Preparation method of carbon nanotube modified foamed ceramics

A carbon nanotube modification and foamed ceramic technology, applied in the field of ceramic materials, can solve the problems of high material performance sensitivity, difficult dispersion of carbon nanotubes, unfavorable mass production, etc., and achieves convenient operation, short preparation period and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

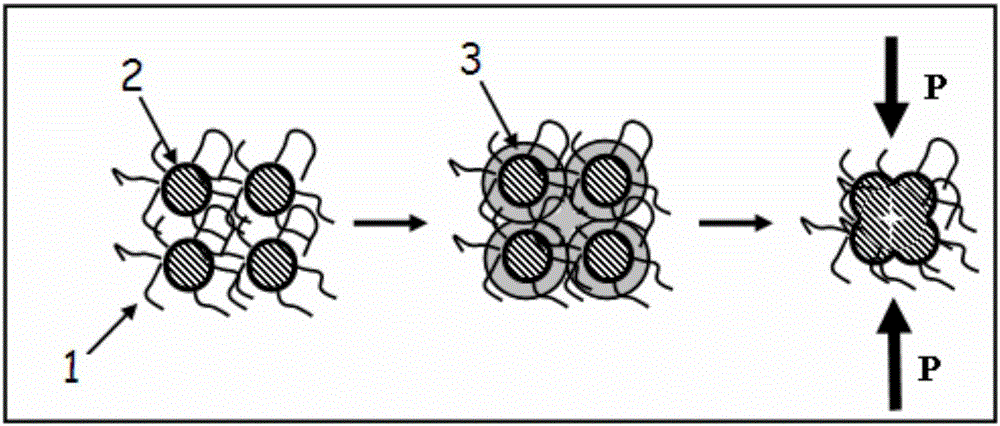

[0021] (1) Add 80g of inorganic ceramic alumina particles and 10g of cationic surfactant cetyltrimethylammonium bromide into deionized water, and stir at a high speed at a speed of 4000r / min to make cetyltrimethylammonium bromide Ammonium chloride is wrapped on the surface of alumina particles, then filtered and dried to obtain positively charged alumina particles;

[0022] (2) Add the positively charged alumina particles and 10 g of carbon nanotubes into deionized water in step (1), so that the positively charged alumina particles and carbon nanotubes are electrostatically adsorbed, and then filtered and dried to obtain a composite powder;

[0023] (3) After grinding 100g of the composite powder in step (2) and 20g of epoxy resin 8 times with a three-roll mill, under the protection of nitrogen, carry out hot-press sintering at 1300°C and 60MPa to obtain the carbon nanotubes Modified foam ceramics1.

Embodiment 2

[0025] According to the steps of Example 1, carbon nanotube modified ceramic foam 2 is prepared. The difference from Example 1 is that in step 1), the amount of inorganic ceramic alumina particles added is 90g, cetyltrimethyl bromide The amount of ammonium chloride added was 1 g.

Embodiment 3

[0027] According to the steps of Example 1, carbon nanotube modified ceramic foam 3 is prepared. The difference from Example 1 is that in step 1), the amount of inorganic ceramic alumina particles added is 90g, cetyl trimethyl bromide The amount of ammonium chloride added was 5 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com