System and method for extracting nickel carbonate from stainless steel acid pickling waste mixed acid

A waste mixed acid and nickel carbonate technology, applied in the direction of improving process efficiency, can solve the problems of low equipment start-up rate, large equipment investment, high operating cost, etc., and achieve fast liquid-solid separation speed, enhanced treatment effect, and fast settling speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

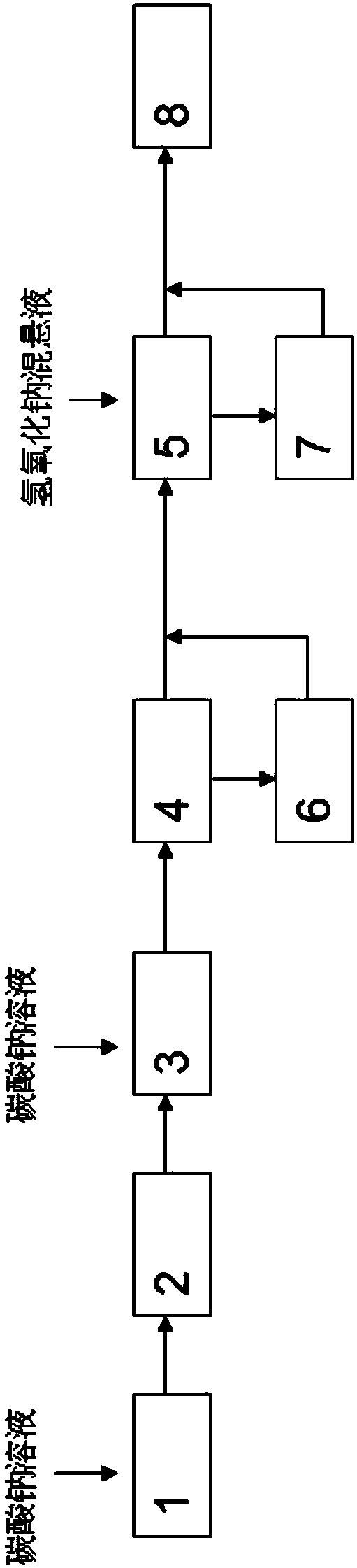

[0118] This embodiment adopts figure 1 The system for extracting nickel carbonate from stainless steel pickling waste mixed acid; the method for extracting nickel carbonate from stainless steel pickling waste mixed acid is as follows:

[0119] (1) The first neutralization reaction: take 1000ml of waste mixed acid, add 25% sodium carbonate solution in mass percentage concentration to the waste mixed acid at a flow rate of 150ml / min, adjust the pH value to 4.5, and let it stand for 1h.

[0120] (2) The first separation: the first separation filter residue is obtained after the first separation, and the iron mass percentage content in the detection residue is 19.19%, the chromium mass percentage content is 2.11%, and the nickel mass percentage content is 0.46%.

[0121] (3) The second neutralization reaction: the first separated filtrate was continuously added with 25% sodium carbonate solution by mass percentage to adjust the pH value to 9.0.

[0122] (4) The second separation:...

Embodiment 2

[0130] This embodiment adopts figure 1 The system for extracting nickel carbonate from stainless steel pickling waste mixed acid; the method for extracting nickel carbonate from stainless steel pickling waste mixed acid is as follows:

[0131] (1) The first neutralization reaction: Take 2000ml of waste mixed acid, add saturated sodium carbonate solution to the waste mixed acid at a flow rate of 200ml / min, adjust the pH value to 5.5, and let it stand for 1h.

[0132] (2) The first separation: the first separation filter residue is obtained after the first separation, and the iron mass percentage content in the detection residue is 17.92%, the chromium mass percentage content is 1.67%, and the nickel mass percentage content is 1.4%.

[0133] (3) The second neutralization reaction: the first separated filtrate was continuously added with 25% sodium carbonate solution by mass percentage to adjust the pH value to 9.5.

[0134] (4) The second separation: the second separation and t...

Embodiment 3

[0142] This embodiment adopts figure 1 The system for extracting nickel carbonate from stainless steel pickling waste mixed acid; the method for extracting nickel carbonate from stainless steel pickling waste mixed acid is as follows:

[0143] (1) The first neutralization reaction: take 2000ml of waste mixed acid, add 25% sodium carbonate solution at a flow rate of 100ml / min to the waste mixed acid, adjust the pH value to 6.0, and let it stand for 1h.

[0144] (2) The first separation: the first separation filter residue is obtained after the first separation, and the iron mass percentage content in the detection residue is 20%, the chromium mass percentage content is 4.5%, and the nickel mass percentage content is 3%.

[0145] (3) The second neutralization reaction: the first separated filtrate was continuously added with 25% sodium carbonate solution by mass percentage to adjust the pH value to 9.8.

[0146] (4) The second separation: the second separation and the first pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com