High-temperature alloy surface treatment method

A high-temperature alloy and pretreatment technology, which is applied in the field of nuclear power, can solve the problems of inability to meet the performance indicators of the chromium nitride layer, loose layer, poor wear resistance, etc., to improve the overall performance and service life, not easy to fall off, low wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

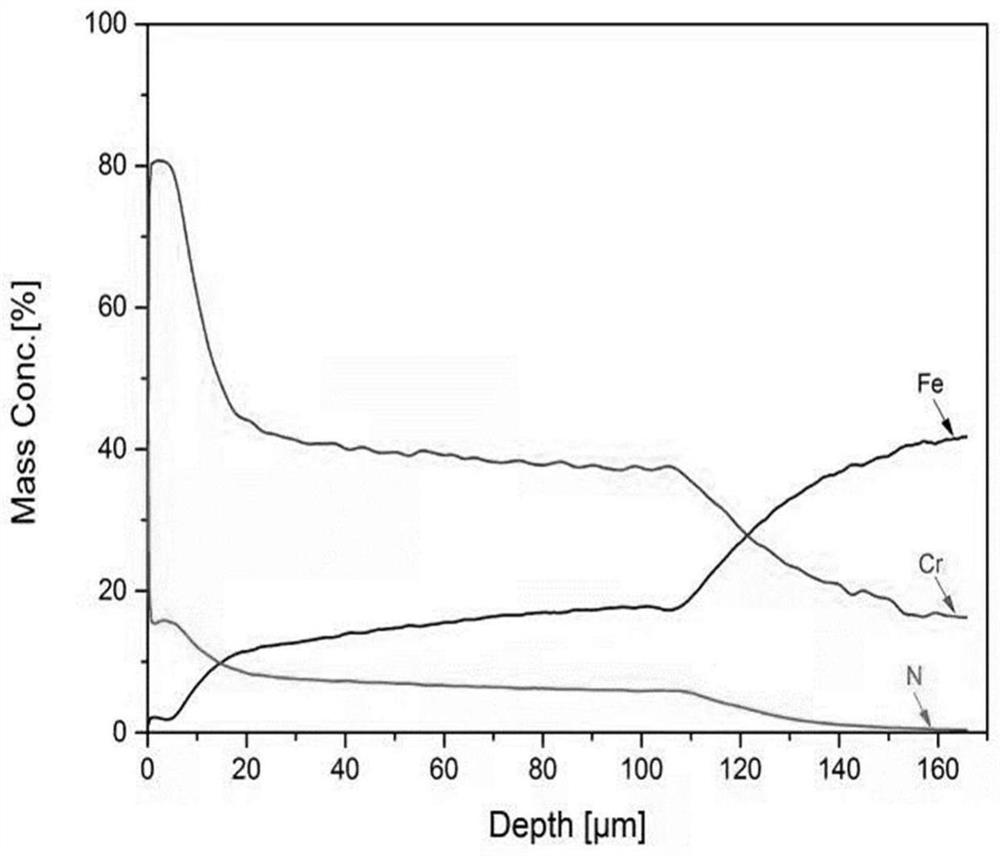

[0042] In this embodiment, the chromizing nitride layer is prepared on the substrate of GH1059, and the preparation method is as follows:

[0043] S1, pre-infiltration treatment

[0044] The substrate was placed in petroleum ether, cleaned with ultrasonic agitation for 15 minutes, removed the oil stain on the surface of the substrate, and then placed in acetone for ultrasonic cleaning for 15 minutes, followed by ultrasonic cleaning in absolute ethanol for 15 minutes, and finally taken out and dried with nitrogen.

[0045] S2, vacuum chromizing

[0046] The process of chromizing is divided into the following four steps:

[0047] S2.1. Bury the GH1059 substrate into a chromizing agent (50% chromium mass fraction, 38% alumina mass fraction, 10% iron mass fraction, NH 4 Cl and NH 4 I mass fraction 2%, NH 4 Cl and NH 4 The mass ratio of I is a container of 2:1), which is sealed into a vacuum pit furnace, and starts to heat up when the degree of vacuum reaches 20Pa or less. Th...

