Method for modifying carbon fibers by dendritic macromoleculars

A macromolecular, carbon fiber technology, applied in carbon fiber, fiber processing, textiles and papermaking, etc., can solve the problems of membrane limitation and poor stability, and achieve the effect of simple process, improved interface strength and unique rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

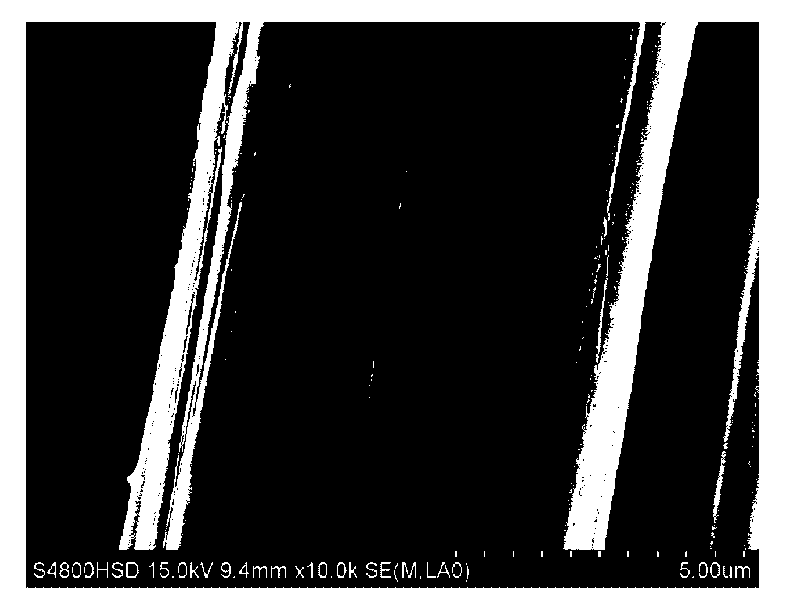

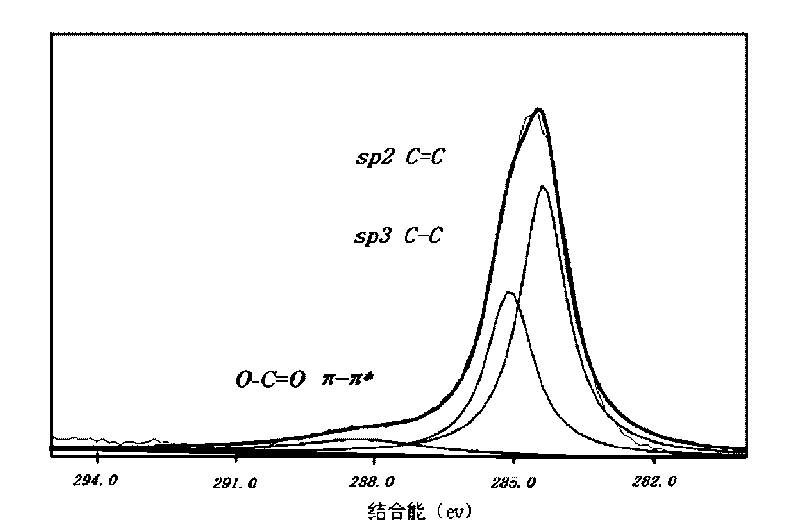

[0008] Embodiment 1: The method for modifying carbon fibers with dendrimers in this embodiment is as follows: 1. Add carbon fibers to a strong oxidizing acid to prepare a mixture, and then ultrasonically treat the mixture for 15 minutes to 60 minutes at a frequency of 10KHz to 100KHz , and then stir the mixture for 10min~20min, then heat to 60℃~100℃ and reflux for 2h~4h, then take out the carbon fiber and wash it with deionized water until the washing liquid is neutral, and then put the carbon fiber at 20℃~100℃, the vacuum degree is - Dry under the condition of 0.05MPa~-0.1MPa for 1h~3h to obtain acidified carbon fiber; 2. Dissolve the dendrimer in the solvent to obtain the dendrimer solution, and then add the acidified carbon fiber into the dendrimer solution , to obtain a mixed solution, then ultrasonically treat the mixed solution for 5min to 30min under the condition of 20KHz to 50KHz, and then react for 1h to 24h under the condition of 20°C to 100°C, and then alternately w...

specific Embodiment approach 2

[0013] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the strong oxidizing acid described in step one is nitric acid with a mass concentration of 1% to 70%, sulfuric acid and permanganese with a mass concentration of 1% to 100%. Potassium permanganate sulfuric acid solution with potassium permanganate concentration of 1g / L~50g / L or nitric acid with mass concentration of 1%~70% and sulfuric acid with mass concentration of 1%~100% according to the volume ratio of 1~9:1. mixed acid. Others are the same as in the first embodiment.

[0014] The interfacial shear strength of the dendrimer-modified carbon fiber / epoxy resin composite material prepared by using the dendrimer-modified carbon fiber obtained in this embodiment is 53.2MPa-55.8MPa, which is higher than that of the ring prepared by using imported carbon fiber at the same level. The interface strength of the oxygen resin composite material is increased by 30% to 70%.

specific Embodiment approach 3

[0015] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the dendrimers described in Step 2 are 1st to 4th generation hydroxyl-terminated dendrimers or 1st to 4th generation amino-terminated dendrimers. macromolecule. Others are the same as in the first or second embodiment.

[0016] The interfacial shear strength of the dendrimer-modified carbon fiber / epoxy resin composite material prepared by using the dendrimer-modified carbon fiber obtained in this embodiment is 53.2MPa-55.8MPa, which is higher than that of the ring prepared by using imported carbon fiber at the same level. The interface strength of the oxygen resin composite material is increased by 30% to 70%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com