Large-mode-field fiber pumped coupler and manufacturing method thereof

A large mode field and coupler technology, applied in the field of lasers, can solve the problems of mode field size and shape damage, low signal coupling efficiency, etc., to achieve high power coupling and improve coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment describes a large mode field optical fiber pumping coupler, including a main optical fiber and a pumping optical fiber bundle containing several pumping optical fibers, one end of the pumping optical fiber bundle is surrounded by the several pumping optical fibers A hollow optical fiber bundle, one end of the main optical fiber is provided with a transition area exposing the inner cladding and inserted into the hollow part of the pumping optical fiber bundle, and the part of the pumping optical fiber corresponding to the transition area of the main optical fiber is the exposed cladding The tapered end of the pump fiber, the cladding at the tapered end of the pump fiber is in close contact with the inner cladding of the transition zone of the main fiber and is fused together.

[0048]The transition zone of the main optical fiber is a cylinder whose radial dimension is smaller than the radial dimension of the inner cladding body of the main optical fiber,...

Embodiment 2

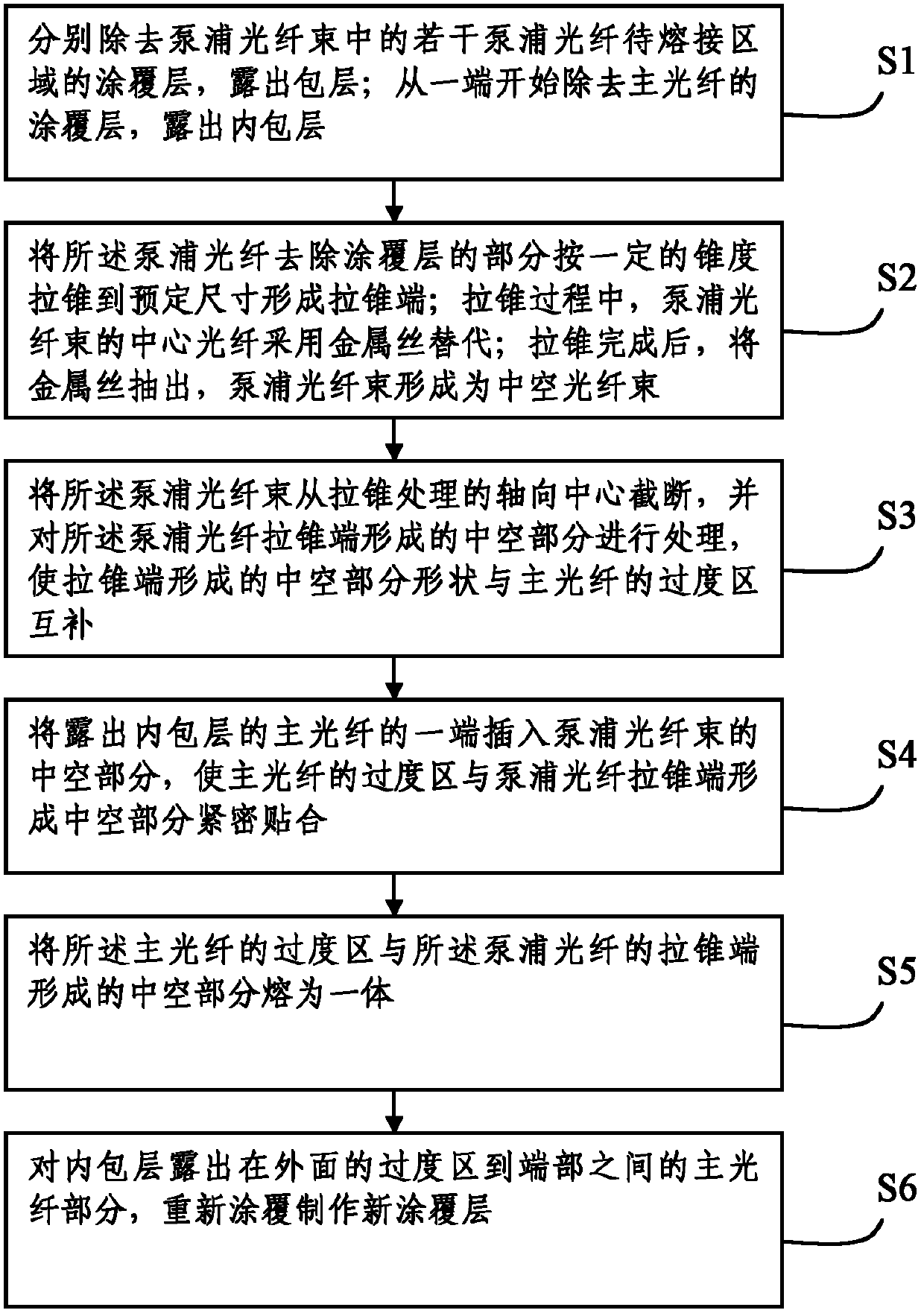

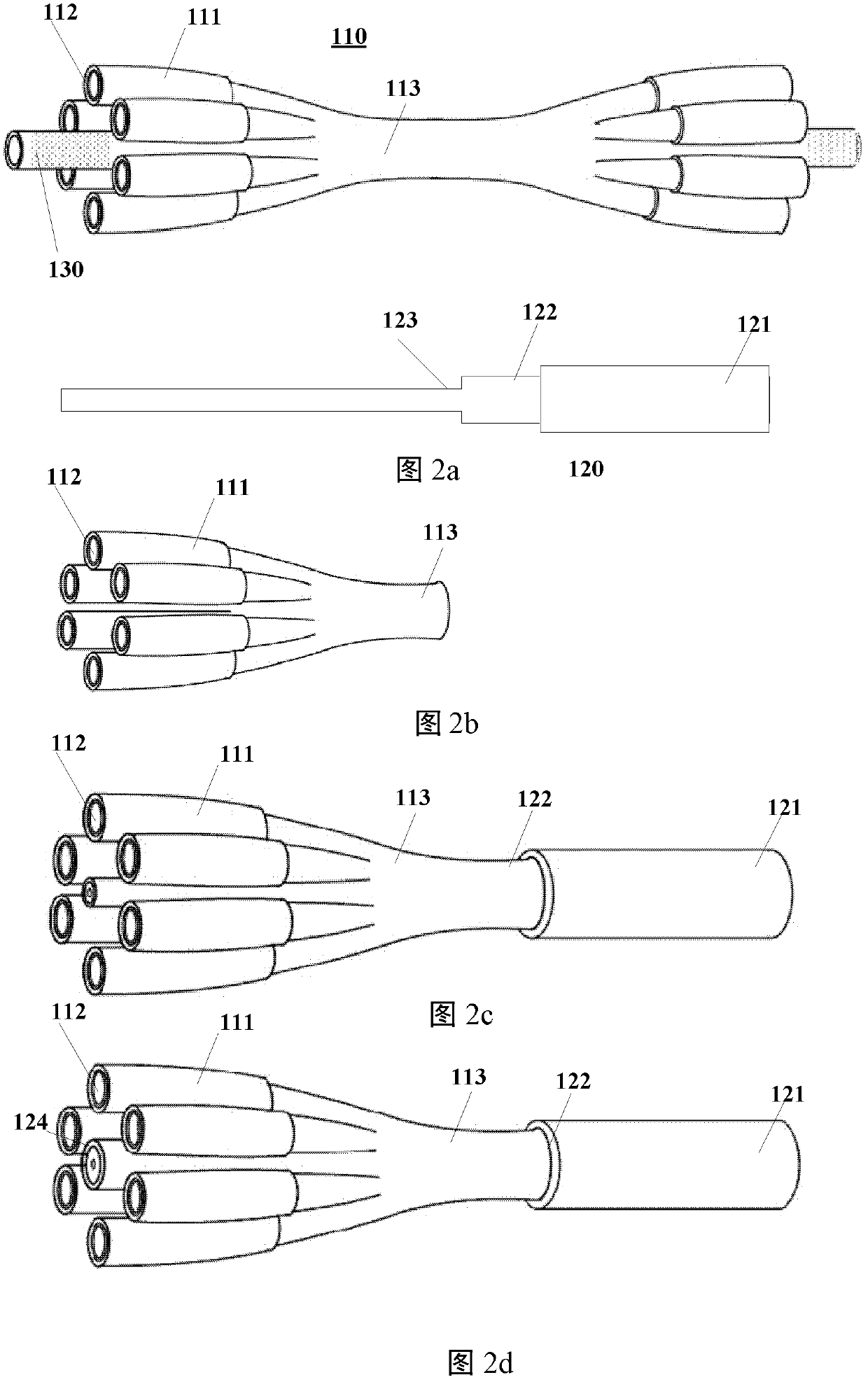

[0054] Such as figure 1 and Figure 2a As shown in -d, this embodiment records the manufacturing method of the above-mentioned large mode field fiber pump coupler, including the following steps:

