MPP power cable protecting tube

A power cable and protection tube technology, applied in the field of MPP power cable protection tube, can solve the problems of low tensile strength, easy to become brittle, poor toughness, etc., and achieve the effect of improving comprehensive performance and improving impact performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: An MPP power cable protection tube is made of modified polypropylene material using a plastic extruder.

[0027] Weigh 2 parts of silicon dioxide by weight and dissolve it in sodium silicate solution, weigh 10 parts of calcium carbonate to make a calcium carbonate suspension, raise the temperature of the obtained sodium carbonate suspension to 80°C, and then dissolve the obtained sodium silicate Add the solution evenly into the sodium carbonate suspension within 3 hours, adjust and maintain the pH of the suspension with hydrochloric acid = 9, and then age for 3 hours after adding, filter and dry at 100°C, sieve (250mesh), that is Nanocomposite particles are obtained. After raising the temperature of the obtained nanocomposite particles in an emulsifier, a silane coupling agent was added and stirred at 60° C. for 1 hour.

[0028] Weigh 65 parts of homopolypropylene, 10 parts of maleic anhydride-grafted polypropylene, 4.4 parts of treated nanocomposite part...

Embodiment 2

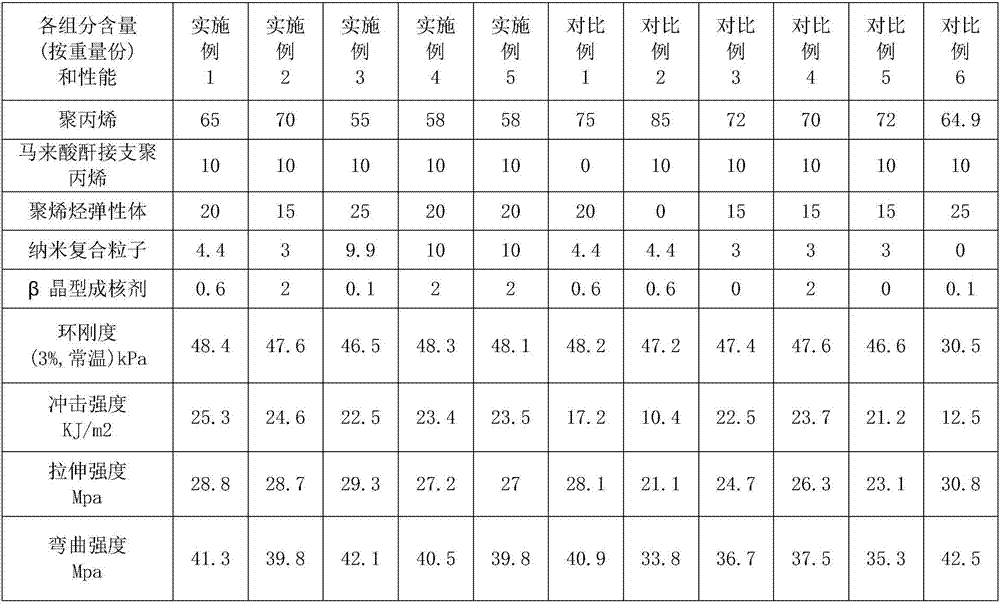

[0029] Embodiment 2: According to the contents of various components listed in Table 1 below, the method of Example 1 was repeated, and the test results were listed in Table 1.

Embodiment 3

[0030] Embodiment 3: According to the contents of various components listed in Table 1 below, the method of Example 1 was repeated, and the test results were listed in Table 1.

[0031] Embodiment 3: According to the contents of various components listed in Table 1 below, the method of Example 1 was repeated, and the test results were listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com