Automatic bar feeder

An automatic feeding and bar material technology, which is applied in metal processing and other directions, can solve the problems of long overall structure of the feeding mechanism, inconvenient transportation and handling, and large space occupied by the machine, and achieve the effect of small machine occupation, simple structure, and convenient feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

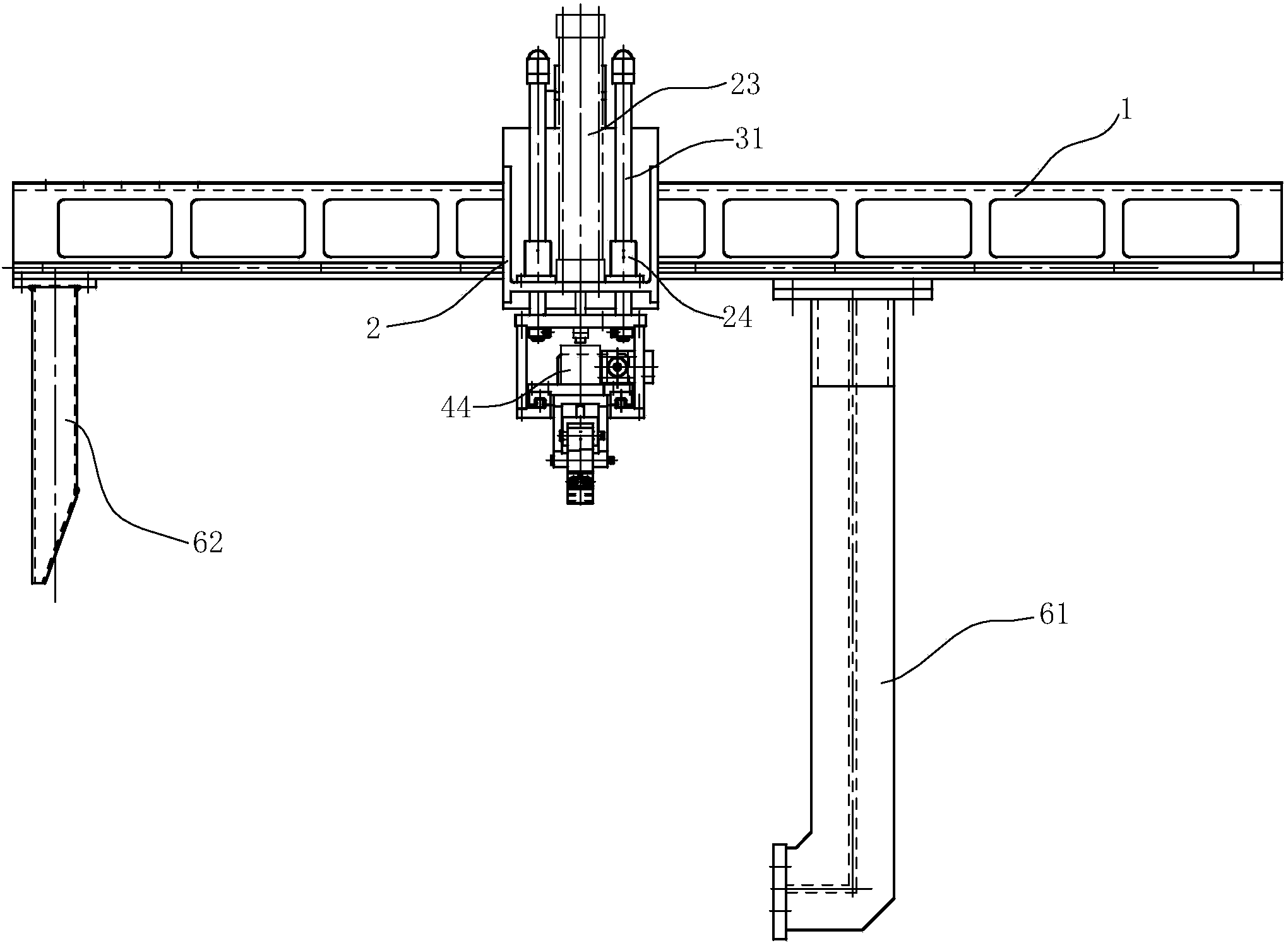

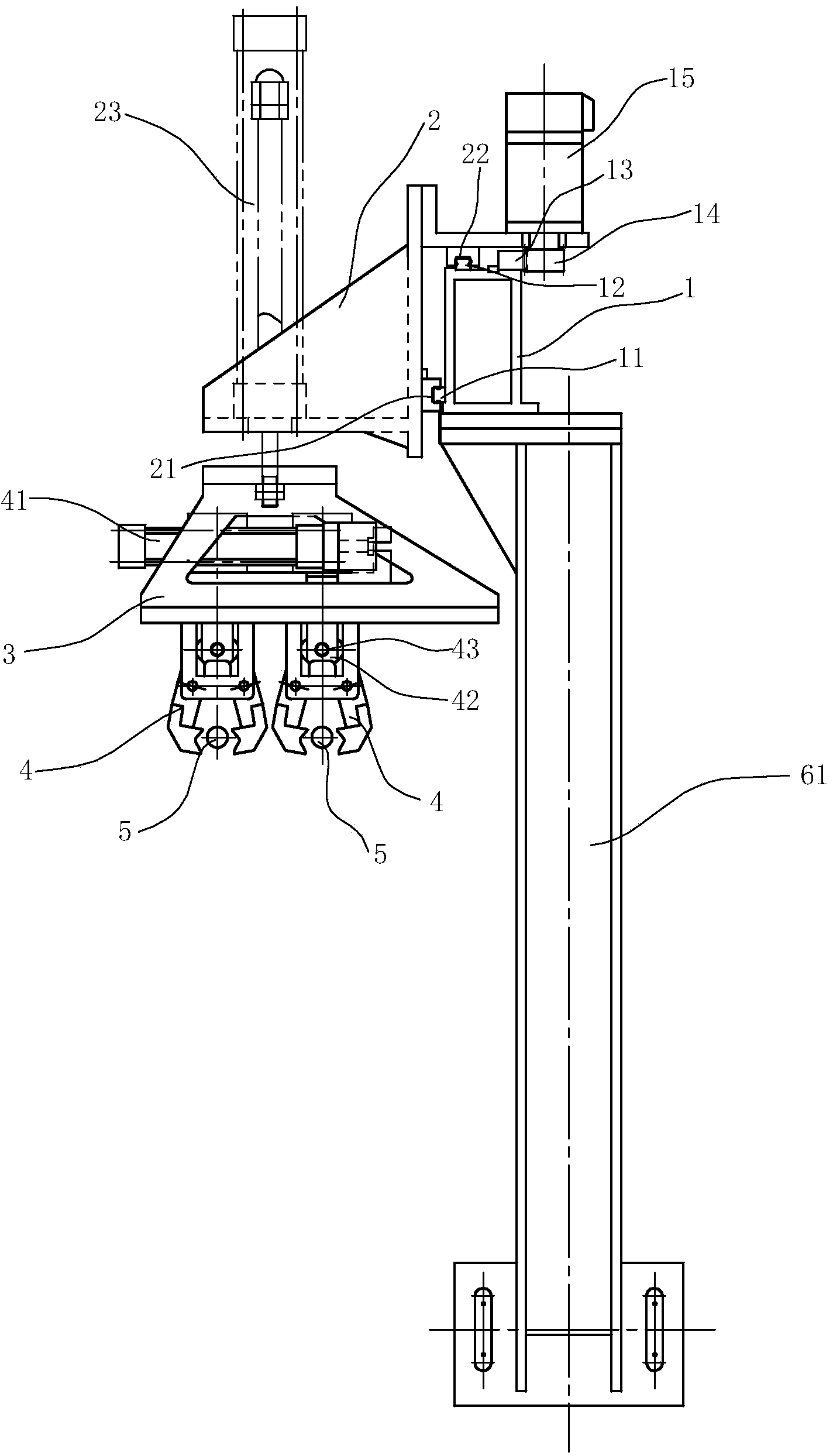

[0019] see figure 1 with figure 2 , a bar automatic feeding machine, including a beam 1, and a slide plate 2 that can slide along the beam 1. Slider 2 and crossbeam 1 sliding fit: the rear side of the slideboard 2 is located in front of the front side of the crossbeam 1, and the rear side of the skateboard 2 is provided with a first chute 21, which cooperates with the first crossbeam guide rail 11 on the front side of the crossbeam 1; The top surface is above the top surface of the crossbeam 1, and the top surface of the slide plate 2 is provided with a second slide groove 22, which cooperates with the second crossbeam guide rail 12 on the top surface of the crossbeam 1, thereby realizing the sliding fit of the crossbeam 1 and the slide plate 2. Those skilled in the art can easily imagine that the above two beam guide rails can also be arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com