Special calcium silicate cement board for green-fabricated building walls and production method of special calcium silicate cement board

A prefabricated, building wall technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of high cost of silicon-calcium boards, pollute groundwater, occupy land resources, etc., to improve the bending resistance Performance, light weight, and high flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

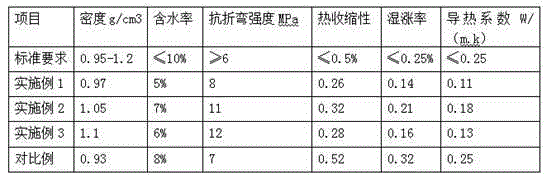

Examples

Embodiment 1

[0018] A silica-calcium cement board for green prefabricated building walls, made of the following raw materials in parts by weight: 20Kg of papermaking sludge, 10-15Kg of zirconium silicon slag, 10-15Kg of fly ash, 8-10Kg of slag powder, and silicic acid Salt cement 10-20 Kg, straw fiber 10-12 Kg, ceramic fiber 1-2 Kg, PC superplasticizer 0.02-0.03 Kg, SM superplasticizer 0.01-0.02Kg, water 15-20 Kg, alumina powder 1- 2Kg, talcum powder 0.5-1Kg, zinc oxide 1-2Kg, antimony oxide 0.2-0.3Kg, sodium silicate 0.2-0.5Kg, silicon nitride 0.1-0.2Kg; papermaking sludge includes the following components by weight: plant fiber 30-40, aluminum oxide 1.4, silicon dioxide 7.95, ferric oxide 1.15, calcium oxide 45.6, magnesium oxide 2.5; the mass fraction of silicon dioxide in zirconium silicon slag is 85.3%; slag powder includes the following parts by weight Components: Silicon dioxide 15.6, aluminum oxide 6.58, calcium oxide 32.8, magnesium oxide 4.68.

[0019] A kind of production metho...

Embodiment 2

[0025] A silica-calcium cement board for green prefabricated building walls, made of the following raw materials in parts by weight: 20-30 Kg of papermaking sludge, 10-15 Kg of zirconium silicon slag, 10-15 Kg of fly ash, and 8-10 Kg of slag powder , Portland cement 10-20 Kg, straw fiber 10-12 Kg, ceramic fiber 1-2 Kg, PC superplasticizer 0.02-0.03 Kg, SM superplasticizer 0.01-0.02Kg, water 15-20 Kg, alumina Powder 1-2Kg, talcum powder 0.5-1Kg, zinc oxide 1-2Kg, antimony oxide 0.2-0.3Kg, sodium silicate 0.2-0.5Kg, silicon nitride 0.1-0.2Kg; papermaking sludge includes the following components by weight Kg : plant fiber 30-40, aluminum oxide 1.4, silicon dioxide 7.95, ferric oxide 1.15, calcium oxide 45.6, magnesium oxide 2.5; the mass fraction of silicon dioxide in zirconium silicon slag is 85.3%; slag powder includes the following Components by weight Kg: silicon dioxide 15.6, aluminum oxide 6.58, calcium oxide 32.8, magnesium oxide 4.68.

[0026] A kind of production method...

Embodiment 3

[0032] A calcium silicate cement board for green prefabricated building walls, made of the following raw materials in parts by weight: 20-30 kg of papermaking sludge, 10-15 kg of zirconium silicon slag, 10-15 kg of fly ash, and 8-10 kg of slag powder , Portland cement 10-20 Kg, straw fiber 10-12 Kg, ceramic fiber 1-2 Kg, PC superplasticizer 0.02-0.03 Kg, SM superplasticizer 0.01-0.02Kg, water 15-20 Kg, alumina powder 1-2Kg, talcum powder 0.5-1Kg, zinc oxide 1-2Kg, antimony oxide 0.2-0.3Kg, sodium silicate 0.2-0.5Kg, silicon nitride 0.1-0.2Kg; papermaking sludge includes the following components by weight : plant fiber 30-40, aluminum oxide 1.4, silicon dioxide 7.95, ferric oxide 1.15, calcium oxide 45.6, magnesium oxide 2.5; the mass fraction of silicon dioxide in zirconium silicon slag is 85.3%; slag powder includes the following Components in parts by weight: silicon dioxide 15.6, aluminum oxide 6.58, calcium oxide 32.8, magnesium oxide 4.68.

[0033] A kind of production m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com