Electric chromium plating waste gas purification system and method

An exhaust gas purification system and electrochrome plating technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve problems such as chromic acid exhaust gas pollution, and achieve the effect of improving condensation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

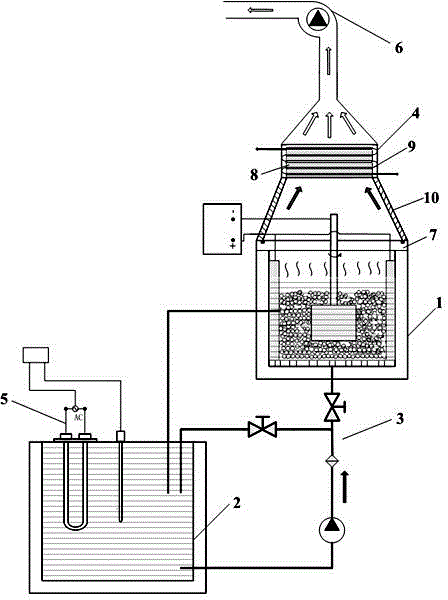

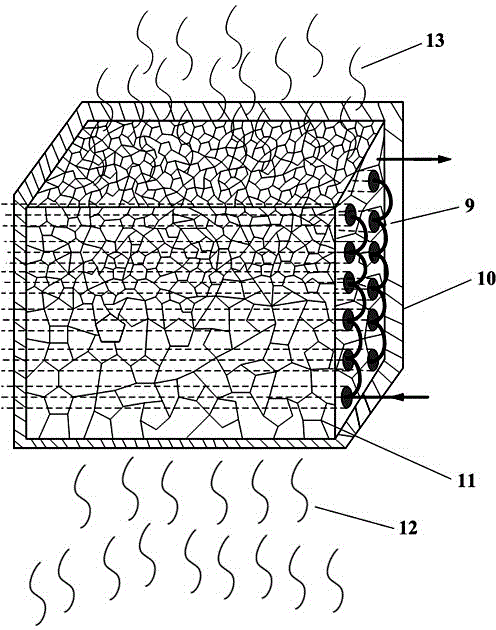

[0015] A chromium electroplating exhaust gas purification system, as shown in Figure 1, the system includes: electroplating unit 1, liquid storage tank 2, electroplating solution circulation system 3, chromic acid condensation cover 4, electroplating solution heating system 5, gas collection system 6, Connecting flange 7, metal foam 8, condensation pipe 9, box body 10, porous titanium foam 11, chromic acid waste gas 12, recovered and purified gas 13, recovered and purified gas. It is characterized by the chromic acid purification system, the chromic acid waste gas is recycled into the electroplating unit 1 through the cooling and purification of the porous titanium foam 11 and the condensation pipe 9, and the rest of the gas is discharged into the atmosphere through the gas collection system.

[0016] The chromic acid condensation cover box and connecting flange are made of chromic acid corrosion-resistant polyethylene or polyvinyl chloride plastic, the condensation pipe is mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com