Patents

Literature

32results about How to "Improve practical safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

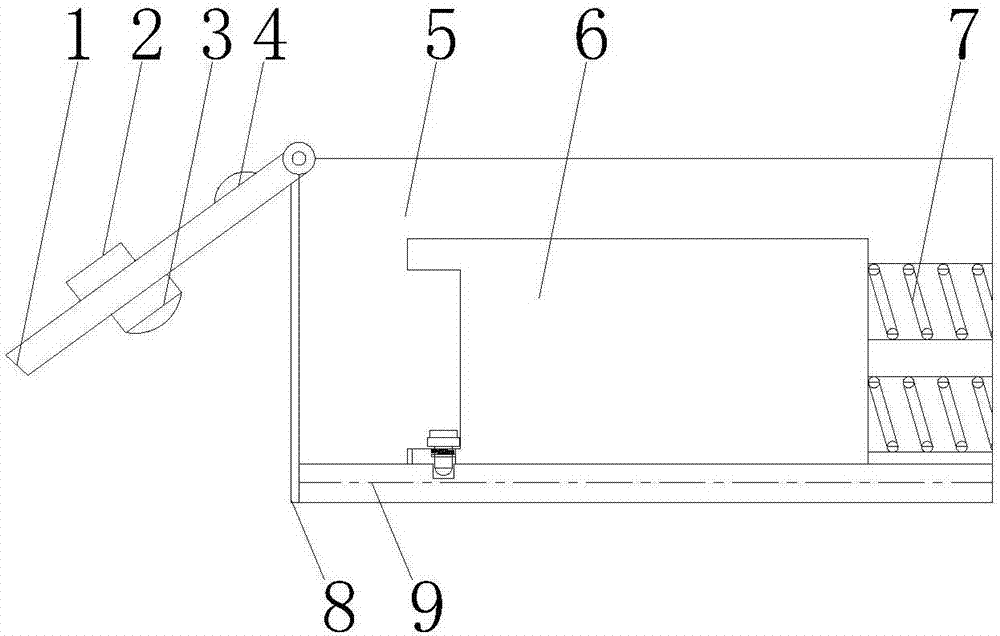

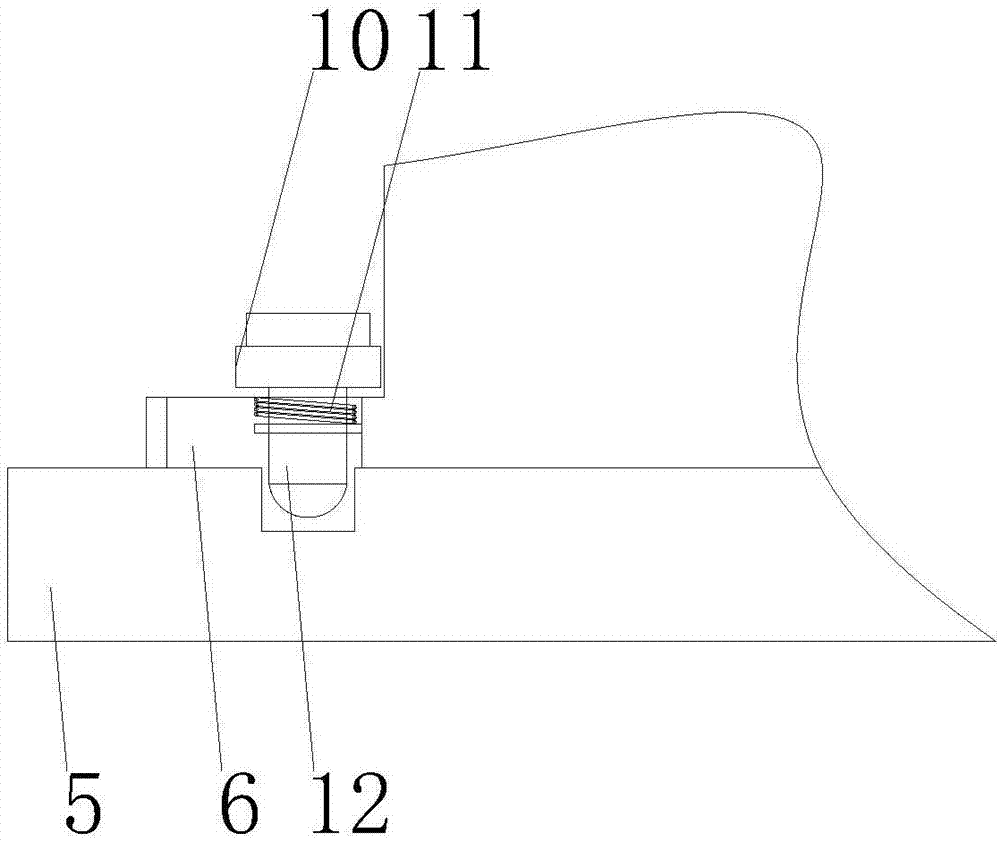

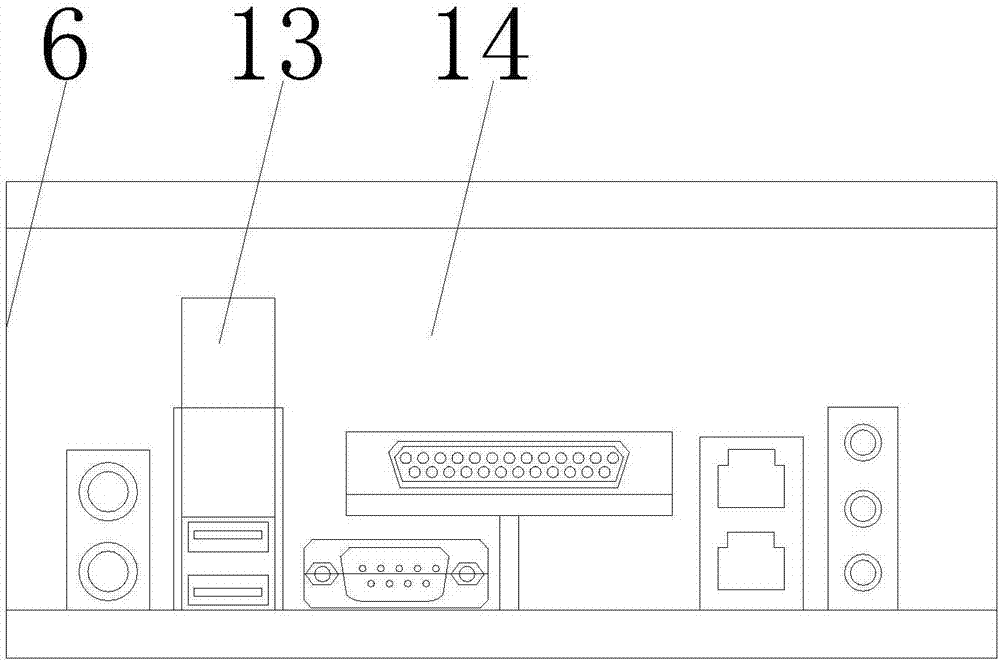

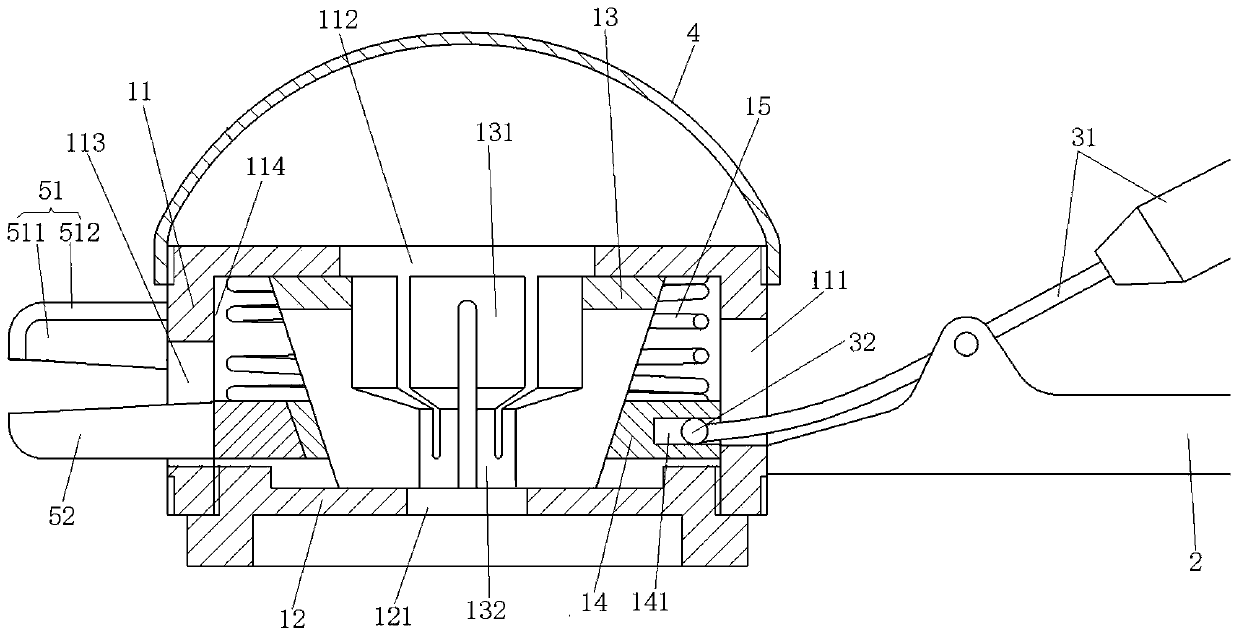

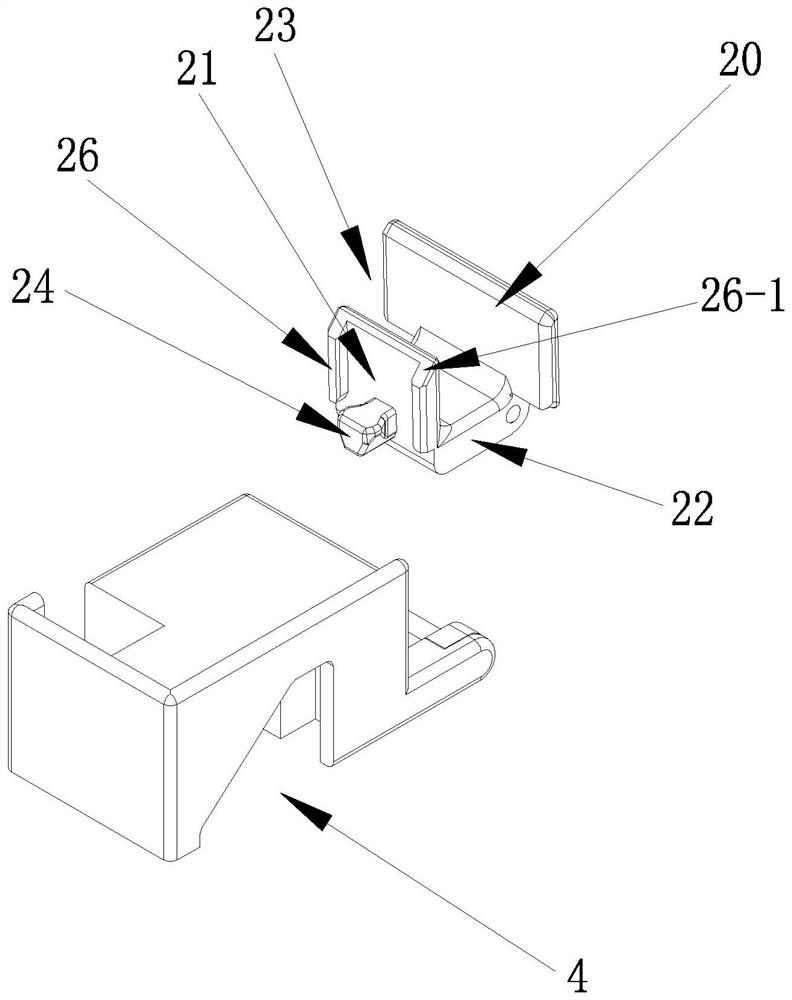

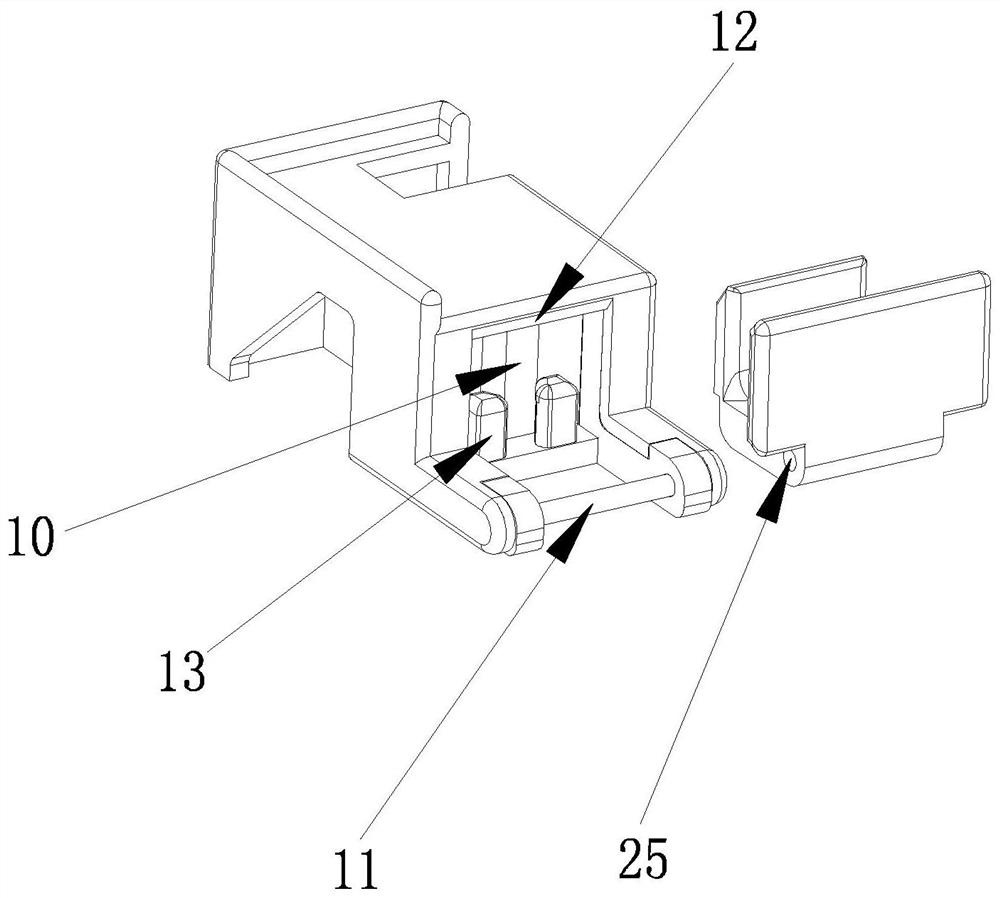

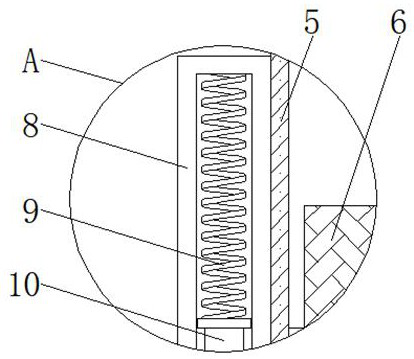

Computer hardware interface with dust cover

InactiveCN107463218APrevent dust damageImprove dustproof effectDigital processing power distributionComputer caseComputer engineering

The invention discloses a computer hardware interface with a dust cover. The computer hardware interface comprises the dust cover, a case, a socket and a jack panel, wherein the socket is arranged in a containing slot in the case, the jack panel is arranged on the surface of the socket, a handle B is arranged on the portion, below the jack panel, of the socket, a locating pin is connected to the position below the handle B, the locating pin penetrates through the socket and is arranged in a locating slot in the base, a baffle is arranged at the middle position of the locating pin, slide rails below the socket are arranged in slide slots in the case, springs A are arranged at the position behind the socket and located between the socket and the case, the dust cover is mounted on the case and covers the containing slot, and the dust cover and the case are connected in a rotary mode. The computer hardware interface is novel in structure, convenient to operate, good in dustproof effect and high in practicability and safety.

