Preparation method of magnetic lignin-based adsorbent and application thereof

An adsorbent, lignin technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problems of unstable properties, easy oxidation, and low adsorption performance, and achieve good adsorption performance. , easy to operate, green and efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

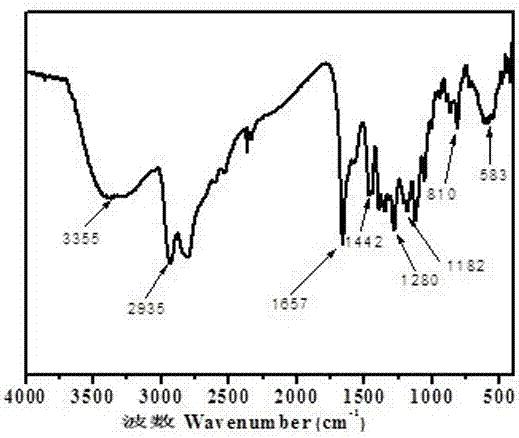

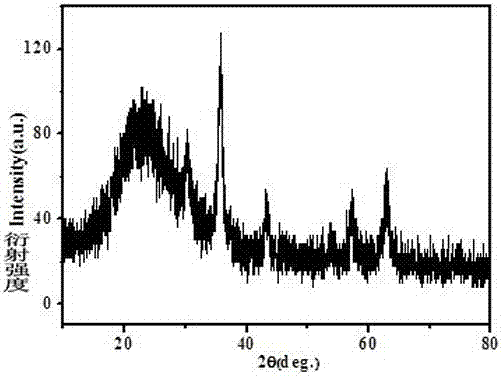

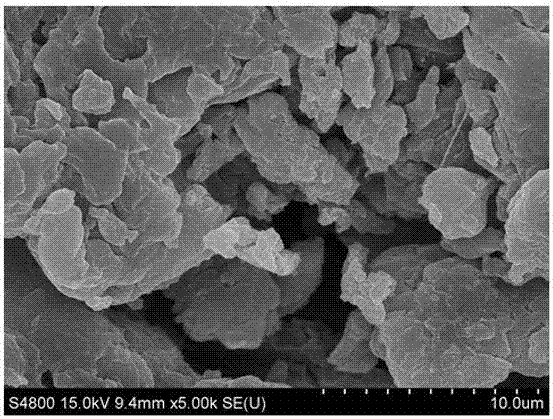

Embodiment 1

[0034] At room temperature, accurately weigh 0.1g of Fe 3 o 4 / C, put it into a 100mL beaker, add 50mL of deionized water to disperse evenly in the ultrasonic wave, and prepare the magnetic fluid. Then, accurately weigh 4g of lignosulfonate, add it into a 250mL three-necked flask, add 39mL of deionized water, then mechanically stir at 60°C, and reflux in a water bath for 30min. Then, the magnetic fluid prepared above was added into the three-necked flask, stirred mechanically, and continued to reflux in the water bath for 30 minutes. Then add 6 mL of triethylenetetramine to the above mixture, stir mechanically, and reflux in the water bath for 10 minutes, then add 5 mL of cross-linking agent dropwise using a constant pressure dropping funnel, stir mechanically, and reflux in the water bath for 70 minutes. After the reaction, it was magnetically separated and washed with deionized water to obtain a beige precipitate, which was dried in vacuum at 60° C. overnight and ground to...

Embodiment 2

[0036] At room temperature, accurately weigh 0.25g of Fe 3 o 4 / C, put it into a 100mL beaker, add 50mL of deionized water to disperse evenly in the ultrasonic wave, and prepare the magnetic fluid. Then, accurately weigh 4g of lignosulfonate, add it into a 250mL three-necked flask, add 39mL of deionized water, then mechanically stir at 60°C, and reflux in a water bath for 30min. Then, the magnetic fluid prepared above was added into the three-necked flask, stirred mechanically, and continued to reflux in the water bath for 30 minutes. Then add 6 mL of triethylenetetramine to the above mixture, stir mechanically, and reflux in the water bath for 10 minutes, then add 5 mL of cross-linking agent dropwise using a constant pressure dropping funnel, stir mechanically, and reflux in the water bath for 70 minutes. After the reaction, it was magnetically separated and washed with deionized water to obtain a beige precipitate, which was dried in vacuum at 60° C. overnight and ground to ...

Embodiment 3

[0041] At room temperature, accurately weigh 0.5g of Fe 3 o 4 / C, put it into a 100mL beaker, add 50mL of deionized water to disperse evenly in the ultrasonic wave, and prepare the magnetic fluid. Then, accurately weigh 4g of lignosulfonate, add it into a 250mL three-necked flask, add 39mL of deionized water, then mechanically stir at 90°C, and reflux in a water bath for 30min. Then, the magnetic fluid prepared above was added into the three-necked flask, stirred mechanically, and continued to reflux in the water bath for 30 minutes. Then add 6 mL of triethylenetetramine to the above mixture, stir mechanically, and reflux in the water bath for 10 minutes, then add 5 mL of cross-linking agent dropwise using a constant pressure dropping funnel, stir mechanically, and reflux in the water bath for 70 minutes. After the reaction, it was magnetically separated and washed with deionized water to obtain a beige precipitate, which was dried in vacuum at 60° C. overnight and ground to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com