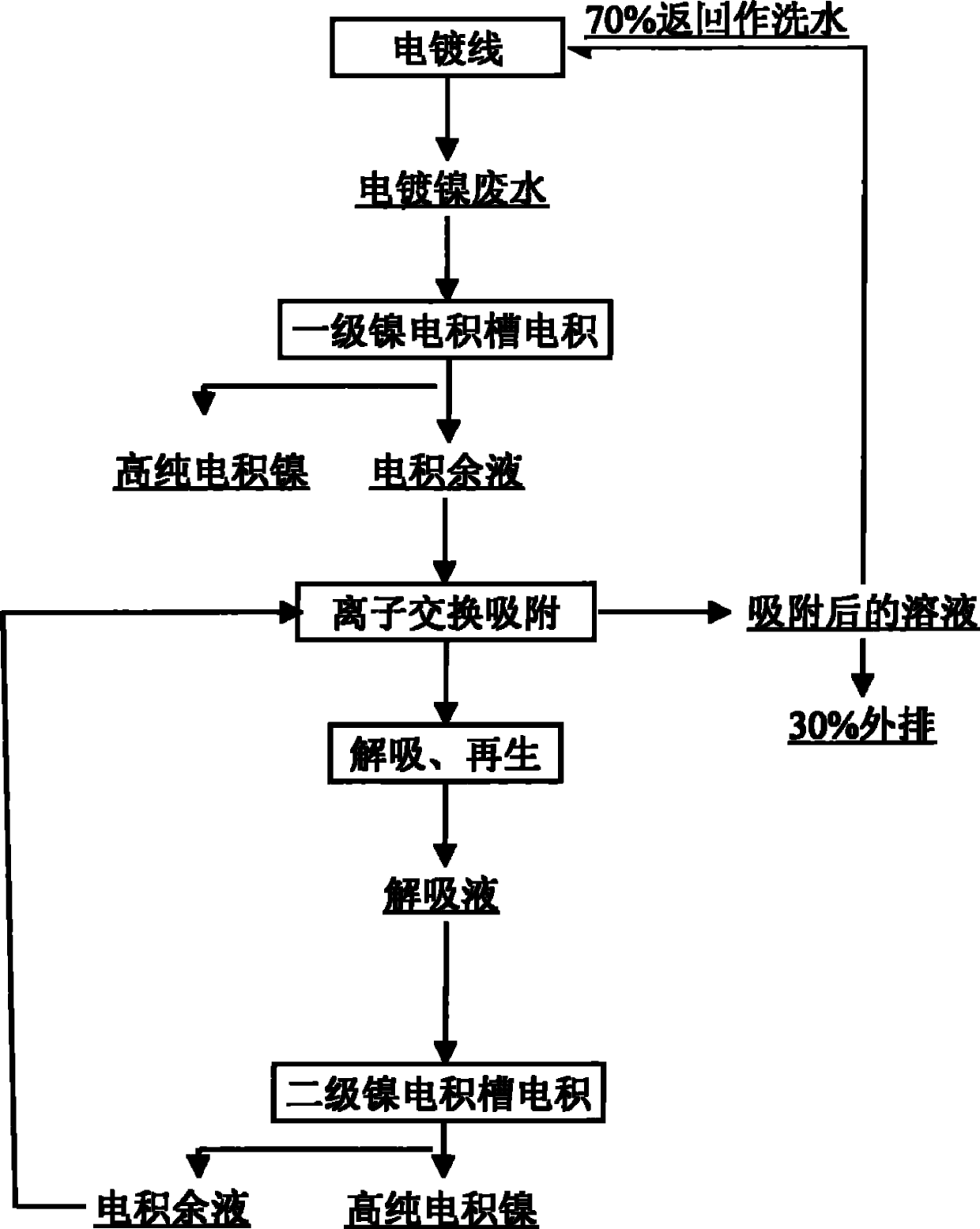

Recycling process of nickel in plating waste water

A technology for electroplating wastewater and electroplating waste liquid, which is applied in photography technology, photography auxiliary technology, metallurgical wastewater treatment and other directions, can solve the problems of difficult recovery, difficulty in meeting environmental protection discharge requirements, and low nickel content in nickel-containing products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] First, add sulfuric acid or sodium hydroxide with a concentration of 10-60% according to the production process requirements of nickel electrowinning, and adjust the pH value of the solution to between 2.5 and 6.5. Coated titanium anode, the material of the cathode is titanium metal. The equipment is equipped with a solution pH adjustment device to ensure the cathode current efficiency in the electrowinning process. The solution is continuously circulated during the electrowinning process. When the nickel ion concentration of the solution is reduced to 0.2-0.5g / L by an electrowinning process, the solution is discharged to the resin adsorption process for adsorption treatment. The specific electrowinning process parameters are as follows:

[0009] Nickel ion initial concentration: 1-8g / L

[0010] Cathode current density: 160-200A / m 2

[0011] Electrodeposition temperature: 15-55°C

[0012] Electrolytic fluid circulation speed: 10-100L / min

[0013] Cathode rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com