Owner:合肥方砖网络科技有限公司

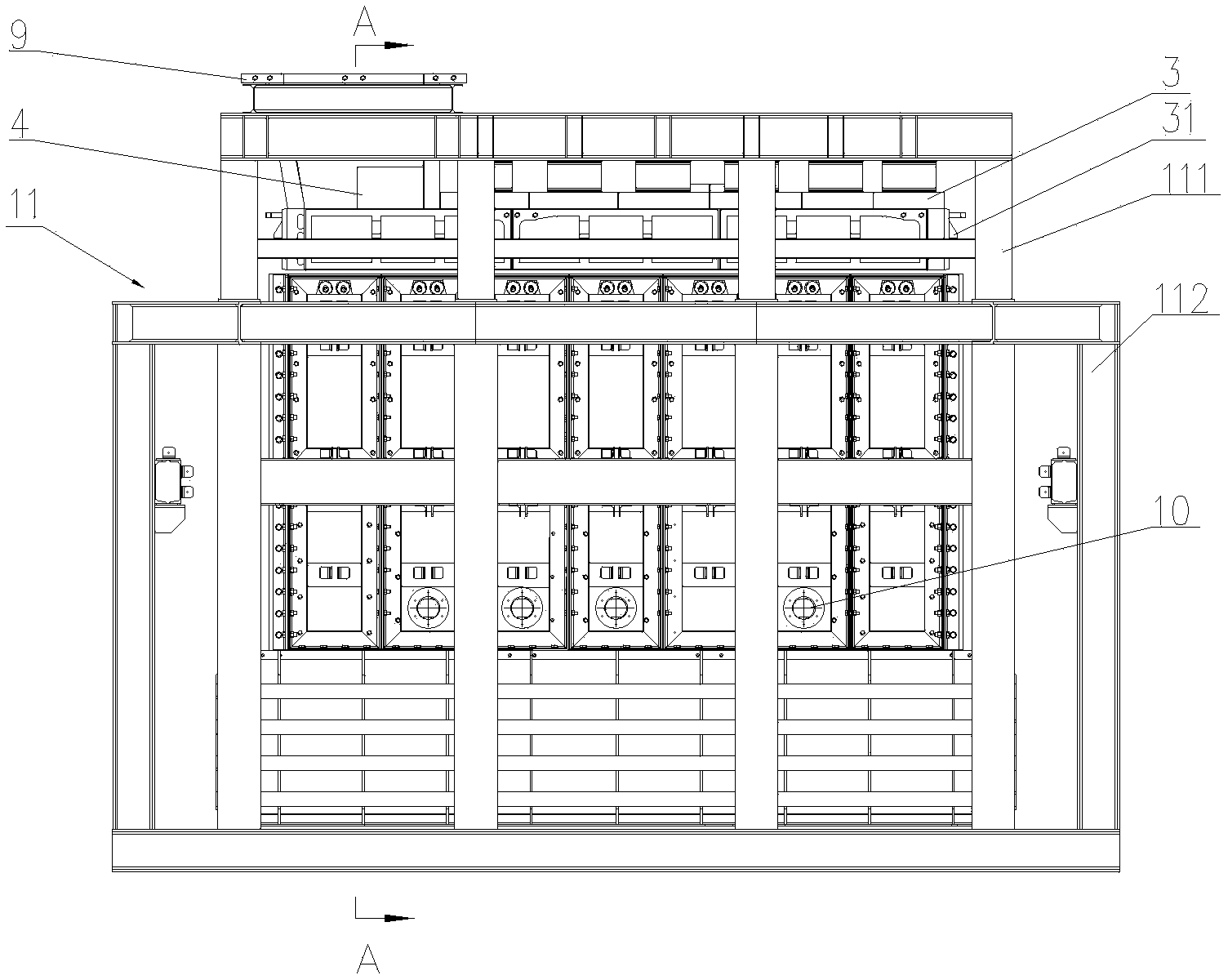

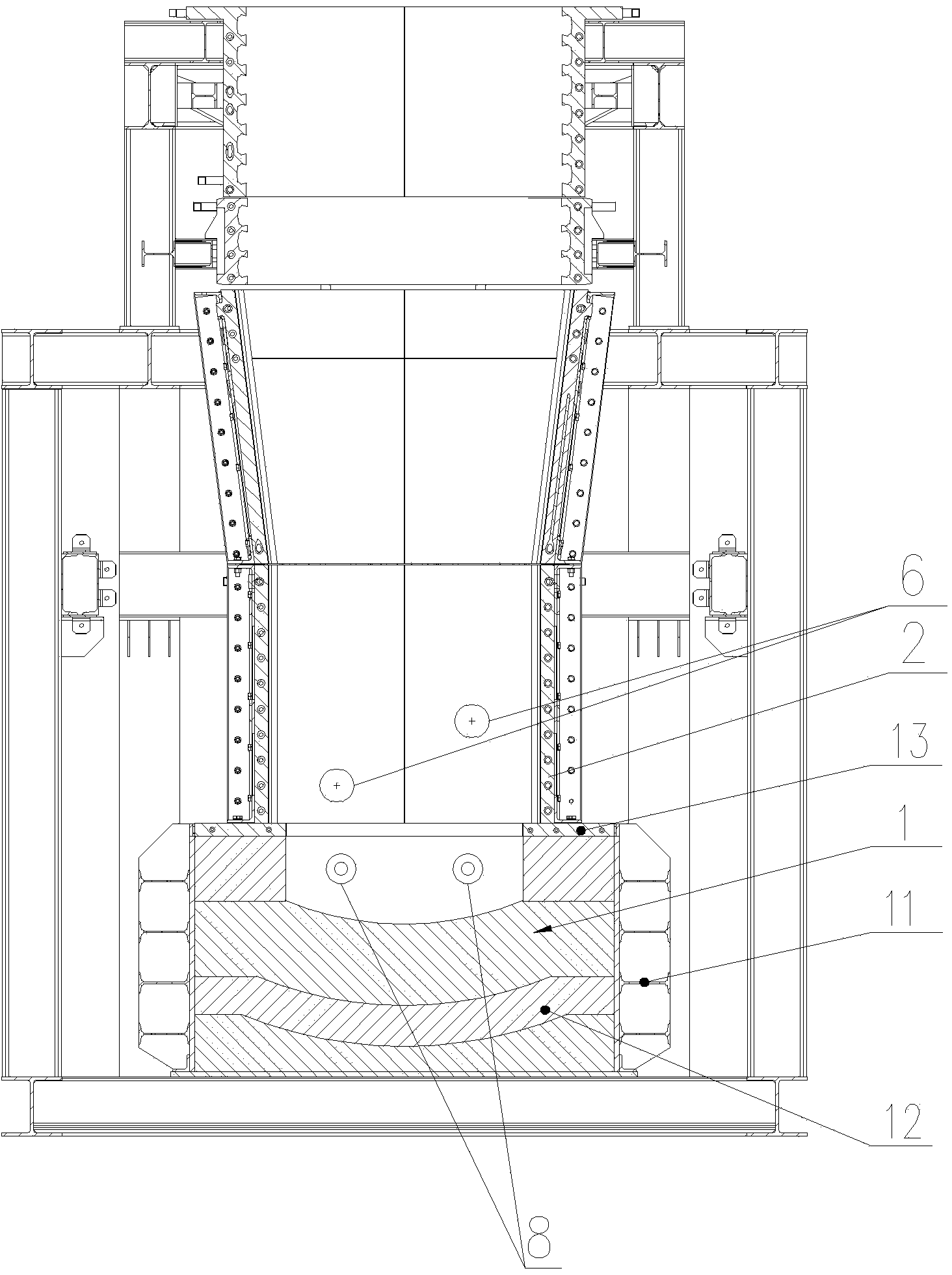

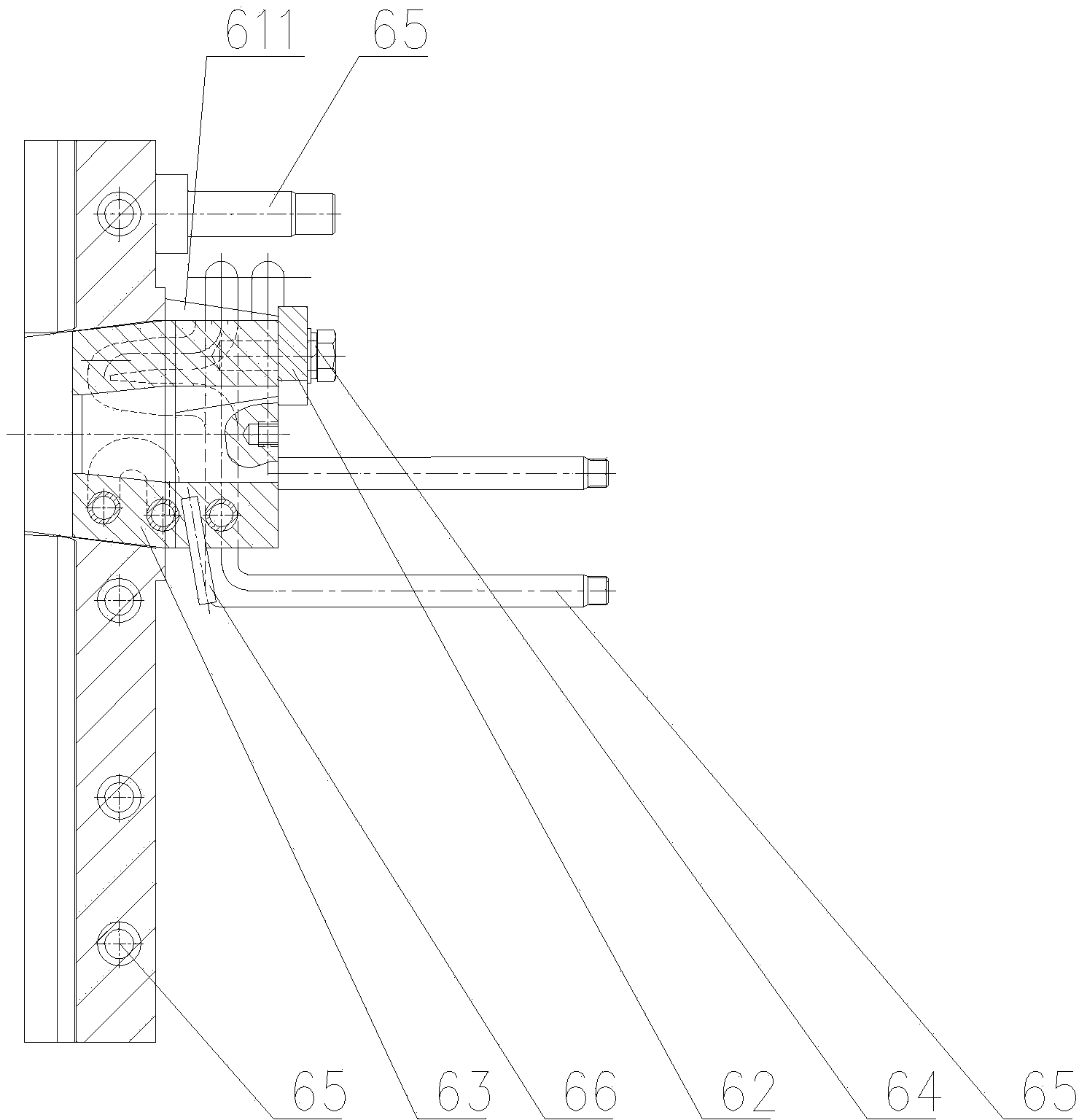

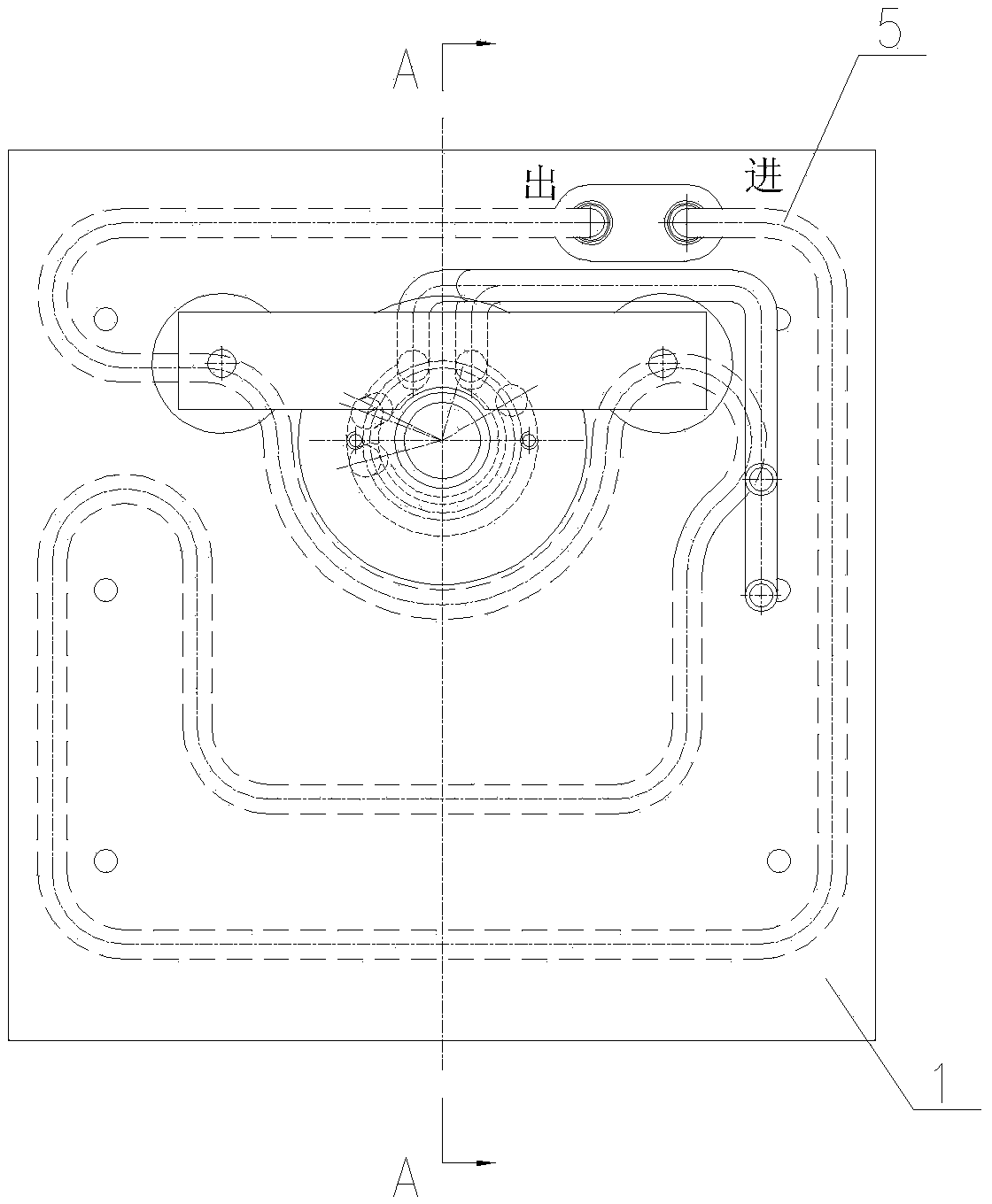

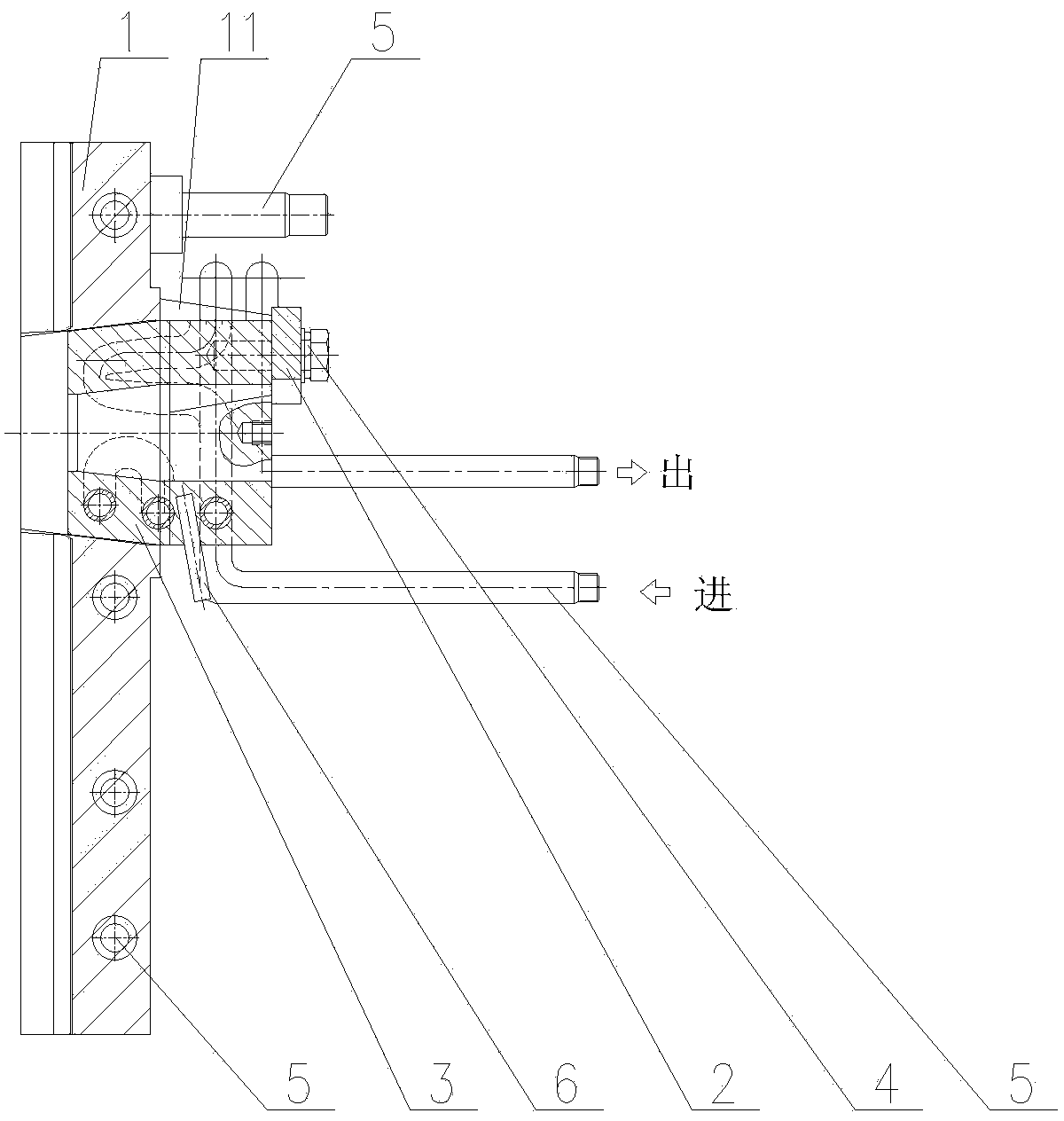

Oxygen-rich reduction furnace for processing low-grade multi-metal material

InactiveCN103397198AExtend your lifeImprove practical safetyCharge manipulationFurnace coolingMelting tankWater leakage

The invention discloses an oxygen-rich reduction furnace for processing a low-grade multi-metal material. The oxygen-rich reduction furnace comprises a furnace crucible, a copper water jacket furnace wall and a copper water jacket furnace top which are sequentially arranged from bottom to top, wherein a steel structure frame body is arranged on the periphery, and the furnace crucible is positioned on a bottom surface framework of the steel structure frame body; the copper water jacket furnace wall comprises a plurality of layers of copper water jackets, an air nozzle and a hole punching and slag discharge device are arranged at the bottom of the copper water jacket at the bottom layer, and a fixed frame for connecting with the steel structure frame body is arranged on the outer wall of the copper water jacket furnace wall; and the copper water jacket furnace top is hung at the upper end of the steel structure frame body, and a solid feed port, a liquid feed port and a flue port for smoke exhaust, which are communicated with the copper water jacket furnace top, are arranged at the upper end of the copper water jacket furnace top. The heating surfaces of all the copper water jackets are embedded with dovetail groove-shaped bricks, so that the service life of the copper water jackets is greatly prolonged, and the structure of the hole punching and slag discharge device can overcome the defects that a water jacket at a slag notch is prone to water leakage, and shutdown is required for replacing the water jacket. The oxygen-rich reduction furnace disclosed by the invention adopts an oxygen-rich melting pool for melting and has the characteristics of small smoke gas amount, low heat which is taken away by smoke gas, high temperature of the melting pool and easiness in volatilization of lead and zinc.

Owner:CINF ENG CO LTD

Punching deslagging device of metallurgical furnace

The invention discloses a punching deslagging device of a metallurgical furnace. The device comprises a slag hole copper water jacket and a copper water jacket plug, wherein copper pipes are pre-buried in the slag hole copper water jacket and the copper water jacket plug; the copper water jacket plug is assembled in the slag hole copper water jacket; a through hole is formed in the axial center of the copper water jacket plug. According to the device, the copper water jacket plug is additionally arranged in the slag hole copper water jacket, the slag hole copper water jacket and the copper water jacket plug are fixed and limited relative to each other through a steel plate connected to lug bosses at the outer end of the slag hole copper water jacket, and the copper pipes are pre-buried in the entities of the slag hole copper water jacket and the copper water jacket plug; when deslagging is needed, all that is needed to do is remove sealing putty in the through hole in the center of the copper water jacket plug; the slag hole copper water jacket and the copper water jacket plug are both copper cooling pieces; the device overcomes the defects in the prior art that a slag hole steel water jacket deforms seriously and is reduced in strength due to corrosion of slag so as to be liable to leak water and the furnace needs to be shut down when the slag hole steel water jacket is replaced, thereby improving the practicability and safety performance of the metallurgical furnace, prolonging the service life of the metallurgical furnace and saving cost.

Owner:CINF ENG CO LTD

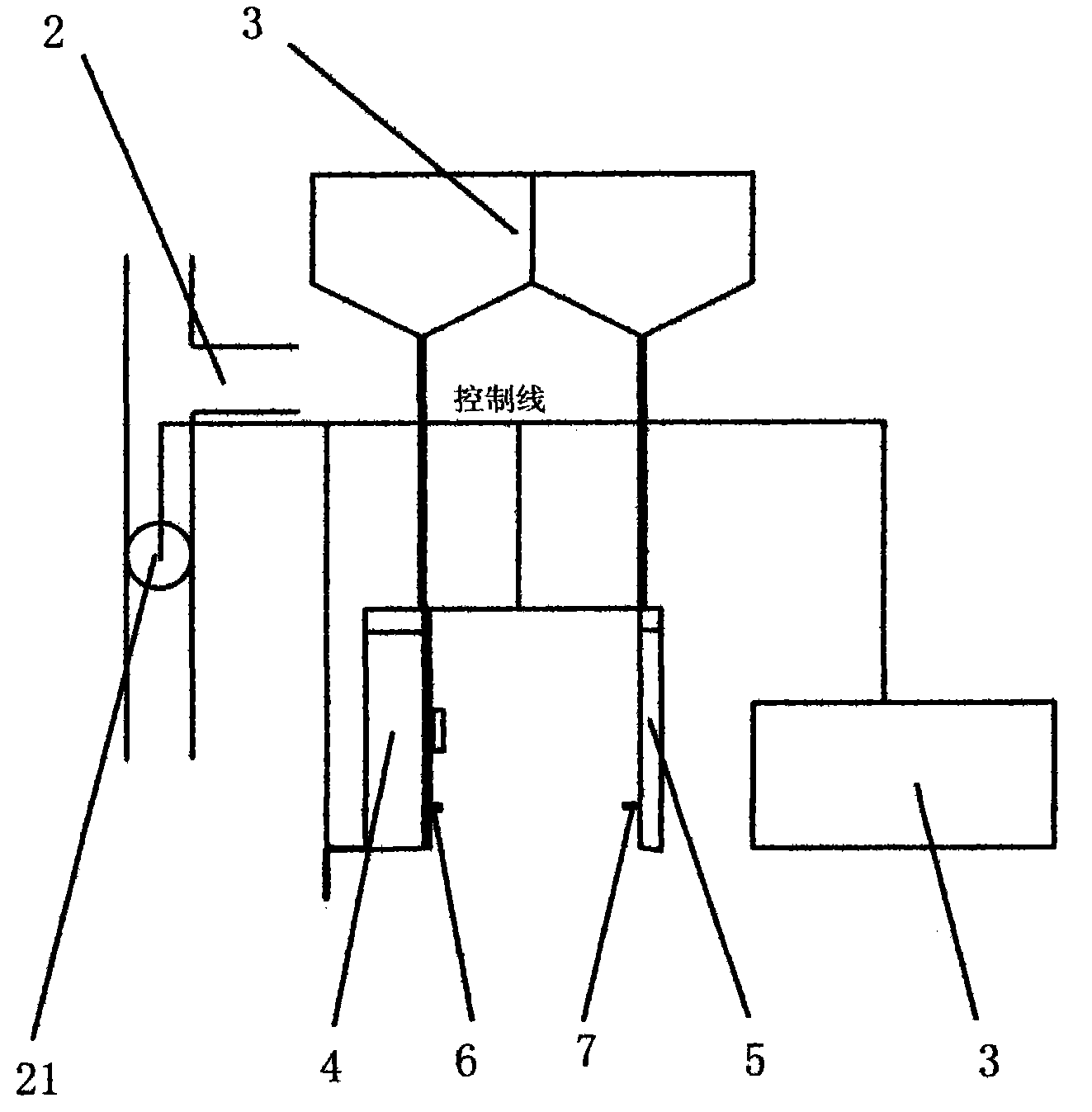

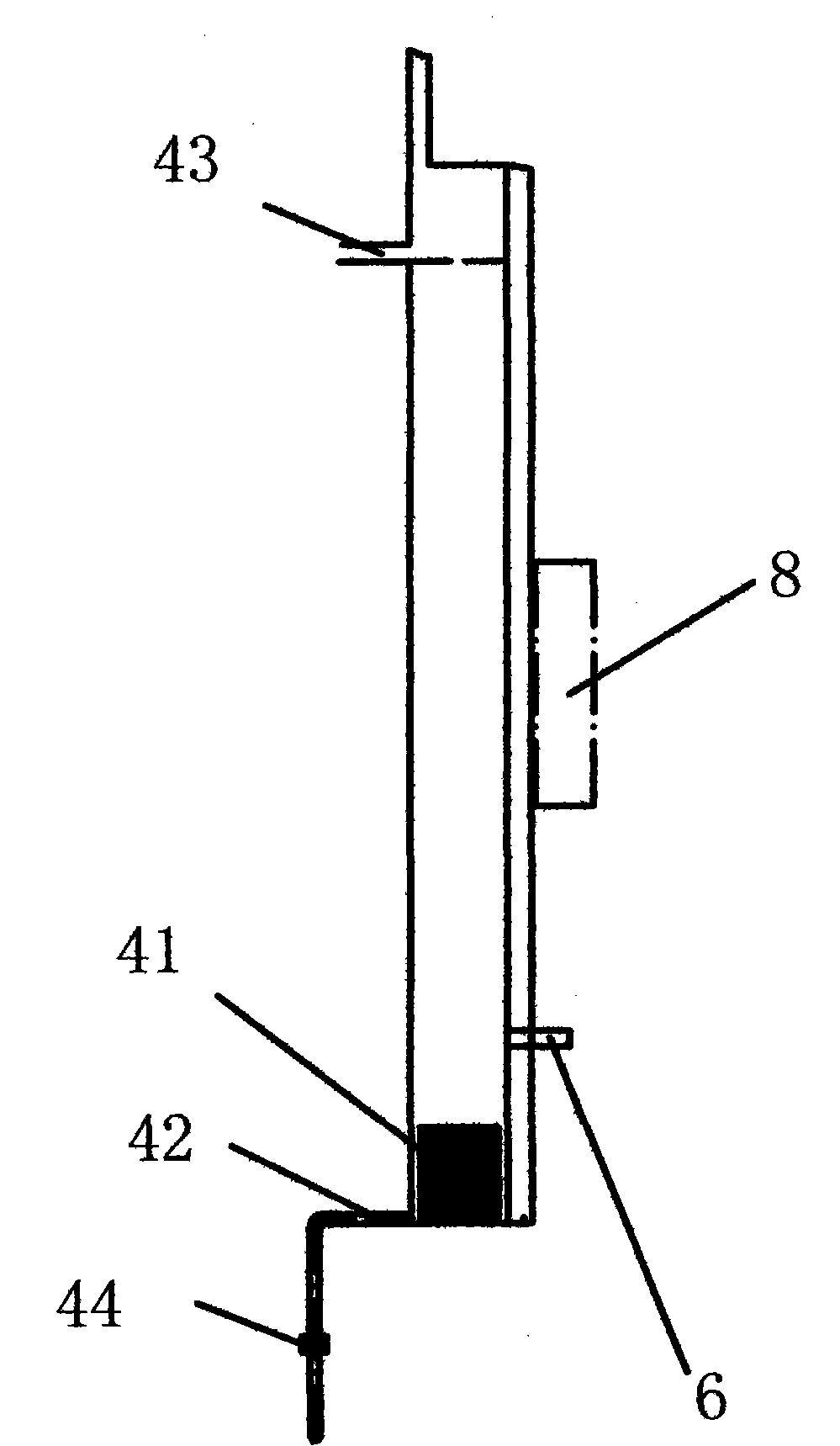

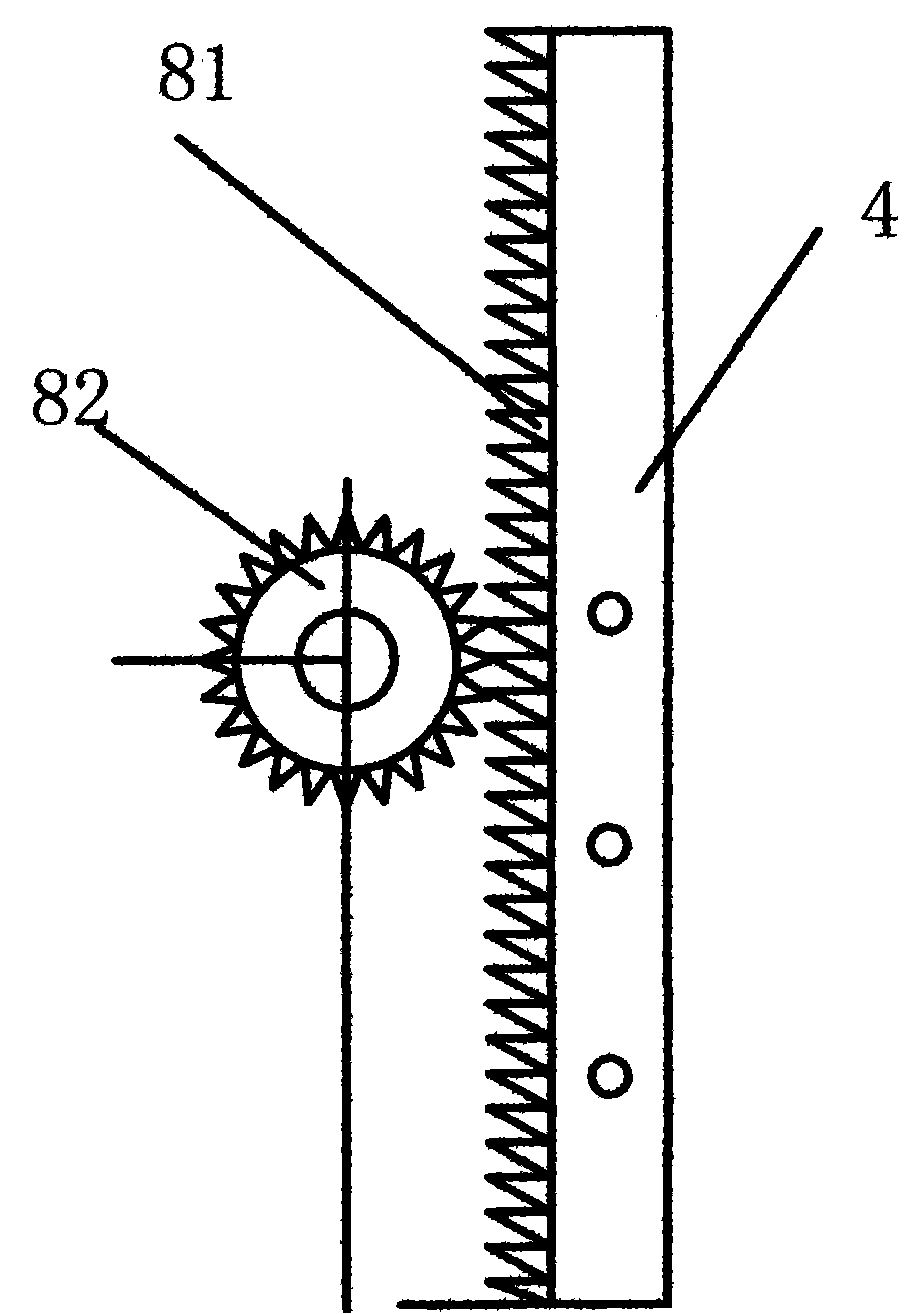

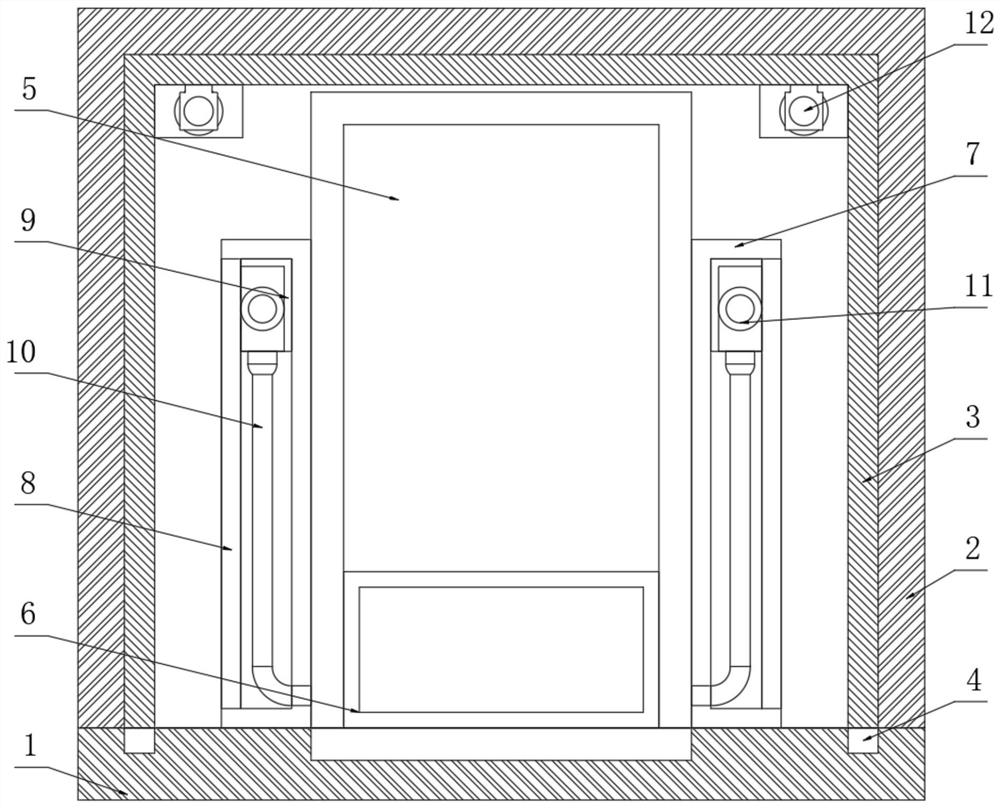

Rainwater runoff control apparatus

InactiveCN101319510BImprove stabilityHigh precisionLevel controlGeneral water supply conservationMicrocomputerStorm water runoff

The invention discloses an initial rainwater runoff control device, which comprises a controller, a runoff collection pipe and a rainwater collection hopper, wherein, an electromagnetic valve connected with the controller is arranged in the runoff collection pipe; the lower end of the rainwater collection hopper is provided with a first rainwater monitoring hopper and a second rainwater monitoring hopper; a first floating ball, a first water outlet, a first overflow port and a first water level probe are arranged in the first rainwater monitoring hopper; a second floating ball, a second wateroutlet, a second overflow port and a second water level probe are arranged in the second rainwater monitoring hopper; and the first water level probe and the second water level probe are respectivelyconnected with the controller. Compared with the prior art, the device adopts a microcomputer control technology and has a control principle different from other devices; the microcomputer control has good stability, high accuracy, convenient operation, practicability and safety, and has greatly improved environment adaptability compared with the prior device; in addition, a microcomputer has lower power, so the device is more environment-friendly and energy-saving.

