Integrative recovering and reusing of heavy metals in wire board plating wastewater treatment sludge

A technology for electroplating wastewater and circuit boards, which is used in energy wastewater treatment, metallurgical wastewater treatment, water/sludge/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

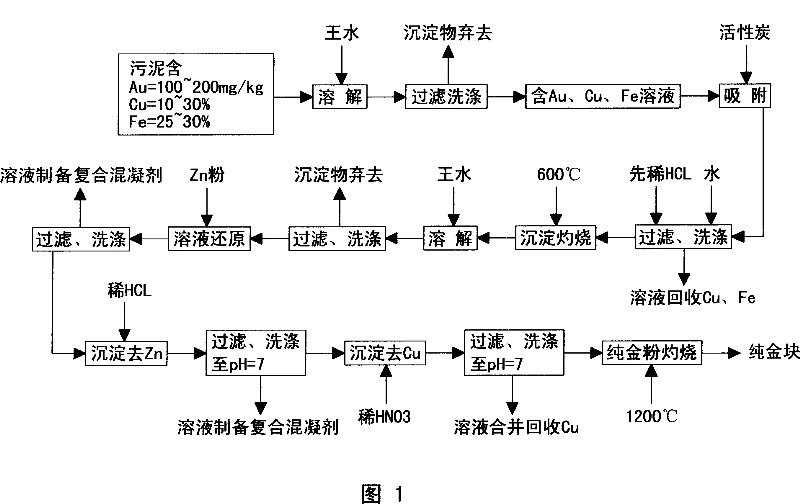

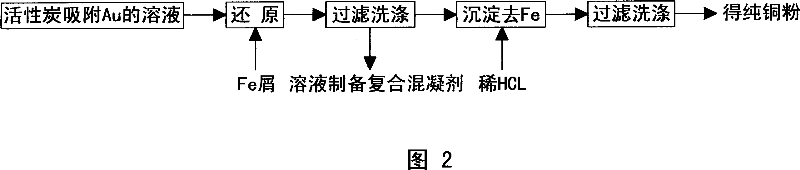

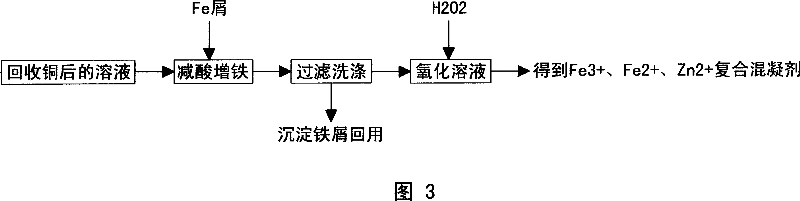

[0046] Embodiment: A kind of comprehensive recycling method of heavy metals in the circuit board electroplating wastewater treatment sludge, using the sludge produced by the circuit board electroplating wastewater treatment as raw material, comprises the following steps in turn:

[0047] (1), recovery gold

[0048] Gold is one of the earliest metals recognized and used by humans, and it is also a symbol of wealth that humans have been pursuing for thousands of years. With the weakening of the currency function and decorative function of gold, the industrial use of gold has become one of the main functions of gold. Electronic sludge contains gold. According to experimental analysis, its content is 10-200 mg / kg. When the content reaches 50 mg / kg or more, it can be recycled. With the development of industry, the demand for gold is also increasing. Making full use of the "secondary mineral" resources of precious metals in these sludges is of great significance to the realization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com