Method of bonding different metals and bonded structure

A technology of dissimilar metals and joining methods, applied in the direction of metal layered products, metal processing equipment, chemical instruments and methods, etc., can solve the problems such as the difficulty of direct joining of materials, and achieve the effect of firm joining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0077] Hereinafter, the present invention will be specifically described based on examples.

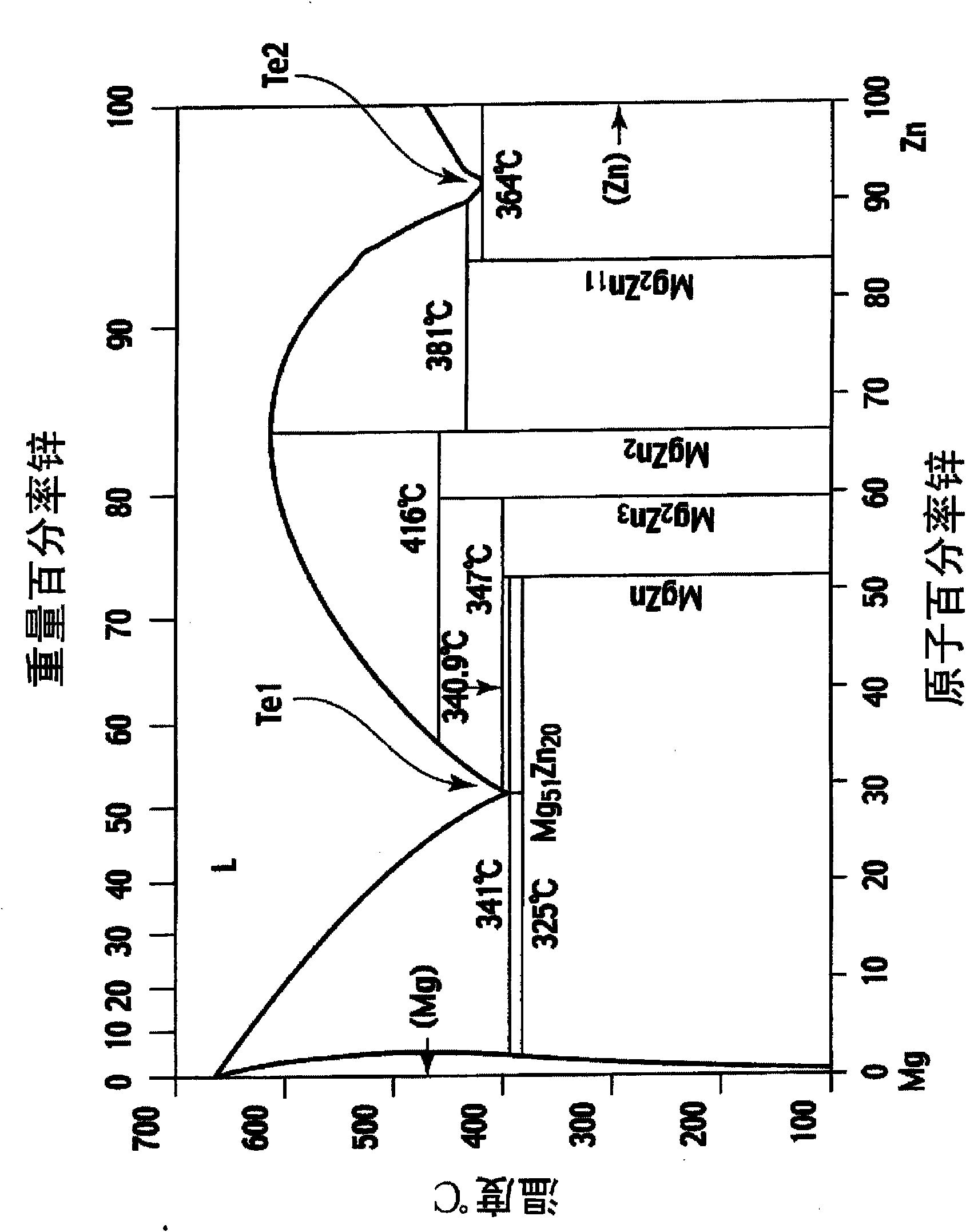

