Flame-retardant insulating paint

A technology of flame-retardant insulating coatings and epoxy resins, which is applied in the direction of fire-resistant coatings, epoxy resin coatings, coatings, etc., and can solve the problems that insulating paints do not have flame-retardant functions, coatings age and powder, and ether bonds are easy to break. , to achieve excellent anti-corrosion and moisture-proof performance, strong adhesion and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

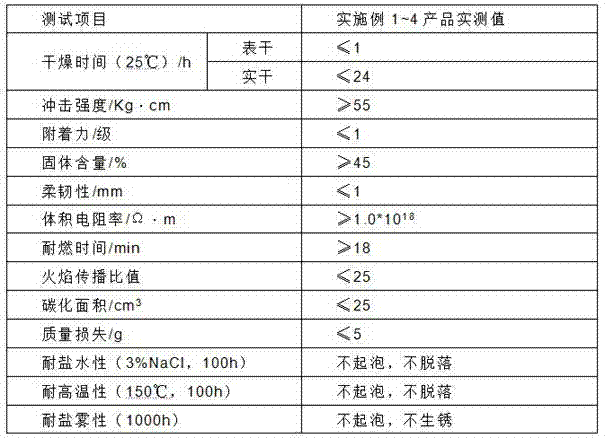

Examples

Embodiment 1

[0015] A flame-retardant insulating coating comprising the following components in parts by weight:

[0016] Component A: 100 parts of epoxy resin E-44, 7 parts of magnesium hydroxide whiskers, 6 parts of resorcinol bis(diphenyl phosphate), 10 parts of silicon powder, 2,4-dihydroxydiphenylmethyl 4 parts of ketones, 0.5 parts of sodium polycarboxylate, 0.2 parts of mineral oil defoamers, 5 parts of acetone, 8 parts of ethyl acetate;

[0017] Component B: 2 parts of curing agent.

[0018] The preparation process of the flame-retardant insulating coating in this embodiment is to stir evenly component A and component B according to the above ratio; when used, mix component A and component B evenly, and then dip coating or roll coating , Brush and spray coating method.

Embodiment 2

[0020] A flame-retardant insulating coating comprising the following components in parts by weight:

[0021] Component A: 120 parts of epoxy resin E-44, 10 parts of magnesium hydroxide whiskers, 12 parts of resorcinol bis(diphenyl phosphate), 25 parts of silicon powder, 2,4-dihydroxydiphenylmethyl 8 parts of ketone, 5 parts of pigment, 2 parts of sodium polycarboxylate, 0.5 part of mineral oil defoamer, 10 parts of acetone, 15 parts of ethyl acetate;

[0022] Component B: 10 parts of curing agent.

[0023] The preparation process of the flame-retardant insulating coating in this embodiment is to stir evenly component A and component B according to the above ratio; when used, mix component A and component B evenly, and then dip coating or roll coating , Brush and spray coating method.

Embodiment 3

[0025] A flame-retardant insulating coating comprising the following components in parts by weight:

[0026] Component A: 110 parts of epoxy resin E-44, 8 parts of magnesium hydroxide whiskers, 10 parts of resorcinol bis(diphenyl phosphate), 18 parts of silicon powder, 2,4-dihydroxydiphenylmethyl 5 parts of ketones, 2 parts of pigments, 1 part of polycarboxylate sodium salt, 0.3 parts of mineral oil defoamer, 6 parts of acetone, 10 parts of ethyl acetate;

[0027] Component B: 5 parts of curing agent.

[0028] The preparation process of the flame-retardant insulating coating in this embodiment is to stir evenly component A and component B according to the above ratio; when used, mix component A and component B evenly, and then dip coating or roll coating , Brush and spray coating method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com