Manufacture method of single-sided flexible circuit board

A technology for flexible circuit boards and manufacturing methods, which is applied in the fields of printed circuit manufacturing, printed circuits, and secondary treatment of printed circuits, etc., and can solve problems such as gold fingers stripping substrates, affecting gold finger surface coating, and alignment accuracy is not very high, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

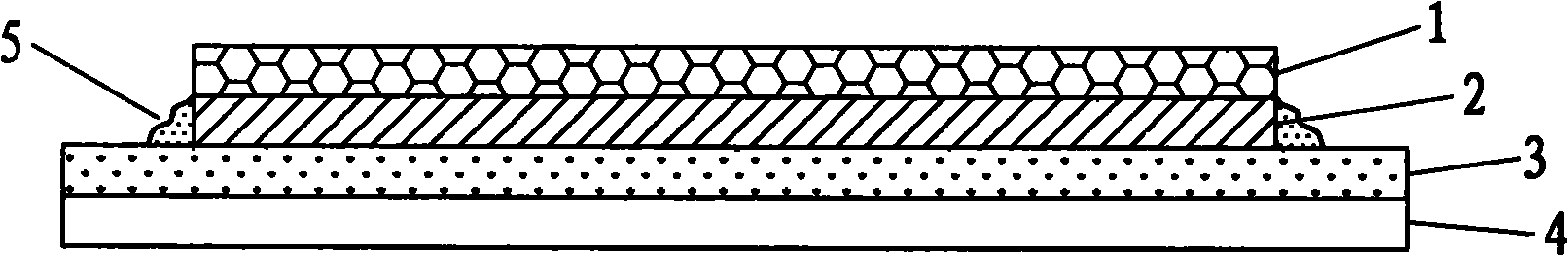

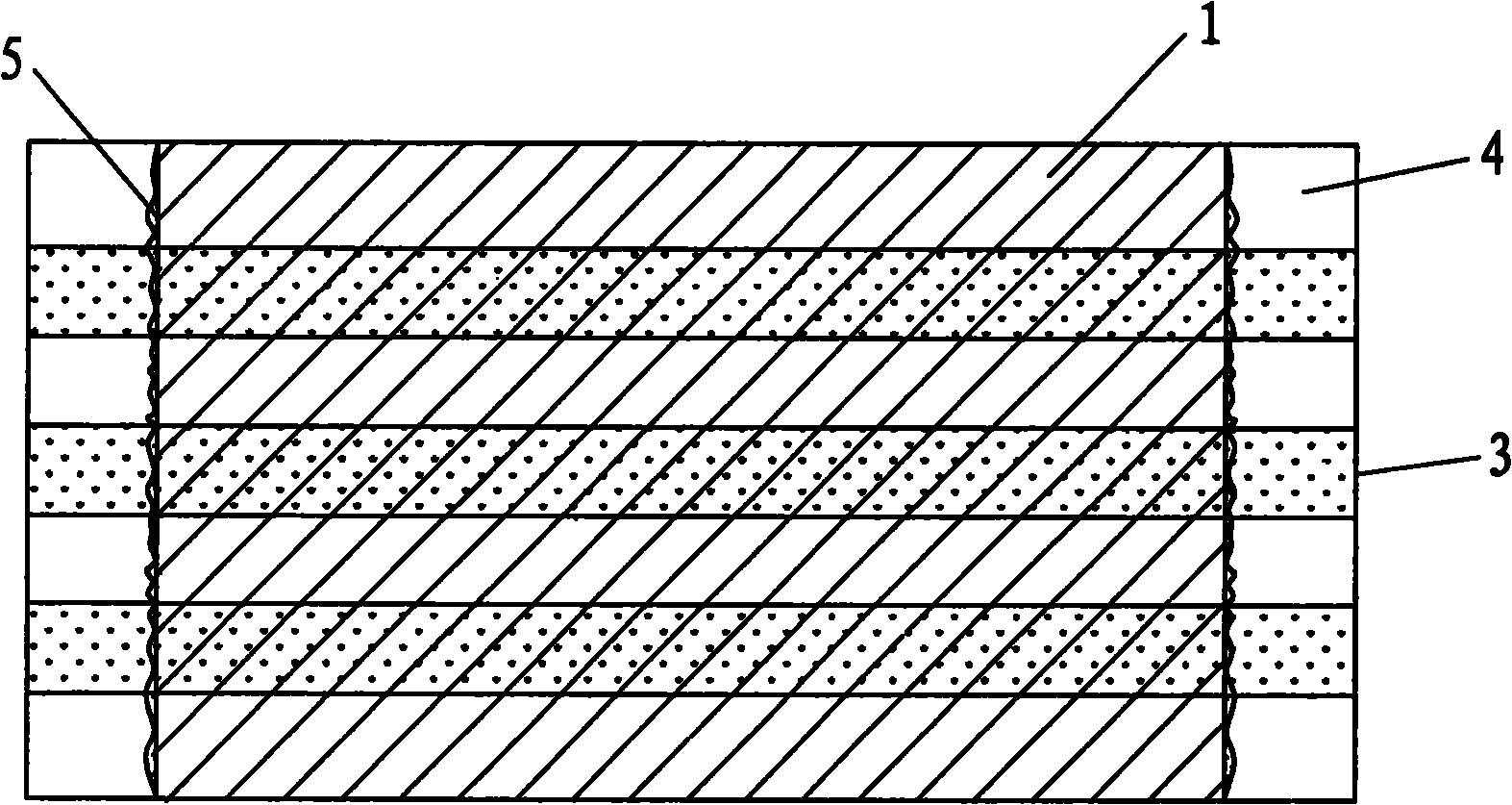

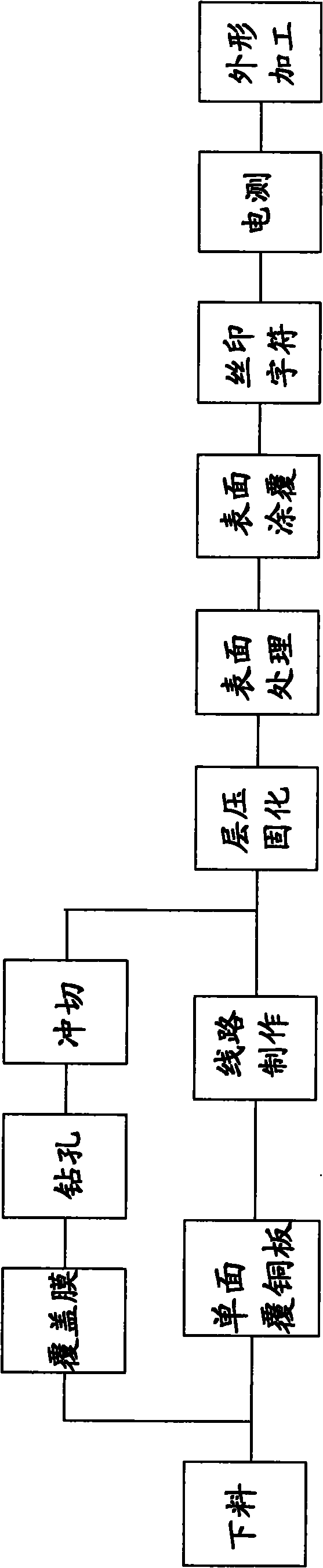

[0019] Such as Figure 4 , 5 As shown, the single-sided flexible circuit board of the present invention is composed of a base material layer 30, a copper foil layer 20 and a cover film layer 10, and the base material layer 30 and the copper foil layer 20 are single-sided copper-clad foil. cooperate again Figure 6 As shown, the manufacturing method of the single-sided flexible circuit board of the present invention specifically comprises the following steps:

[0020] (1) Cutting: Cut the materials used according to the specifications and sizes required for production;

[0021] (2) Cover film 10 drilling: cover film 10 is the top cover film of the product, and it is necessary to drill the cover film alignment holes and other auxiliary holes;

[0022] Circuit making: making circuits and laser alignment cross targets on the copper foil layer 20 of the single-sided copper clad laminate;

[0023] (3) lamination curing: the cover film 10 obtained in step (2) is pasted on the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com