Radiation-proof coating and preparation method thereof

A technology for anti-radiation coatings and raw materials, applied in the field of coatings, can solve problems such as excessive toxic substances, and achieve the effects of low preparation cost, strong absorption capacity and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

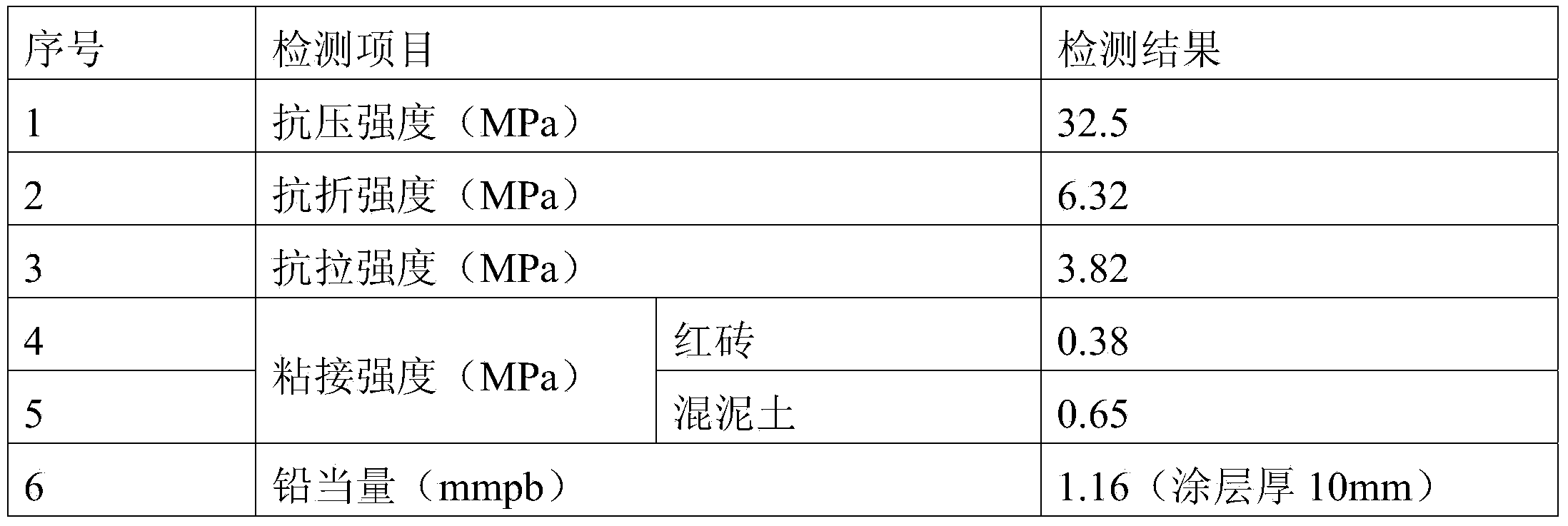

Embodiment 1

[0012] 1.1 A radiation-proof coating, which is made of the following raw materials in parts by weight: 10 parts of talcum powder, 10 parts of lime powder, 45 parts of porous starch, 10 parts of titanium dioxide, 10 parts of quartz powder, 40 parts of barium carbonate, epoxy modified 14 parts of silicone resin powder, 10 parts of styrene-acrylic emulsion, 1.1 parts of sodium polycarboxylate dispersant, 0.6 parts of thickener, 0.35 parts of defoamer, 1.05 parts of coupling agent, and 55 parts of water.

[0013] Prepare radiation protection coating 1000Kg of the present invention, the weight of each raw material used is: talcum powder 48.3Kg, lime powder 48.3Kg, porous starch 217.3Kg, titanium dioxide 48.3Kg, quartz powder 48.3Kg, barium carbonate 193.1Kg, epoxy modified Silicone resin powder 67.6Kg, styrene-acrylic emulsion 48.3Kg, sodium polycarboxylate dispersant 5.3Kg, thickener 2.9Kg, defoamer 1.7Kg, coupling agent 5.1Kg, water 265.6Kg.