Owner:SOUTHEAST UNIV

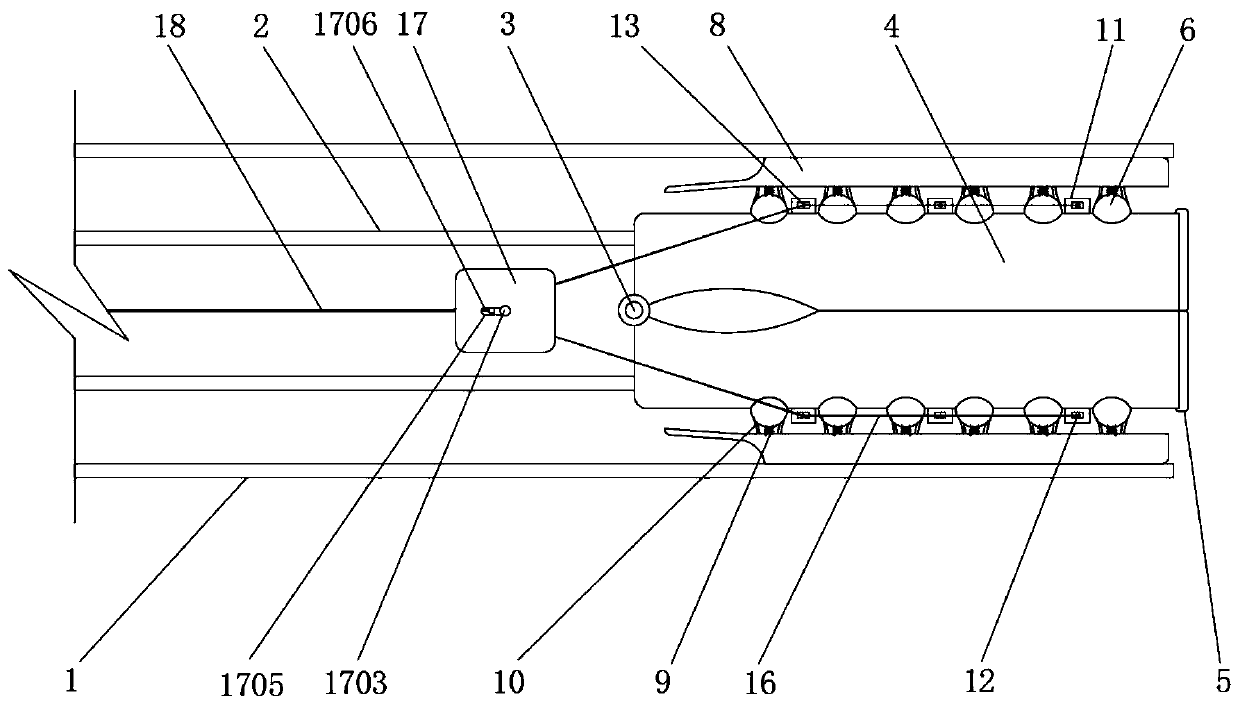

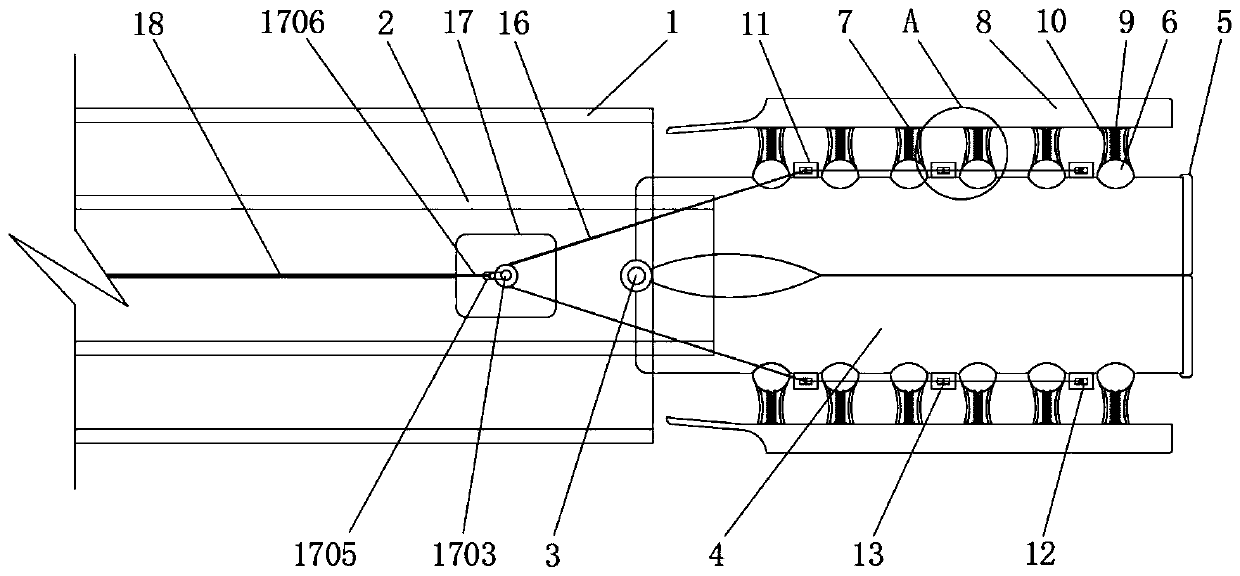

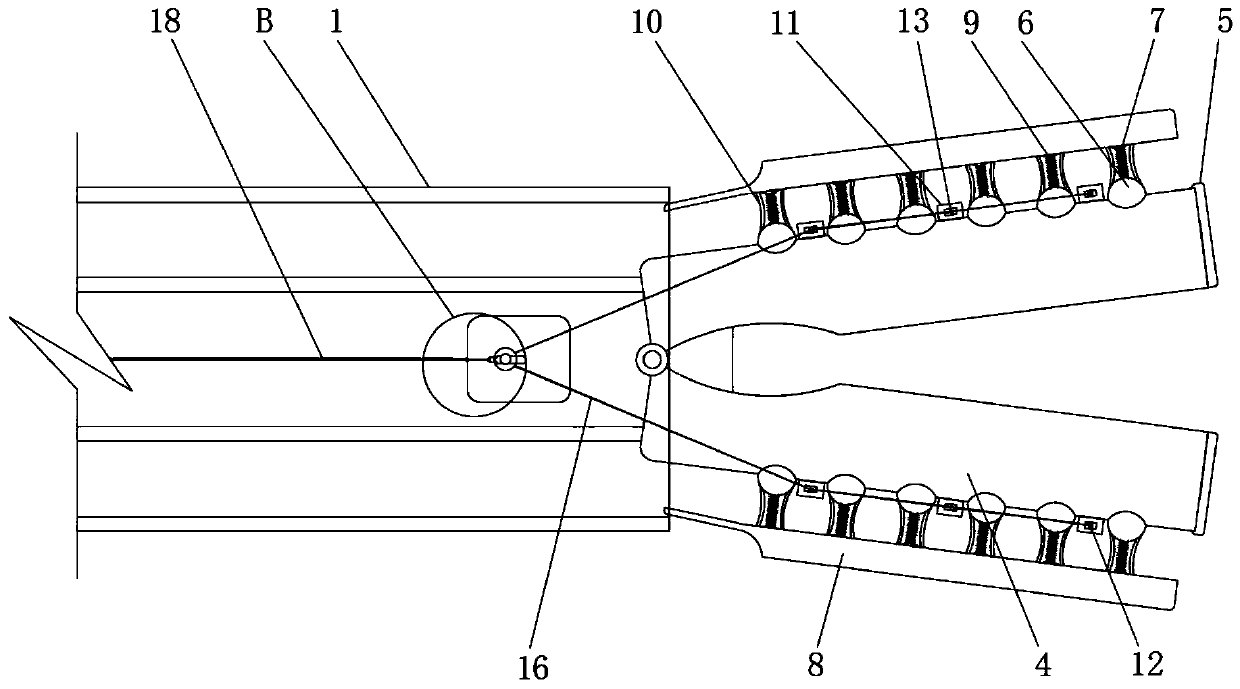

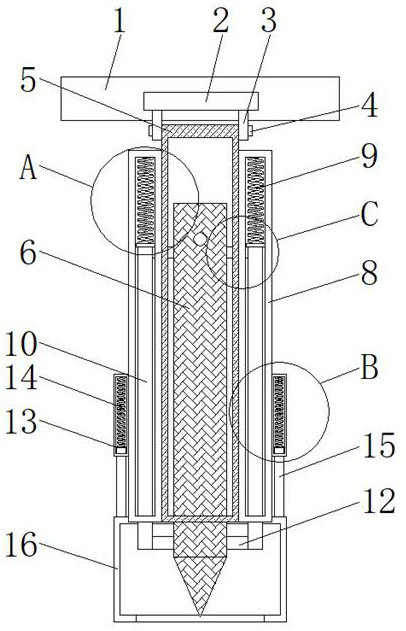

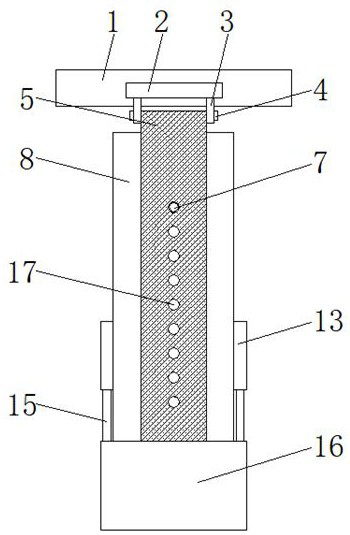

Lung fixing device used under thoracoscope

ActiveCN110141377AAvoid damageAvoid obstructionInstruments for stereotaxic surgeryFixed frameEngineering

The invention discloses a lung fixing device used under thoracoscope. The lung fixing device comprises an outer tube and a sleeve tube, wherein an inner tube is arranged in the outer tube; first fixing balls are respectively arranged on one side away from the center line of the inner tube, of a fixing clip; each first fixing ball is connected with a corresponding second fixing ball through a corresponding spring; fixing pieces are respectively fixed to one side away from the axis of the inner tube, of the fixing clip; each fixing frame is arranged on the left side of a corresponding fixing shaft seat; each connecting rod is fixed to the front side of the corresponding fixing frame; each fixing shaft seat is connected with the right end of a corresponding first connecting rope; the left endof each first connecting rope sequentially penetrates through a place between every two connecting rods; a fixed seat is arranged on the front side of the right end of the inner tube, and is arrangedon the left sides of the fixed seats; and the right end of the sleeve tube is connected with the left end of the fixed seat. According to the lung fixing device used under thoracoscope disclosed by the invention, lung parts on two sides of the inner tube are fixed through the fixing clamp, so that the situation that the thoracoscope lens in the inner tube is blocked by lung parts is avoided, andthe using convenience is improved.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

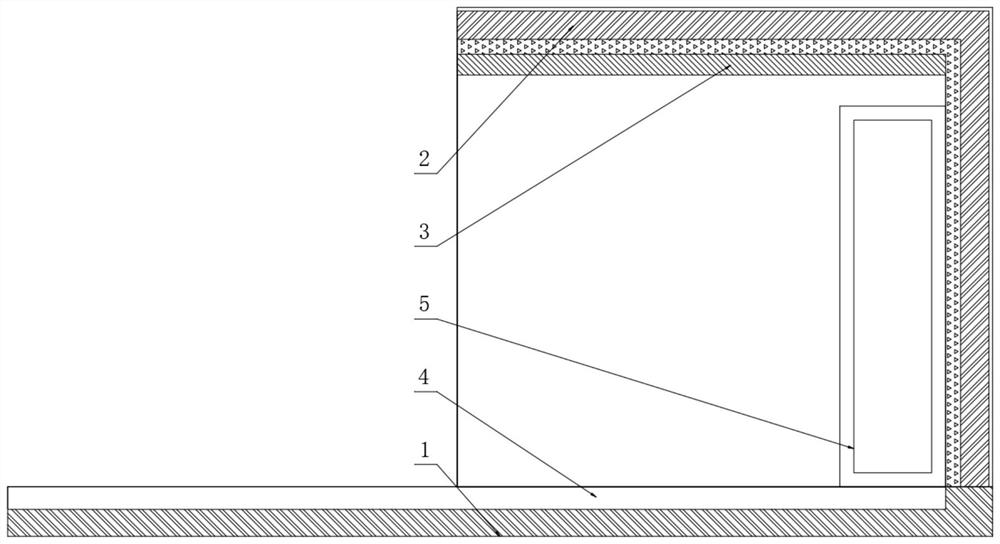

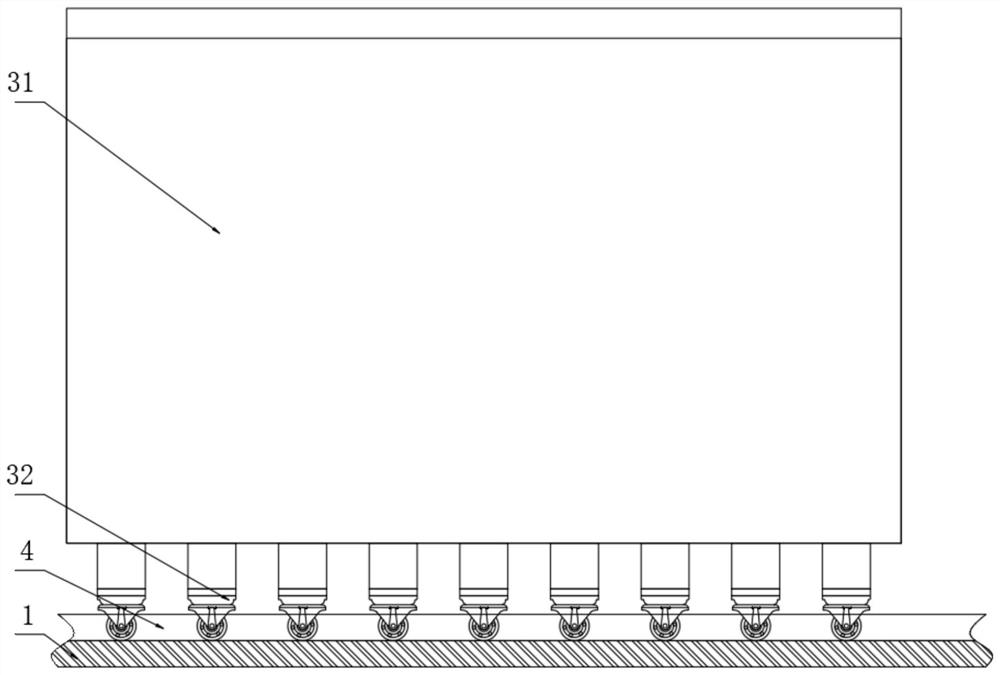

New energy automobile charging pile based on smart city

InactiveCN112647746AReduce damageReduce aging rateCharging stationsSubstation/switching arrangement cooling/ventilationNew energyStructural engineering

The invention discloses a new energy vehicle charging pile based on a smart city, and particularly relates to the technical field of smart cities. The charging pile comprises a plastic insulation base, a shed is fixedly installed on the top surface of the plastic insulation base, a movable telescopic shed body movably connected with the top surface of the plastic insulation base is movably sleeved in the shed, and the bottom ends of the left side wall and the right side wall of the movable telescopic shed body are movably connected with limiting sliding grooves formed in the top face of the plastic insulation base in an embedded mode. According to the new energy vehicle charging pile, through arrangement of the shed and the movable telescopic shed body, in the working process of the charging pile, the sliding shed and the shed are movably connected into a whole through cooperation of electric hydraulic rods, two limiting sliding grooves and two sets of limiting pulleys, and a Dike aluminum foil heat insulation coiled material arranged on the outer surface of the shed is used for being matched with an aerogel felt arranged on the inner wall of the shed to isolate light radiation heat in a double-layer mode, so that the damage degree of outdoor high temperature to an intelligent charging unit is reduced, the aging rate of the intelligent charging unit is delayed, and the service life of the charging pile is prolonged.

