Preparation method of mullite whisker enhanced silicon carbide porous ceramic

A technology of mullite whiskers and porous ceramics, which is applied in the field of preparation of mullite whiskers reinforced silicon carbide porous ceramics, can solve the problems of limited application and poor bending strength, and achieve low cost, excellent high temperature resistance, superior Effect of Thermal Shock Stability and Mechanical Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

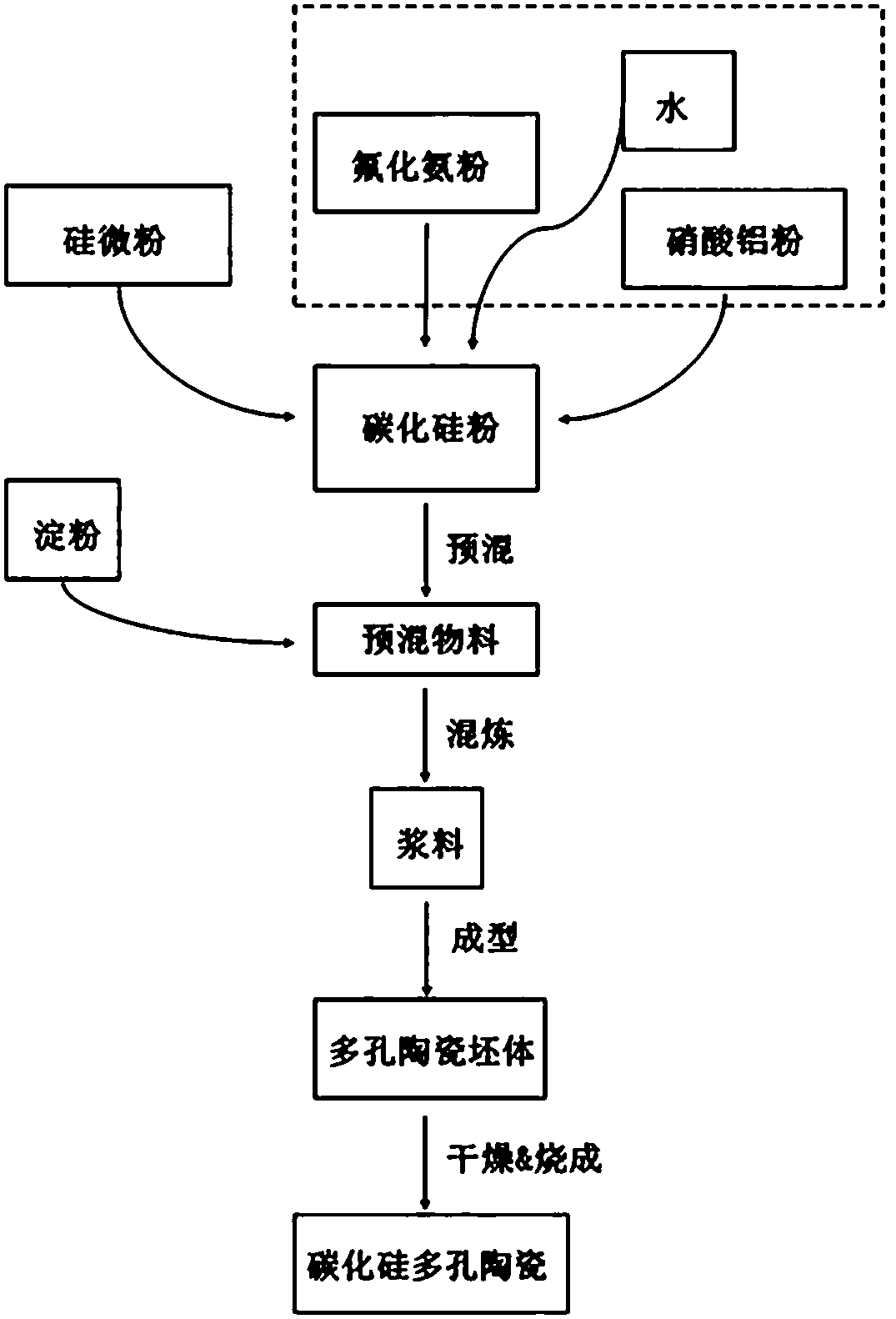

[0025] The silicon carbide porous ceramic material reinforced by mullite whiskers provided in this example has the following raw materials: 66 kg of silicon carbide powder with a particle diameter of less than 0.045 mm, 8 kg of silicon powder with a particle diameter of less than 0.045 mm, and a particle diameter of less than 0.045 mm. 22kg of aluminum nitrate and 4kg of ammonium fluoride with particle size less than 0.045mm. Using starch as a binder and pore-forming agent, premixing, dissolving, kneading, molding, drying and firing are used to prepare mullite whisker-reinforced silicon carbide porous ceramic materials. The specific operation steps are as follows:

[0026] Step 1, pre-mixing, fully stirring silicon carbide powder and silicon powder in a mixer to obtain a mixed powder;

[0027] Step 2, dissolving, dissolving aluminum nitrate and ammonium fluoride in an appropriate amount of water in a magnetic stirrer, and stirring continuously for 10 minutes to fully react to ...

Embodiment 2

[0034] The silicon carbide porous ceramic material reinforced by mullite whiskers provided in this example has the following raw materials: 65 kg of silicon carbide powder with a particle diameter less than 0.045 mm, 10 kg of silicon powder with a particle diameter less than 0.045 mm, and a particle diameter less than 0.045 mm. 20kg of aluminum nitrate and 5kg of ammonium fluoride with particle size less than 0.045mm. Using starch as a binder and pore-forming agent, premixing, dissolving, kneading, molding, drying and firing are used to prepare mullite whisker-reinforced silicon carbide porous ceramic materials. The specific operation steps are as follows:

[0035] Step 1, pre-mixing, fully stirring silicon carbide powder and silicon powder in a mixer to obtain a mixed powder;

[0036] Step 2, dissolving, dissolving aluminum nitrate and ammonium fluoride in an appropriate amount of water in a magnetic stirrer, and stirring continuously for 10 minutes to fully react to obtain a...

Embodiment 3

[0043] The silicon carbide porous ceramic material reinforced by mullite whiskers provided in this example has the following raw materials: 60 kg of silicon carbide powder with a particle diameter of less than 0.045 mm, 13 kg of silicon powder with a particle diameter of less than 0.045 mm, and a particle diameter of less than 0.045 mm. 22kg of aluminum nitrate and 5kg of ammonium fluoride with particle size less than 0.045mm. Using starch as a binder and pore-forming agent, premixing, dissolving, kneading, molding, drying and firing are used to prepare mullite whisker-reinforced silicon carbide porous ceramic materials. The specific operation steps are as follows:

[0044] Step 1, pre-mixing, fully stirring silicon carbide powder and silicon powder in a mixer to obtain a mixed powder;

[0045] Step 2, dissolving, dissolving aluminum nitrate and ammonium fluoride in an appropriate amount of water in a magnetic stirrer, and stirring continuously for 10 minutes to fully react to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com