Welding method for focusing ring assembly

A welding method and focus ring technology, applied in welding equipment, electron beam welding equipment, metal processing equipment, etc., can solve the problems of poor welding quality and complicated welding process of focus ring components, so as to improve welding efficiency, simplify welding process, The effect of increasing the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] As described in the background, in the existing method, there is a problem that the welding process is complicated during the process of welding the focus ring and the fixed assembly, and the welding quality of the existing focus ring assembly is poor.

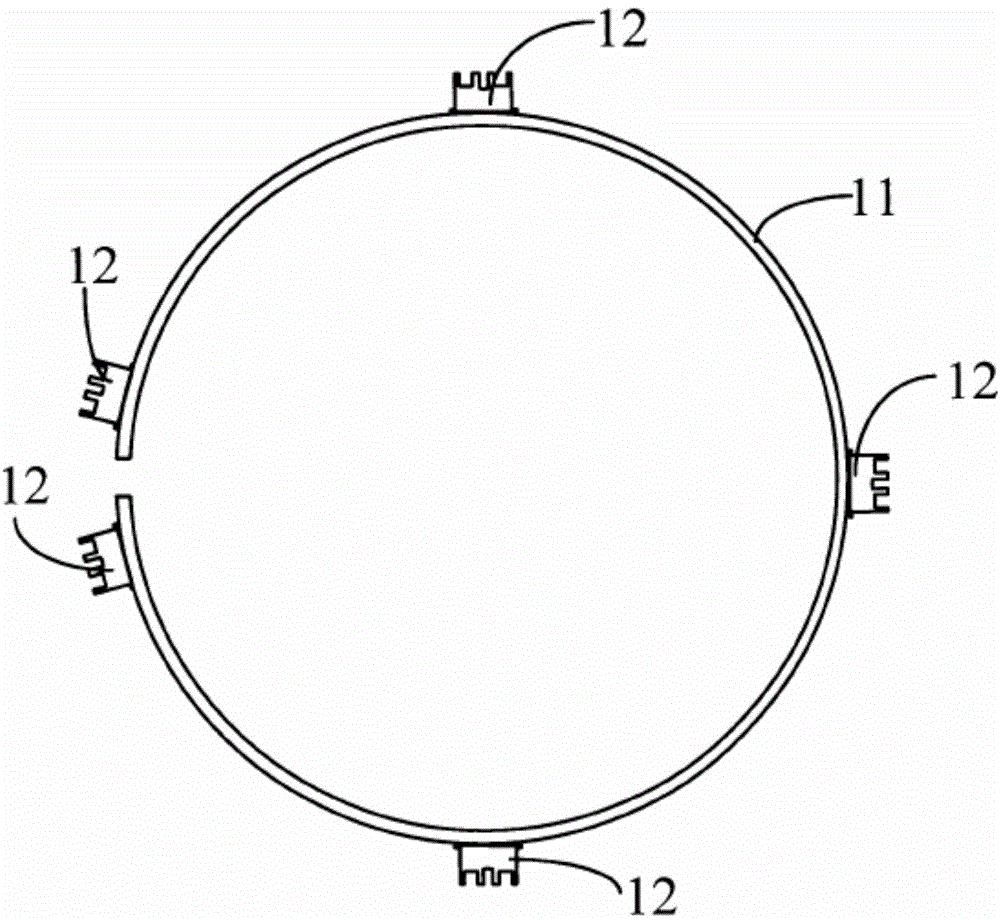

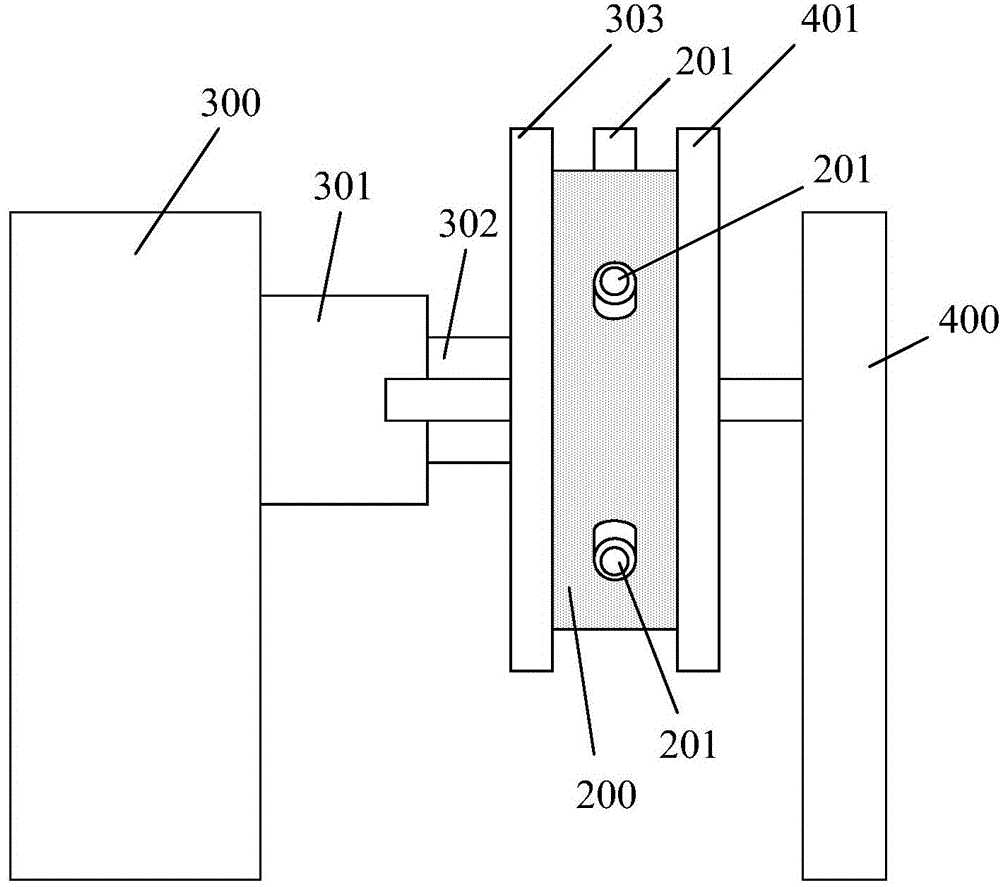

[0028] It turns out that the existing method usually chooses vacuum electron beam welding to weld the fixed component and the focus ring together. However, in the existing method, when welding the fixing component and the focus ring, one fixing component is usually welded to the focus ring, and a vacuuming process is required during this process. After one welding, it is necessary to open the vacuum chamber, then rotate the focus ring, and make another fixed component align with the welding port, and then weld this fixed component. This process continues until all mounting components are welded together with the focus ring. This welding method is very inefficient, and repeating the same complicated welding process also...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com