Owner:李志超

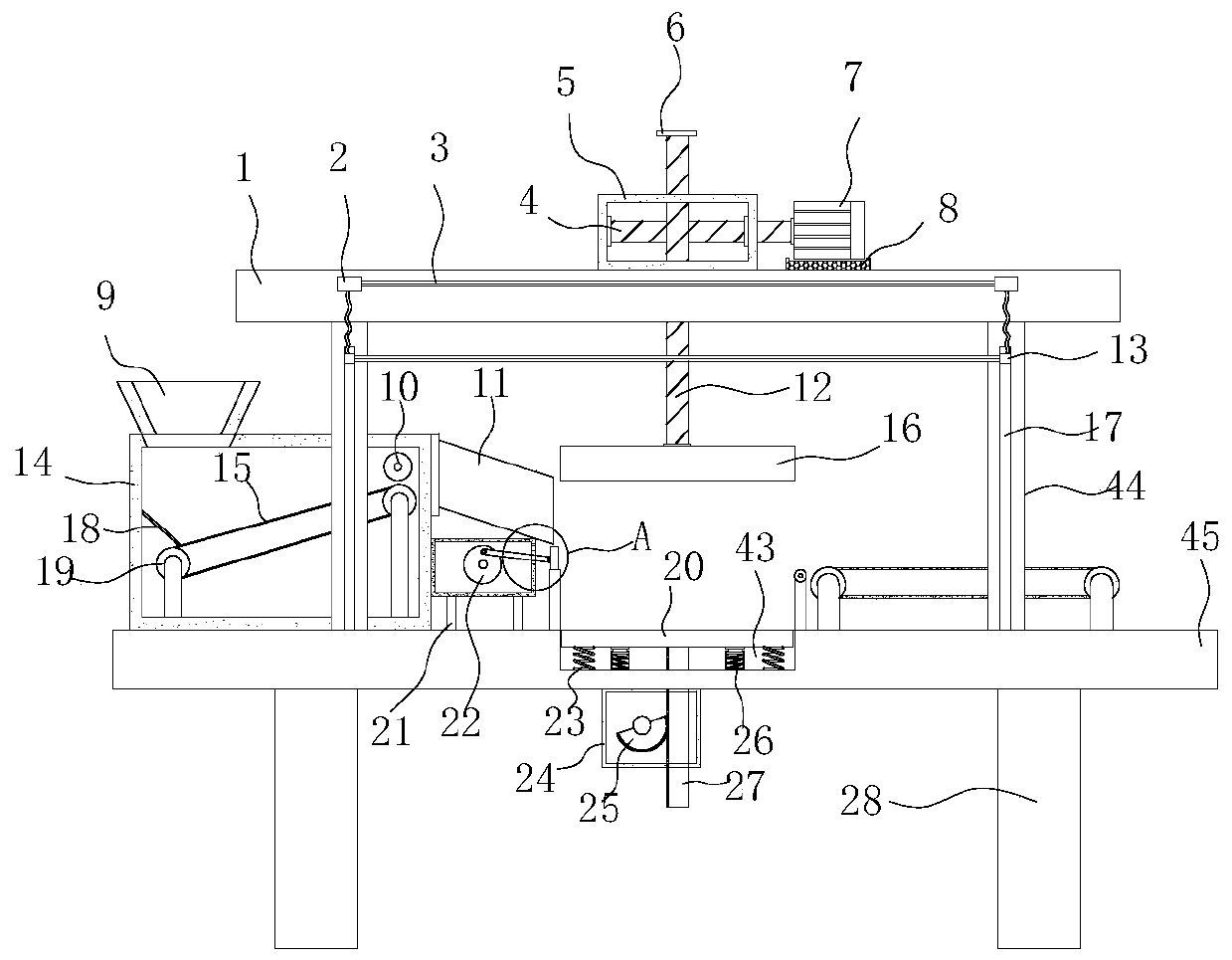

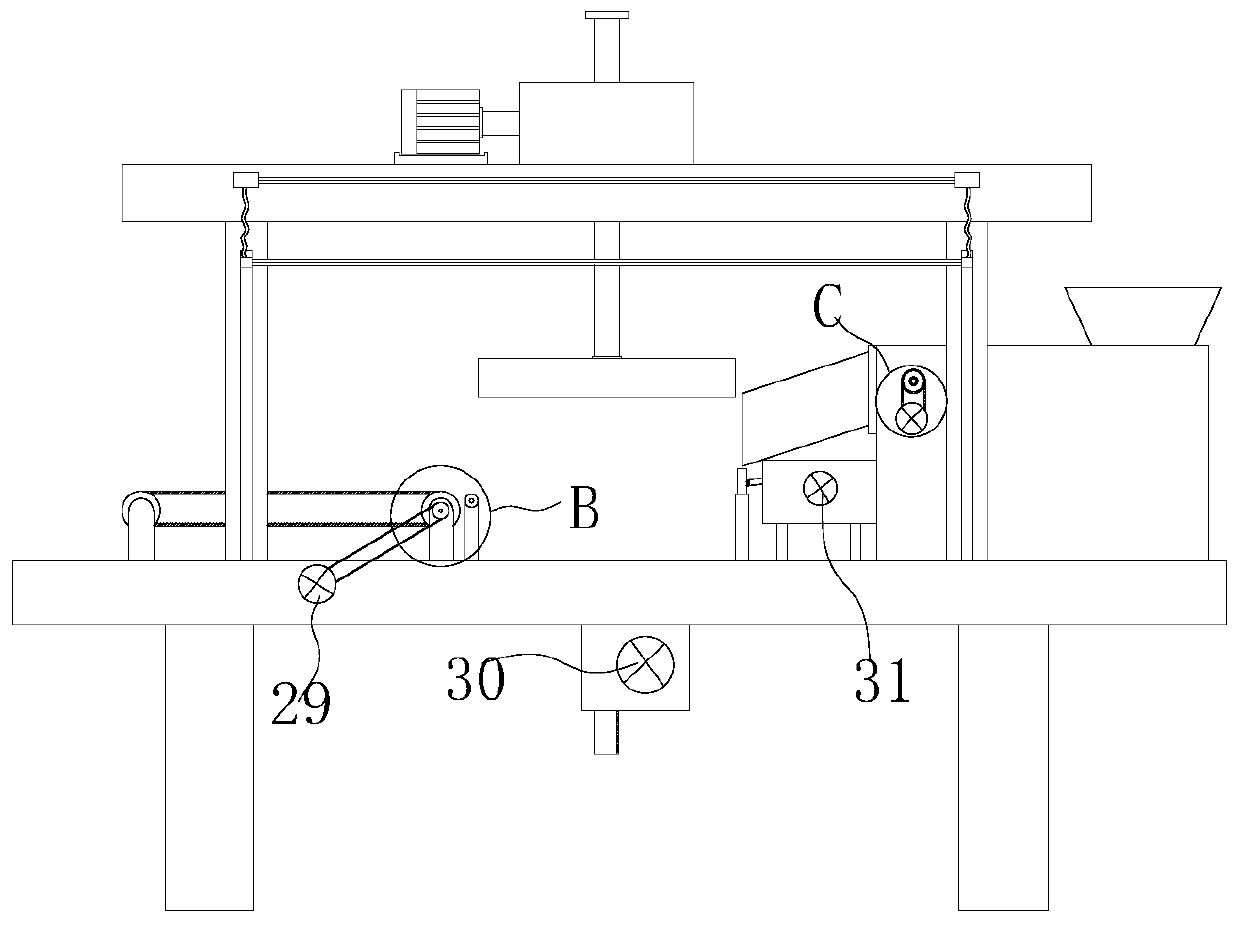

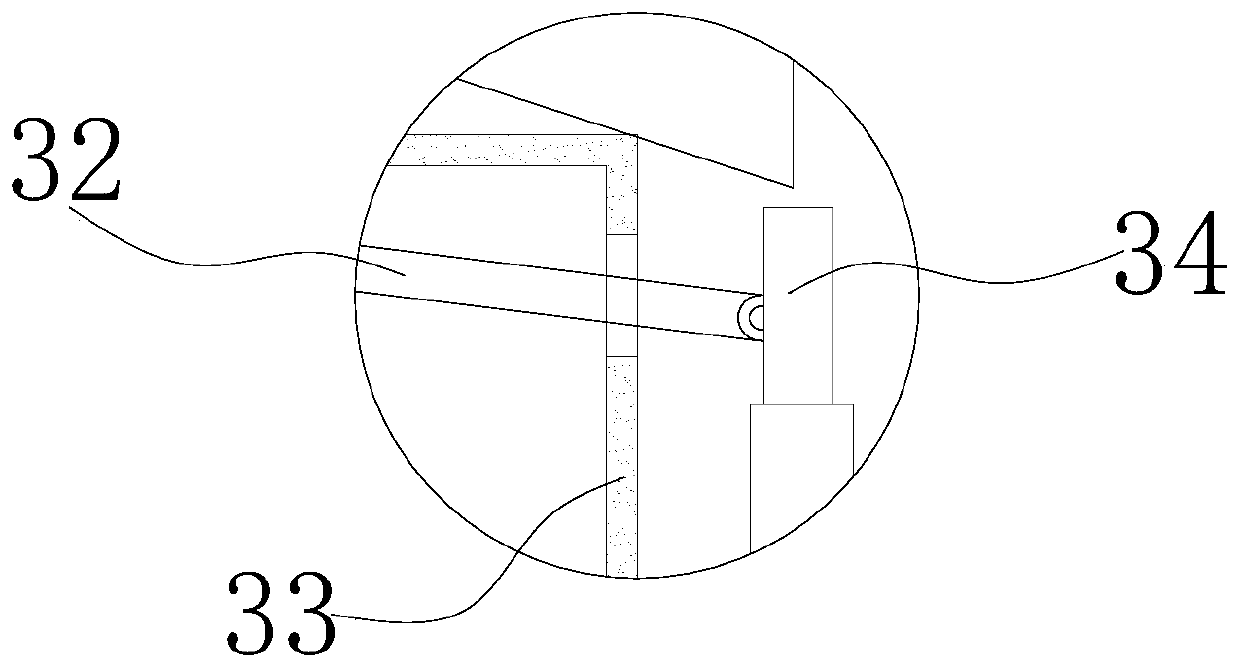

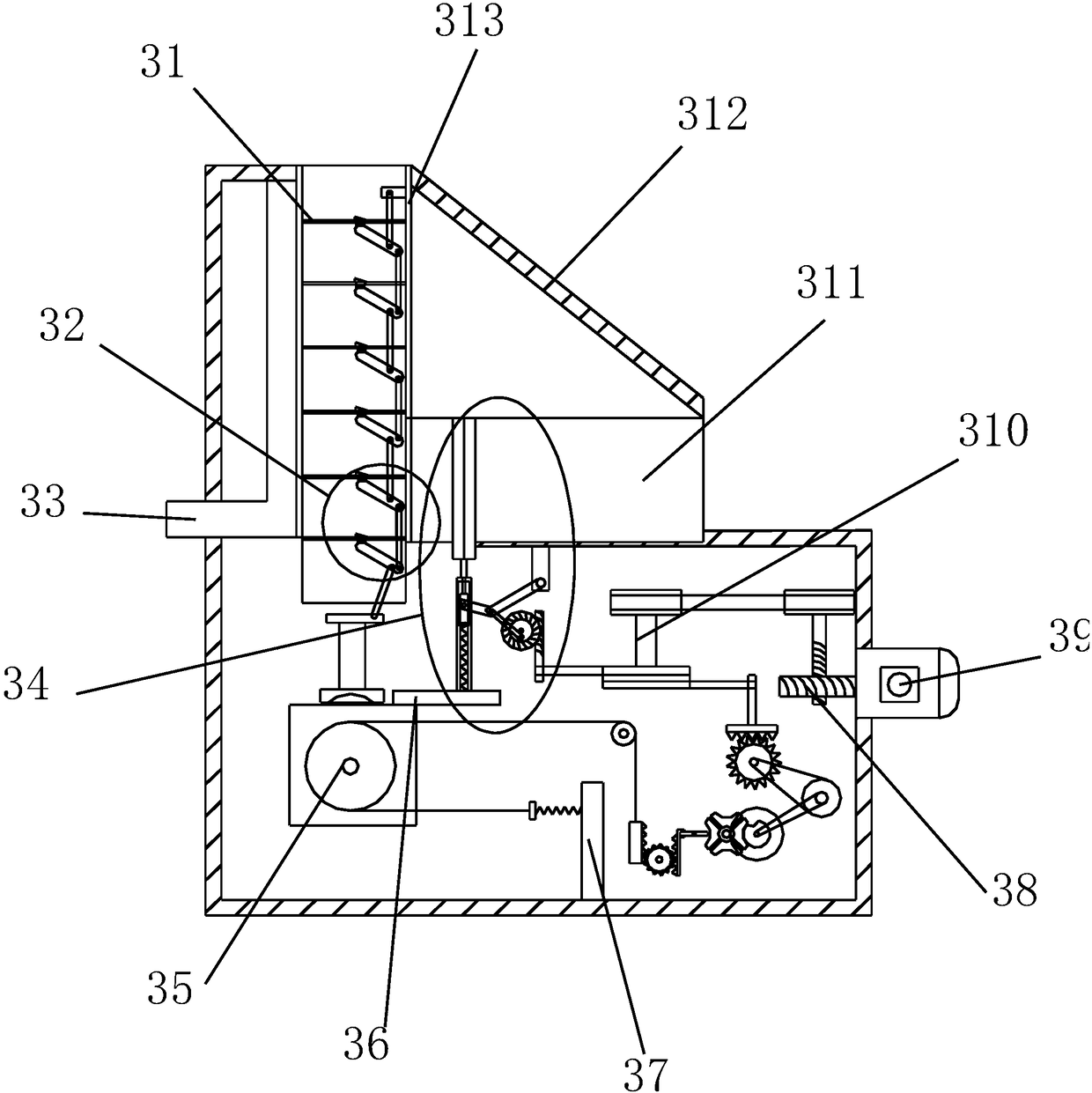

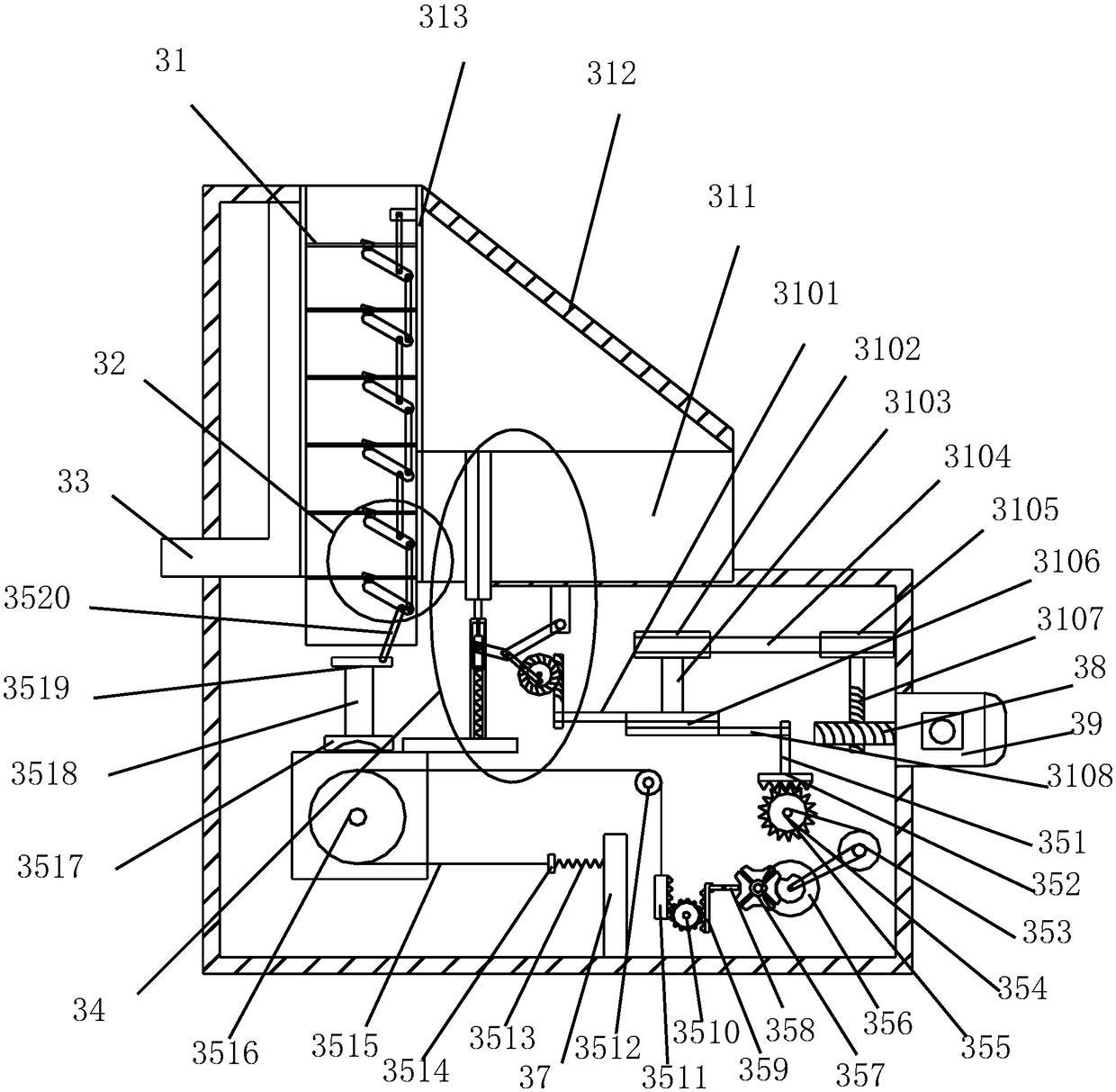

Cotton wool flattening device for efficiently producing clothes

ActiveCN111074467AReduce labor intensityIncrease production speedTextile shapingGear wheelElectric machinery

The invention discloses a cotton wool flattening device for efficiently producing clothes and relates to the technical field of clothes production. The cotton wool flattening device for efficiently producing the clothes comprises a workbench; supporting legs and a first mounting box are welded to and mounted at the bottom of the workbench; the supporting legs are provided with four sets and are arranged at the bottom of the workbench in a rectangular array; rubber patches are arranged at the bottoms of the supporting legs; a half gear is rotationally mounted on the front and rear inner walls of the first mounting box and the first mounting box is located at the middle of the bottom of the workbench; a third motor is welded to and mounted on the rear wall of the first mounting box; and an output end of the third motor transversely runs through the first mounting box through a coupler and is arranged in a manner of being welded to and connected with a rotating shaft of the half gear. According to the cotton wool flattening device for efficiently producing the clothes, machinery is adopted to replace manual work to perform compaction and flattening work on the cotton wool, so that thelabor intensity of workers is reduced to a certain extent, and meanwhile, substitution of the manual work by the machinery accelerates the production speed and improves the production efficiency to acertain extent.

Owner:曲阜东方服装有限公司

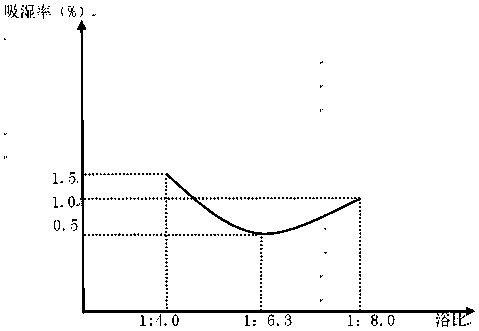

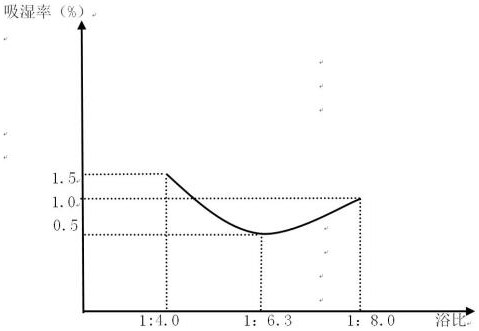

Long-acting flame-retardant treatment method suitable for wicker artware

ActiveCN111113605ADimensional Stability EffectStrong loss resistanceWood treatment detailsReed/straw treatmentThermodynamicsHigh humidity

The invention relates to the technical field of wicker artware development, and discloses a long-acting flame-retardant treatment method suitable for wicker artware. According to the method, a prepared flame-retardant material is allowed to infiltrate into a wicker material by adopting a normal-pressure heating impregnation treatment method; in the treatment process, adverse effects on the dimensional stability of the wicker material are avoided; the flame-retardant material has hydrophobicity, can shield the influence of moisture, can stably exist in the wicker material even under the conditions of high humidity and strong light irradiation, does not fade away flame-retardant effect, and is high in loss resistance and remarkable in flame-retardant effect; and the flame-retardant materialis economical and environment-friendly, is very stable in physical and chemical properties, large in specific heat capacity and capable of insulating heat and oxygen, can generate a free radical inhibitor when being heated, interrupts conditions for forming a combustion reaction, and expands the application range of wicker artware in other fields.

Owner:阜南佳利工艺品股份有限公司

Electrostatic spraying antirust oil and preparation method thereof

PendingCN109321338AGood dispersionImprove resistance to acidic atmosphereLubricant compositionSulfonateWax

The invention belongs to the field of metal surface protection and provides electrostatic spraying antirust oil and a preparation method thereof. The antirust oil is prepared from the following ingredients in parts by weight: 5 to 15 parts of oxidized petroleum wax salt, 0 to 5 parts of synthesized ammonium sulfonate and 35 to 90 parts of hydrorefined mineral oil, wherein the oxidized petroleum wax salt is at least one of calcium salt of oxidized petroleum wax, sodium salt of the oxidized petroleum wax or ammonium salt of the oxidized petroleum wax, and the base number of the oxidized petroleum wax salt is 100 to 500 mgKOH / g; the hydrorefined mineral oil is at least one of refined mineral oil with the viscosity of 5 mm<2> / s under 40 DEG C, refined mineral oil with the viscosity of 32 mm<2> / s under 40 DEG C or refined mineral oil with the viscosity of 68 mm<2> / s under 40 DEG C. The antirust oil disclosed by the invention has good environmental protection property and in the meantime, has a reasonable resistance value; the resistance value is only 0.1 to 20 M omega under the temperature of 20 to 60 DEG C; the antirust oil is suitable for electrostatic atomization spraying of metal, can form an even oil film on the plate surface, which cannot be broken down to generate electric spark to be combusted, and has high use safety; furthermore, the antirust performance is excellent, lowtemperature resistance of the product is good, and good fluidity can be achieved under the -20 DEG C environment.

Owner:SHANGHAI PARKER CHEM IND

Method for improving fruit tree cultivating soil

InactiveCN111955089AImprove qualityIncrease productionCalcareous fertilisersSoil-working methodsFruit treeDitch

The invention discloses a method for improving fruit tree cultivating soil. The method comprises the following steps: step I, performing integral ploughing on to-be-improved soil with the ploughing depth of 100-120cm, and breaking soil blocks, and maintaining sizes uniform; step II, adding improving fertilizer to the ploughed soil, and performing ploughing again to mix the improving fertilizer evenly, wherein the adding amount is 2000kg / mu, and standing is performed for 15 days; step III, ploughing the soil after standing in step II again, and opening furrows, wherein the furrowing depth is 15-25cm, and the line spacing is kept at 1.5-2m; and step IV, conducting a water test on the furrows, checking the drainage fluency of a water ditch of the furrow and the firmness of planting ridges, and performing natural air drying on the planting soil after checking. The fruit tree cultivating soil improved by the method of the invention adapts to planting of multiple types of fruit trees, and isgreatly helpful for improving the quality of fruits and the yield of the fruits.

Owner:郭树河

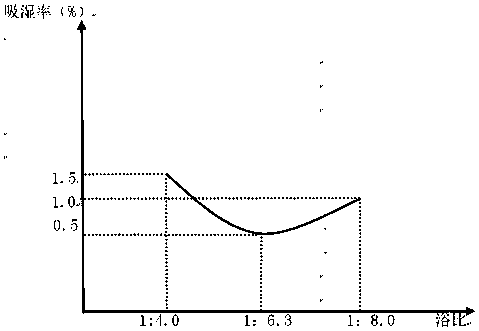

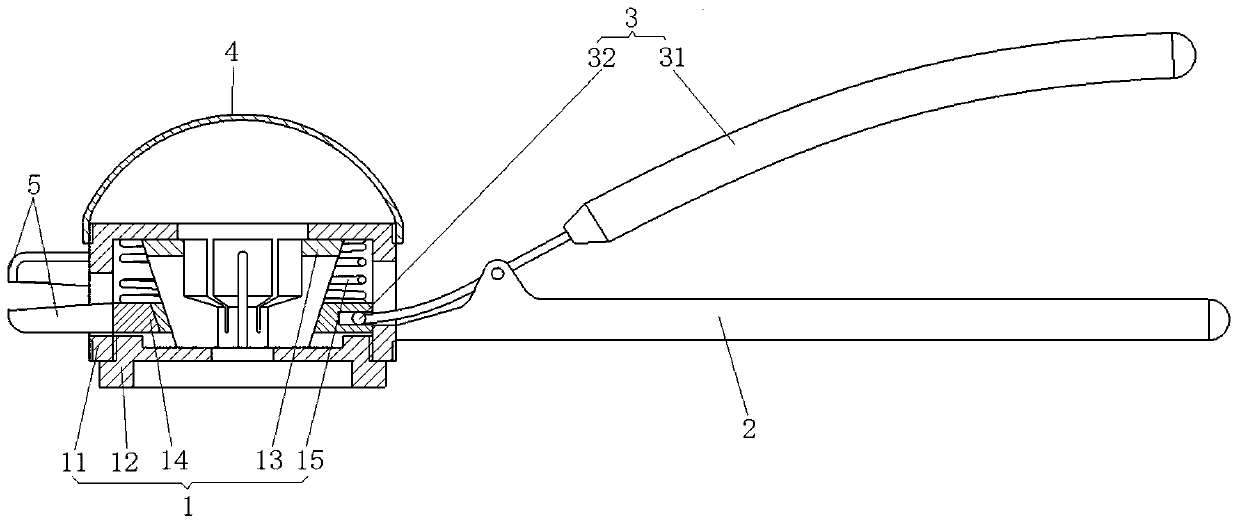

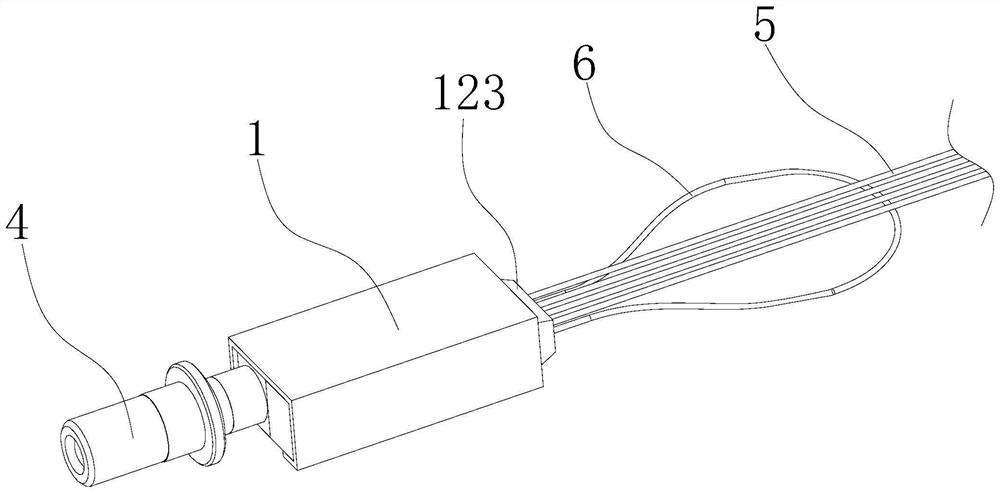

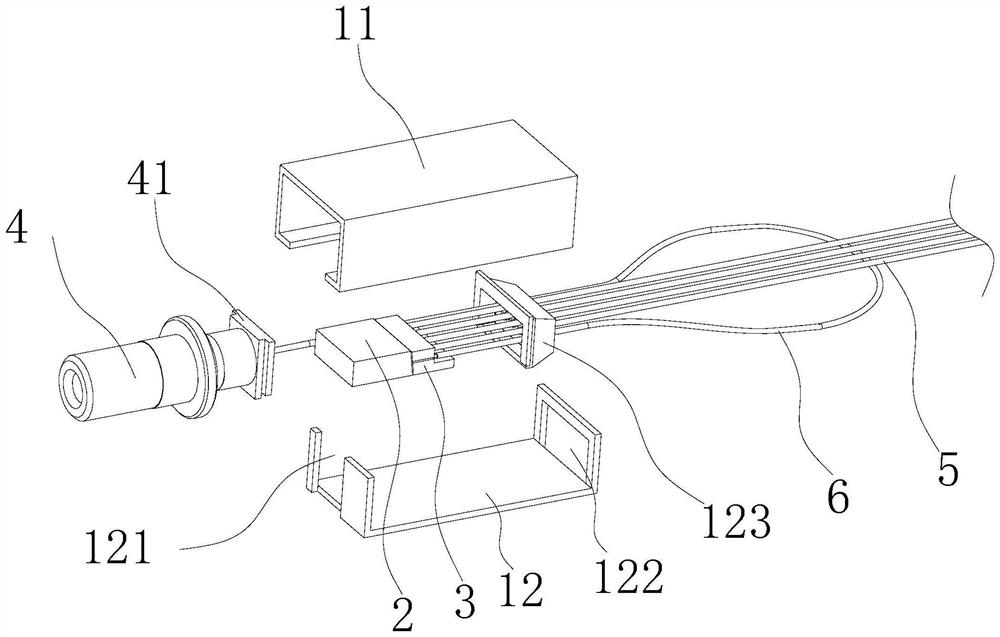

Syringe needle dismounting device

The invention discloses a syringe needle dismounting device, relates to the field of clamping and shearing tools, and provides a syringe needle dismounting device suitable for dismounting various syringe needles. The syringe needle dismounting device comprises a handle, an operating rod, a clamping head and a shearing structure; the clamping head comprises an outer sleeve, an end cover, a telescopic sleeve, a movable sleeve and a spring; a guide hole is formed in the outer sleeve, a large syringe needle hole is formed in one end of the outer sleeve, the other end of the outer sleeve is connected with the end cover through threads, and the end cover is provided with a small syringe needle hole; the telescopic sleeve, the movable sleeve and the spring are all located in the outer sleeve; thetelescopic sleeve is in a cone frustum shape, a large clamping hole is formed in the large end of the telescopic sleeve, and a small clamping hole is formed in the small end of the telescopic sleeve;the movable sleeve sleeves the telescopic sleeve and is matched with the guide hole; the spring supports the movable sleeve; the shearing structure comprises a fixed shearing structure connected withthe outer sleeve and a movable shearing structure connected with the movable sleeve; and the operating rod comprises an operating rod body and a cylindrical driving head, the driving head is matchedwith a driving head hole, and the operating rod body is hinged to the handle and connected with the driving head.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

