Method for manufacturing medium-strength aluminum alloy wire with electric conductivity of 59 percent

A medium-strength aluminum alloy, electrical conductivity technology, used in the manufacture of extensible conductors/cables, metal/alloy conductors, cable/conductor manufacturing, etc., can solve problems such as unachieved tensile strength and unstable manufacturing processes

Active Publication Date: 2011-08-24

JIANGSU ZHONGTIAN TECH CO LTD +1

View PDF1 Cites 32 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the defects of the manufacturing equipment and the instability of the manufacturing process, the main properties (conductivity, tensile strength) of the high-conductivity medium-strength aluminum alloy wire have not yet reached the level of stable production.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

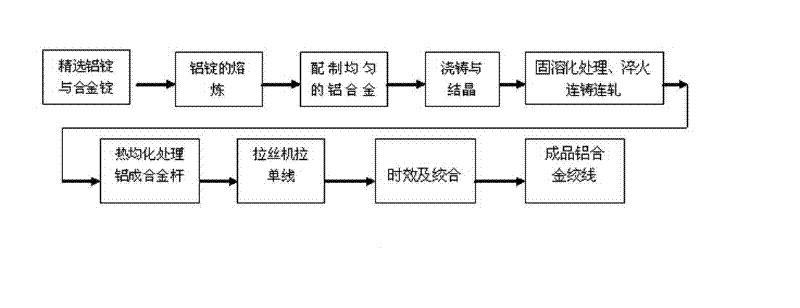

[0028] The present invention will be further described below in conjunction with the accompanying drawings and the process of the embodiment.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

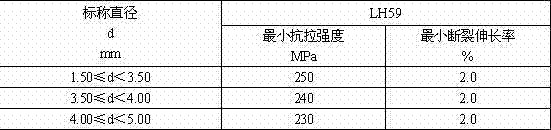

The invention discloses a method for manufacturing a medium-strength aluminum alloy wire with the electric conductivity of 59 percent (International Annealed Copper Standard, IACS), and relates to a method for manufacturing a medium-strength aluminum alloy wire with high conductivity. The method is characterized by comprising the following steps of: (1) selecting an aluminum matrix and an aluminum intermediate alloy ingot; (2) performing on-the-spot sample analysis and adjustment, namely putting the selected aluminum ingot into a shaft furnace, melting to form molten aluminum, and refining by using a refining agent; (3) casting and crystallizing, namely allowing molten aluminum alloy in a kettle furnace to pass through a runner and filtering by using a ceramic filtering plate, adding rare earth to ensure that the content of the rare earth is 0.05 to 0.15 percent, feeding into an aluminum alloy continuous casting machine, performing continuous casting to form an aluminum alloy cast ingot, and rolling a medium-strength alloy rod by using an aluminum alloy continuous mill; (4) performing solid solution treatment and quenching, namely performing thermal homogenization treatment on the aluminum alloy rod; and (5) drawing, aging and twisting, namely drawing the aluminum alloy rod treated in the previous working procedure into an aluminum alloy wire with the required diameter on an aluminum alloy wire drawing machine, and twisting on a frame type wire twisting machine to obtain the medium-strength aluminum alloy wire with the electric conductivity of 59 percent IACS.

Description

technical field [0001] The invention is a method for manufacturing medium-strength aluminum alloy wire with 59% conductivity (IACS), which involves a manufacturing process of electrical materials, and is a manufacturing technology of high-conductivity aluminum alloy, more precisely, a high-conductivity aluminum alloy wire. A method of manufacturing a medium-strength aluminum alloy wire. Background technique [0002] In the past, my country did not develop and apply medium-strength aluminum alloys for electrical conduction, but with the development of overhead lines to large capacity and ultra-high voltage, the use of split wires and wires with large cross-sections and heat resistance has gradually developed. In this way, not only heat-resistant aluminum alloy wires are required, but also medium-strength or high-strength aluminum alloy wires should be used instead of general steel-cored aluminum stranded wires, medium-strength or high-strength aluminum alloy stranded wires to...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C21/02C22C21/08C22C1/03C22F1/05B22D1/00B21C37/04H01B13/00H01B13/008H01B13/02H01B1/02

Inventor 薛驰薛济萍陆伟尤伟任冯爱军缪小林徐一峰

Owner JIANGSU ZHONGTIAN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com