Latent curing agent capable of toughening imidazole epoxy resin, and preparation method thereof

A technology of latent curing agent and epoxy resin, which is applied in the direction of organic chemistry, can solve the problems that the compatibility of epoxy resin is not as good as that of liquid curing agent, there are many factors affecting the formation of microcapsules, and the physical and mechanical properties are affected, and the room temperature can be extended. Effect of storage time, guaranteed curing time and guaranteed curing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

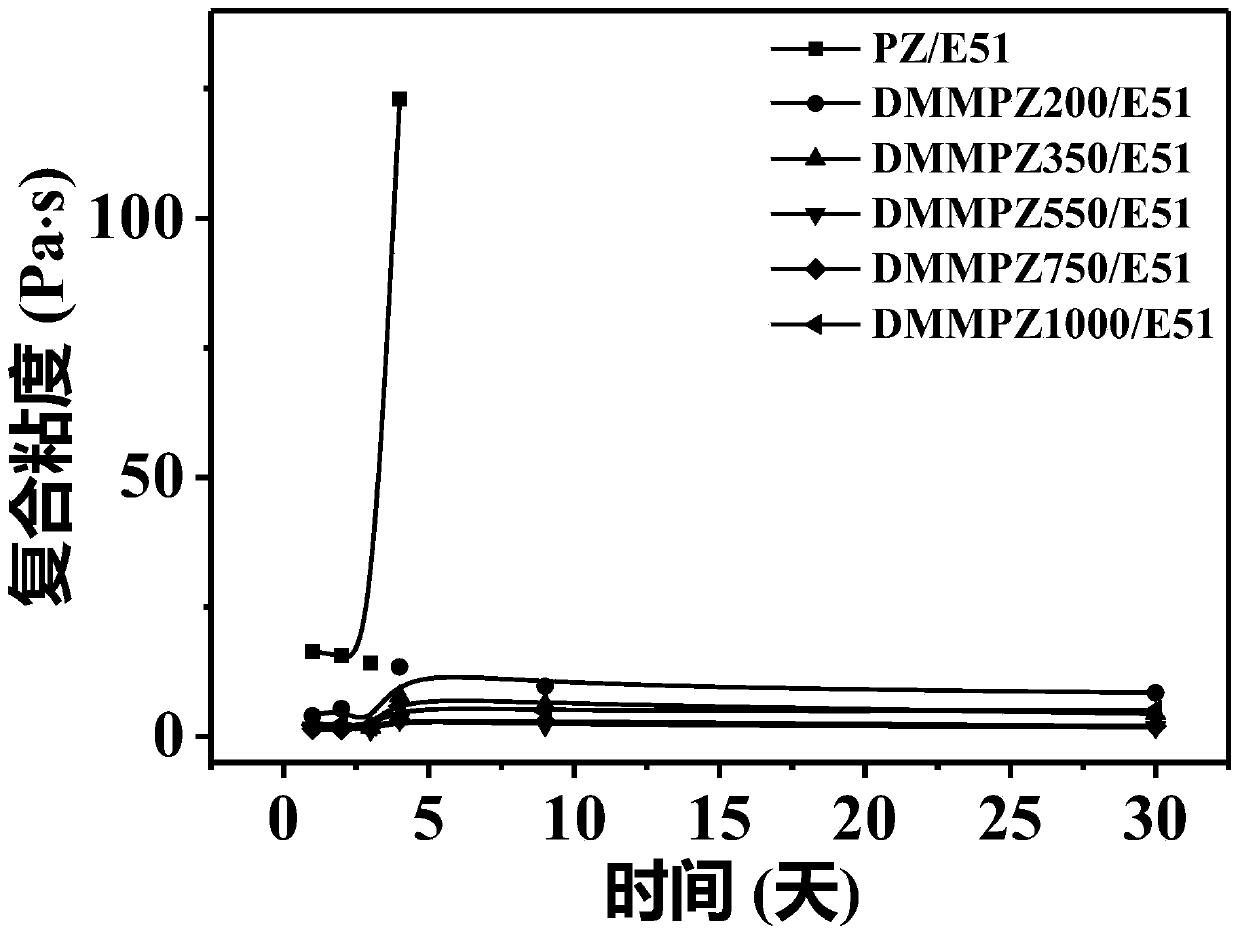

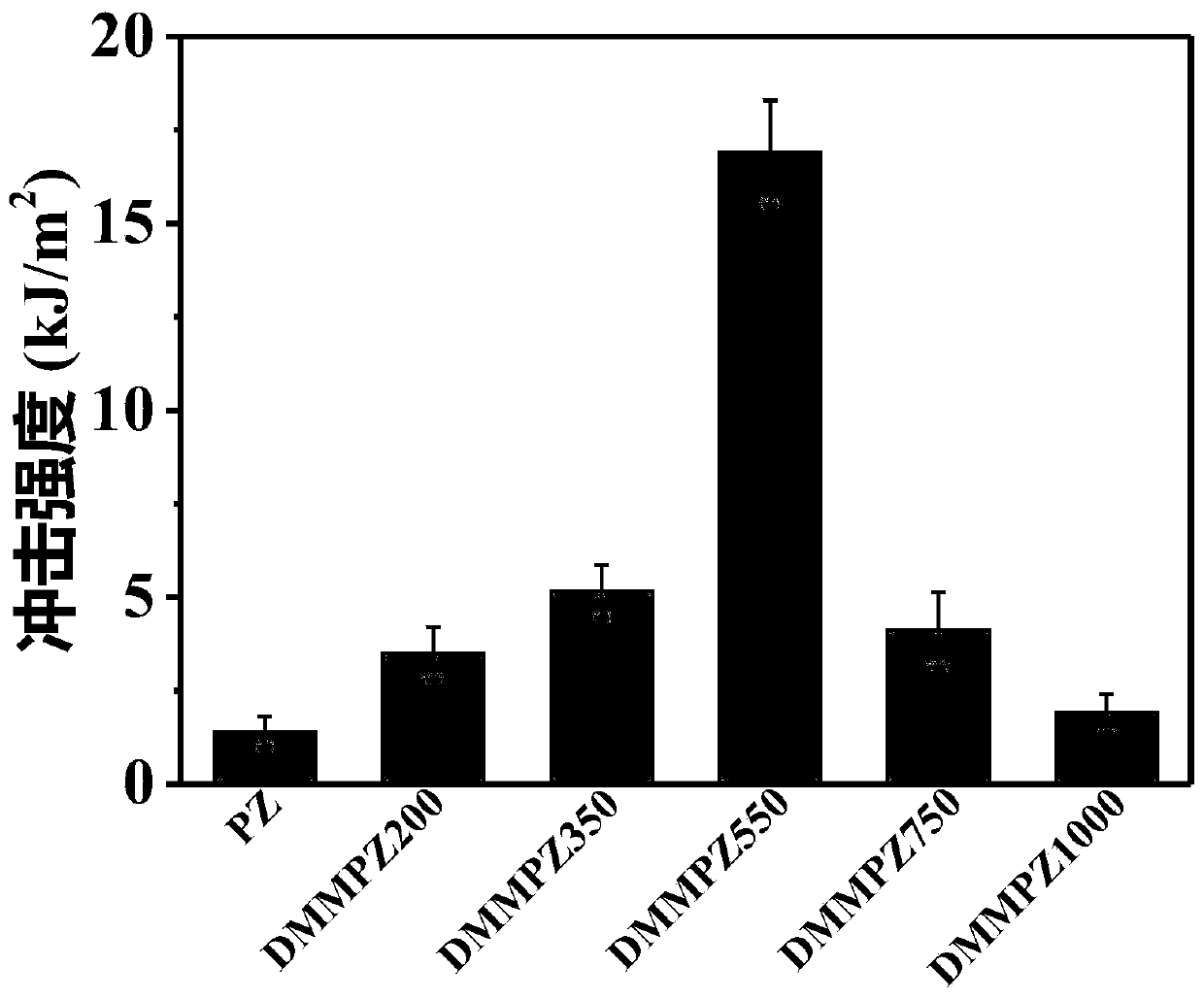

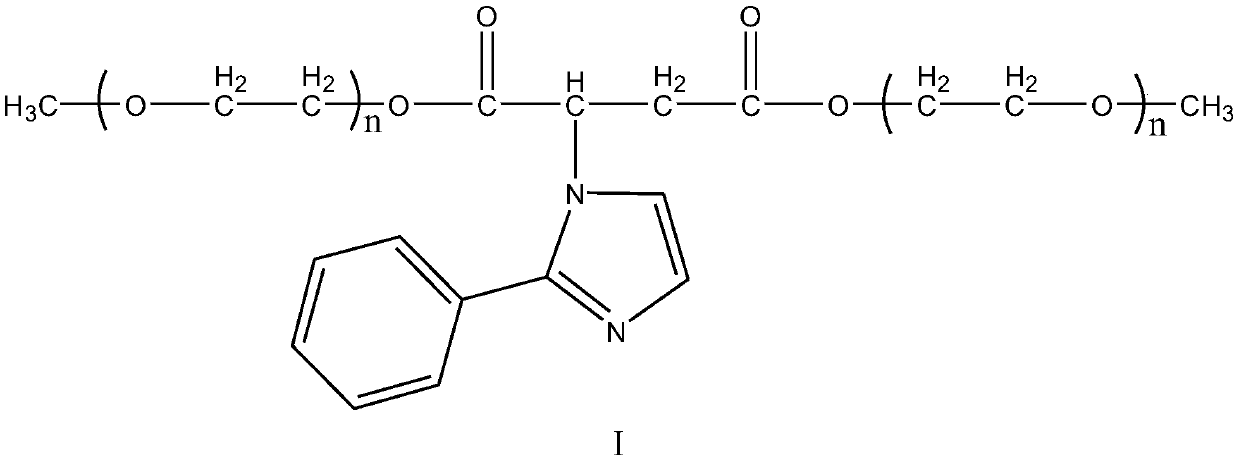

[0029] Add maleic anhydride and polyethylene glycol monomethyl ether (n=4) with a molecular weight of 200 in a molar ratio of 1:2.1 into the flask, then add a catalyst p-toluenesulfonic acid with a mass fraction of 3%, and react at 50°C for 5 hours. Reaction under vacuum at 100°C for 5h. After the reaction, the product was dissolved in dichloromethane, washed three times with saturated sodium carbonate solution and saturated sodium chloride solution, and the dichloromethane was removed to obtain maleic acid polyethylene glycol