Converter slag-stopping sliding plate brick added with titanium nitride composite powder and preparation method of converter slag-stopping sliding plate brick

A composite powder, converter slag blocking technology, applied in the field of refractory materials, can solve problems such as complex production process, achieve the effects of high melting point, simple composition of raw materials, and good thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

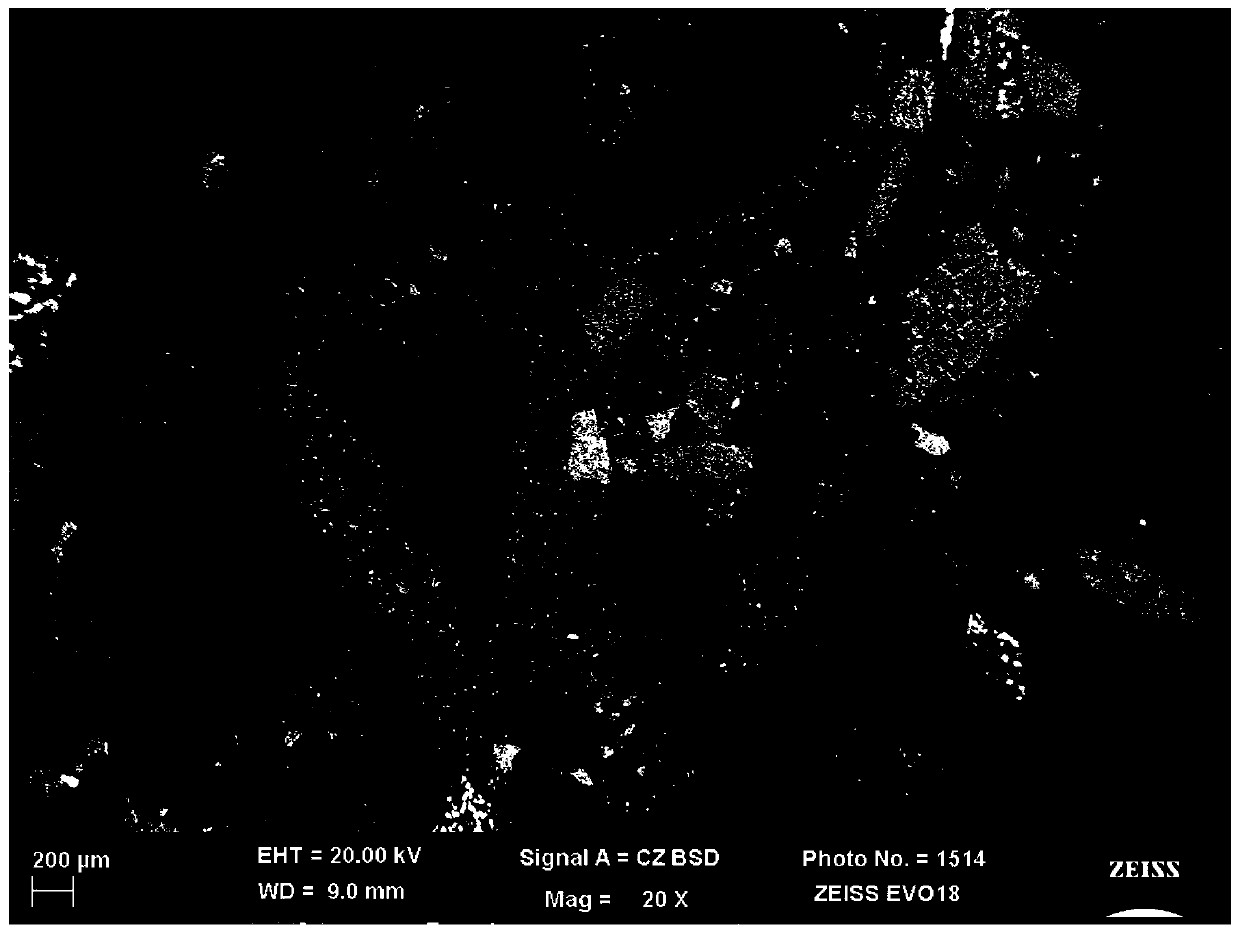

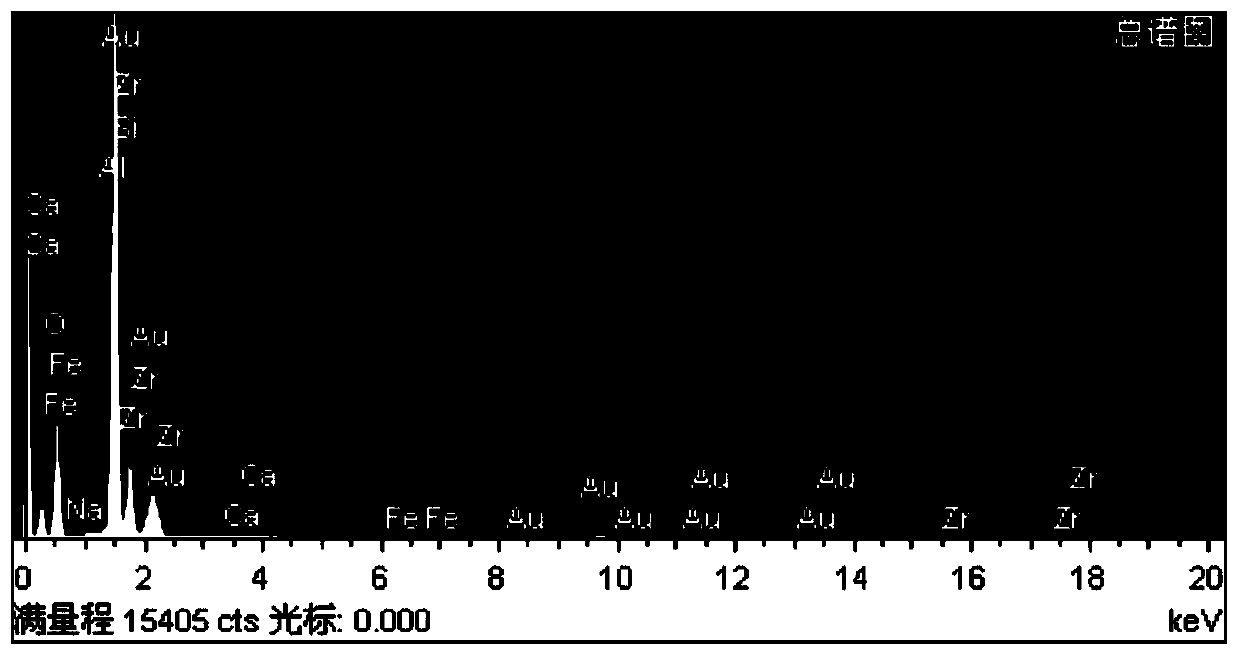

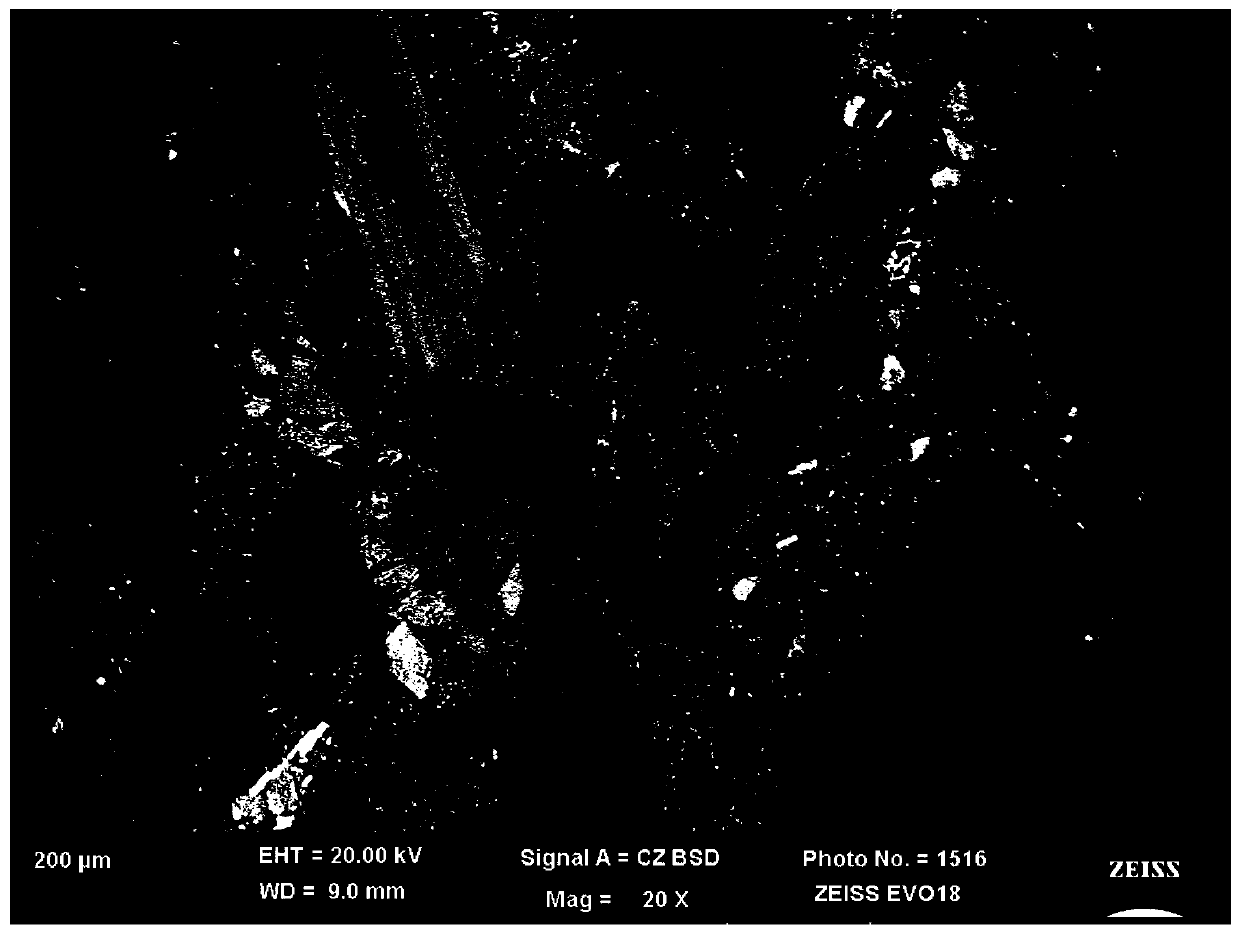

Image

Examples

Embodiment 1

[0063] A converter slag-blocking sliding brick containing titanium nitride composite powder in this embodiment, the composition and mass parts of its formula are:

[0064] 5 parts of fused zirconia corundum with a particle size of 1-3mm;

[0065] 25 parts of tabular alumina with a particle size of 1-2mm;

[0066] 15 parts of tabular alumina with a particle size of 1-0.5mm;

[0067] 15 parts of tabular alumina with a particle size of 0.5-0mm;

[0068] 5 parts of silicon carbide with a particle size of 1-0 mm;

[0069] 15 parts of tabular corundum powder with a particle size of 325 mesh;

