Method for recovering ruthenium trichloride from ruthenium plating waste liquid

A technology of ruthenium trichloride and waste liquid is applied in the field of recovering ruthenium trichloride in ruthenium plating waste liquid, which can solve the problem of low recovery rate of ruthenium, improve social and environmental benefits, reduce discharge, and reduce secondary The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

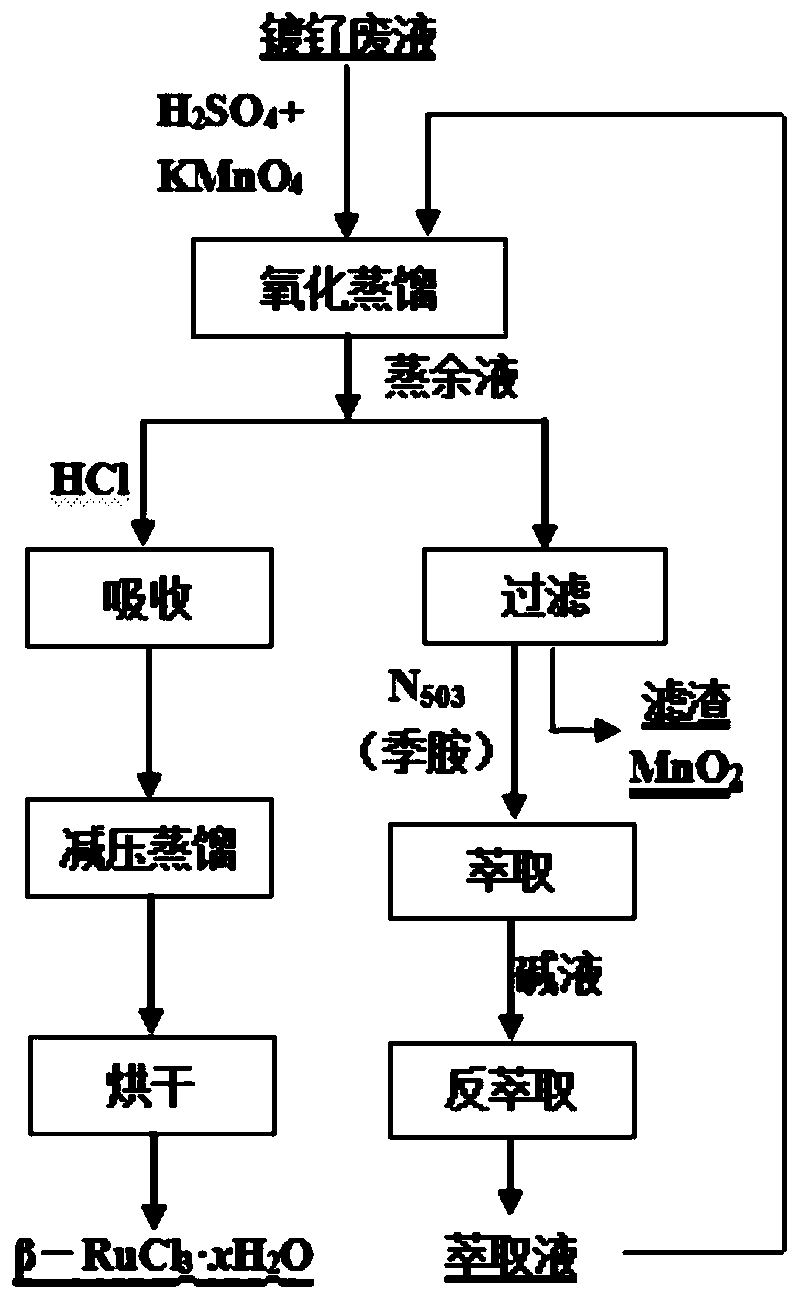

[0070] The present embodiment provides a method for reclaiming ruthenium trichloride in waste ruthenium plating solution, the method comprising:

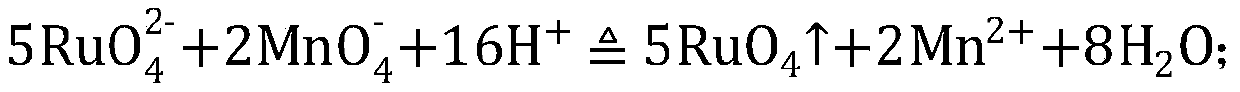

[0071] S1-1: Accurately pipette 30ml of waste ruthenium plating solution into a three-necked flask, and slowly add 8ml of sulfuric acid and m 1 =0.8gKMnO 4 , at T 1 = Heating in a water bath at 75°C for t=1h, oxidative distillation of RuO 4 and distillate;

[0072] S1-2: the RuO 4 The gas is absorbed by the HCl solution of n=6mol / L to generate RuCl hydrochloric acid solution;

[0073] S1-3: Distill under reduced pressure at 55°C for 8 hours to obtain β-RuCl 3 ·xH 2 O crystals;

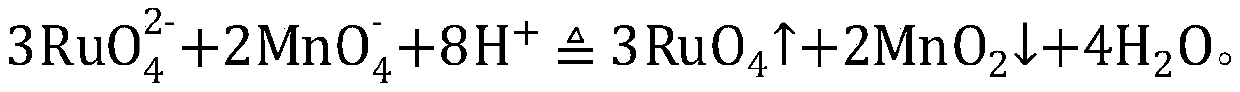

[0074] S2-1: Filter the obtained distillate, discard the filter residue, and obtain the filtrate;

[0075] S2-2: Add NaOH solution to the filtrate to adjust the pH to alkaline, add 5ml of pre-oxidant 10% NaClO and 1g of NaCl, and keep warm in a water bath at 80°C for 30min to obtain a pre-oxidized distillate;

[0076] S2-3: Using sulfonated kerosene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com