monomethyl ether diester. Dissolve maleic acid polyethylene glycol monomethyl ether diester with a molecular weight of 480 and 2-phenylimidazole at a molar ratio of 1:1 in acetonitrile, and add a catalyst 1,8-diazepine with a mass fraction of 5%. Dicycloundec-7-ene, react at 40°C for 20h, remove acetonitrile by distillation under reduced pressure at the end of the reaction, dissolve the product in ethanol, and use petroleum ether to settle and purify to ...

Embodiment 2

[0033] Add maleic anhydride and polyethylene glycol monomethyl ether (n=12) with a molecular weight of 550 in a molar ratio of 1:2.1 into the flask, then add a catalyst with a mass fraction of 3% p-toluenesulfonic acid, and react at 60°C for 4 hours. Reacted under vacuum at 110°C for 4h. After the reaction, the product was dissolved in dichloromethane, washed four times with saturated sodium carbonate solution and saturated sodium chloride solution, and the dichloromethane was removed to obtain maleic acid polyethylene glycol monomethyl ether diester. Dissolve maleic acid polyethylene glycol monomethyl ether diester with a molecular weight of 2080 and 2-phenylimidazole at a molar ratio of 1:1 in acetonitrile, and add a catalyst 1,8-diazepine with a mass fraction of 7%. Dicycloundec-7-ene, react at 45°C for 24h, remove acetonitrile by distillation under reduced pressure after the reaction, dissolve the product in ethanol, and use petroleum ether for sedimentation and purificati...

Embodiment 3

[0037] Add maleic anhydride and polyethylene glycol monomethyl ether (n=22) with a molecular weight of 1000 into the flask at a molar ratio of 1:2.1, then add a catalyst p-toluenesulfonic acid with a mass fraction of 5%, and react at 70°C for 3 hours. Reaction under vacuum at 120°C for 5h. After the reaction, the product was dissolved in dichloromethane, washed three times with saturated sodium carbonate solution and saturated sodium chloride solution, and the dichloromethane was removed to obtain maleic acid polyethylene glycol monomethyl ether diester. Dissolve the molecular weight of 1000 and 2-phenylimidazole in acetonitrile in a molar ratio of 1:1, add the catalyst 1,8-diazabicycloundec-7-ene with a mass fraction of 10%, and react at 50°C for 48h After the reaction, the acetonitrile was distilled off under reduced pressure, the product was dissolved in ethanol, and petroleum ether was used for sedimentation and purification to obtain the modified imidazole epoxy resin lat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com