Low-noise and easy-maintenance honeycomb plate waste crushing decomposer

A pulverizer and easy-to-maintain technology, which is applied in the fields of dust removal, cleaning methods and utensils, grain processing, etc., can solve the problems of serious personal injury to the operator, poor environmental protection, and loud noise, so as to improve practical safety and prolong service life , Improve the effect of environmental protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

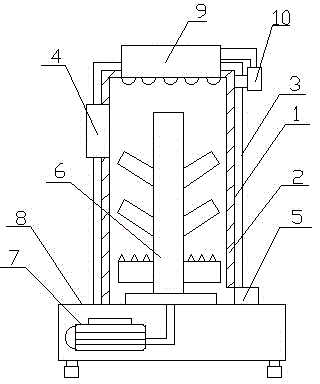

[0011] The present invention is a low-noise, easy-to-maintain waste crushing and decomposing machine for honeycomb panels, which includes a crusher body 1, a wear-resistant layer 2, a silent protective cover 3, a feeding port 4, a discharging port 5, a classification crushing device 6, and a motor 7 , Mute sound box 8, Dust suction device 9, 10 in the dust collection box, wear-resistant layer 2 is installed on the inner wall of the pulverizer body 1, a silent protective cover 3 is set on the outside of the pulverizer body 1, and one side of the pulverizer body 1 is set The feeding port 4, the other side is provided with the discharge port 5, the interior of the pulverizer body 1 is provided with a classification pulverization device 6, the classification pulverization device 6 is connected with the motor 7, the motor 7 is installed in the silent box 8, and the top of the pulverizer body 1 is provided with a Dust suction device 9, one end of dust suction device 9 is connected wi...

Embodiment 2

[0013] When working, the operator puts the plastic waste of the honeycomb panel into the feeding port 4, adjusts the motor 7 to a suitable power and starts the motor 7, and the classification and crushing device 6 grades and pulverizes the plastic waste of the honeycomb panel, and then discharges it from the discharge port 5, and is provided with The silent protective cover 3, on the one hand, can prevent the waste from splashing and falling during the crushing and decomposition process, which makes it difficult to clean the production area; There is a wear-resistant layer 2 inside, which can prevent the waste materials from scratching the grinder body 1 during the crushing and decomposition process, effectively prolonging the service life and improving practical safety; it is equipped with a dust suction device 9, which can reduce the waste generated during the crushing and decomposition process. The floating dust is absorbed and discharged into the dust collecting box 10, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com