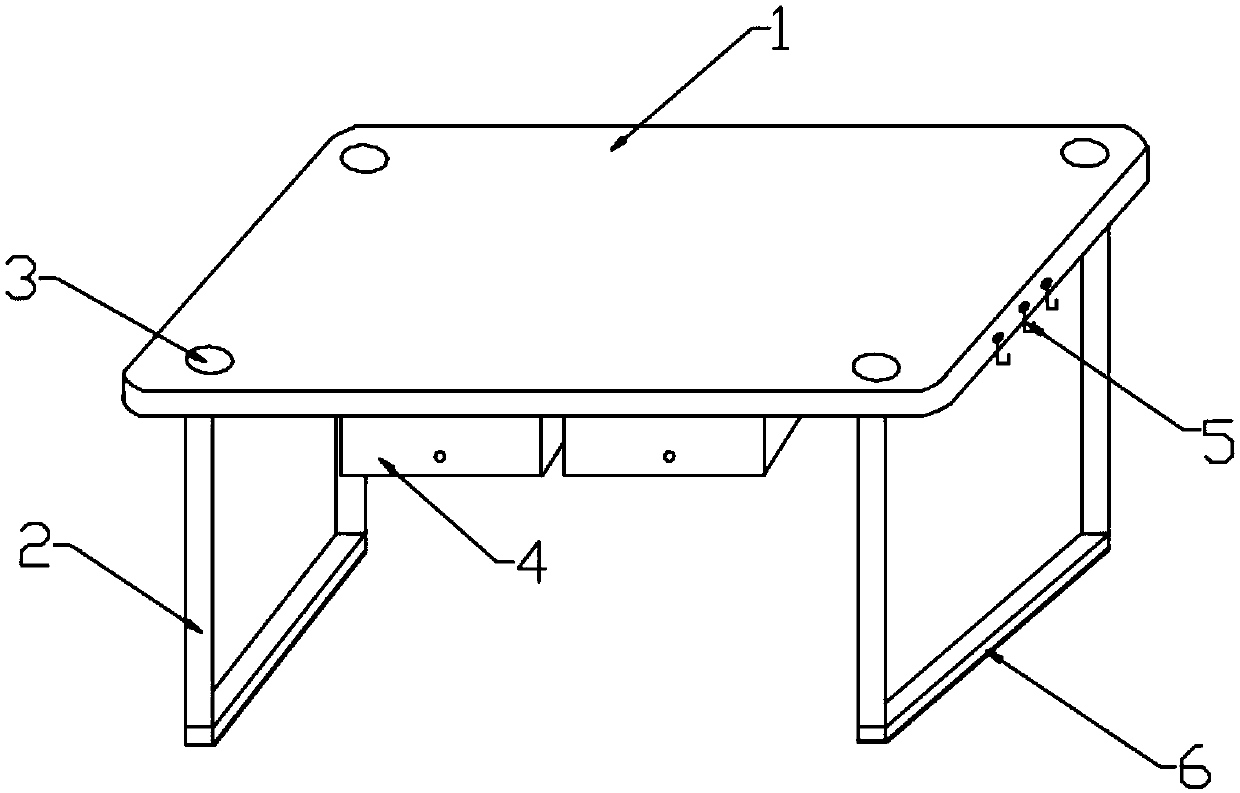

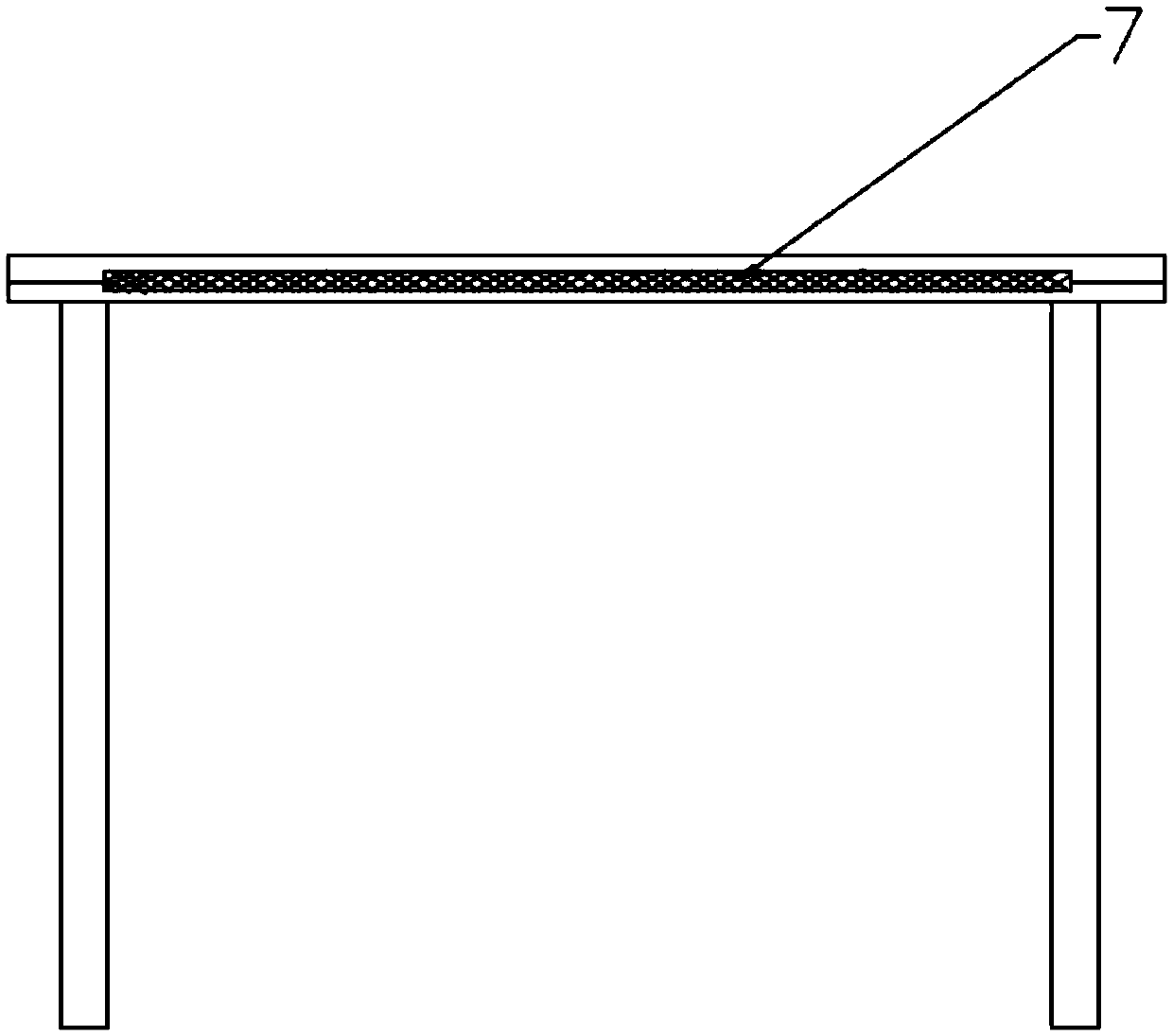

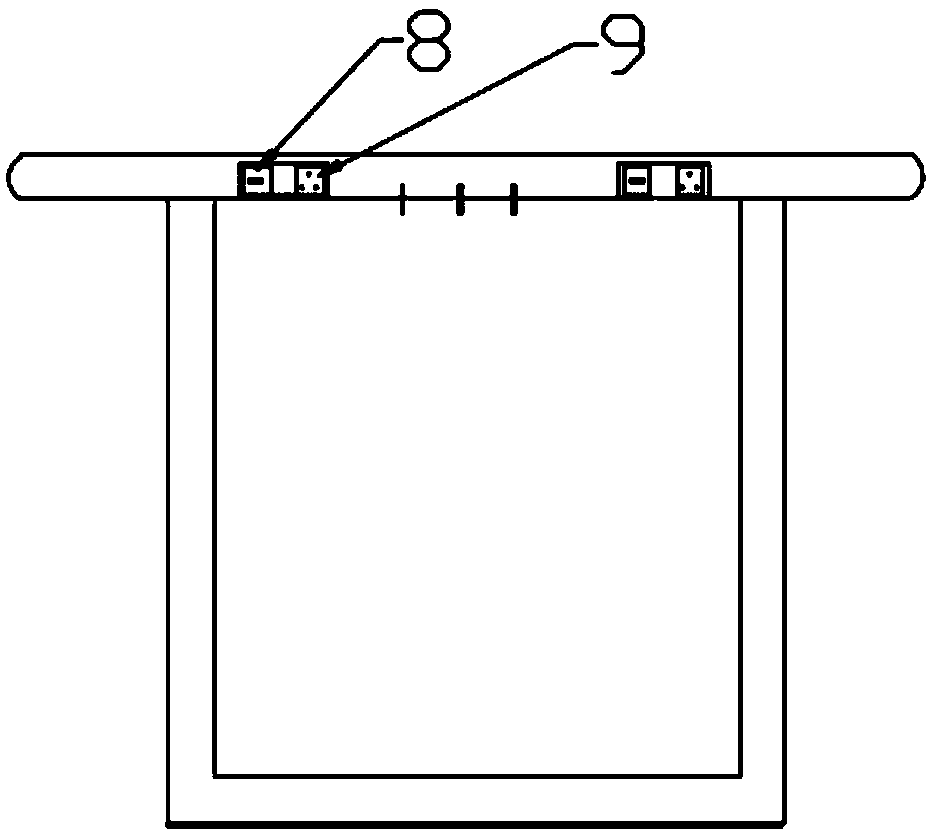

Library multifunctional desk

The invention discloses a library multifunctional desk which comprises a desk board and desk legs, and further comprises water cup placement grooves, a drawer, antiskid cushions, an inner groove, a network cable socket and a power socket. The desk legs are arranged on the lower side of the two ends of the desk board. The desk legs are each of a U-shaped structure. The water cup placement grooves are formed in the four corners of the upper surface of the desk board and are each of a circular structure. The power socket and the network cable socket are formed in the groove in the side wall of the desk board without occupying the area of the desk board, the use area is further increased for people, the power socket and the network cable socket are placed in the groove, the situation that people passing by touch the power socket and the network cable socket is reduced as much as possible, and practicability and safety are enhanced; by means of the antiskid cushions arranged on the lower sides of the desk legs, the antiskid effect is further enhanced; by means of hooks on the side wall of the desk board, clothes, school bags and the like can be hung, and use is simple and convenient.

Owner:XUZHOU COLLEGE OF INDAL TECH

Quick-frozen dumpling fat antioxidant composition and preparation process thereof

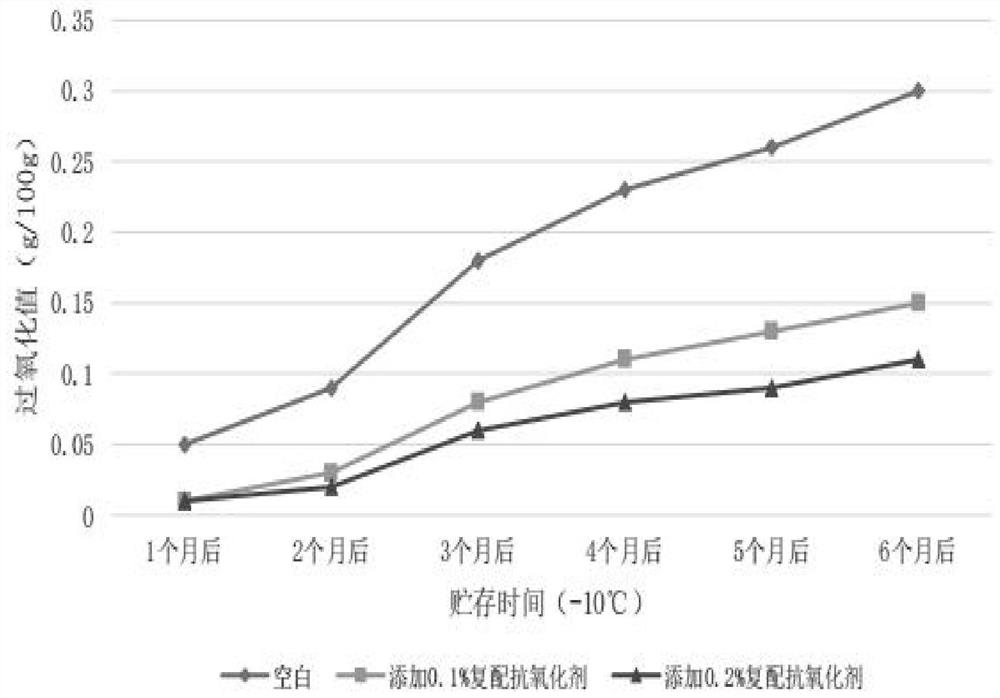

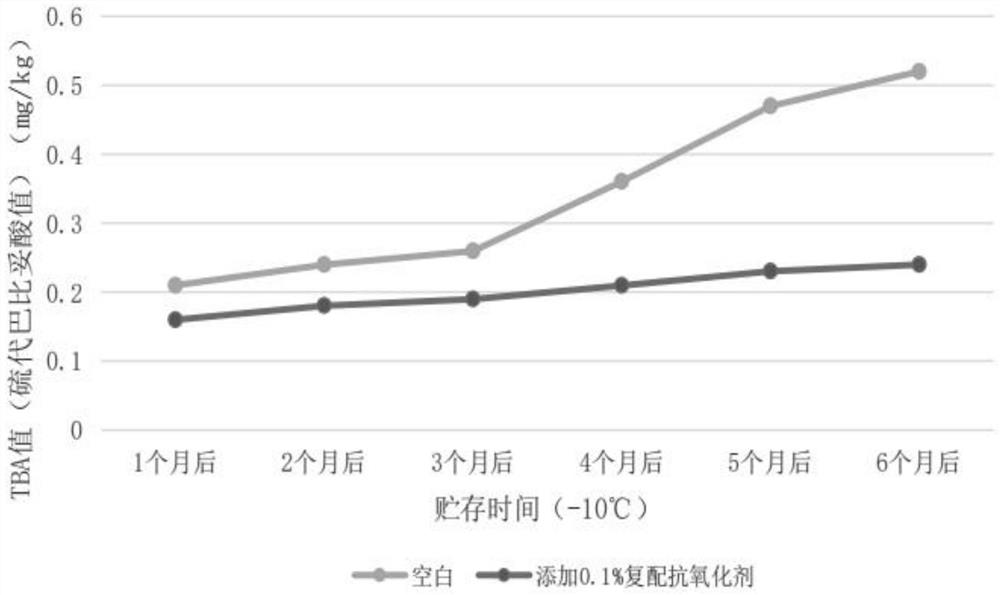

PendingCN111758876AEffective complexationReduce catalysisFood ingredient as antioxidantFatty substance preservation using additivesPhospholipinPhenolic content in tea

The invention relates to a quick-frozen dumpling fat antioxidant composition. The composition comprises the following components in percentages by weight: 55% of phospholipid, 20% of beta sitosterol ferulate, 15% of tea polyphenol and 10% of an olive extract. The addition amount of the fat antioxidant composition is 0.02%-0.2% of the total amount of dumpling stuffing. The composition is scientificand reasonable in design and unique in process, and can effectively permeate and migrate antioxidant components to a water-oil interface formed by ice crystals and various materials, the interface inthe system is a hot spot area where oxidation occurs, and the traditional monomer antioxidant is either water-soluble or oil-soluble and cannot migrate to the oil-water interface. According to the composition, immobilized lipase is added through compounding and innovation of a water-soluble antioxidant monomer and an oil-soluble antioxidant monomer, a unique processing technology is adopted, thus, the technical breakthrough that the water-soluble antioxidant migrates to the direction of oil and the oil-soluble antioxidant migrates to the direction of water is realized, and the effective components of the antioxidant play an antioxidant role on the interface to the maximum extent. The composition is not only suitable for quick-frozen dumpling products, but also suitable for being widely popularized and applied in quick-frozen foods.

Owner:天津融信蓝海生物科技有限公司

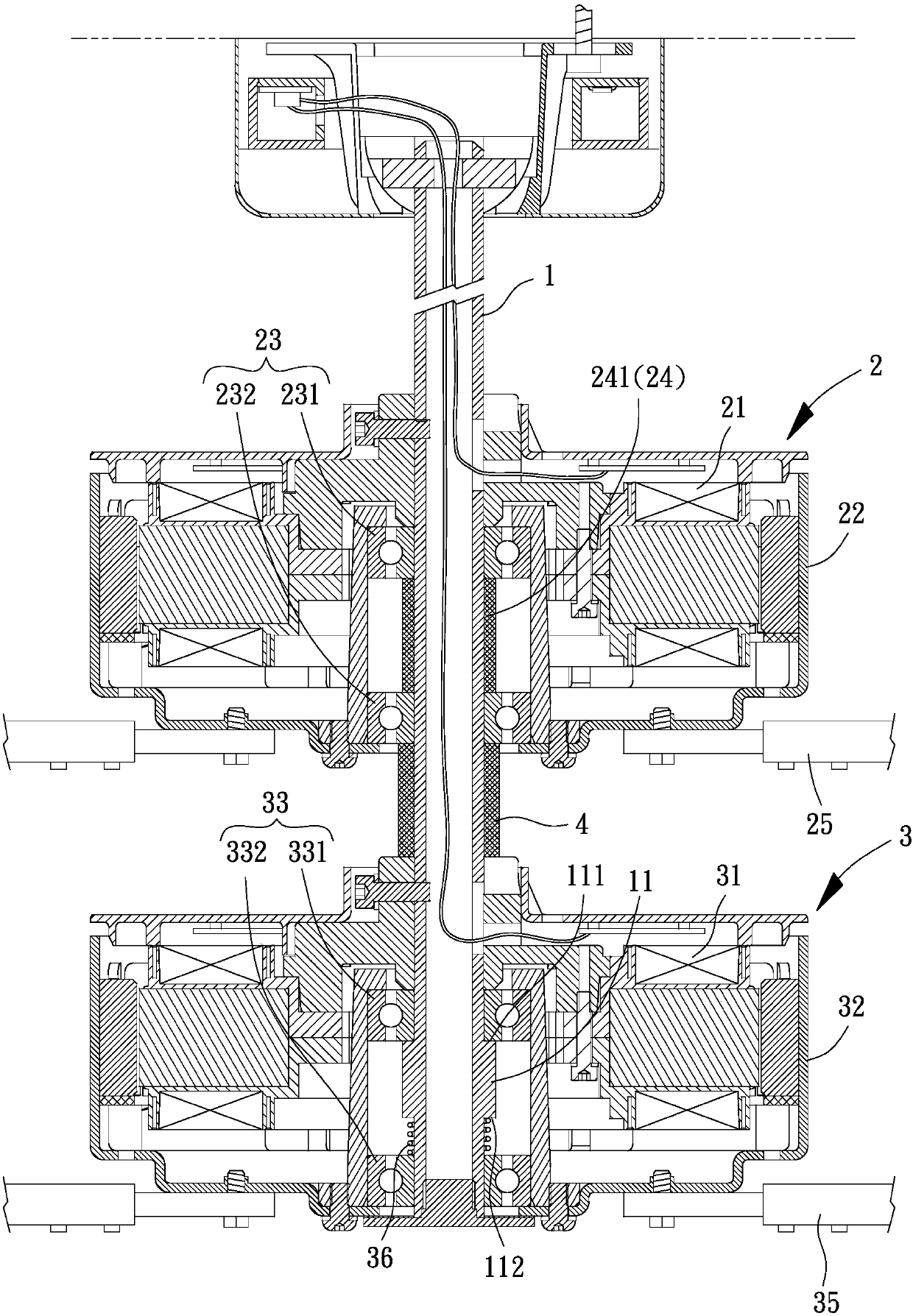

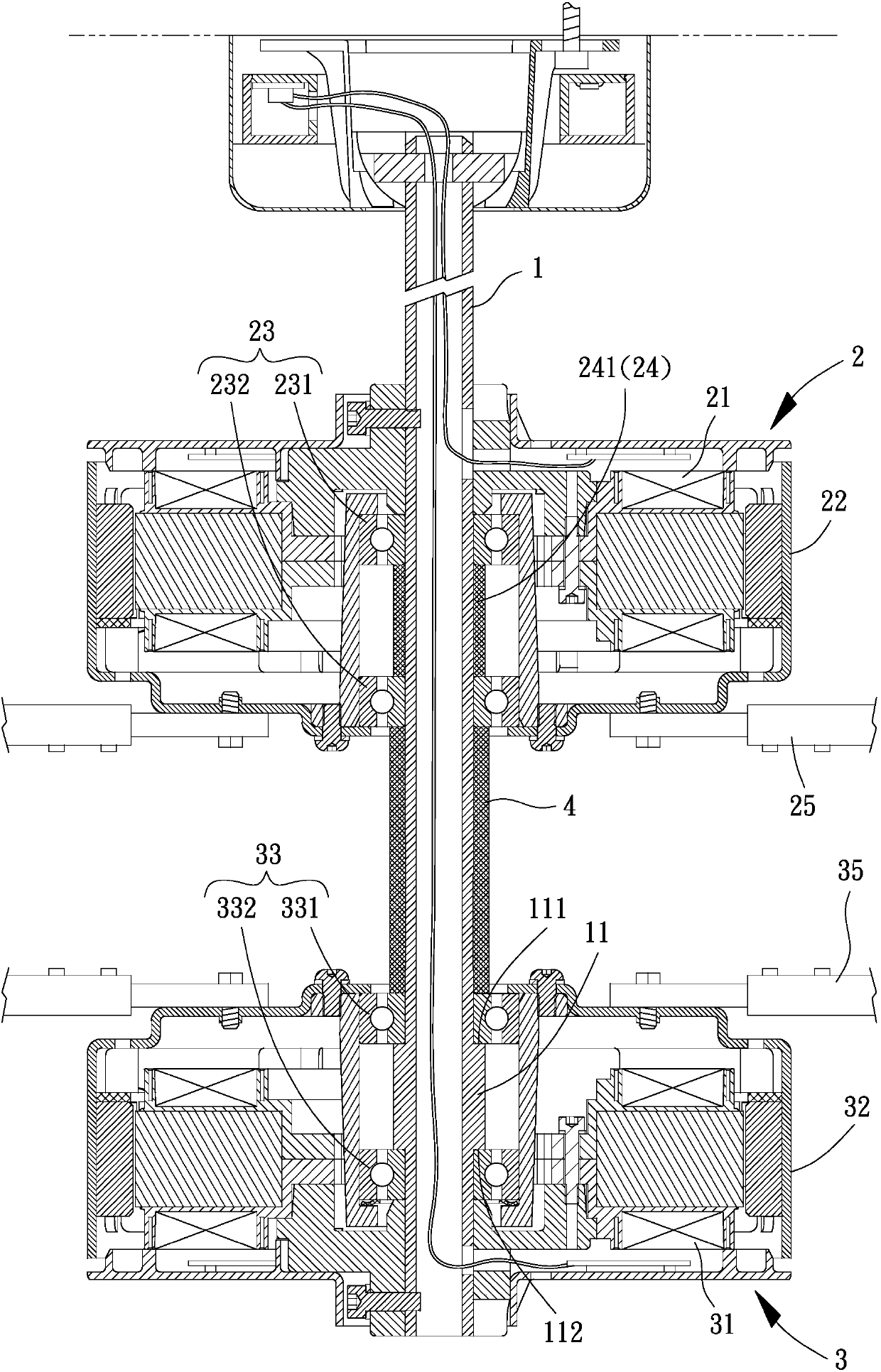

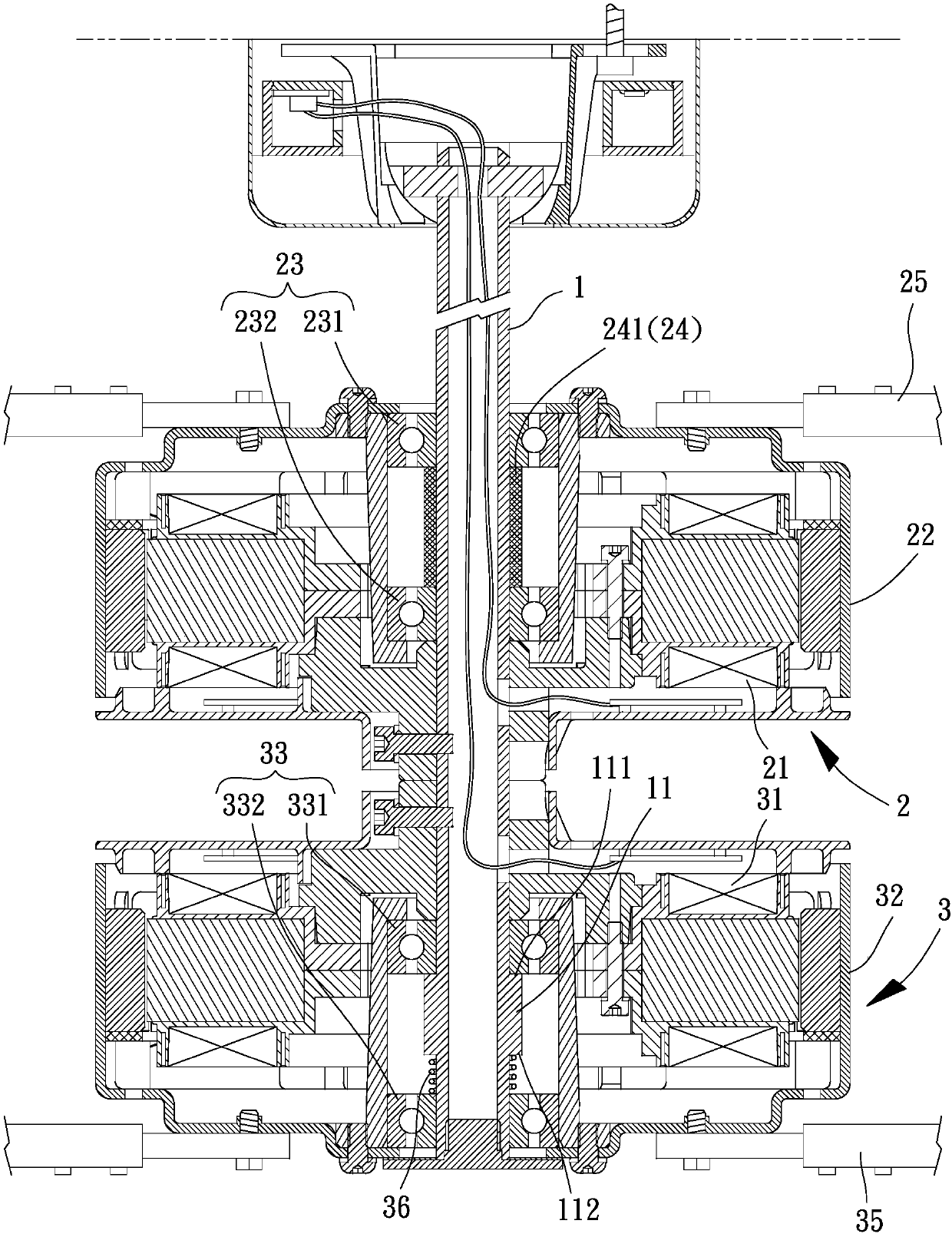

Coaxial dual ceiling fan device

InactiveCN109751262ASave assembly timeSave assembly costPump installationsAxial flow pumpsCeiling fanEngineering

