Modified epoxy resin adhesive used for polyimide flexible copper-clad plate

A technology of epoxy resin and adhesive, which is applied in the direction of epoxy resin glue, novolac epoxy resin adhesive, adhesive, etc., can solve the problems of poor processability, miscibility, bismaleimide homopolymer It is difficult to dissolve and other problems, and achieve the effect of improving the heat resistance of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

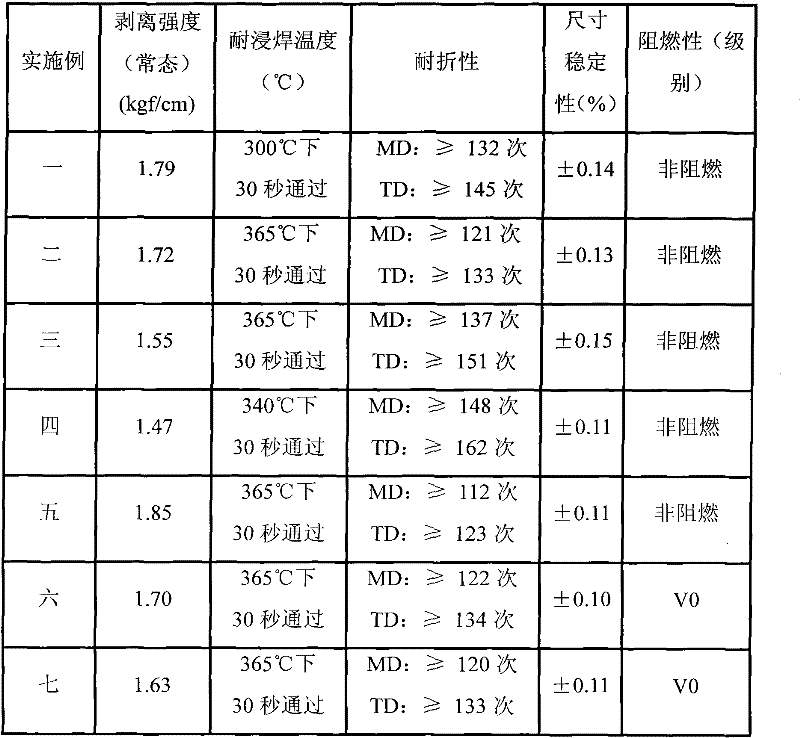

Examples

Embodiment 1

[0026] Composition and mass parts of modified epoxy resin adhesive:

[0027] 5 copies of BDME;

[0028] EC 20 copies;

[0029] 75 parts of bisphenol A type epoxy resin;

[0030] 5 parts of talcum powder;

[0031] 30 copies of DDE;

[0032] 5 parts of 704 curing agent.

[0033] The detailed composition (mass fraction) of BDME in this example: PBMI 12%; BMI12%; DDE 20%; Bisphenol A type epoxy resin 56%; The detailed composition (mass fraction) of EC: CTBN (acrylonitrile mass content in CTBN 25%) 30%; bisphenol A type epoxy resin 70%.

[0034] The solid components are dissolved in an organic solvent, the organic solvent is a mixed solvent obtained by mixing acetone and methyl ethyl ketone at a ratio of 3:2 by mass, and the solid content of the whole system is 30%.

[0035] The preparation method of the adhesive is:

[0036] 1) PBMI, BMI, DDE and bisphenol A type epoxy resin were stirred and reacted at a constant temperature at 70° C. for 2 hours in a reactor with reflux an...

Embodiment 2

[0041] Composition and mass parts of modified epoxy resin adhesive:

[0042] 20 copies of BDME;

[0043] EC 20 copies;

[0044] 60 parts of bisphenol A type epoxy resin;

[0045] 5 parts of talcum powder;

[0046] DDE 27.5 parts;

[0047] 7 parts of 704 curing agent;

[0048] In this example, the composition of BDME and EC is the same as in Example 1.

[0049] The solid components are dissolved in an organic solvent, the organic solvent is a mixed solvent obtained by mixing acetone and methyl ethyl ketone at a ratio of 3:2 by mass, and the solid content of the whole system is 30%.

[0050]The preparation method of the adhesive and the method of preparing the polyimide flexible copper-clad laminate are the same as the first embodiment. When using the adhesive prepared in this example to prepare a flexible copper-clad laminate, the thickness of the polyimide film used is 0.025mm, the thickness of the copper foil is 0.018mm, and the thickness of the glue is 0.020mm.

Embodiment 3

[0052] Composition and mass parts of modified epoxy resin adhesive:

[0053] 20 copies of BDME;

[0054] EC 20 copies;

[0055] 60 parts of bisphenol A type epoxy resin;

[0056] 5 parts of talcum powder;

[0057] 30 copies of DDE;

[0058] 5 parts of 781 curing agent;

[0059] The composition of BDME in this example is (mass fraction): PBMI 24%; DDM 20%; bisphenol A type epoxy resin 56%. And the composition of EC is identical with embodiment one.

[0060] The solid components are dissolved in an organic solvent, the organic solvent is a mixed solvent obtained by mixing acetone and methyl ethyl ketone at a ratio of 3:2 by mass, and the solid content of the whole system is 30%.

[0061] The preparation method of the adhesive is:

[0062] 1) PBMI, DDM and bisphenol A type epoxy resin were stirred and reacted at a constant temperature of 80° C. for 3.5 hours in a reactor with reflux and filled with nitrogen, and then cooled to room temperature to obtain a bismaleimide copo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com