[0055] S1: Removing the coating layers 111 of several pumping fibers 110 in the pumping fiber bundle to be fused to expose the cladding layer 112; removing the coating layer 121 of the main optical fiber 120 from one end to expose the inner cladding layer 122;

[0056] S2: The inner cladding 122 of the main optical fiber whose coating layer has been removed is reduced in diameter by chemical etching or mechanical polishing to form the desired shape of the transition zone 123; The method of tapering is tapered according to a certain taper to a predetermined size to form a tapered end 113; during the tapering process, the central optical fiber of the pump fiber bundle is replaced by a metal wire 130; after the tapering is completed, the metal wire 130 is pulled out and pumped The opt...

Embodiment 3

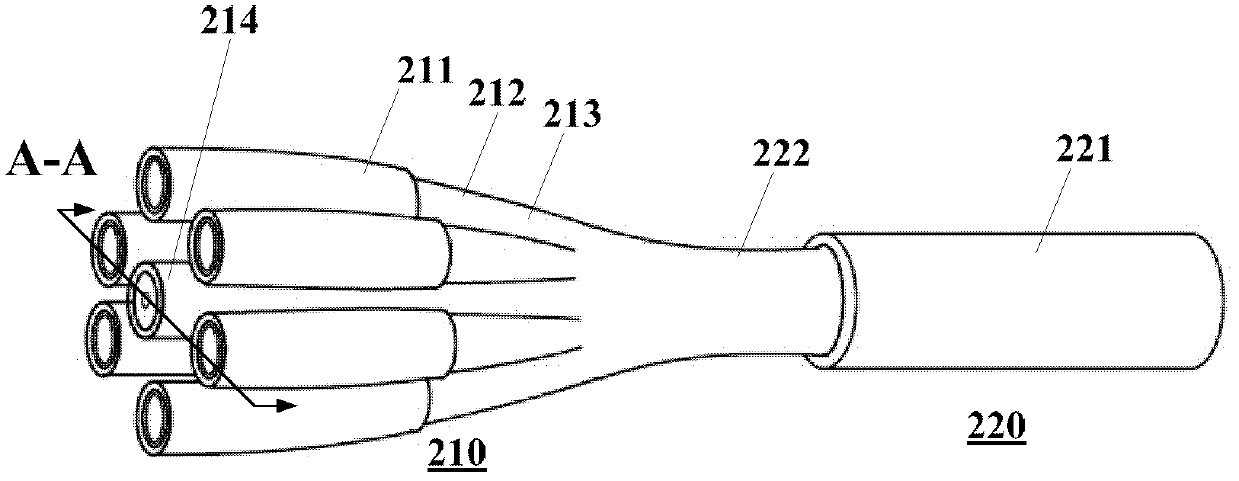

[0063] Such as Figure 3a and 3b Shown is the large mode field fiber pump coupler of this embodiment. Its production method is:

[0064] Remove an axial length of 30 cm from the coating 221 of a circular double-clad main optical fiber 220 with core / inner cladding diameters of 50 / 400um respectively, exposing the inner cladding 222;

[0065] The core / cladding diameters of the six pumping fibers 210 are 200 / 220um, and the coating layer 211 of each pumping fiber 210 is removed by 3cm axial length to expose the cladding 212;

[0066] Use HF to chemically corrode the decoating layer of the double-clad main optical fiber 220, so that the diameter of the inner cladding is reduced to 133um, and the inner cladding 222 of the transition zone 223 and the inner cladding 222 of the main optical fiber 220 are stepped;

[0067] The 6 pumping optical fibers 210 are melted and tapered by using the hydrogen-oxygen flame heating fusion tapering method. During the tapering process, the center o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com