Descaling blocking remover for high-temperature and high-pressure oil-gas well and preparation method of descaling blocking remover

A high-temperature, high-pressure, plugging-removing agent technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of exacerbating high-temperature and high-pressure wellbore corrosion, aggravating the possibility of sand production in formations, and inability to dissolve sulfate scale, etc., to achieve Improve oil and gas seepage channels, avoid formation rock strength reduction, and meet the effect of repeated plugging removal construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

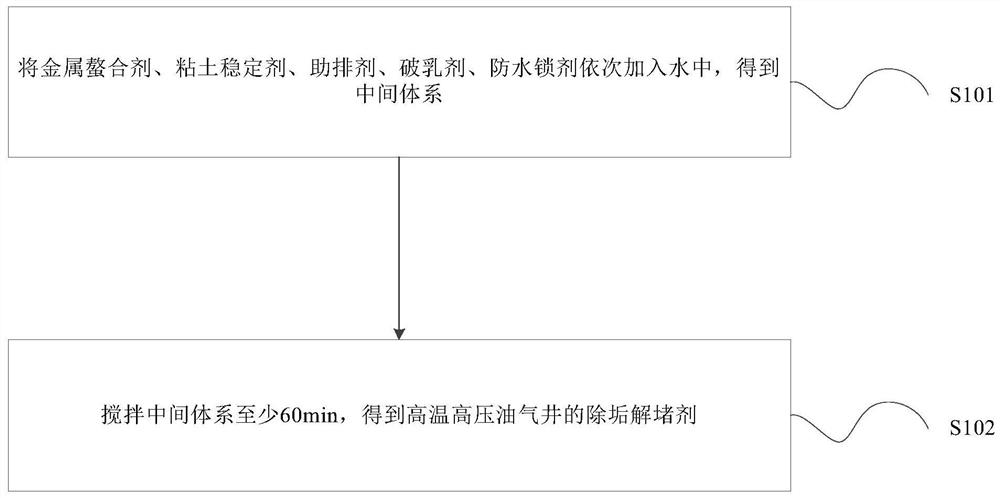

[0045] figure 1 It is a schematic flow chart of an embodiment of the preparation method of the descaling and plugging removal agent for high temperature and high pressure oil and gas wells of the present invention. Such as figure 1 Shown, the preparation method of the present embodiment comprises:

[0046] S101: adding metal chelating agent, clay stabilizer, drainage aid, demulsifier, and waterproof locking agent into water in sequence to obtain an intermediate system;

[0047] S102: Stir the intermediate system for at least 60 minutes to obtain a scale-removing and blocking-removing agent for high-temperature and high-pressure oil and gas wells.

[0048] When the descaling and plugging removal agent for high temperature and high pressure oil and gas wells to be prepared does not contain scale inhibitor, it can be carried out according to the above preparation method.

[0049] In the above preparation method, each component is sequentially added into water according to the ...

Embodiment 1

[0064] The descaling and plugging removal agent for high-temperature and high-pressure oil and gas wells of this embodiment includes the following components in terms of mass percentages:

[0065] Metal chelating agent: 8%

[0066] Antiscalant: 1%

[0067] Clay Stabilizer: 2%

[0068] Drainage aids: 2%

[0069] Demulsifier: 2%

[0070] Waterproof lock agent: 5%

[0071] The balance is clear water.

[0072] Wherein, the metal chelating agent includes according to mass percentage: 70% of aminocarboxylic acid chelating agent, 20% of hydroxycarboxylic acid chelating agent, and 10% of organic polyphosphonic acid chelating agent;

[0073] Specifically, aminocarboxylic acid chelating agents include ethylenediaminetetraacetic acid disodium salt (accounting for aminocarboxylic acid chelating agent mass percentage content is 30%), ethylenediaminetetraacetic acid tetrasodium salt (accounting for aminocarboxylic acid chelating agent mass percentage content is 30%), ethylenediaminetet...

Embodiment 2

[0084] The descaling and plugging removal agent for high-temperature and high-pressure oil and gas wells of this embodiment includes the following components in terms of mass percentages:

[0085] Metal chelating agent: 10%

[0086] Antiscalant: 2%

[0087] Clay Stabilizer: 1%

[0088] Drainage aids: 1%

[0089] Demulsifier: 0.5%

[0090] Waterproof lock agent: 10%

[0091] The balance is clear water.

[0092] Among them, the metal chelating agent includes according to the mass percentage: 60% of aminocarboxylic acid chelating agent, 25% of hydroxycarboxylic acid chelating agent, and 15% of organic polyphosphonic acid chelating agent;

[0093] Specifically, the aminocarboxylic acid chelating agent includes ethylenediaminetetraacetic acid disodium salt (accounting for 40% of the mass percentage of aminocarboxylic acid chelating agent), ethylenediaminetetraacetic acid tetrasodium salt (accounting for aminocarboxylic acid chelating agent mass percentage content is 40%), ethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com