Grain drying device

A technology of grain drying and drying racks, which is applied in the direction of drying and preserving seeds, etc. It can solve the problems of affecting the drying effect of metal wires, the quality of grain raw materials, and the lack of time control devices, so as to reduce manpower consumption and enhance the effect , to avoid the effect of human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

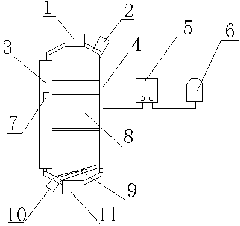

[0013] A kind of grain drying device, it comprises housing 4, drying frame 8, vibrating unit 3, sieve plate 9, time relay 5 and alarm device 6, and described housing 4 top is provided with air outlet 1, and described housing 4 is facing The position below the air outlet 1 is provided with an air inlet 11, the vicinity of the air outlet 1 is provided with a feed port 2, the vicinity of the air inlet 11 is provided with a discharge port 10, and the bottom of the drying rack 8 is provided with a sieve. plate 9. The sieve plate 9 is arranged at a certain angle with the ground, and the lower end points to the discharge port 10. The aperture of the sieve plate 9 is larger than the maximum particle diameter of the grain, and the vibration motor 7 is arranged in the vibration unit 3 , The described drying r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com