Embodiment 2

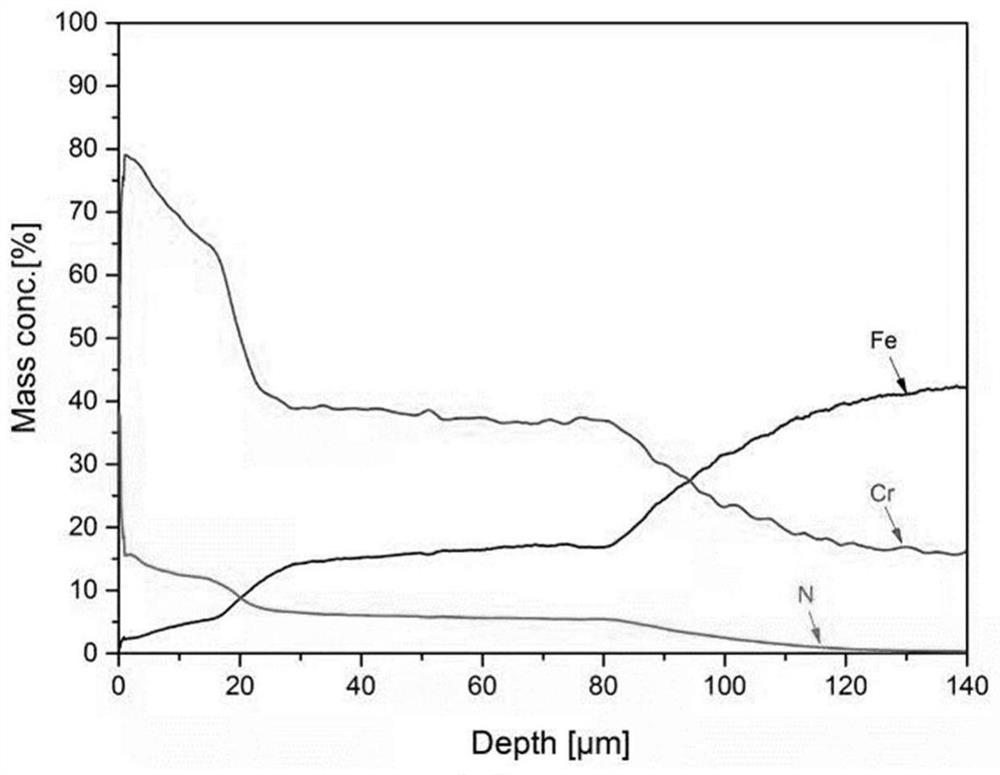

[0063] In the present embodiment, the specific steps of preparing the chromizing nitride layer on the XH35BT alloy substrate are as follows:

[0064] S1. Pretreatment of chromizing

[0065] Same as step 1) in Example 1

[0066] S2, the concrete steps of vacuum chromizing are:

[0067] S2.1, is basically the same as step (1) in Example 1, the difference is that the penetration agent (the mass fraction of chromium is 60%, the mass fraction of alumina is 24%, the mass fraction of iron is 15%, the mass fraction of NH 4 Cl and NH 4 I mass fraction 1%), the temperature was raised to 300°C at a rate of 80°C / h, and the temperature was maintained for 1 h.

[0068] S2.2. It is basically the same as step (2) in Example 1, except that the temperature rise rate is 50°C / h, the temperature is raised to 600°C, and the holding time is 3h.

[0069] S2.3. It is basically the same as step (3) in Example 1, the difference is: the heating rate is 30°C / h, the temperature is raised to 1120°C, and...

Embodiment 3

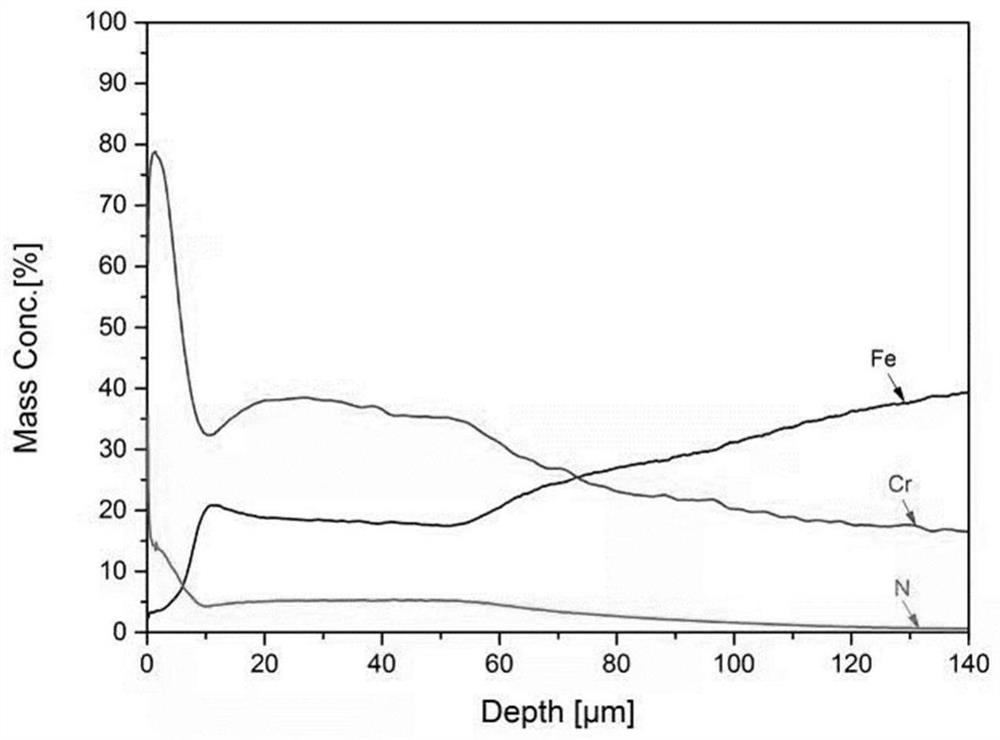

[0083] In the present embodiment, the specific steps for preparing the chromed nitride layer on the control rod moving conduit body made of GH1059 material are as follows:

[0084] S1. Pretreatment of chromizing

[0085] Same as 1) step in embodiment 1 and 2

[0086] S2, the concrete steps of vacuum chromizing are:

[0087] S2.1, the same as step (1) in Examples 1 and 2, the difference is that the penetration agent (the mass fraction of chromium is 60%, the mass fraction of alumina is 28%, the mass fraction of iron is 10%, the mass fraction of NH 4 Cl and NH 4 I mass fraction 2%), the temperature was raised to 300°C at a rate of 90°C / h, and the temperature was maintained for 1.5h.

[0088] S2.2, the same as step 1) in Example 2; the difference is that the holding time is 2.5h.

[0089] S2.3. The temperature is increased from 600°C to 1140°C at a rate of 40°C / h, and the temperature is maintained for 25 hours. During the heat preservation process, diffusion chromizing is per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com