[0070] 3 parts of 98 metal silicon powder with a particle size of 325 mesh;

[0071] 6 parts of metal aluminum powder with a particle size of 200 mesh;

[0072] 7 parts of α calcined alumina powder with a particle size of 2 μm;

[0073] 1.5 parts of boron carbide powder with a particle size of 325 mesh;

[0074] 1 part of nano zirconia powder with a particle size of 1 μm;

[0075] 1.5 ...

Embodiment 2

[0091] In this example, the formula of Example 2 shown in the following Table 2 was used to prepare converter slag-blocking sliding bricks containing titanium nitride composite powder, and the parameter conditions of the preparation method were slightly different.

[0092] Utilize the recipe of Example 2 shown in Table 2 to prepare the converter slag-blocking sliding brick containing titanium nitride composite powder of this example, the steps are:

[0093] (1) Ingredients of pellets: mix pellets according to the mass parts of the above raw materials, that is, 5 parts of fused zirconia corundum of 1-3mm, 25 parts of tabular corundum of 1-2mm, 15 parts of tabular alumina of 1-0.5mm, 0.5- 15 parts of 0mm tabular alumina, 5 parts of 1-0mm silicon carbide;

[0094] (2) Premixed powder: The composite powder and solid phenolic resin powder are vacuumized (to prevent oxidation) and dry mixed for 25 minutes by a planetary vibrating high-energy ball mill, so that the fine powder compon...

Embodiment 3

[0103] In this example, the formula of Example 3 shown in the following Table 2 was used to prepare converter slag-blocking sliding bricks containing titanium nitride composite powder, and the parameter conditions of the preparation method were slightly different.

[0104] Utilize the recipe of Example 3 shown in Table 2 to prepare the converter slag-blocking sliding brick containing titanium nitride composite powder of this example, the steps are:

[0105] (1) Ingredients of pellets: mix pellets according to the mass parts of the above raw materials, that is, 5 parts of fused zirconia corundum of 1-3mm, 25 parts of tabular corundum of 1-2mm, 15 parts of tabular alumina of 1-0.5mm, 0.5- 15 parts of 0mm tabular alumina, 5 parts of 1-0mm silicon carbide;

[0106] (2) Premixed powder: The composite powder and solid phenolic resin powder are vacuumized (to prevent oxidation) and dry mixed for 35 minutes by a planetary vibrating high-energy ball mill, so that the fine powder compon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com