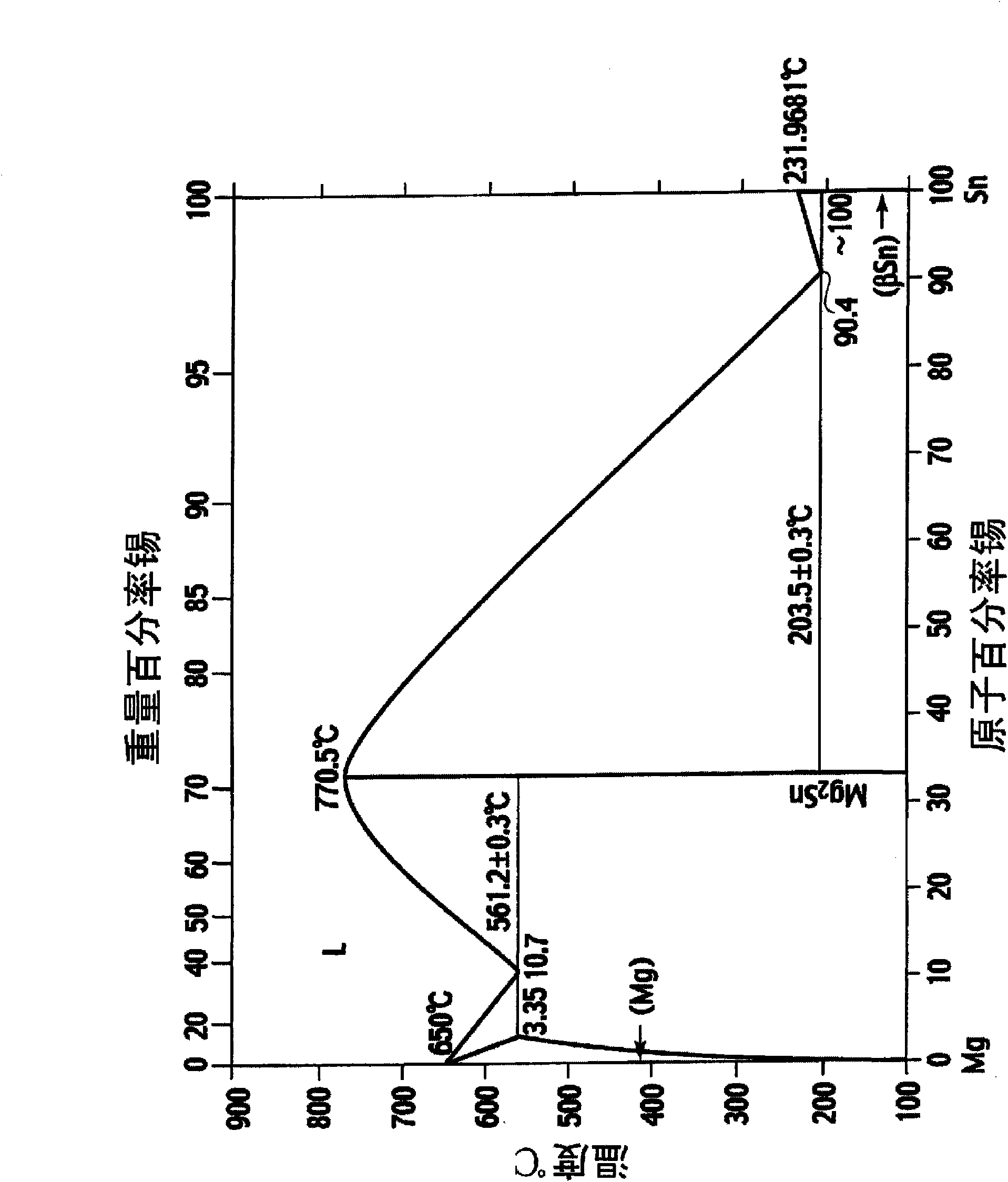

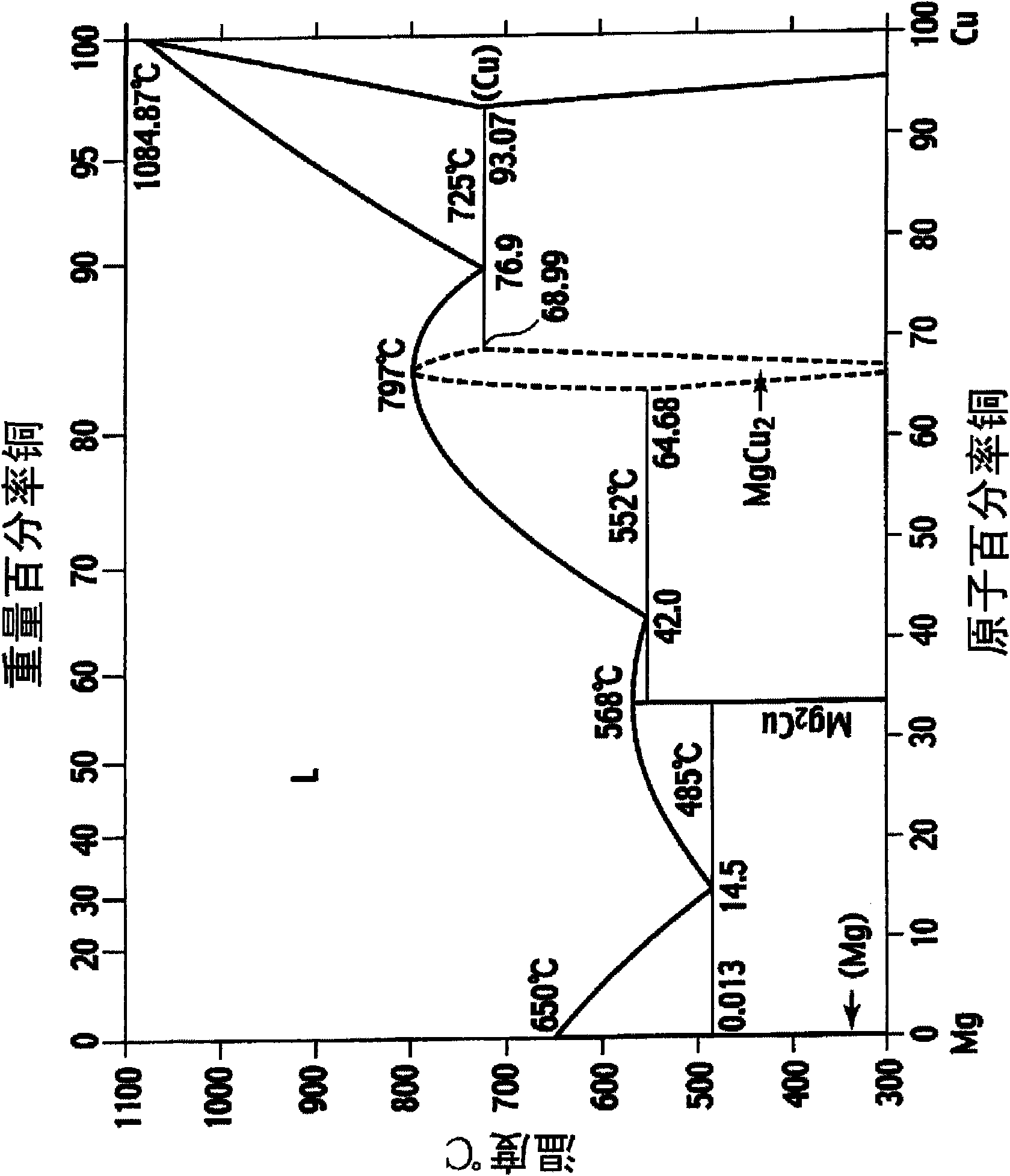

[0078] When joining dissimilar metals between a magnesium-based material as a first material and steel as a second material, bare steel sheets and galvanized steel sheets coated with zinc (metal C) are used as steel materials. On the other hand, three types of magnesium alloys with different additions of pure magnesium and aluminum (metal D) were prepared as magnesium materials, these steel materials and magnesium materials were joined under various conditions, and the relationship between the obtained interface structure and strength was investigated.

[0079] Figure 12 It is a schematic diagram showing the structure of the bonding apparatus used in this embodiment. The bonding apparatus 20 shown in the figure is a general diffusion bonding apparatus, and has a heating furnace 21 and a temperature control device 22 for adjusting the temperature of the atmosphere in the heating furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com