Method of reclaiming silver from silver ion containing solution by polydiaminoanthraquinone as adsorbent

A polydiaminoanthracene and silver ion solution technology is applied in the field of silver recovery, can solve problems such as polydiaminoanthraquinone that have not yet been seen, and achieves the effects of good heavy metal ion adsorption selectivity, low price, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

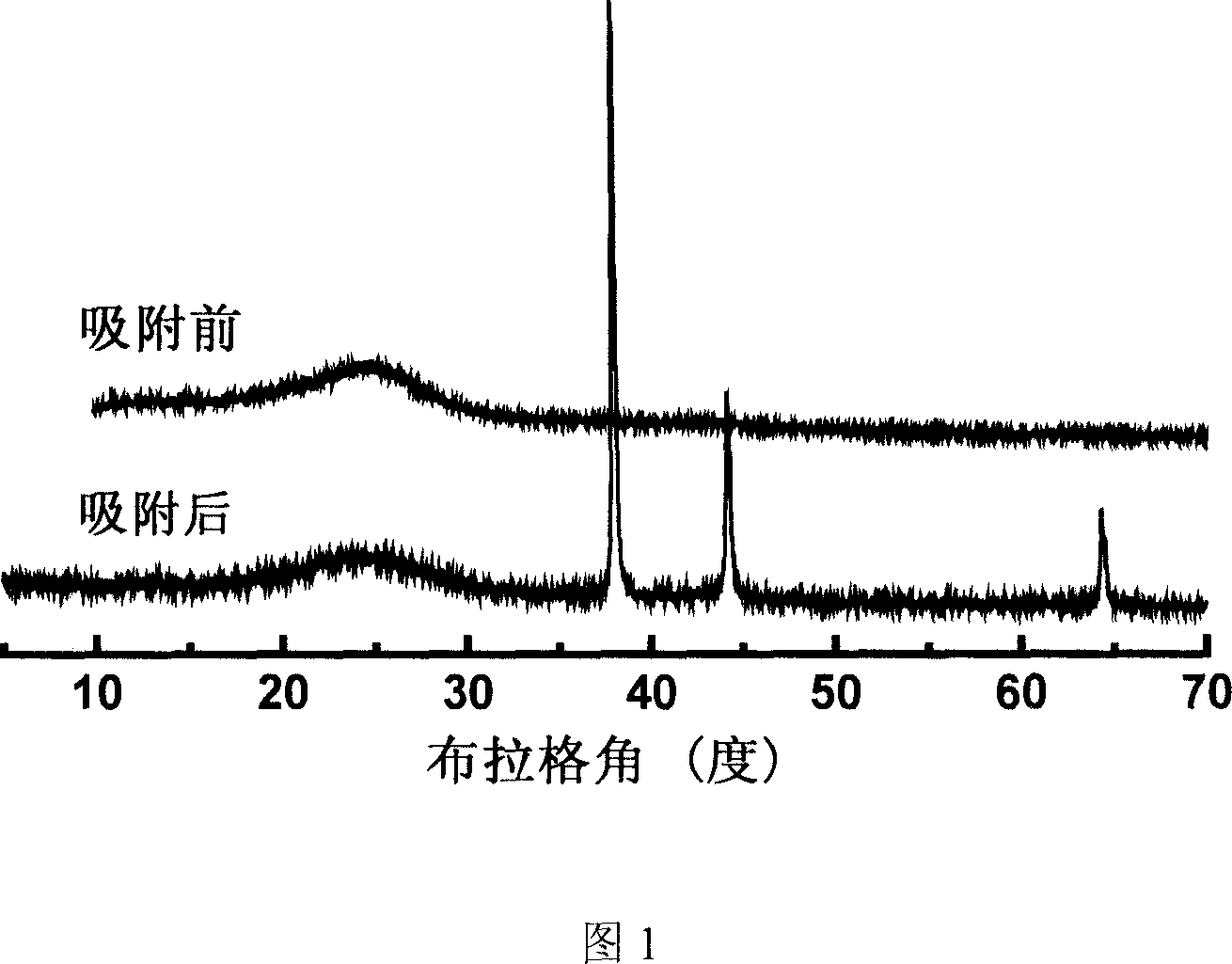

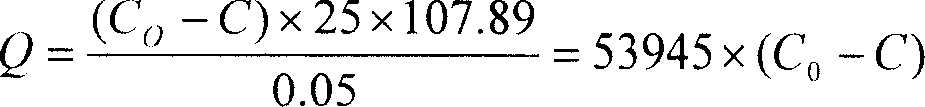

[0015] In a 50mL dry Erlenmeyer flask, add 50mg of doped polydiaminoanthraquinone polymer (particle size: 20-80nm) and 25mL of 0.09615mol / L silver ion solution, put the Erlenmeyer flask into an ultrasonic oscillator Shake for 30-90 minutes, then take it out, and put it in a water bath at 30°C for 24 hours with stirring and adsorption. Filter through filter paper, and analyze the concentration of residual silver ions after adsorption by Volhard's titration method. The adsorption capacity is 467.1 mg / g. The adsorbed silver was confirmed to be elemental silver by the wide-angle X-ray diffraction pattern (Fig. 1). Other conditions are the same, and the corresponding de-doped polymer is used instead, and the adsorption capacity is 560.5mg / g. It can be seen that the performance of the dedoped state is better than that of the doped state.

Embodiment 2

[0017] In a 50mL dry Erlenmeyer flask, add 50mg of doped polydiaminoanthraquinone polymer (particle size 20-80nm) and 30mL of 0.083mol / L silver ion solution, put the Erlenmeyer flask into an ultrasonic oscillator for ultrasonic oscillation After 1 hour of treatment, it was taken out and placed in a water bath at 30°C for 24 hours with stirring and adsorption. Filter through filter paper, and analyze the concentration of silver ions after adsorption by Volhard's titration method. The adsorption capacity is 327.0mg / g. Other conditions are the same, and the corresponding de-doped polymer is used instead, and the adsorption capacity is 460.7mg / g. It can be seen that the performance of the dedoped state is better than that of the doped state.

Embodiment 3

[0019] In a 50mL dry Erlenmeyer flask, add 50mg of doped polydiaminoanthraquinone polymer (the number-average particle diameter of the laser particle size test is 1.3-2.5μm and 0.09615mol / L silver ion solution 40mL, put the Erlenmeyer flask Put it into an ultrasonic vibrator and take it out after ultrasonic vibration treatment for 1 hour, place it in a water bath at 30° C. for stirring and adsorption for 15 hours. Filter through filter paper, analyze the concentration of residual silver ions after adsorption by Volhard method titration, and its adsorption capacity is 243.0 mg / g. Other conditions are the same, and the corresponding de-doped state polymer is used instead, and the adsorption capacity is 322.5 mg / g. It can be seen that the performance of the de-doped state is better than that of the doped state.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Number average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com