The invention discloses a coaxial dual ceiling fan device, and aims to solve the problem that the assembly is complicated and time-consuming in the prior art. The coaxial dual ceiling fan device comprises a central shaft provided with an expanded section; a first ceiling fan set provided with a first stator and a first rotor, wherein the first rotor is rotatingly combined with the central shaft, and when the first ceiling fan set is provided with a first bearing set and a first blade, the first blade is combined with the first rotor; and a second ceiling fan set, which comprises a second stator and a second rotor, wherein the second stator is fixedly combined with the central shaft, the second rotor is rotatingly combined with the central shaft, the second ceiling fan set comprises a second bearing set and a second blade, the second blade is combined with the second rotor, and the first bearing set or the second bearing set is positioned in the expanded section.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

A sputum collection method for the detection of respiratory bacteria 16s rRNA gene sequence

InactiveCN104306028BReduce pollutionImprove practical safetySurgeryVaccination/ovulation diagnosticsSaline waterSalbutamol

Owner:张清玲 +5

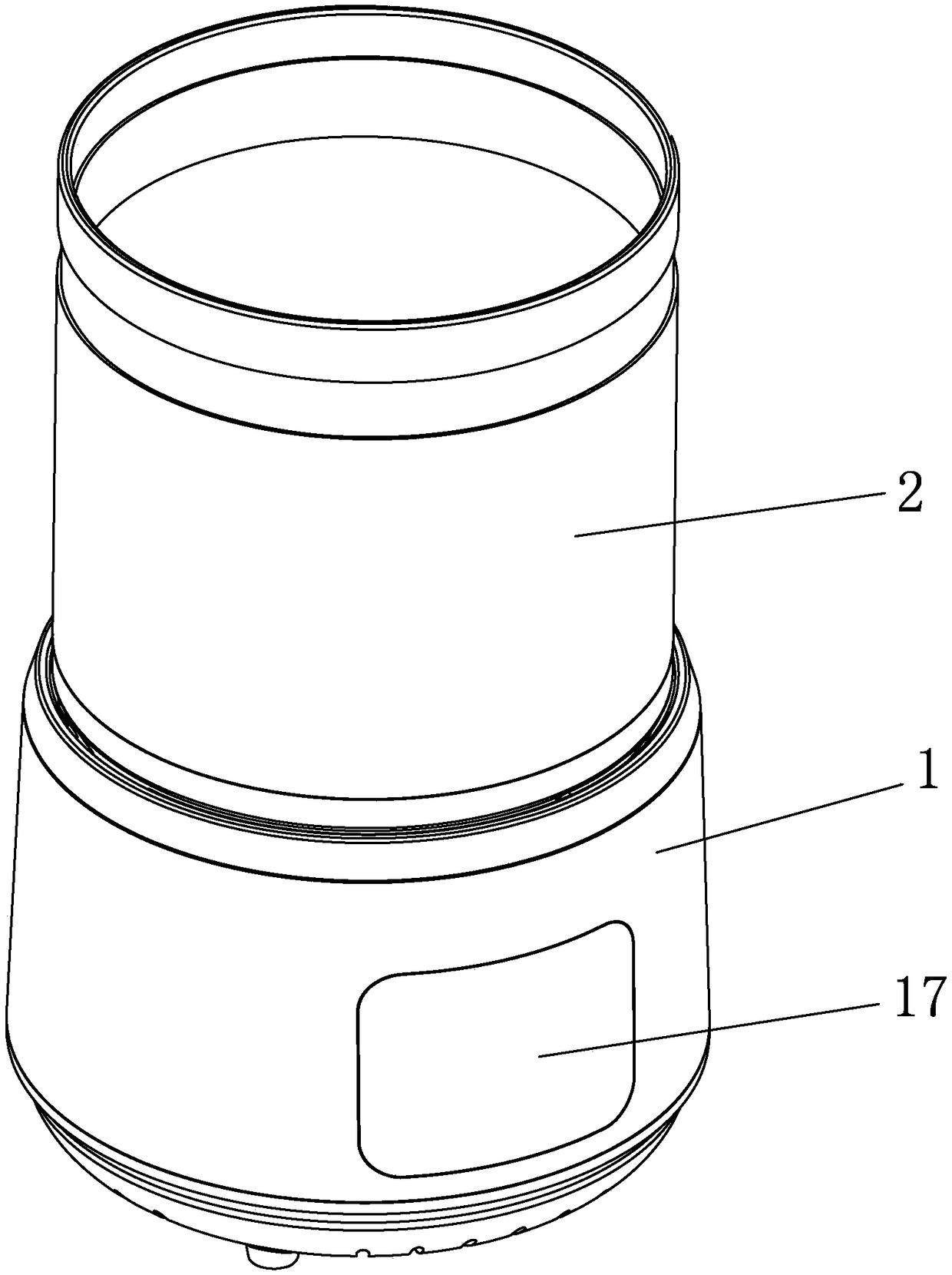

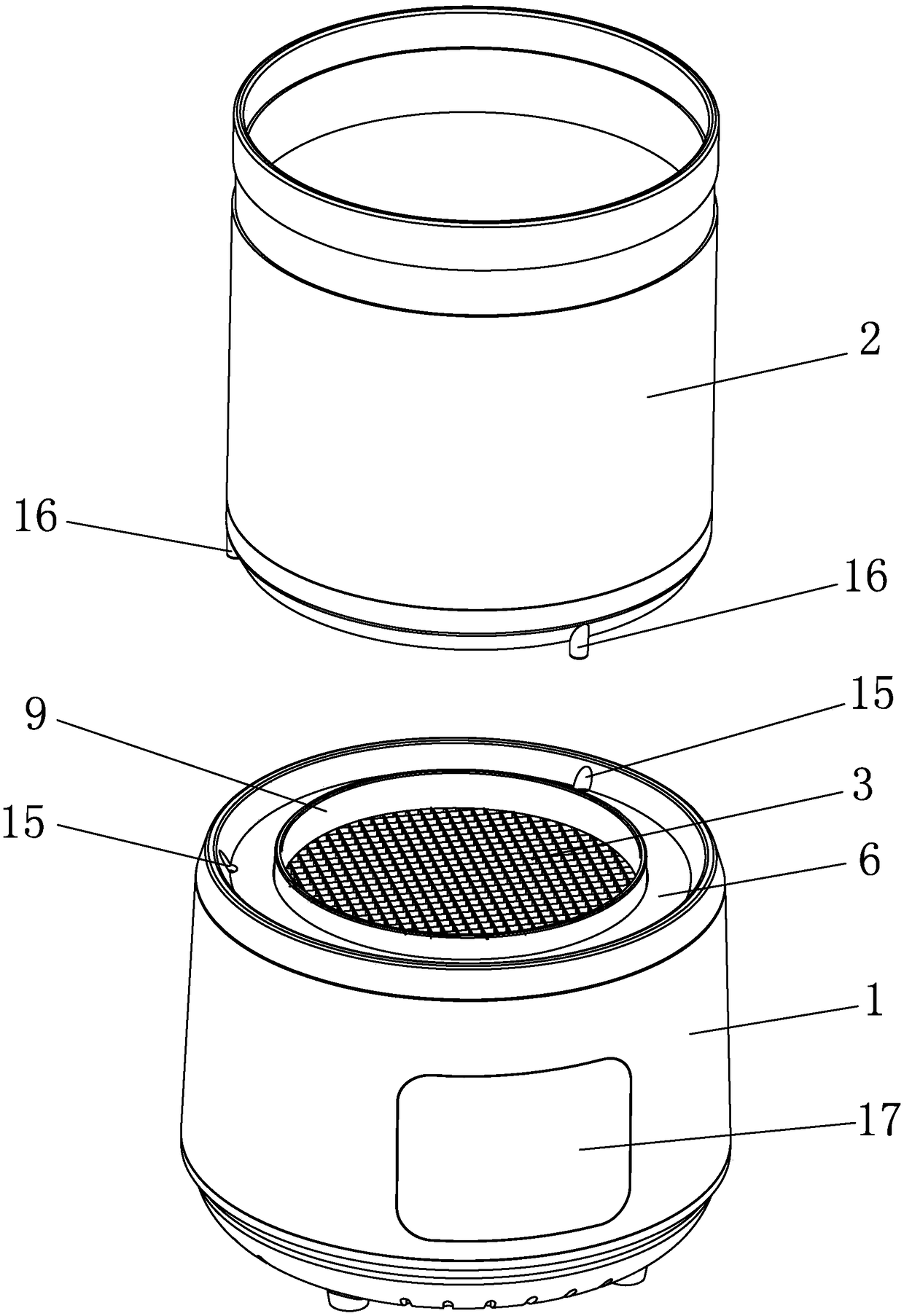

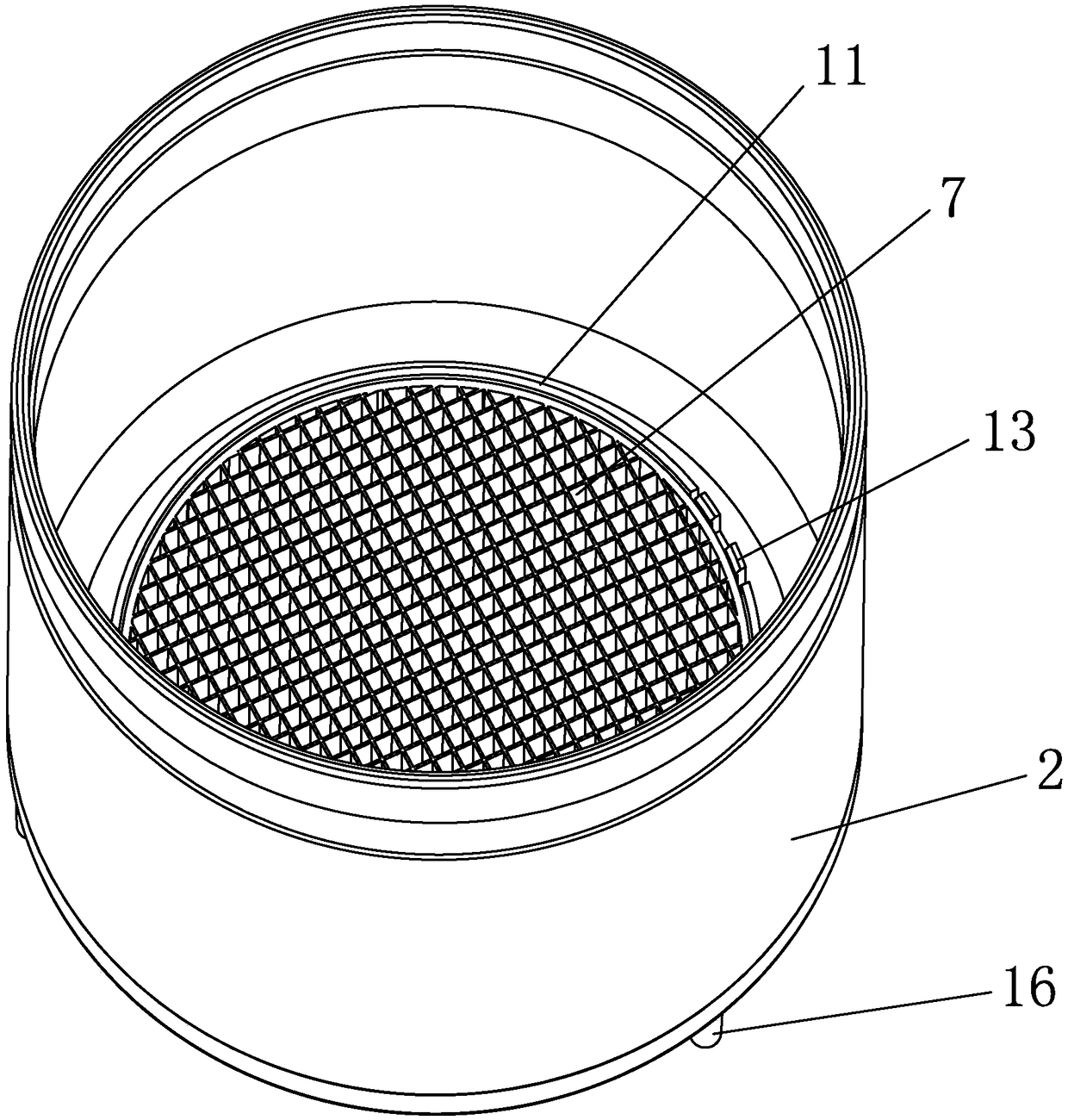

Air fryer

PendingCN109431306ASimple structureImprove practical safetyRoasters/grillsCeramicPulp and paper industry

The invention discloses an air fryer. The air fryer comprises a base and a fryer body connected with the base. A base ceramic net penetrating through the top face is arranged on the top face of the base, a heating device and a fan are sequentially arranged at the portion, below the base ceramic net, in the base, a connecting groove is formed in the top face of the base, a fryer body ceramic net penetrating through the bottom face is arranged on the bottom face of the fryer body, a connecting protruding block clamped into the connecting groove is arranged on the bottom face of the fryer body, when the fryer body and the base are clamped, the fryer body ceramic net is arranged above the base ceramic net, the heating device and the fan are arranged in the base, the fryer body is arranged on the upper portion of the base to fry foods from bottom to top, and the structure of the fryer body is simplified.

Owner:中山市鑫能电器制造有限公司

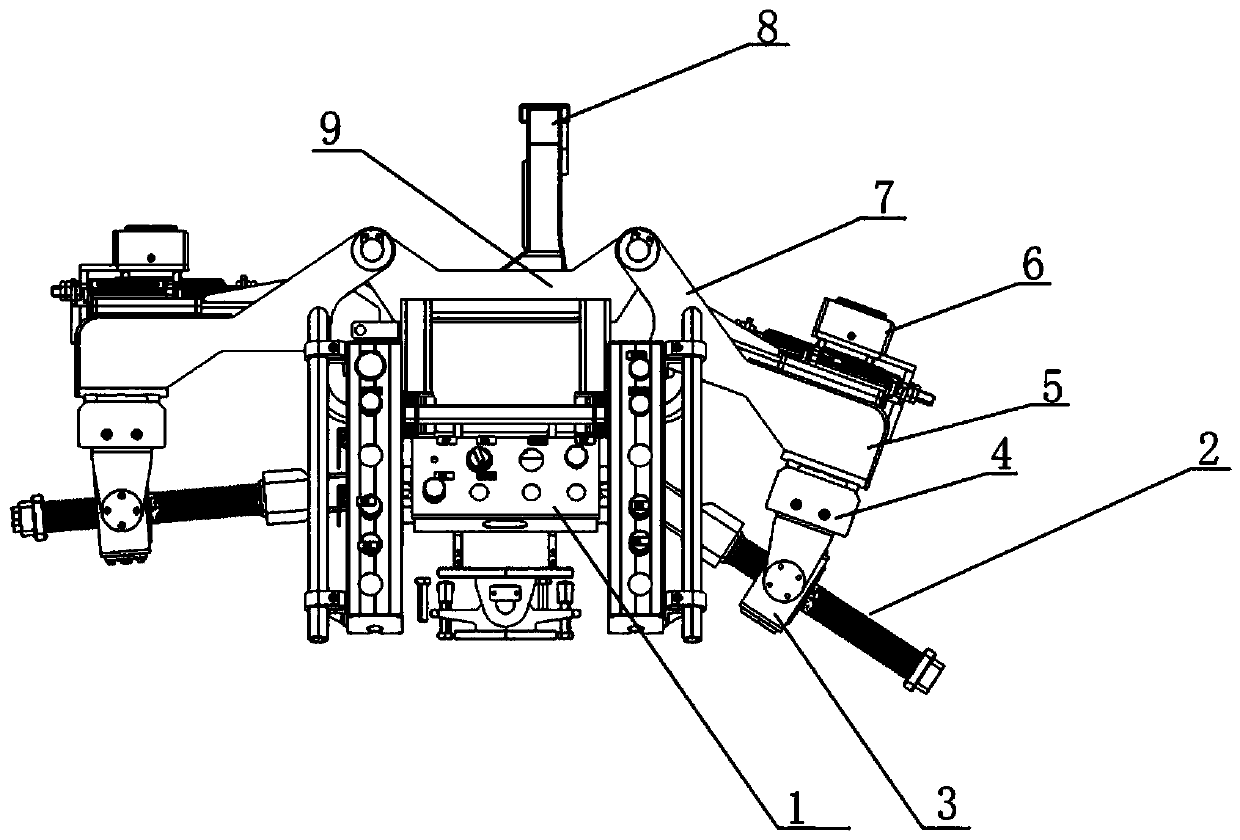

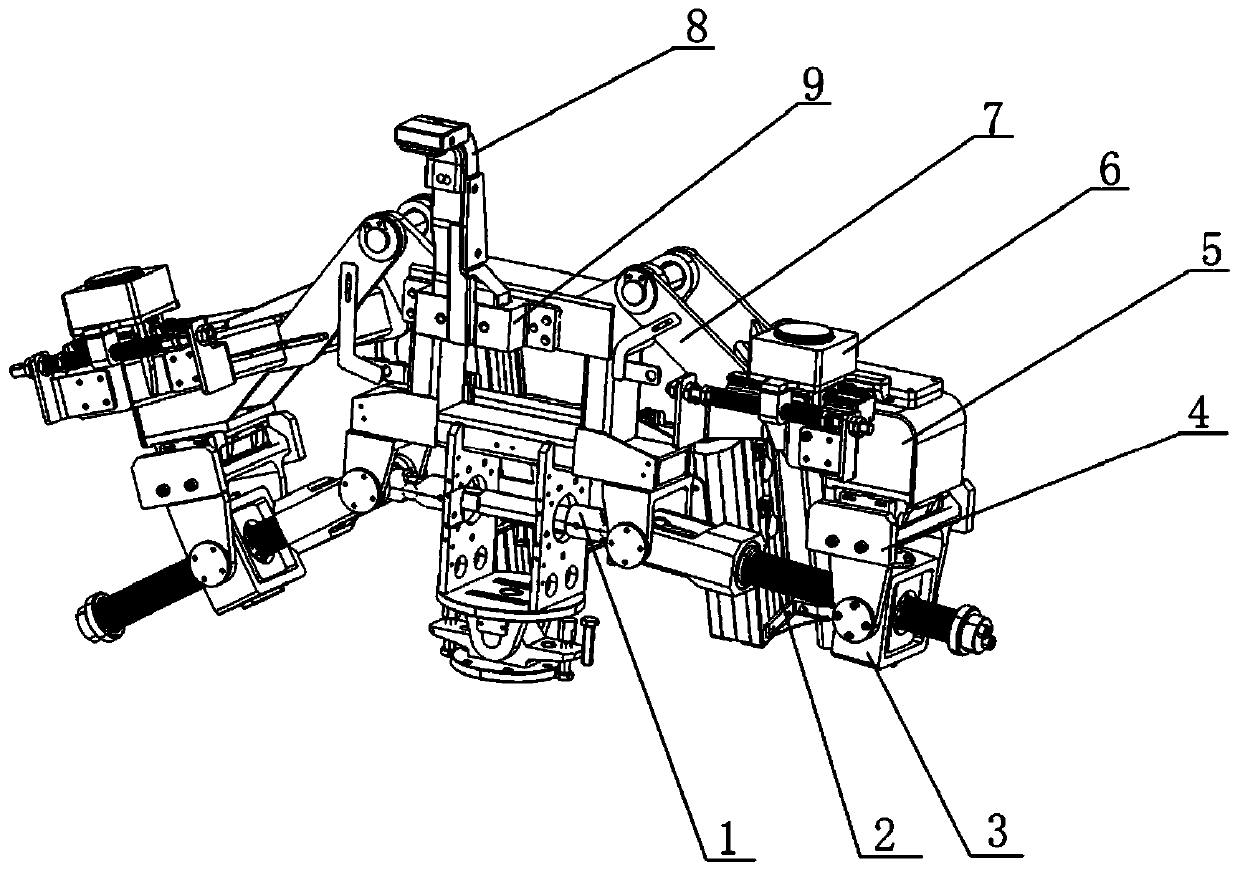

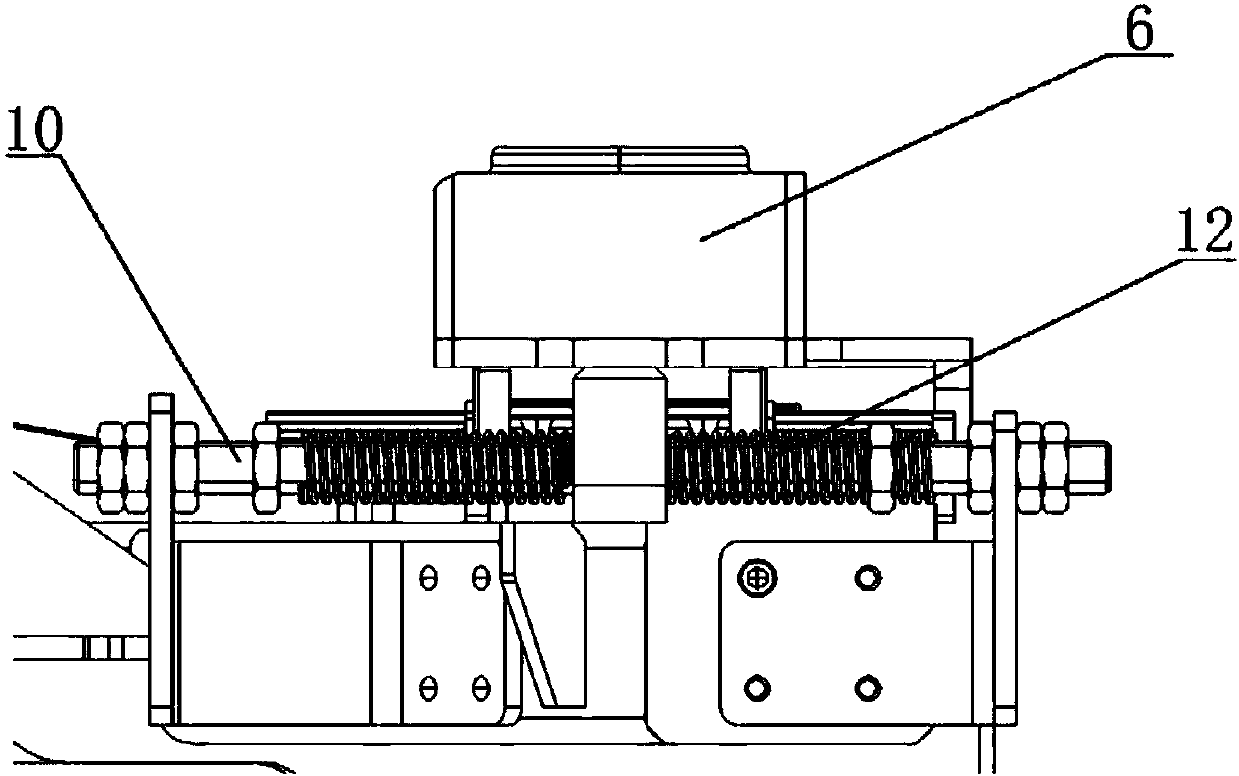

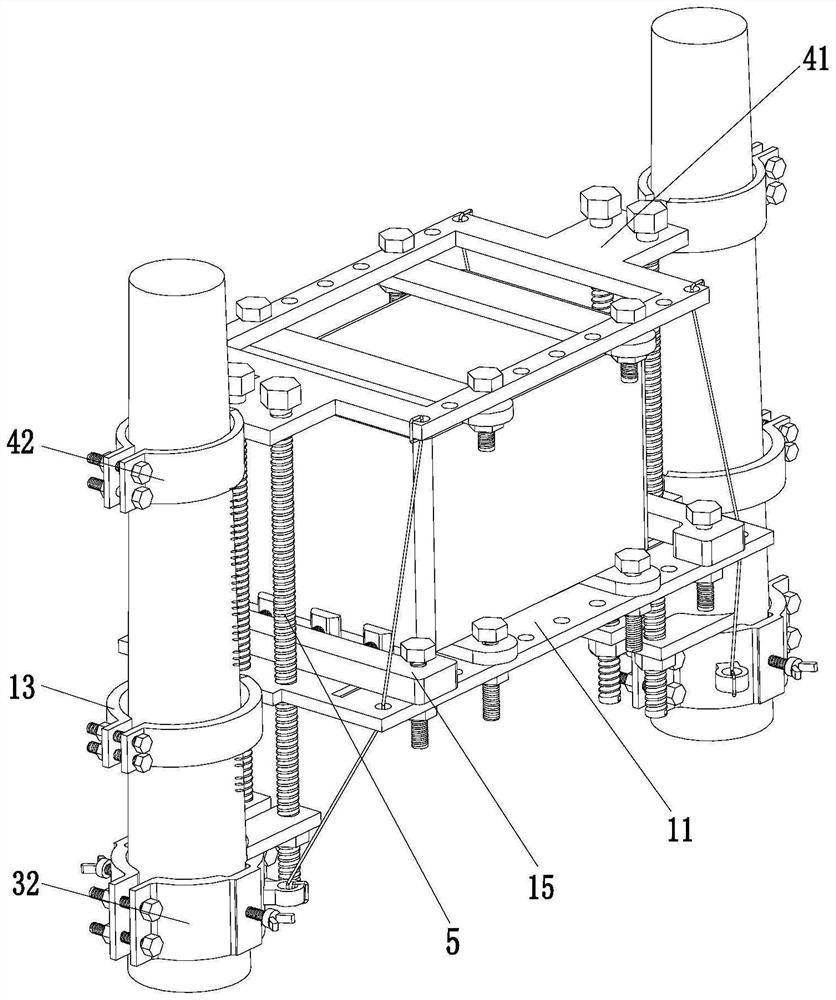

Jacking equipment for rear suspension assembly

PendingCN110640427AFlexible operationBig spaceAssembly machinesMetal working apparatusUniversal jointMan machine

The invention provides jacking equipment for a rear suspension assembly. The jacking equipment for the rear suspension assembly comprises a suspended balance power-assisting mechanism and an operatingmechanism. The operating mechanism comprises a rack, a hook, a power mechanism, a screw rod, a sliding block and a jacking structure. The hook is located at the top of the rack, the bottom of the rack is connected to the balance power-assisting mechanism, the screw rod is in transmission connection with the power mechanism through a universal joint, the sliding block is connected to the screw rodthrough internal threads, the sliding block is hinged to the jacking structure, the jacking structure is hinged to the rack, and the sliding block moves on the screw rod to drive the jacking structure to ascend and descend. According to the jacking equipment, the operation mechanism is ingenious in structure, the operator can operate the equipment more flexibly, the operation man-machine performance is high, and the fatigue strength of the operating personnel can be lowered.

