Rotary-wheel-type small sewage treatment device

A sewage treatment device and runner-type technology, applied in the field of runner-type small sewage treatment devices, can solve the problems of long and heavy, laborious and time-consuming, trachea blockage, etc., and achieve the effect of less floor space and high treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

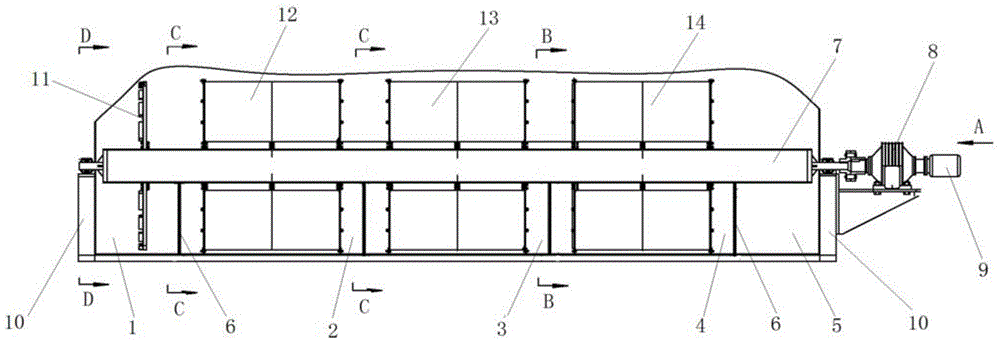

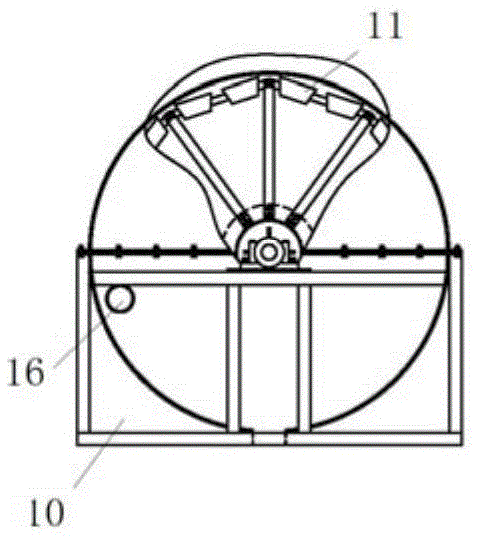

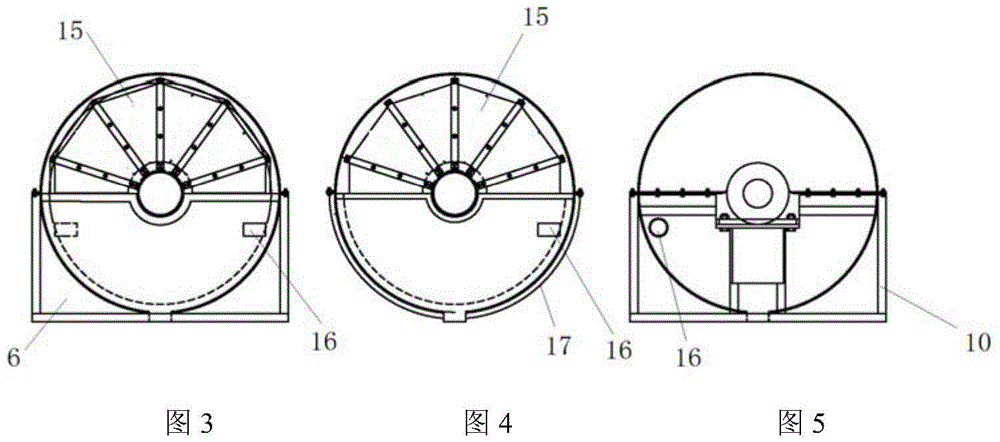

[0026] Further illustrate the present invention below in conjunction with accompanying drawing.

[0027] Referring to the accompanying drawings, the wheel-type small-scale sewage treatment device of the present invention comprises a horizontal cylindrical sewage bin, a main shaft 7, a motor 9, a reducer 8, and the lower semicircle of the cylindrical sewage bin is divided into five successively by a partition 6. Sub-bins 1-5 have water inlet and outlet 16 on the partition 6. The water outlet of the previous sub-bin is the water inlet of the next sub-bin. The water inlets and outlets of the five sub-bins have a drop in turn, so that sewage can flow in from the previous sub-bin. The next sub-position. The main shaft 7 is installed on the brackets 10 at both ends of the sewage tank through bearings, one end of the main shaft is fixed to the output shaft of the reducer 8, the input shaft of the reducer 8 is fixed to the rotating shaft of the motor 9, and the stirring wheel 11 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com