Three-stage biological comprehensive treatment method for printed circuit board waste water

A printed circuit board and comprehensive treatment technology, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve difficult, complicated components, complex copper-containing wastewater Remove problems such as poor effect, achieve the effect of low cost and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

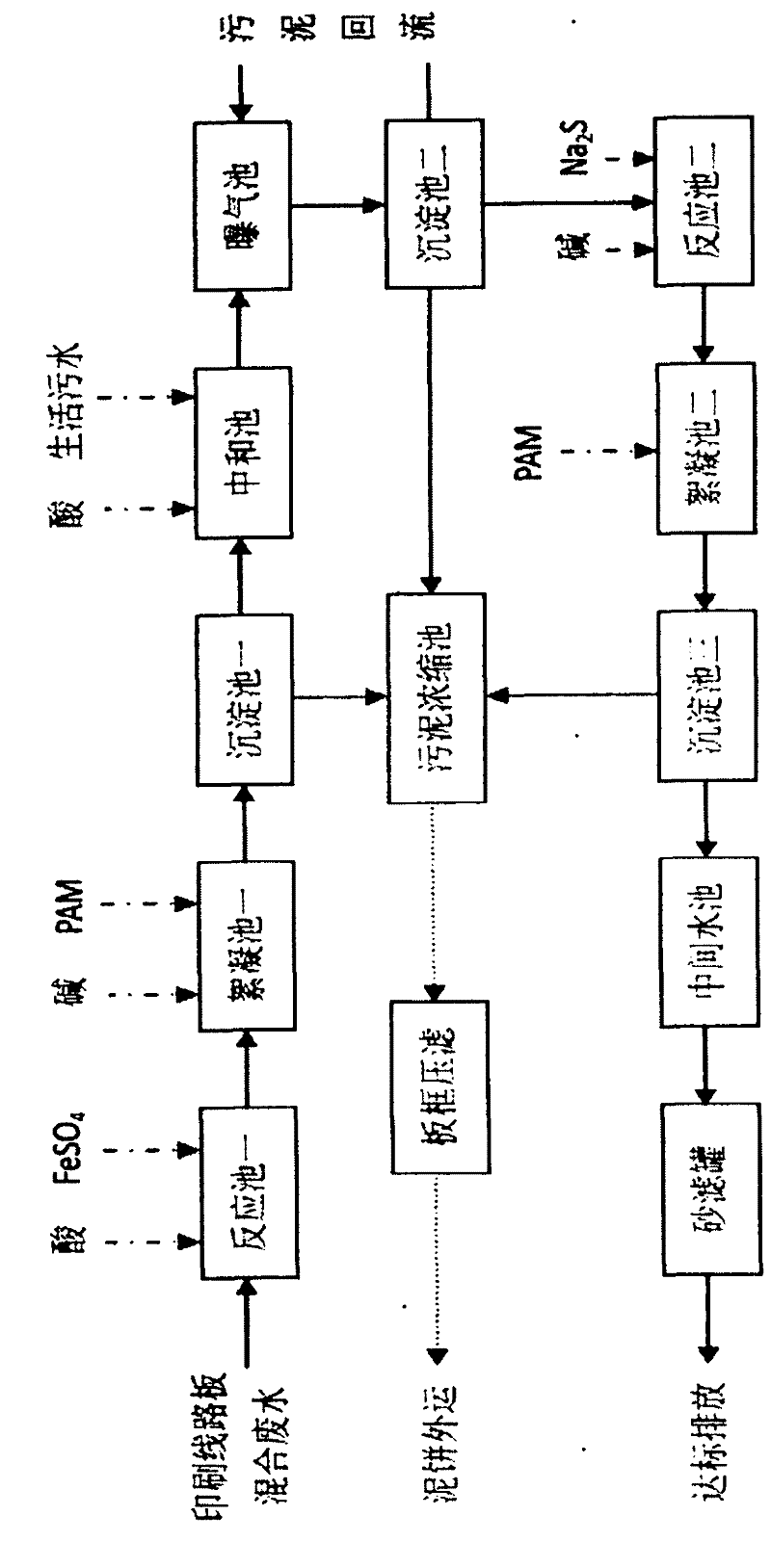

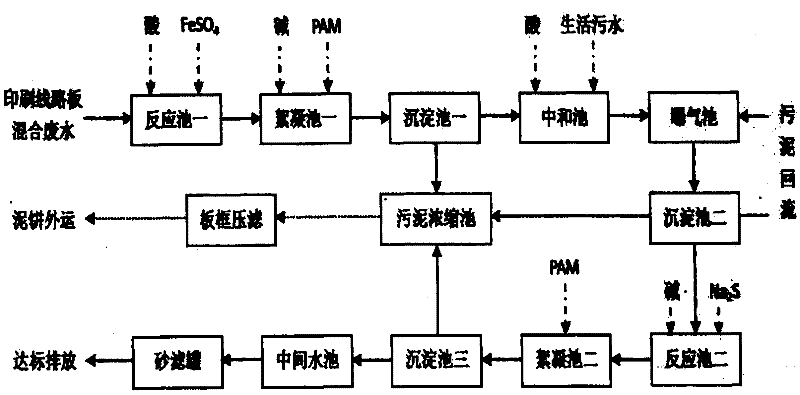

Image

Examples

Embodiment 1

[0024] Types of printed circuit board mixed wastewater: a mixture of grinding wastewater containing suspended solids, ordinary copper-containing wastewater with a pH of 3 and a copper ion concentration below 100mg / L, and electroplating wastewater containing heavy metals.

[0025] (1) Put the printed circuit board mixed wastewater into the reaction tank 1, adjust the pH to 2.7-3.2 with sulfuric acid, and put in ferrous sulfate, then transfer the above wastewater into the flocculation tank 1, use alkaline solution to adjust the pH to greater than 7, and then add polypropylene Accelerate the precipitation of amides to generate cuprous oxide, put all the waste water and cuprous oxide precipitation into sedimentation tank 1, make the precipitation complete and stay in sedimentation tank 1, and completely dehydrate into cuprous oxide, and the waste water is transferred to neutralization pool for the next biological treatment process;

[0026] (2) Add carbon source and nitrogen sourc...

Embodiment 2

[0031] Printed circuit board mixed wastewater types: grinding board wastewater containing suspended matter, ink wastewater with extremely high COD, complexed copper wastewater and electroplating wastewater. Contains complex copper and a large amount of heavy metal ions.

[0032] (1) Put the printed circuit board mixed wastewater into the reaction tank 1, adjust the pH to 2.7-3.2 with sulfuric acid, and put in ferrous sulfate, then transfer the above wastewater into the flocculation tank 1, use alkaline solution to adjust the pH to greater than 7, and then add polypropylene Accelerate the precipitation of amides to generate cuprous oxide, put all the waste water and cuprous oxide precipitation into sedimentation tank 1, make the precipitation complete and stay in sedimentation tank 1, and completely dehydrate into cuprous oxide, and the waste water is transferred to neutralization pool for the next biological treatment process;

[0033](2) Add carbon source and nitrogen source...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com