Owner:GUANGZHOU AUTOMIBILE GRP MOTOR

A long-term flame-retardant treatment method suitable for wicker crafts

ActiveCN111113605BDimensional Stability EffectStrong loss resistanceWood treatment detailsReed/straw treatmentHigh humidityLight irradiation

Owner:阜南佳利工艺品股份有限公司

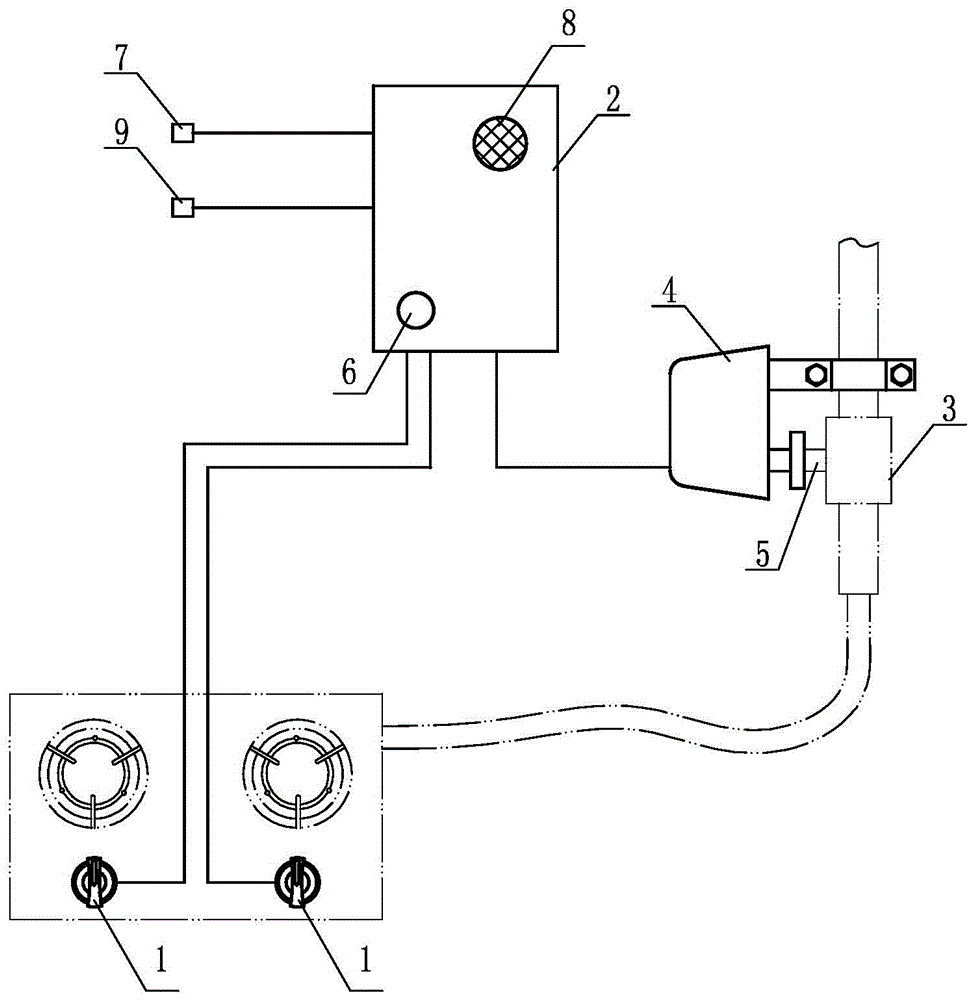

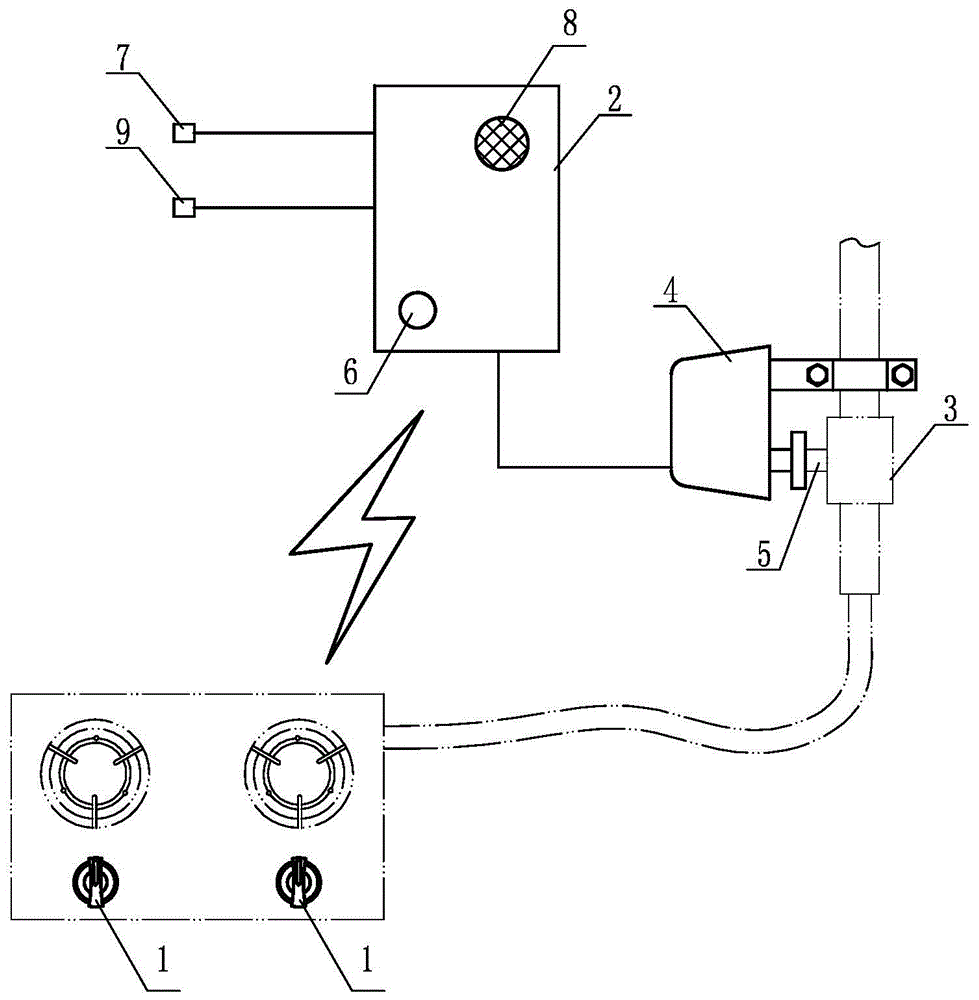

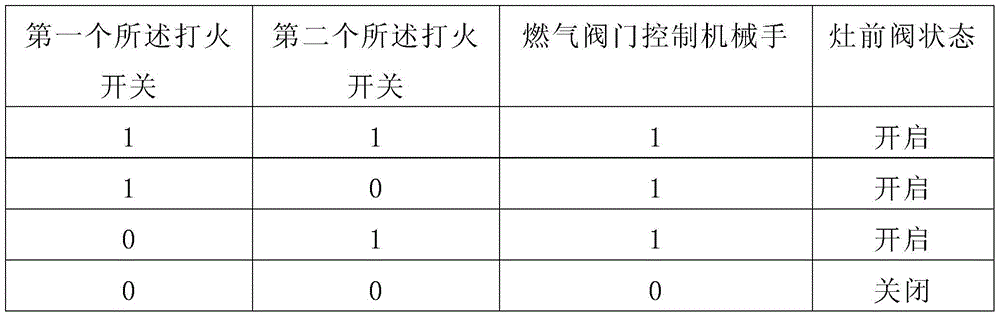

Gas stove front valve automatic control device

InactiveCN104197381BReduce the possibility of electrificationEasy to installDomestic stoves or rangesLighting and heating apparatusAutomatic controlControl signal

The invention discloses an automatic control device for a front valve of a gas stove, which is arranged between each ignition switch of the gas stove and the front valve of the stove, and includes a controller, and each ignition switch is respectively connected to the signal input of the controller end, the output end of the controller is connected with a gas valve control manipulator, and the gas valve control manipulator is fixedly installed on the gas pipeline and connected to the control handle of the front-of-stove valve; Next, this device is directly installed between the front valve of the stove and the ignition switch, and the installation process is very simple, and this device uses the gas valve control manipulator to connect with the control handle of the front valve of the stove, so as to separate the electrical components from the gas pipeline. It eliminates the hidden danger of gas explosion and reduces the possibility of metal pipes being electrified, which greatly improves the practical safety of the whole device. It has reliable operation, less faults, high safety and long service life.

Owner:王新民

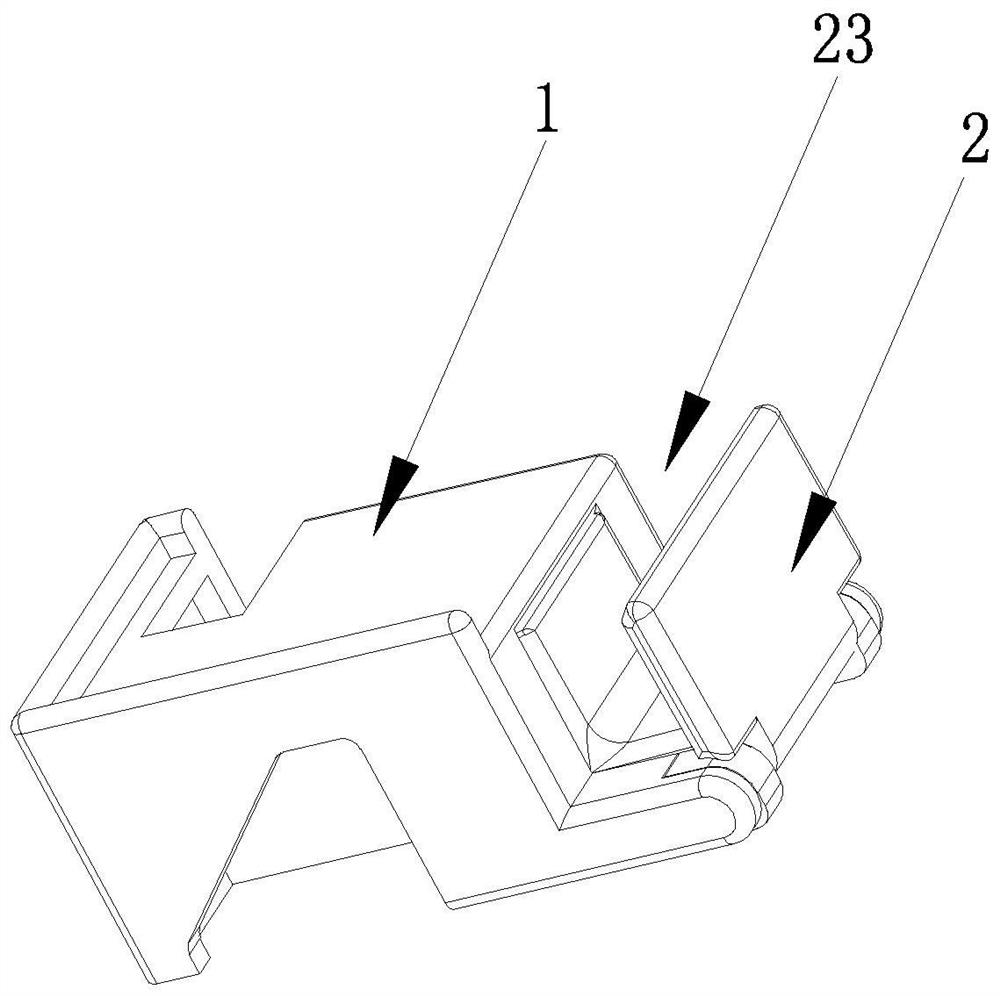

A push-pull connector

ActiveCN110805373BAchieve separationSimple structureWing fastenersWing suspension devicesEngineeringMechanical engineering

Owner:PINGHU BELLAVIA SANITARY TECH CO LTD

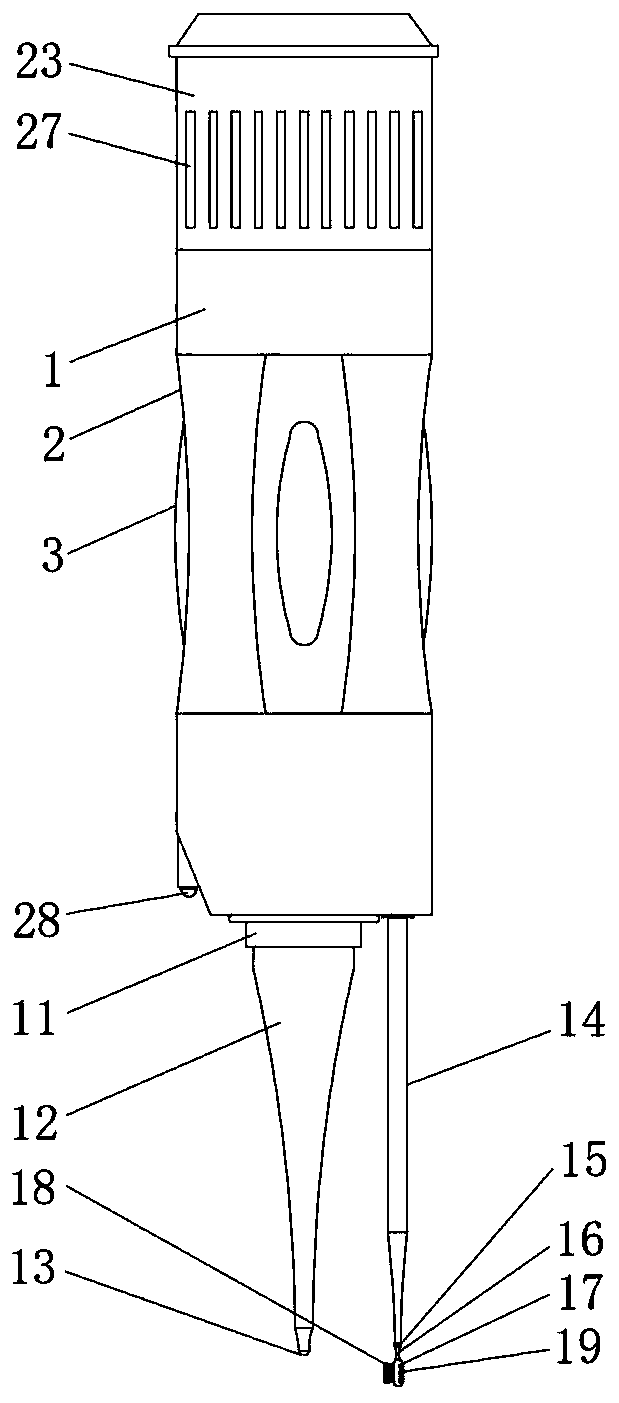

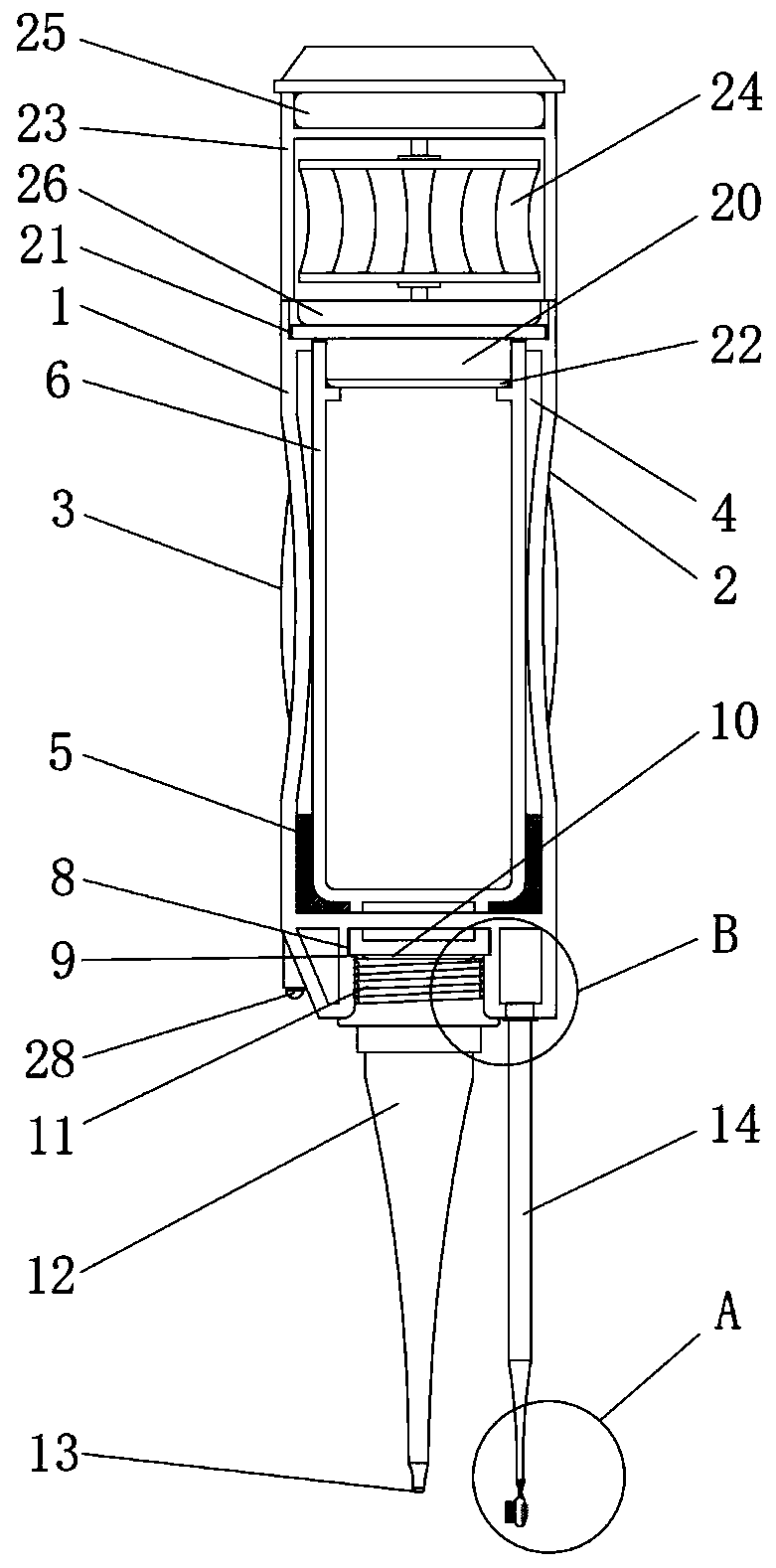

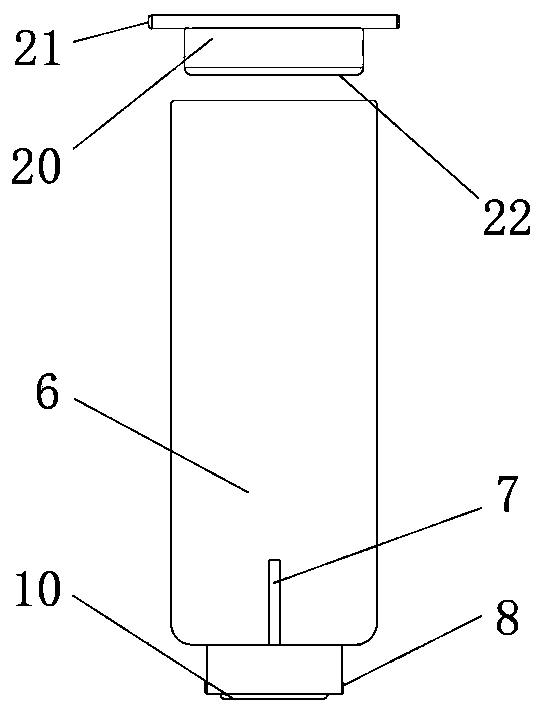

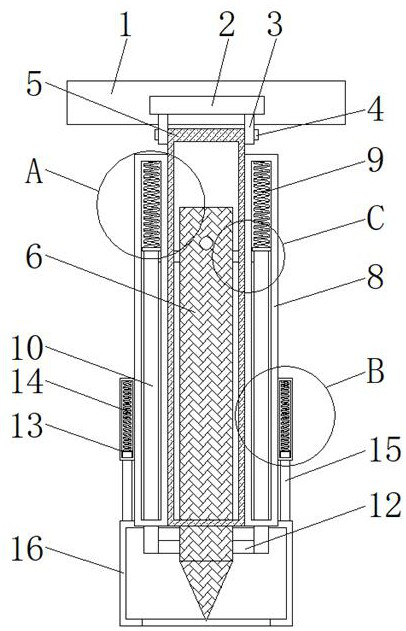

Building construction orientation fixed point auxiliary measuring equipment

InactiveCN113048963AGuarantee the safety of useImprove practical safetySurveying instrumentsArchitectural engineeringMeasuring equipment

Owner:李达

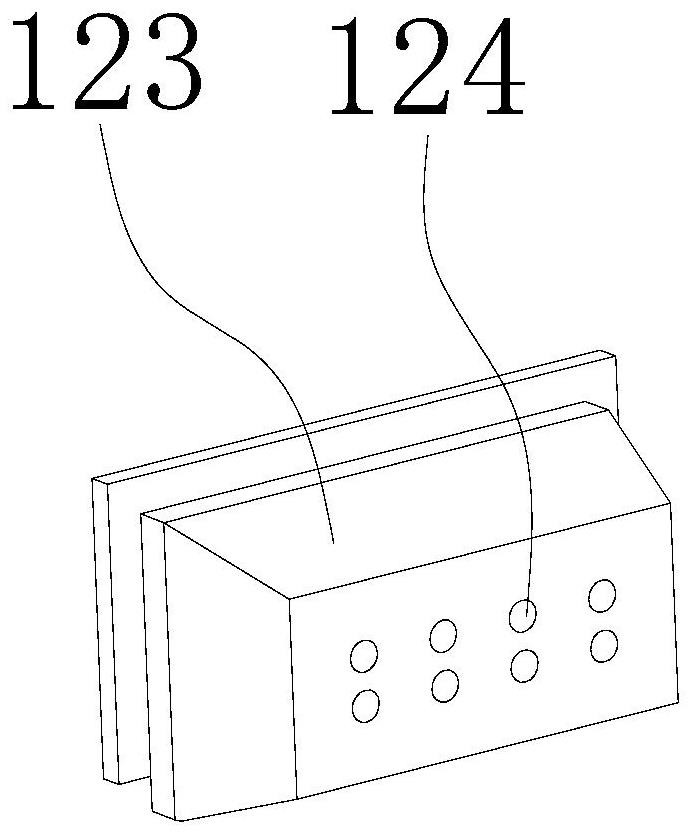

Miniaturized CWDM passive optical module

PendingCN114019627APlay a protective effectImprove practical safetyCoupling light guidesOptical ModuleFiber array

The invention is suitable for the field of optical devices, and provides a miniaturized CWDM passive optical module which comprises a module box, wherein an AWG chip and an FA optical fiber array assembly connected with the AWG chip are arranged in the module box, an optical fiber adapter is arranged at one end of the module box, the input end of the optical fiber adapter extends into the module box and is connected with the output end of the FA optical fiber array assembly through a 180-degree bypassing optical fiber, the other end of the module box is connected with a plurality of output optical fibers, and the output ends of the plurality of output optical fibers extend into the module box and are connected with the output end of the FA optical fiber array assembly. The AWG chip and the FA optical fiber array assembly are arranged in the module box, MUX wave combining and DEMUX wave dividing functions can be achieved in a compatible mode, the optical fiber adapter is adopted for outputting optical signals, meanwhile, the small-size module box is adopted for packaging, the whole CWDM assembly is effectively protected, and the practical safety is improved.

