Gas-liquid separation for compressed air method and device

A gas-liquid separation device and gas-liquid separation technology are applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., to achieve the effects of excellent gas-liquid separation, increase residence time, and improve condensation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

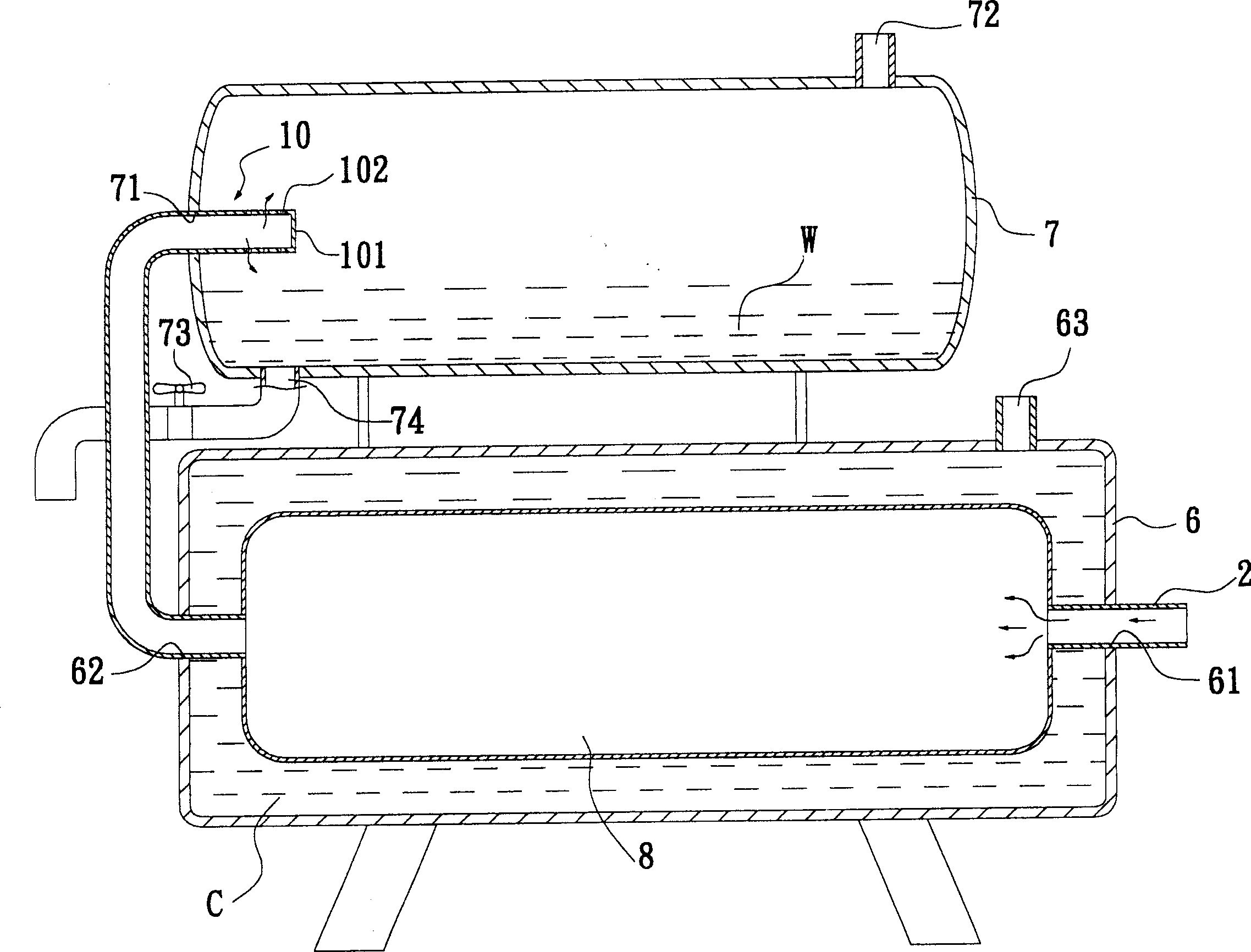

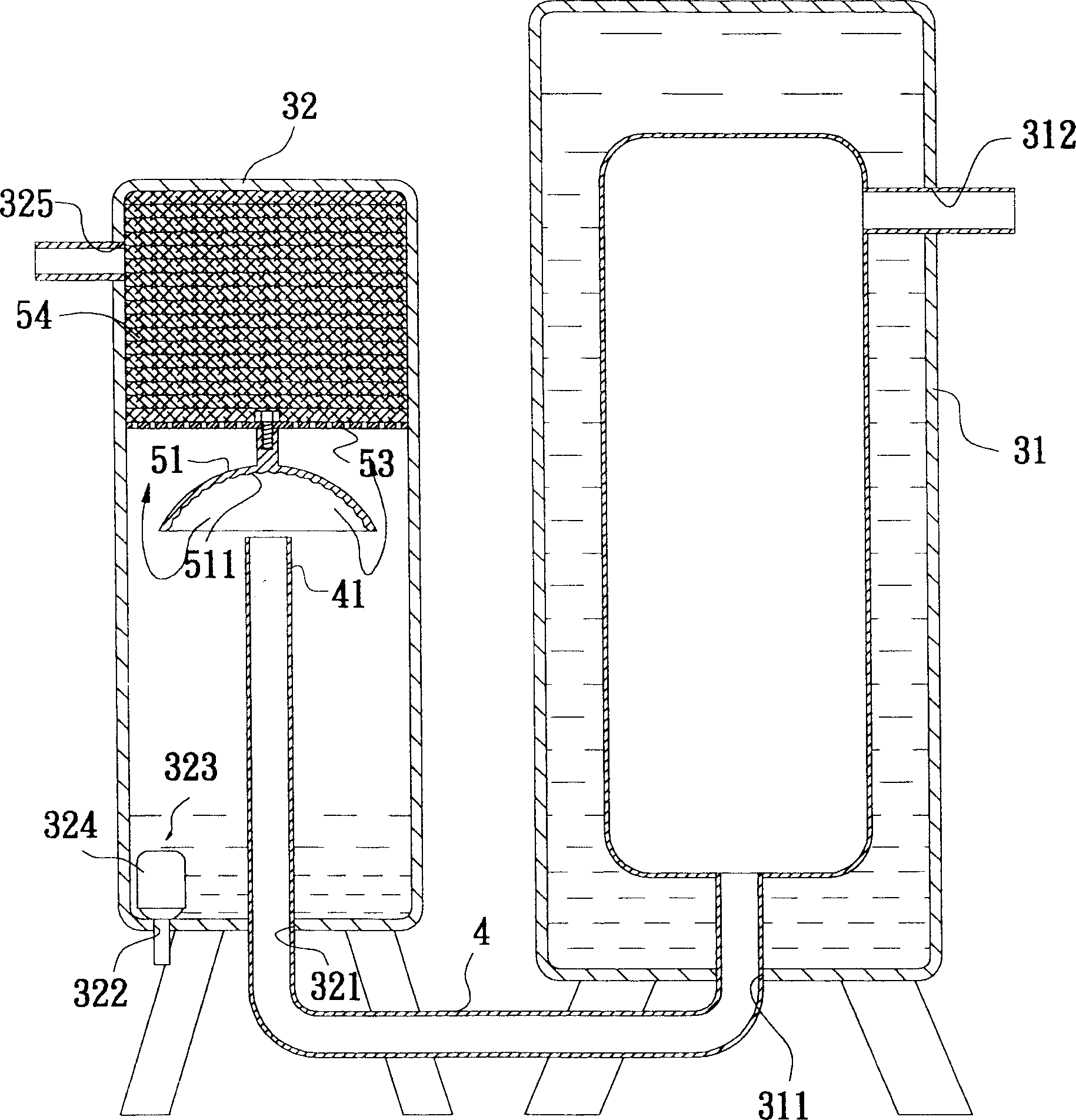

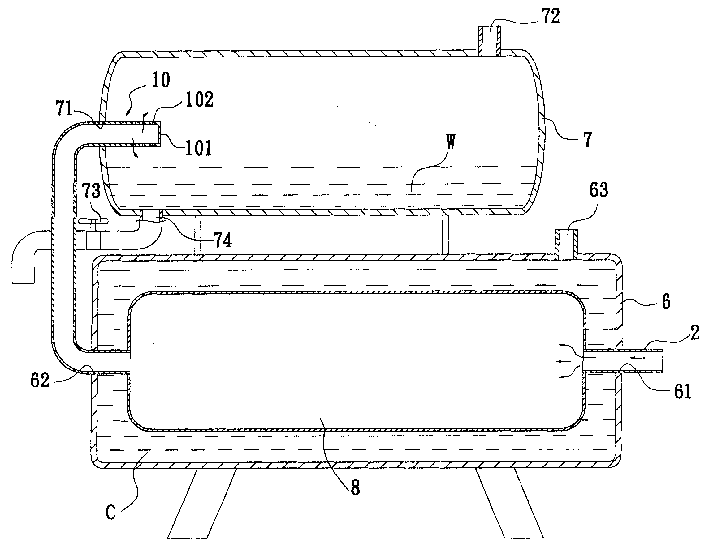

[0022] see figure 1 The embodiment of the gas-liquid separation device used in the present invention includes an airtight cooling barrel 6 and an airtight gas-liquid separation barrel 7, the cooling barrel and the gas-liquid separation barrel are horizontal, and the gas-liquid separation barrel 7 is Placed on the upper side of the cooling bucket 6.

[0023] The top of the cooling barrel 6 has a water injection port 63 through which the cooling liquid is injected into the cooling barrel. In this embodiment, the cooling liquid is water at normal temperature. There is an inlet 61 and an outlet 62 at both ends of the cooling drum respectively, and the inlet 61 is connected with an air compressor (not shown) by a delivery pipe 2, and a connecting pipe is connected between the inlet 61 and the outlet 62 in the cooling drum 6 . A cooling pipe 8 with a large diameter and extending straight.

[0024] One end of the gas-liquid separation barrel 7 has an air inlet 71, and the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com