Short glass fiber reinforced polyphenylene sulfide resin material and preparation method thereof

A technology of polyphenylene sulfide resin and chopped glass fiber is applied in the field of chopped glass fiber reinforced polyphenylene sulfide resin material and its preparation, and can solve the problems of easy burrs on the surface of polyphenylene sulfide and poor product appearance quality. , to achieve the effect of good appearance quality, improved fluidity and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

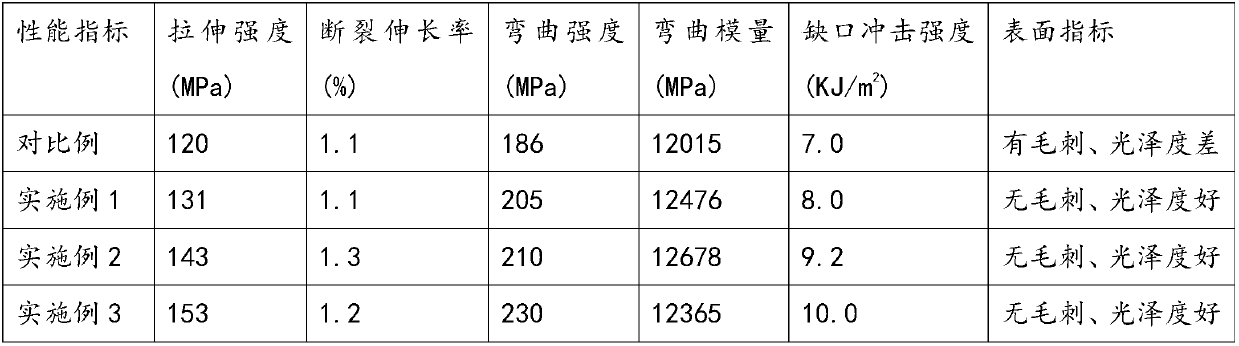

Examples

Embodiment 1

[0021] A preparation method of chopped glass fiber reinforced polyphenylene sulfide resin material, comprising the following steps:

[0022] (1) 55.2wt% polyphenylene sulfide, 0.3wt% antioxidant 1010, 1.5wt% silicone powder and 3wt% maleic anhydride grafted hydrogenated styrene-butadiene block copolymer in a high mixer Mix evenly to obtain a masterbatch;

[0023] (2) The masterbatch prepared in step (1) is added by the hopper of the extruder, and 40wt% chopped glass fiber is added by the side feed hopper of the extruder, and extruded, cooled, dried and granulated, The chopped glass fiber reinforced polyphenylene sulfide resin material was prepared.

Embodiment 2

[0025] A preparation method of chopped glass fiber reinforced polyphenylene sulfide resin material, comprising the following steps:

[0026] (1) 52.2wt% polyphenylene sulfide, 0.3wt% antioxidant 1010, 1.5wt% silicone powder and 6wt% maleic anhydride grafted hydrogenated styrene-butadiene block copolymer in a high mixer Mix evenly to obtain a masterbatch;

[0027] (2) The masterbatch prepared in step (1) is added by the hopper of the extruder, and 40wt% chopped glass fiber is added by the side feed hopper of the extruder, and extruded, cooled, dried and granulated, The chopped glass fiber reinforced polyphenylene sulfide resin material was prepared.

Embodiment 3

[0029] A preparation method of chopped glass fiber reinforced polyphenylene sulfide resin material, comprising the following steps:

[0030] (1) Mix 52.2wt% polyphenylene sulfide, 0.3wt% antioxidant 1010, 1.5wt% silicone powder and 6wt% glycidyl methacrylate grafted POE in a high mixer to prepare a masterbatch ;

[0031] (2) The masterbatch prepared in step (1) is added by the hopper of the extruder, and 40wt% chopped glass fiber is added by the side feed hopper of the extruder, and extruded, cooled, dried and granulated, The chopped glass fiber reinforced polyphenylene sulfide resin material was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com