot for the automobile processing plate, including a workbench 1, a placement frame 2 is placed on the upper surface of the workbench 1, and the shape of the placement frame 2 can be set according to the shape of the actual workpiece to be welded. In this embodiment, the placement frame 2 The shape is cuboid, and the top and bottom ends of the placement frame 2 are open, so that the placement frame 2 is a frame structure. There are several poles 3 fixedly connected to the opposite sides of the placement frame 2. In this embodiment, the poles 3 are welded to both sides of the placement frame 2. The two adjacent poles 3 are parallel to each other, and the distance between the two adjacent poles 3 is There are gaps in between.

[0041] The workbench 1 is provided with a welding mechanism, an overturning mechanism and a pressing mechanism. The welding mechanism includes a fixed frame 4, a lifting ...

Embodiment 2

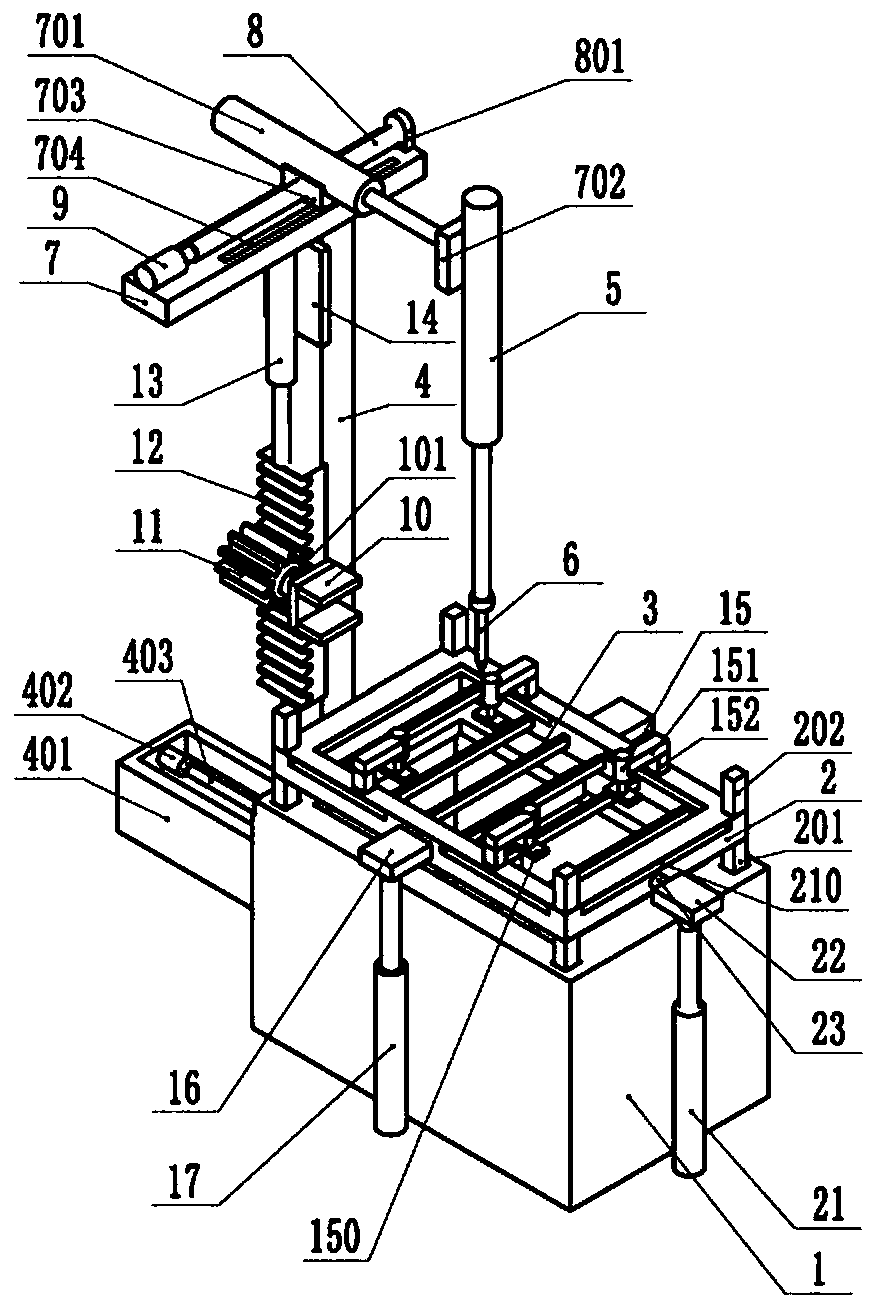

[0059] Such as image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the difference between the laser welding robot for automobile processing plate and the first embodiment is that the inside of the workbench 1 is a hollow structure, and the top of the workbench 1 is open.

[0060] A positioning cylinder 18 is arranged in the workbench 1 , and the output end of the positioning cylinder 18 is arranged facing the direction of the placing frame 2 . The bottom of the positioning cylinder 18 is fixedly connected with the bottom of the workbench 1 by bolts. The output end of the positioning cylinder 18 is fixedly connected with a partition 19 by bolts, and the width of the partition 19 is the distance between the welds of the two workpieces in the actual processing. The partition 19 is arranged parallel to the poles 3 and is located between two adjacent poles 3 , so that the poles 3 do not obstruct the rising and falling of the partition 19 . In this implementation, the posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com