Heat-resistant long glass fiber enhanced nylon composite material and preparation method thereof

A nylon composite material and long glass fiber technology, which is applied in the field of chemical materials, can solve the problems of serious environmental pollution of cuprous iodide, complex thermal stabilizer components, harsh production process conditions, etc., and achieves improved interface bonding force and good processing performance. , the effect of increasing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

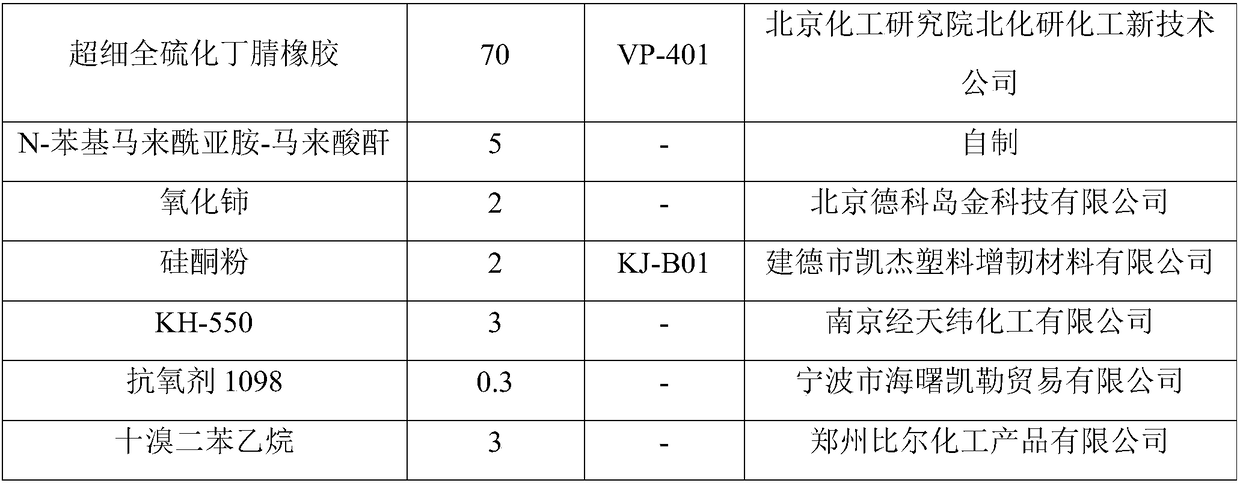

[0042] Example 1 Reinforced nylon 6 composite material and its preparation

[0043]

[0044]

[0045] The viscosity of the nylon 6 is 2.3;

[0046] The long glass fiber has an average length of 13mm and an average diameter of 11μm;

[0047] The average particle size of the ultrafine fully vulcanized powder rubber is 130 nm.

[0048] Preparation:

[0049] (1) Preparation of N-phenylmaleimide-maleic anhydride: N-phenylmaleimide and maleic anhydride are mixed in a molar ratio of 2:1, and xylene is added and stirred at 65°C for 60 minutes , N 2 Add dicumyl peroxide under protection and increase the temperature to 110℃ to react for 4h, the product obtained is dissolved in acetone, precipitated with anhydrous ethanol, and dried.

[0050] (2) Surface treatment of long glass fiber: KH-550 is dissolved in 100% ethanol, the long glass fiber is soaked in it for 35 minutes, and then dried for use;

[0051] (3) Dry nylon 6 and add it to a high-speed mixer, then add ultra-fine fully vulcanized nitrile...

Embodiment 2

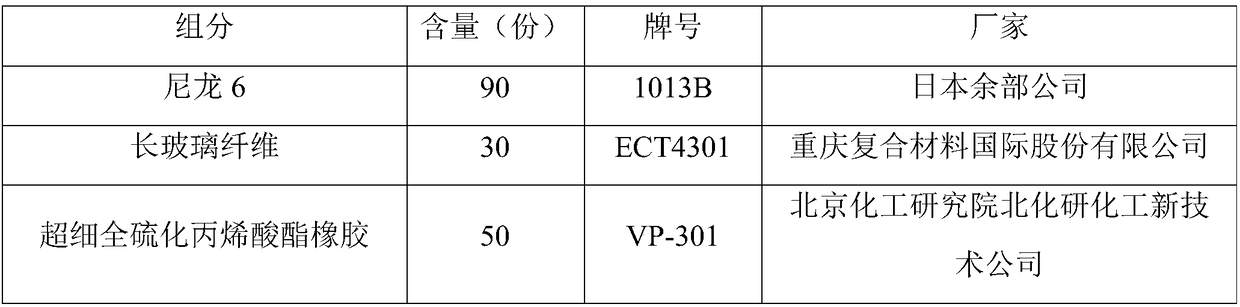

[0053] Example 2 Reinforced nylon 6 composite material and its preparation

[0054]

[0055]

[0056] The viscosity of the nylon 6 is 2.5;

[0057] The long glass fiber has an average length of 15mm and an average diameter of 10μm;

[0058] The average particle size of the ultrafine fully vulcanized powder rubber is 50 nm.

[0059] Preparation:

[0060] (1) Preparation of N-phenylmaleimide-maleic anhydride: N-phenylmaleimide and maleic anhydride are mixed in a molar ratio of 3:1. After adding xylene, stir at 65°C for 70 minutes , N 2 Add dicumyl peroxide under protection and increase the temperature to 120℃ to react for 3h, the product obtained is dissolved in acetone, precipitated with anhydrous ethanol, and dried.

[0061] (2) Surface treatment of long glass fiber: KH-171 alkane is dissolved in 100% ethanol, the long glass fiber is soaked in it for 35 minutes, and then dried for use;

[0062] (3) Dry nylon 6 and add it to a high-speed mixer, and then add ultra-fine fully vulcanized acr...

Embodiment 3

[0064] Example 3 Reinforced nylon 6 composite material and its preparation

[0065]

[0066]

[0067] The viscosity of the nylon 6 is 2.4;

[0068] The long glass fiber has an average length of 12mm and an average diameter of 10μm;

[0069] The average particle size of the ultrafine fully vulcanized powder rubber is 100 nm.

[0070] Preparation:

[0071] (1) Preparation of N-phenylmaleimide-maleic anhydride: N-phenylmaleimide and maleic anhydride are mixed in a molar ratio of 2:1, add xylene and stir at 60°C for 70min , N 2 Under protection, dicumyl peroxide was added and the temperature was raised to 110° C. to react for 4 hours. The obtained product was dissolved in acetone, precipitated with anhydrous ethanol, and dried.

[0072] (2) Surface treatment of long glass fiber: KH-550 is dissolved in 95% ethanol, the long glass fiber is soaked in it for 35 minutes, and then dried for use.

[0073] (3) Dry nylon 6 and add it to the high-speed mixer, then add ultra-fine fully vulcanized powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com