Cement clinker production method by utilization of artificial slabstone waste

A cement clinker and artificial stone slab technology, applied in the field of cement clinker production, can solve the problems of polluting cement, difficult waste disposal, high energy consumption, etc., and achieve the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

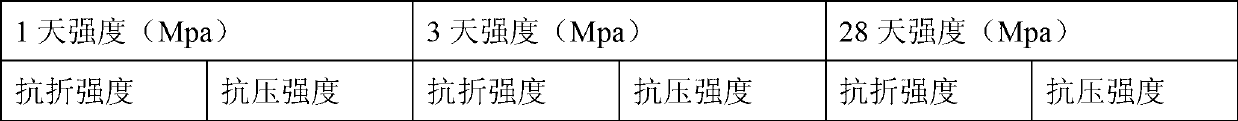

[0081] The method for making cement clinker by using artificial slate wastes comprises the steps of:

[0082] In step 1, 80 parts of artificial stone calcium-aluminum board waste and 13 parts of quartz stone board waste are mixed, dried, and ground, and the obtained waste mixture is sieved with a sieve with an aperture of 0.080 mm, and the sieve residue is 13%. Sieve through a 0.20mm sieve, and the remaining 0.8% is sieved;

[0083] In step 2, the steel slag is ground with a mill, sieved with a sieve with an aperture of 0.080mm, and the sieve residue is 12.8%, and then sieved with a 0.20mm sieve with an aperture, and the sieve residue is 0.75%;

[0084] Step 3 Take 7 parts of ground steel slag and mix them evenly with the above-mentioned waste mixture to obtain cement raw meal. The cement raw meal is sieved with a sieve with an aperture of 0.080mm, and the sieve residue is 13%, and then passed through a sieve with an aperture of 0.20mm Sieve, the sieve residue is 0.4%;

[00...

Embodiment 2

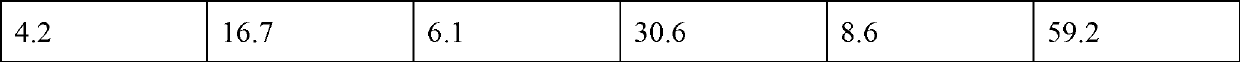

[0109] In this embodiment, the steps of the method for producing cement clinker from artificial slate wastes are the same as those in Embodiment 1, except that the ratio of raw materials is changed.

[0110] The proportion of artificial stone calcium aluminum plate waste, quartz stone plate waste and steel slag is:

[0111] Artificial stone calcium aluminum plate waste: 84.1 parts;

[0112] Quartz slab waste: 10.3 parts;

[0113] Steel slag: 5.6 parts;

[0114] The parts are parts by mass.

[0115] In the present embodiment, the artificial stone calcium aluminum plate waste, its component content percentage is as shown in table 7:

[0116] Table 7 The content percentage of each component in artificial stone calcium aluminum plate waste

[0117] SiO 2

al 2 o 3

CaO

MgO

Fe 2 o 3

K 2 o

Na 2 o

Impurities

[0118] 0

2.68

41.96

0.32

0

0.08

0.17

54.79

[0119] Described quartz s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com