[0014] 1.2 Preparation method of ant...

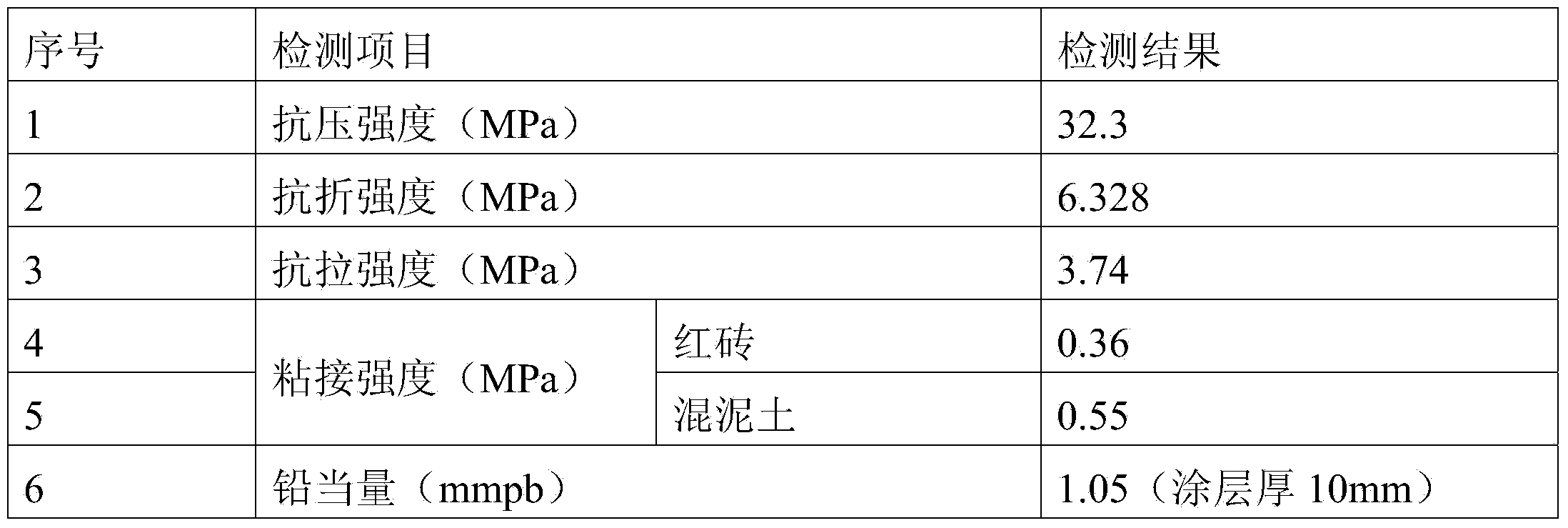

Embodiment 2

[0021] 2.1 A radiation-proof coating, which is made of the following raw materials in parts by weight: 9 parts of talcum powder, 11 parts of lime powder, 48 parts of porous starch, 9 parts of titanium dioxide, 11 parts of quartz powder, 42 parts of barium carbonate, epoxy modified 12 parts of silicone resin powder, 11 parts of styrene-acrylic emulsion, 1.3 parts of sodium polycarboxylate dispersant, 0.4 parts of thickener, 0.4 parts of defoamer, 1.1 parts of coupling agent, 60 parts of water.

[0022] Prepare radiation protection coating 1000Kg of the present invention, the weight of each raw material used is: talcum powder 41.6Kg, lime powder 50.9Kg, porous starch 222.0Kg, titanium dioxide 41.6Kg, quartz powder 50.9Kg, barium carbonate 194.3Kg, epoxy modified Silicone resin powder 55.5Kg, styrene-acrylic emulsion 50.9Kg, sodium polycarboxylate dispersant 6.0Kg, thickener 1.9Kg, defoamer 1.9Kg, coupling agent 5.1Kg, water 277.5Kg.

