Novel silk softening agent and preparation method thereof

A technology of softener and silk, which is applied in the field of new silk softener and its preparation, can solve the problems that cannot meet the actual production of the factory, silk is soft, fluffy, elastic, etc. The effect of low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

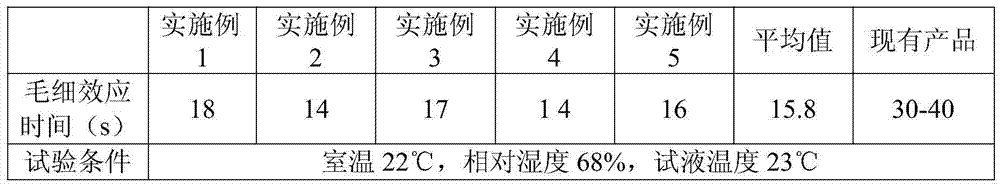

Embodiment 1

[0025] A new type of silk softener, in parts by weight, comprising the following raw materials: 6 parts of ester group quaternary ammonium salt, 0.3 part of silane-modified polyurethane, 0.2 part of polyether-modified silane, 0.1 part of sodium lignosulfonate, alkyl 0.1 part of sodium benzenesulfonate, 0.2 part of starch grafted sodium acrylate, 0.2 part of sodium polyacrylate, 0.2 part of sodium N-lauroyl glutamate, 0.2 part of calcium lignosulfonate, 0.2 part of citronellal, 0.3 part of malic acid , 0.1 part of carrageenan, 0.1 part of locust bean gum, 0.1 part of triadimefon, 40 parts of deionized water.

[0026] The preparation method of described novel silk softening agent comprises the following steps:

[0027] S1: Add the ester quaternary ammonium salt into deionized water, raise the temperature to 50°C, stir to dissolve the ester quaternary ammonium salt, and obtain the mixed solution A;

[0028] S2: Add starch-grafted sodium acrylate, sodium polyacrylate, sodium N-la...

Embodiment 2

[0032] A new type of silk softener, in parts by weight, comprising the following raw materials: 10 parts of ester quaternary ammonium salt, 0.5 part of silane-modified polyurethane, 0.4 part of polyether-modified silane, 0.4 part of sodium lignosulfonate, alkyl 0.3 parts of sodium benzenesulfonate, 0.4 parts of starch grafted sodium acrylate, 0.3 parts of sodium polyacrylate, 0.4 parts of sodium N-lauroyl glutamate, 0.3 parts of calcium lignosulfonate, 0.5 parts of citronellal, 0.5 parts of malic acid , 0.3 parts of carrageenan, 0.2 parts of locust bean gum, 0.3 parts of triadimefon, 70 parts of deionized water.

[0033] The preparation method of described novel silk softening agent comprises the following steps:

[0034] S1: Add the ester quaternary ammonium salt into deionized water, raise the temperature to 60°C, stir and dissolve the ester quaternary ammonium salt to obtain a mixed solution A;

[0035] S2: Add starch-grafted sodium acrylate, sodium polyacrylate, sodium N-...

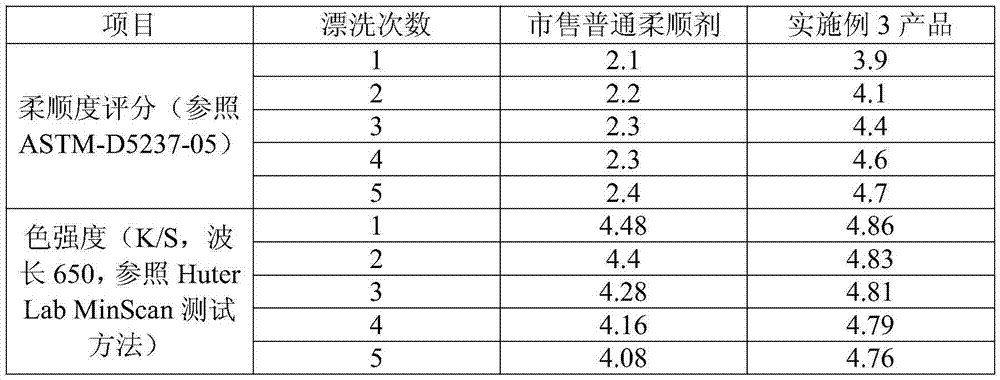

Embodiment 3

[0039] A new type of silk softener, in parts by weight, comprising the following raw materials: 9 parts of ester quaternary ammonium salt, 0.4 part of silane-modified polyurethane, 0.3 part of polyether-modified silane, 0.3 part of sodium lignosulfonate, alkyl 0.2 parts of sodium benzenesulfonate, 0.3 parts of starch grafted sodium acrylate, 0.3 parts of sodium polyacrylate, 0.3 parts of sodium N-lauroyl glutamate, 0.3 parts of calcium lignosulfonate, 0.4 parts of citronellal, 0.4 parts of malic acid , 0.2 parts of carrageenan, 0.2 parts of locust bean gum, 0.3 parts of triadimefon, 60 parts of deionized water.

[0040] The preparation method of described novel silk softening agent comprises the following steps:

[0041] S1: Add the ester quaternary ammonium salt into deionized water, raise the temperature to 55°C, stir and dissolve the ester quaternary ammonium salt, and obtain the mixed solution A;

[0042] S2: Add starch-grafted sodium acrylate, sodium polyacrylate, sodium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com