Preparation method of chitosan leather mildew-proof novel material

A new material, chitosan technology, applied in botany equipment and methods, chemicals for biological control, animal repellents, etc., can solve problems such as adverse human health, achieve strong bactericidal effect and long duration , evenly dispersed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

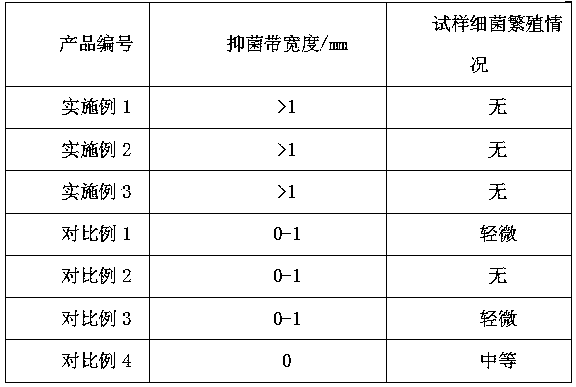

Examples

Embodiment 1

[0020] In the reaction kettle, add 100Kg of carboxymethylcellulose, 2Kg of ethylene bis(oxyethylene) dicaproate, 2Kg of 1,3-adamantanediol diacrylate, 0.3Kg of yttrium disilicate, N-sulfonic acid 0.2Kg of acid butylpyridine p-toluenesulfonate ionic liquid, 0.2Kg of calcium lignosulfonate, 200Kg of ethanol, 0.3Kg of benzoyl peroxide, 2Kg of gelatin, heated to 85°C, and stirred at a speed of 250rpm for 3h to obtain Chitosan leather anti-mildew new material.

Embodiment 2

[0022] In the reaction kettle, add 100Kg of carboxymethylcellulose, 1Kg of ethylene bis(oxyethylene) dicaproate, 1Kg of 1,3-adamantanediol diacrylate, 0.1Kg of yttrium disilicate, N-sulfonic acid 0.1Kg of acid butylpyridine p-toluenesulfonate ionic liquid, 0.1Kg of calcium lignosulfonate, 150Kg of ethanol, 0.1Kg of benzoyl peroxide, and 1Kg of gelatin, heated to 80°C, and stirred at a speed of 200rpm for 2h to obtain Chitosan leather anti-mildew new material.

Embodiment 3

[0024] In the reaction kettle, add 100Kg of carboxymethylcellulose, 3Kg of ethylene bis(oxyethylene) dicaproate, 3Kg of 1,3-adamantanediol diacrylate, 0.5Kg of yttrium disilicate, N-sulfonic acid Acid butylpyridine p-toluenesulfonate ionic liquid 0.3Kg, calcium lignosulfonate 0.3Kg, ethanol 250Kg, benzoyl peroxide 0.5Kg, gelatin 5Kg, heat up to 90°C, stir at 300rpm for 4h, and obtain Chitosan leather anti-mildew new material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com