[0023] 2.2 Preparation method of anti-radiat...

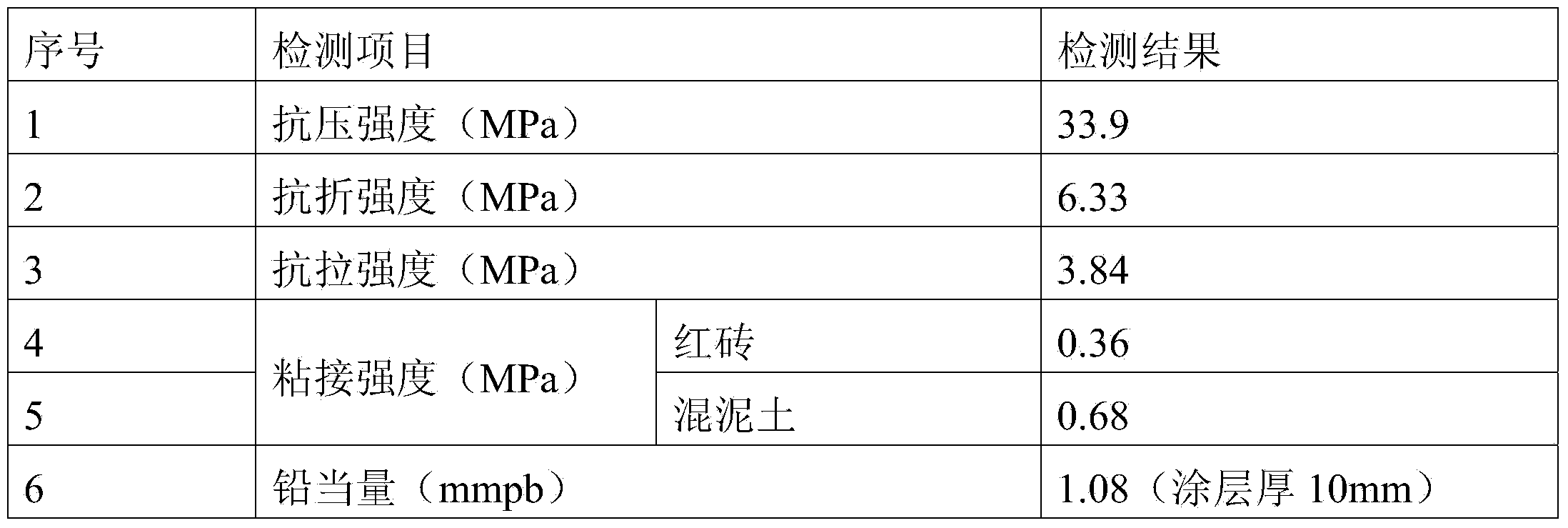

Embodiment 3

[0029] 3.1 An anti-radiation coating, which is made of the following raw materials in parts by weight: 11 parts of talcum powder, 9 parts of lime powder, 48 parts of porous starch, 11 parts of titanium dioxide, 9 parts of quartz powder, 35 parts of barium carbonate, epoxy modified 10 parts of silicone resin powder, 12 parts of styrene-acrylic emulsion, 0.9 parts of sodium polycarboxylate dispersant, 0.8 parts of thickener, 0.2 parts of defoamer, 0.9 parts of coupling agent, and 50 parts of water.

[0030] Prepare radiation protection coating 1000Kg of the present invention, the weight of each raw material used is: talcum powder 55.6Kg, lime powder 45.5Kg, porous starch 242.7Kg, titanium dioxide 55.6Kg, quartz powder 45.5Kg, barium carbonate 176.9Kg, epoxy modified Silicone resin powder 50.6Kg, styrene-acrylic emulsion 60.7Kg, sodium polycarboxylate dispersant 4.6Kg, thickener 4.0Kg, defoamer 1.0Kg, coupling agent 4.6Kg, water 252.8Kg.

[0031] 3.2 Preparation method of anti-ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com