CuCrZr alloy with high strength and high conductivity, and preparation and processing method thereof

A processing method and high-conductivity technology, which is applied in the fields of non-ferrous metal casting processing, friction contact materials, and alloy materials, can solve problems such as failure to achieve strength, and achieve excellent comprehensive performance, short process flow, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

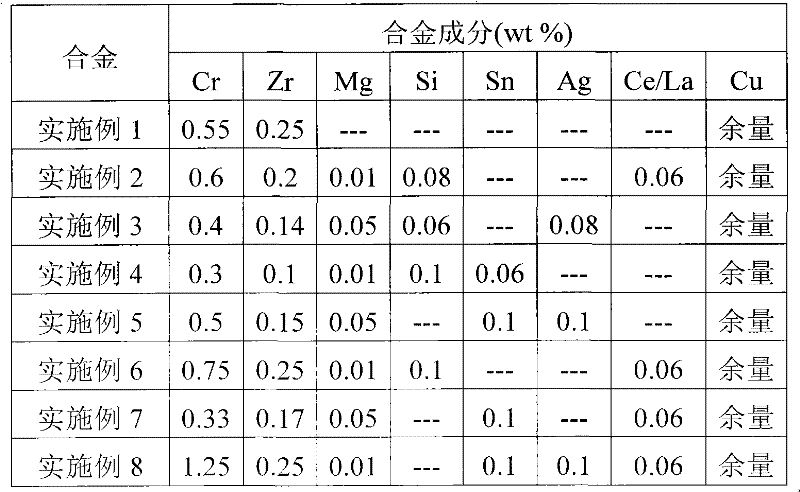

[0027] The alloy of the invention is smelted using the following raw materials: electrolytic copper, copper-chromium master alloy, copper-zirconium master alloy. The composition of the alloy is shown in Example 1 of Table 1.

[0028] 1. Melting: use non-vacuum induction furnace for melting. The order of adding the alloy is: first add Cu, after melting, add covering agent (charcoal) for 5-10 minutes, add CuCr master alloy and CuZr master alloy, after fully degassing and removing impurities, then cover the burning layer with a thickness of about 10mm. charcoal. The smelting temperature is 1250°C. After holding the heat for 10 minutes, let it stand for 5-10 minutes and then cast it out of the furnace. The casting temperature is 1200°C.

[0029] 2. Face milling: face milling of the alloy (1mm milling on the upper and lower surfaces).

[0030] 3. Hot rolling: the alloy is heated, the heating temperature is 900°C, the holding time is 1h, and the total processing rate of hot rolli...

Embodiment 2

[0038] The alloy of the present invention is smelted using the following raw materials: electrolytic copper, pure magnesium, pure silicon, copper-cerium or copper-lanthanum master alloy, copper-chromium master alloy, copper-zirconium master alloy. The composition of the alloy is shown in Example 2 of Table 1.

[0039] 1. Melting: use non-vacuum induction furnace for melting. The order of alloy addition is: first add Cu, after melting, add covering agent (charcoal) for 5-10 minutes, add CuCe or CuLa master alloy, CuCr master alloy and CuZr master alloy, pure Si, pure Mg, after fully degassing, After removing impurities, cover with burning charcoal about 10mm thick. Finally, pure magnesium is added, and the melting temperature is 1300°C. After holding the heat for 10 minutes, let it stand for 5-10 minutes and then cast it out of the furnace. The casting temperature is 1150°C.

[0040] 2. Face milling: face milling of the alloy (1mm milling on the upper and lower surfaces).

[0...

Embodiment 3

[0049] The alloy of the invention is smelted using the following raw materials: electrolytic copper, pure magnesium, pure silicon, pure silver, copper-chromium master alloy, copper-zirconium master alloy. The composition of the alloy is shown in Example 3 of Table 1.

[0050] 1. Melting: use non-vacuum induction furnace for melting. The order of adding the alloy is: first add Cu, after melting, then add Si, add covering agent (charcoal) and keep it warm for 5-10 minutes, add CuCr master alloy and CuZr master alloy, pure Si, pure Ag, after fully degassing and removing impurities Finally, cover it with burning charcoal about 10mm thick. Finally, pure magnesium is added, and the melting temperature is 1260°C. After holding the heat for 10 minutes, let it stand for 5-10 minutes and then cast it out of the furnace. The casting temperature is 1200°C.

[0051] 2. Face milling: face milling of the alloy (1mm milling on the upper and lower surfaces).

[0052] 3. Hot rolling: heating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com