Combined forging die and manufacturing method thereof

A combined, forging die technology, used in forging/pressing/hammering machinery, manufacturing tools, heat treatment equipment, etc., can solve problems such as difficulty and poor forging die stability, and achieve extended life, small welding deformation, and processing difficulty. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

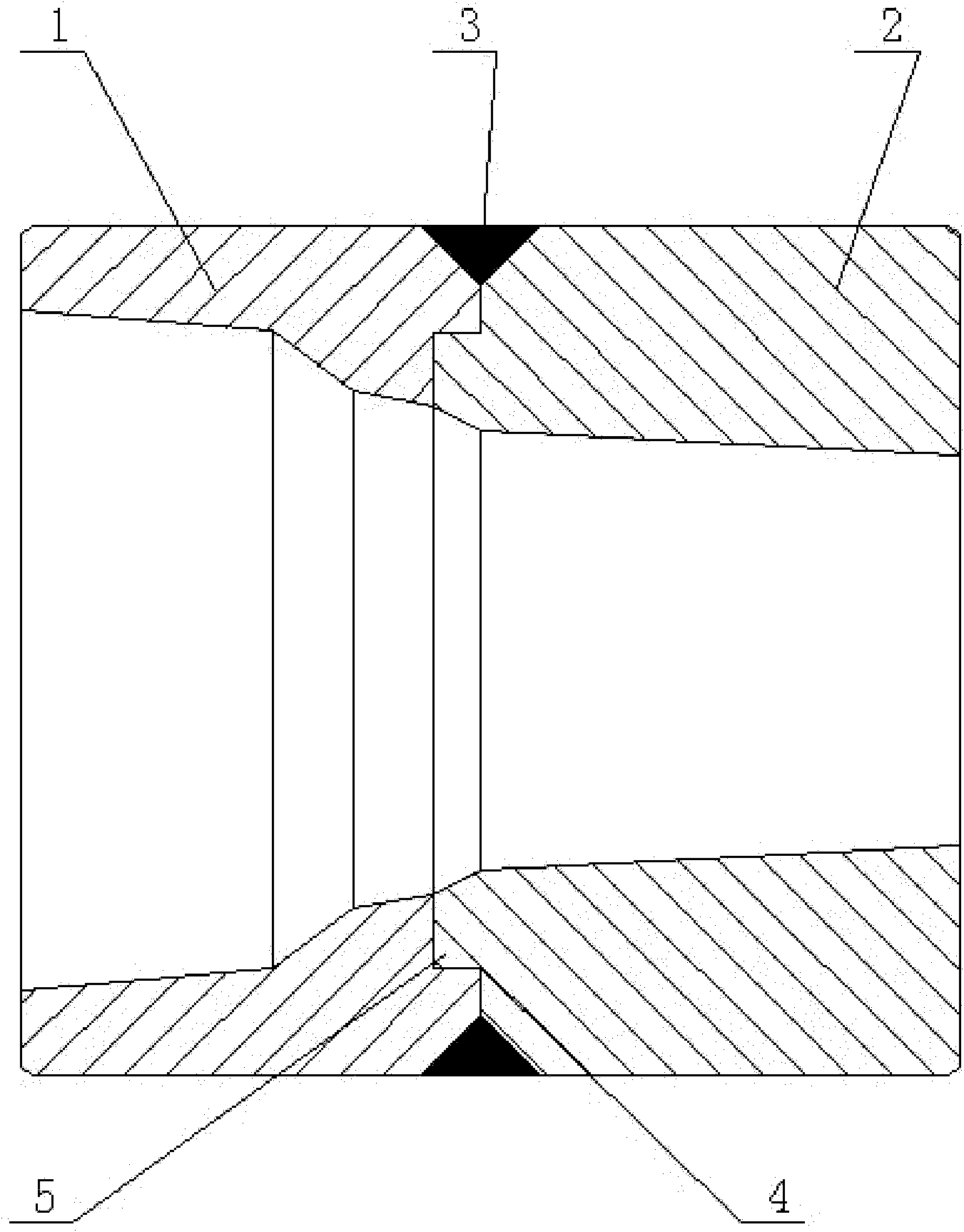

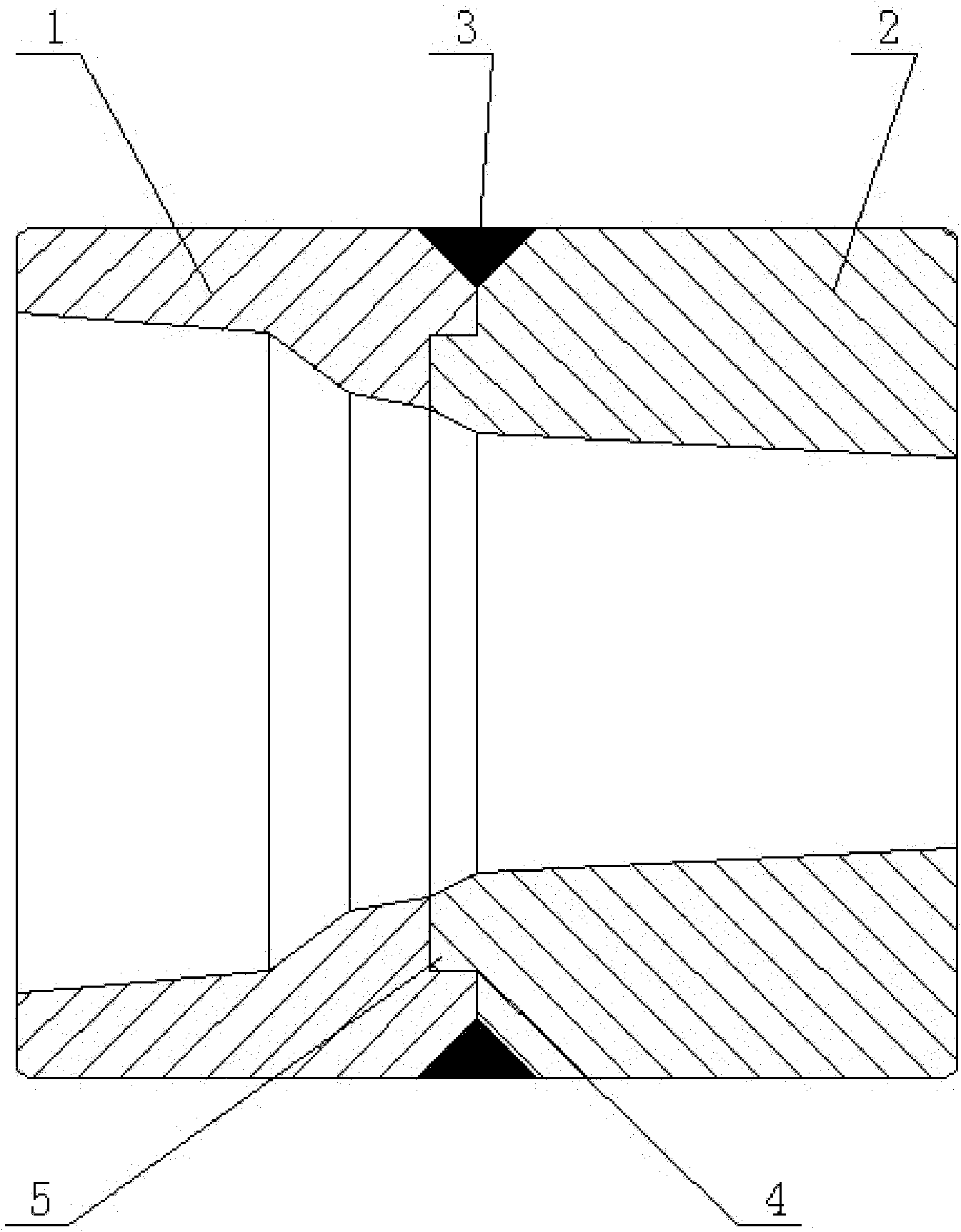

[0032] A combined forging die comprises a die head 1 and a die body 2. The outer edge of the lower end surface of the die head 1 is fixedly connected to the outer edge of the upper end face of the die body by welding. The original overall forging die was set up as upper and lower parts, and the two parts were connected together by welding, which not only maintained the mechanical strength of the overall forging die, but also made it easier and faster to replace parts of the forging die.

Embodiment 2

[0034] A combined forging die as described in Example 1, the difference is that: the lower end surface of the die head 1 is provided with an outer annular boss 4, and the upper end surface of the mold body 2 is provided with an inner annular boss 5. The heights of the inner annular boss 5 and the outer annular boss 4 are the same; the inner diameter of the outer annular boss 4 is adapted to the outer diameter of the inner annular boss 5; the outer annular boss 4 The outer edge of the mold body is fixedly connected with the outer edge of the upper end surface of the mold body by welding.

[0035] On the opposite surface of the die head 1 and the die body 2, a boss is correspondingly arranged, so that the die head and the die body are installed tightly, and problems such as displacement and deformation are avoided; the die head and the die body are fixedly connected by welding, which increases the The stability of the forging die; only welding the edge part is the prerequisite f...

Embodiment 3

[0037] A method for manufacturing the combined forging die described in embodiment 2, the specific steps are as follows:

[0038] 1) The lower end surface of the die head 1 is provided with an outer annular boss 4, and the upper end surface of the mold body 2 is provided with an inner annular boss 5, and the height of the inner annular boss 5 and the outer annular boss 4 is the same; The inner diameter of the outer annular boss 4 is compatible with the outer diameter of the inner annular boss 5;

[0039] 2) The operator uses a lathe to process grooves on the outer edge of the outer annular boss 4 and the outer edge of the upper end surface of the mold body 2 respectively, and the depth of the groove is 13% of the thickness of the forging die;

[0040] 3) Heat the die head 1 to 240-280°C, put the heated die head 1 on the upper end surface of the mold body 2 at room temperature, and the groove on the outer edge of the outer annular boss 4 and the upper end surface of the mold bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com