Owner:SHENZHEN ADTEK TECH CO LTD

A kind of gout crystal clearing device

ActiveCN110141302BIncrease frictionImprove comfortDiagnosticsAbrasive surgical cuttersRubber ringLight head

The invention discloses a gout crystal removal device. The device comprises a first housing and an LED lamp head, the upper end of the surface of the first housing is provided with a groove, the bottom of a support rod is connected to a fixing member, the top of an impurity storage tank is connected to the bottom of a sealing plug, the top of the sealing plug is connected to the top of the first housing, the top side of the sealing plug is provided with a second sealing rubber ring, the inner side of the bottom of the sealing plug is provided with a filter element, the top of the first housingis connected to a second housing, a storage battery is fixedly in the inner part of the second housing, the bottom of the second housing is provided with a filter screen, the surface of the second housing is provided with air outlets, the LED lamp head is arranged at the left side of a sucking tube, and the LED lamp head is fixed at the left side of the bottom of the first housing. The gout crystal removal device can guarantee that it is not prone to damaging the cartilages of the joint parts when removing the gout crystals by scraping through a damping shaft convenient for adjusting the angle of the fixing member, a soft brush and friction balls made from silica gel materials, thus improving the practical safety.

Owner:阳信华胜清真肉类有限公司 +1

Building construction orientation fixed point auxiliary measuring equipment

InactiveCN113048962AGuarantee the safety of useImprove practical safetySurveying instrumentsArchitectural engineeringMeasuring equipment

The invention relates to the technical field of buildings, and discloses building construction orientation fixed point auxiliary measuring equipment, which comprises an instrument mounting top plate, support fixing blocks are uniformly and fixedly mounted on the outer surface of the instrument mounting top plate in the circumferential direction, support connecting rods are fixedly mounted at the left and right ends of the bottom surface of each support fixing block, and the bottom ends of the two supporting connecting rods are fixedly sleeved with supporting driving shafts. According to the building construction orientation fixed point auxiliary measuring equipment, through the arrangement of a protective safety cover and the mutual cooperation of a fixed telescopic rod, a telescopic reset spring and an active telescopic rod, when the auxiliary measuring equipment is not installed, the bottom end of a secondary supporting telescopic rod cannot be exposed outside, the condition that the conical bottom end of the secondary supporting telescopic rod can injure an operator is prevented, and the use safety of the auxiliary measuring equipment is ensured, so that the practical safety of the auxiliary measuring equipment is improved.

Owner:李达

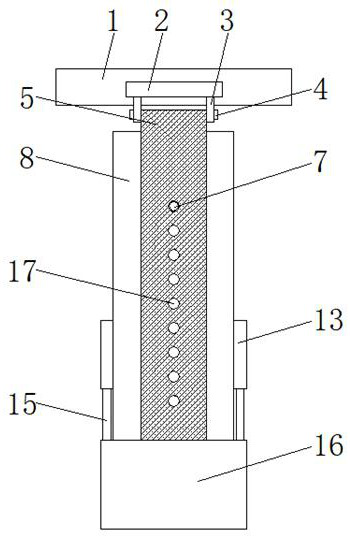

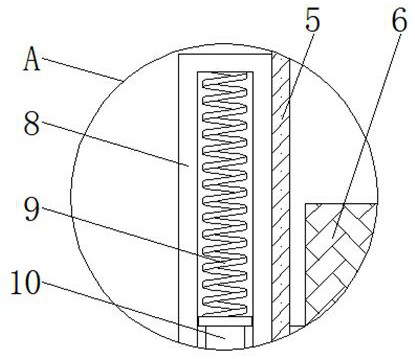

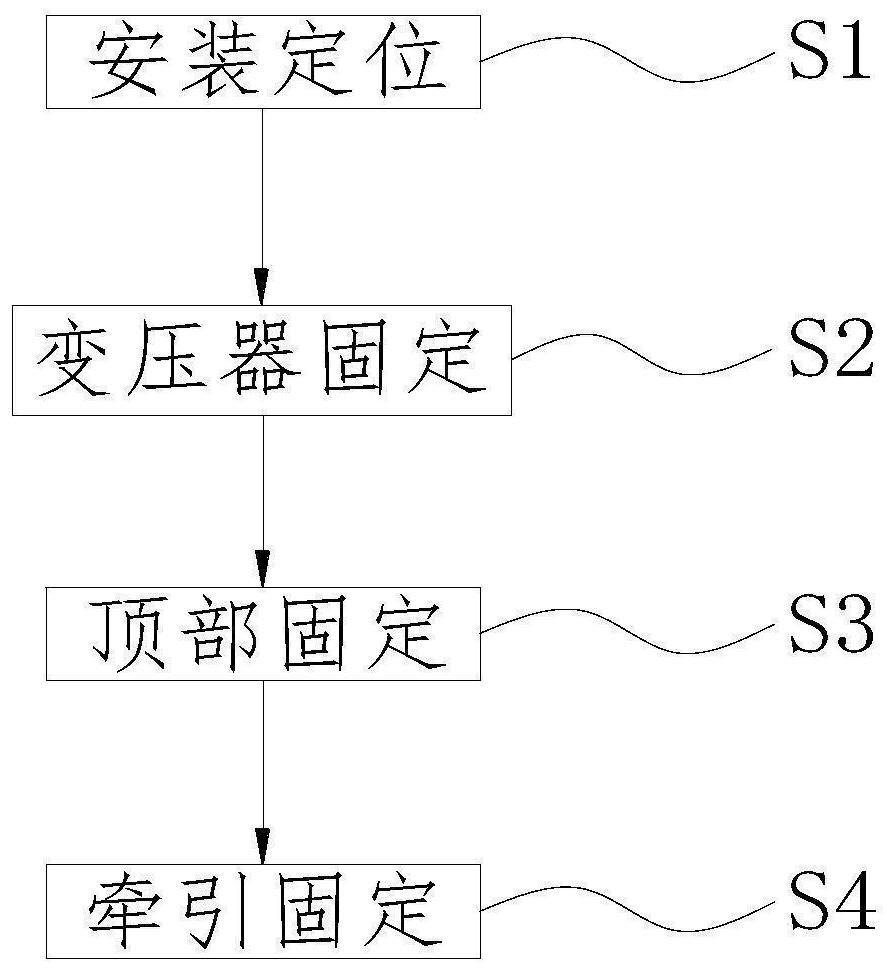

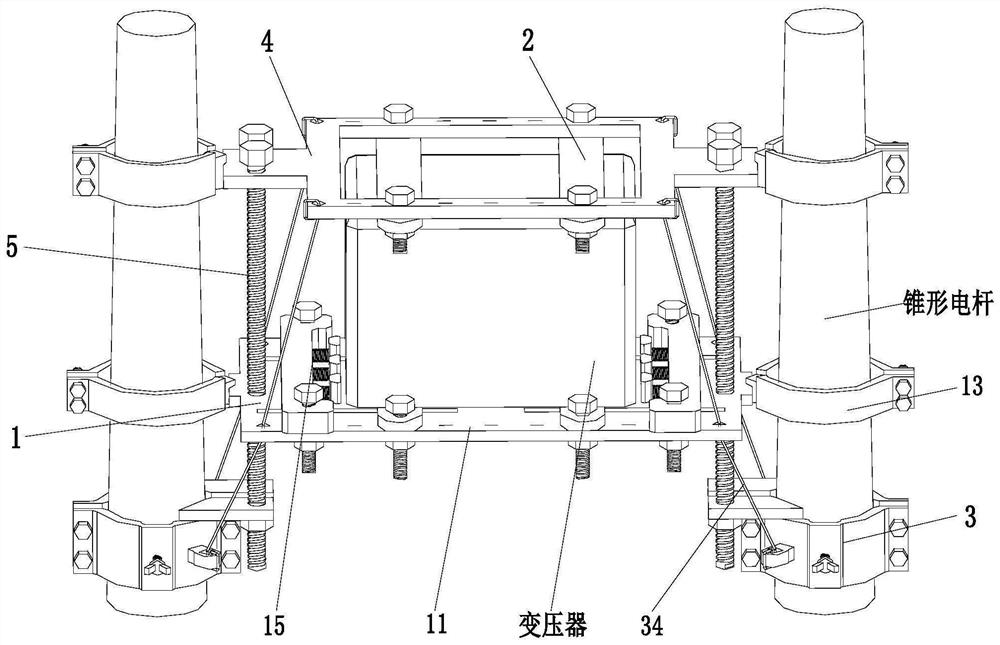

A kind of power transformer installation construction method

ActiveCN111063514BFixedImprove the effect of fixed protectionTransformers/reacts mounting/support/suspensionSubstation mounted on poleExtreme weatherTransformer

The invention relates to a power transformer installation construction method. The power transformer installation construction method adopts a power transformer installation structure, the power transformer installation structure comprises a supporting device, a mounting strip, a traction fixing mechanism, a positioning and fixing mechanism and adjusting bolts, the supporting device comprises a supporting plate, a supporting pin shaft, a supporting embracing ring, supporting bolts and a limiting mechanism, and the positioning and fixing mechanism comprises a positioning and fixing plate, a positioning embracing ring, a positioning pin shaft and positioning bolts. The power transformer installation construction method adopting the power transformer installation structure comprises the following steps: S1, installation and positioning; S2, fixation of a transformer; S3, fixation of the top; and S4, traction fixing. The problems that an existing power transformer is poor in transformer fixing effect and cannot adapt to some extreme weather conditions, the transformer possibly shakes or even falls off, and the public is threatened can be solved.

Owner:盛隆电气集团电力工程有限公司

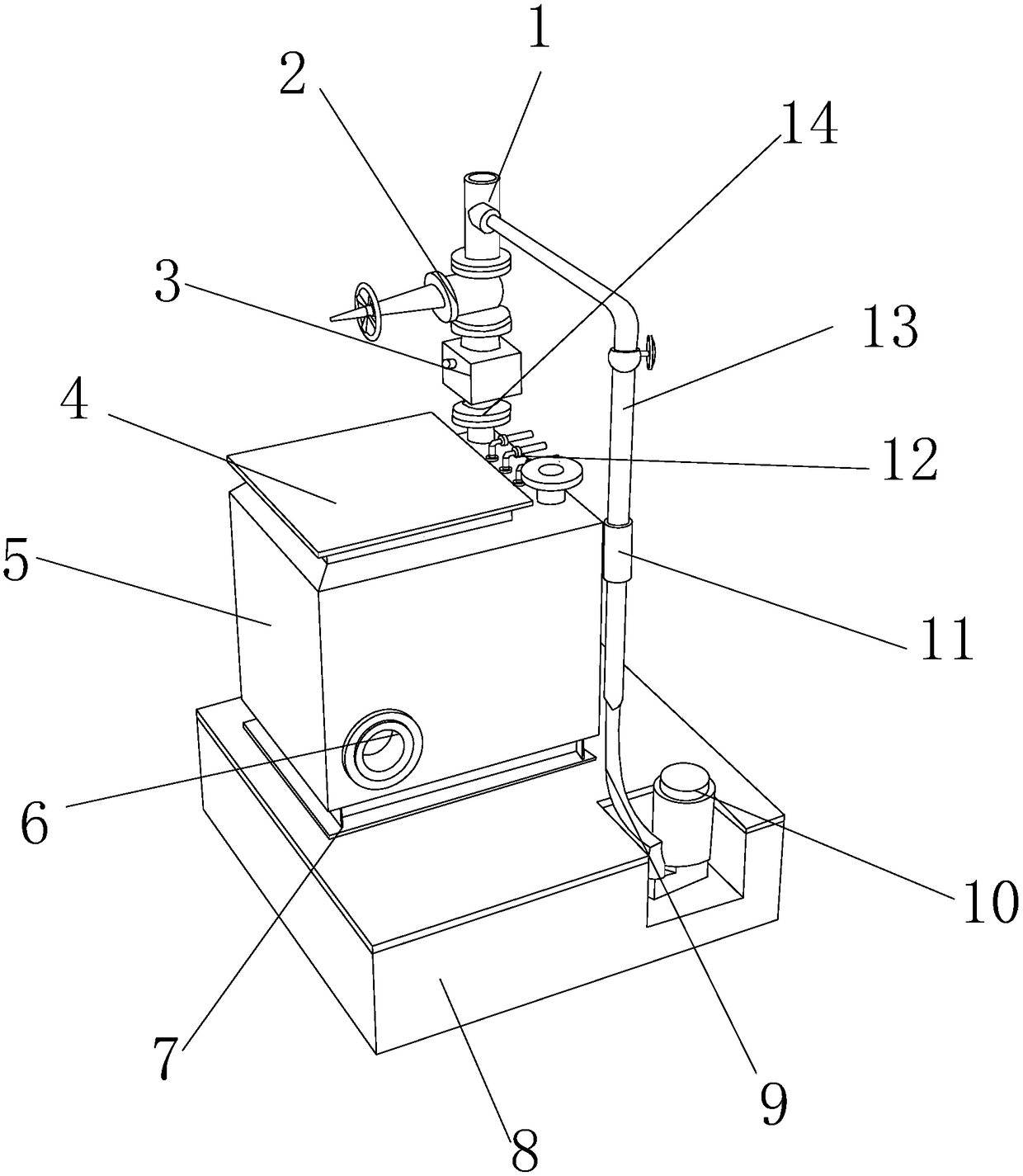

Automatic water injection and drainage device

InactiveCN108325267ADischarge in timePromote sportsFiltration circuitsEnvironmental engineeringEngineering

The invention discloses an automatic water injection and drainage device; a structure of the device comprises an exhaust hole, a water stop valve, a blowdown device, a water tank top cover, a water purification tank, a drainage pipe, a water sink base, a support base, a U-shaped water connection pipe, a water suction pump, a regulating pipe, a three-way water stopper, a connecting pipeline and a regulating valve; the middle part of the upper end of the support base is welded at the lower end of the water sink base; the upper end of the water sink base is arranged at the lower end of the waterpurification tank. The automatic water injection and drainage device has the beneficial effects that with addition of the blowdown device on the device, the device can automatically filter impuritiesin water while automatically doing water injection and drainage operation, so that the quality of testing equipment is protected, the impurities are discharged in time, the practicality of the deviceis ensured, the practical safety of the device is increased, the workload of the staff is also greatly reduced, and the device is practical.

Owner:商球

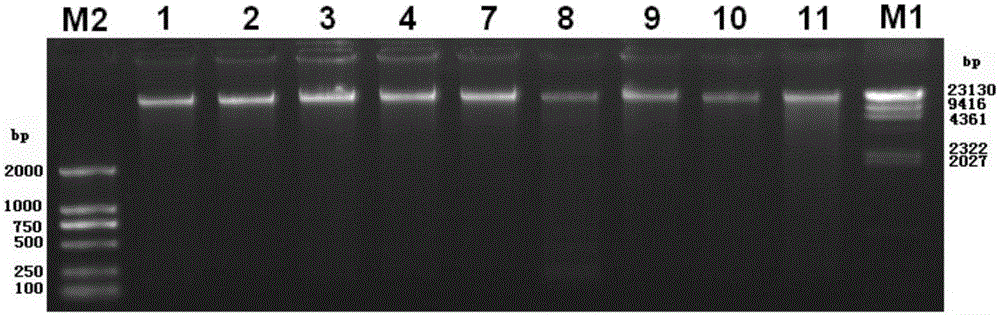

Sputum collection method for detecting 16SrRNA gene sequence of respiratory tract bacteria

InactiveCN104306028AReduce the impactReduce pollutionSurgeryVaccination/ovulation diagnosticsBacteroidesNose

The invention discloses a sputum collection method for detecting the 16SrRNA gene sequence of respiratory tract bacteria. The sputum collection method comprises the following steps: step one, measuring the forced vital capacity FEV1 in the first second of the foundation; step two, absorbing 200 mu. G of salbutamol aerosol; step three, blowing the nose and rinsing the mouth with 0.9% of sterilization normal saline water; step four, carrying out atomization induction with 3% of sterilization saline water for 10 min, stopping atomization, rinsing the mouth for three times with 0.9% of sterilization normal saline water, and holding the breath to cough up deep sputum, so that the sputum is colleted in a sterile culture dish; step five, carrying out atomization with 4% and 5% sterilization saline water respectively to repeat the above steps, and collecting the deep sputum; step six, separating sputum bolt collected in the step four and the step five and preserving the sputum bolt at a low temperature. The sputum collection method for detecting the 16SrRNA gene sequence of respiratory tract bacteria provided by the invention is low in possibility to contaminate an oral cavity, and is simple and convenient.

Owner:张清玲 +5

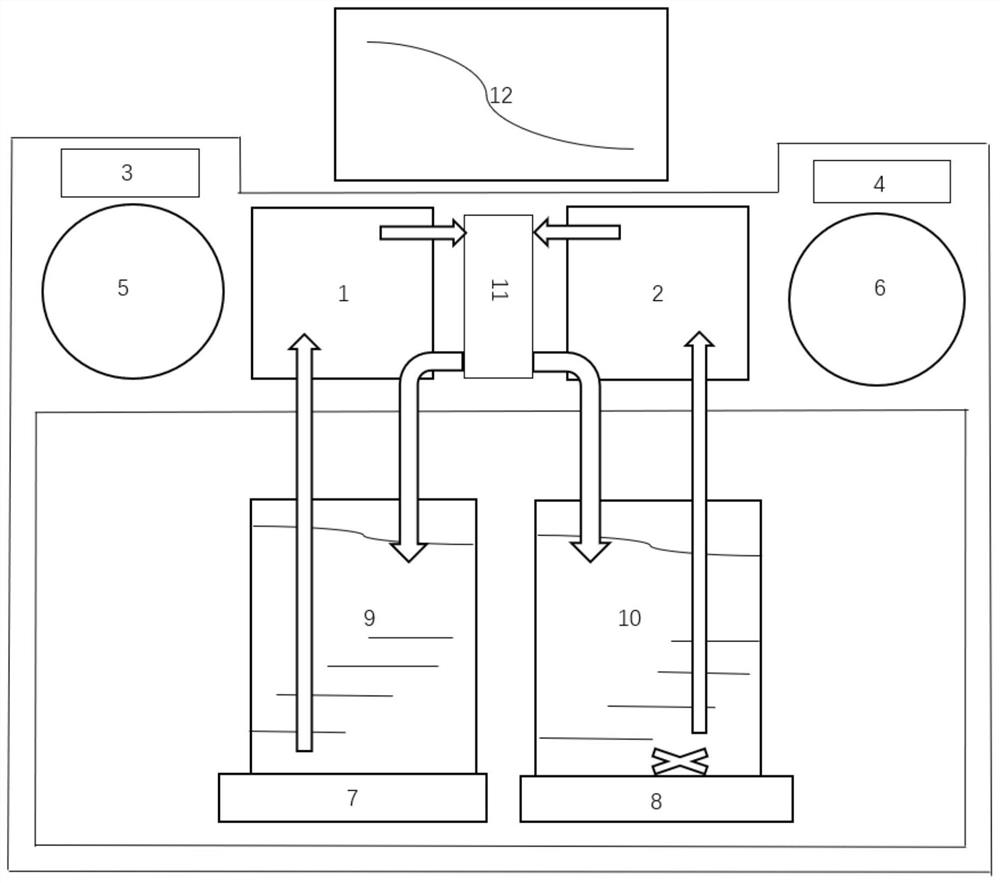

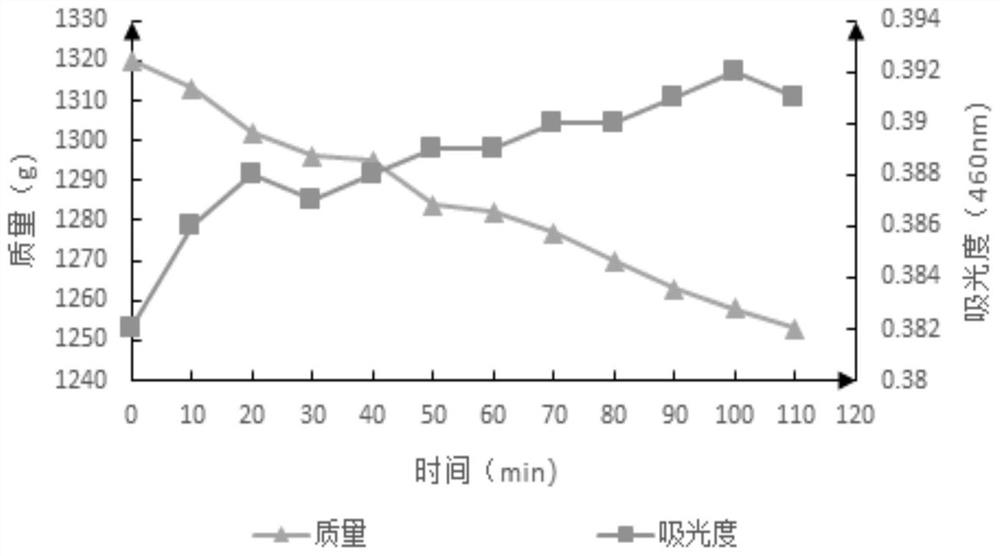

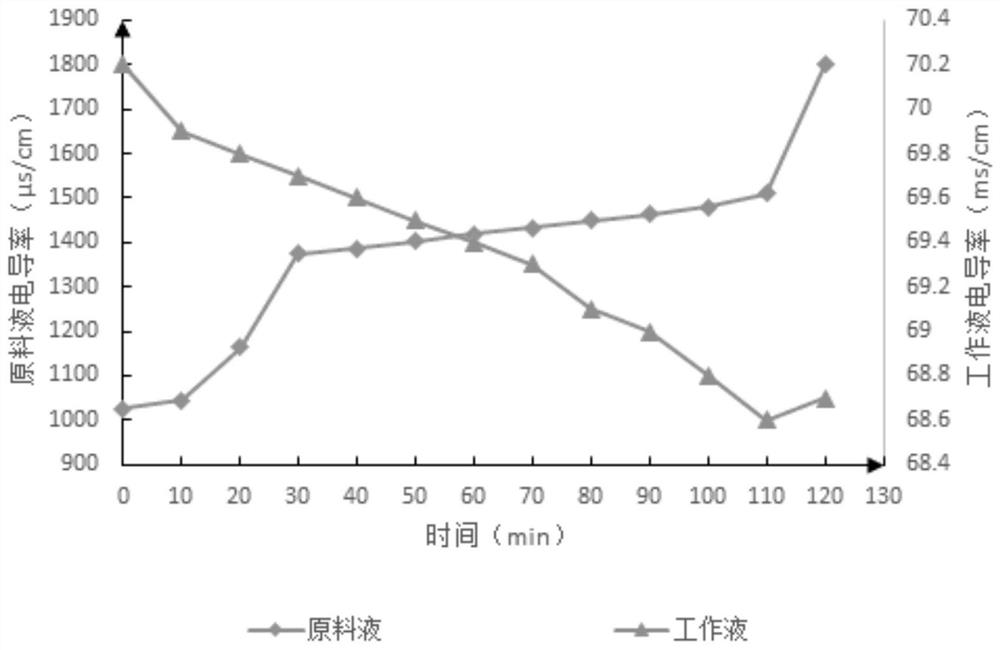

Forward osmosis membrane water treatment teaching experiment device and method

A forward osmosis membrane water treatment teaching experiment device comprises a raw material liquid measuring cup, a drawn liquid measuring cup, a first peristaltic pump, a second peristaltic pump and a membrane assembly, the membrane assembly is composed of a forward osmosis membrane and a clamp of the forward osmosis membrane, and the raw material liquid measuring cup, the first peristaltic pump and a membrane chamber cavity on one side of the membrane assembly form a loop, the drawn liquid measuring cup, the second peristaltic pump and a membrane chamber cavity on the other side of the membrane assembly form a loop, the first peristaltic pump is connected with a first conductivity meter and a photometer, the second peristaltic pump is connected with a second conductivity meter and a pressure meter, an electronic balance is arranged below the raw material liquid measuring cup in an auxiliary mode, and all measuring devices are connected with a computer. A self-circulation draw solution treatment mode is adopted, and the working principle of the forward osmosis membrane is learned and mastered through real-time data acquisition of multiple factors such as salinity, luminosity, water pressure, water temperature and flow on the two sides of the FO membrane by virtue of permeation volume and mass changes. The ergonomically designed device equipment structure meets the requirements of teaching experiments on full-parameter opening, visual operation, obvious explanation of effects, safety, low consumption and efficient space utilization.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

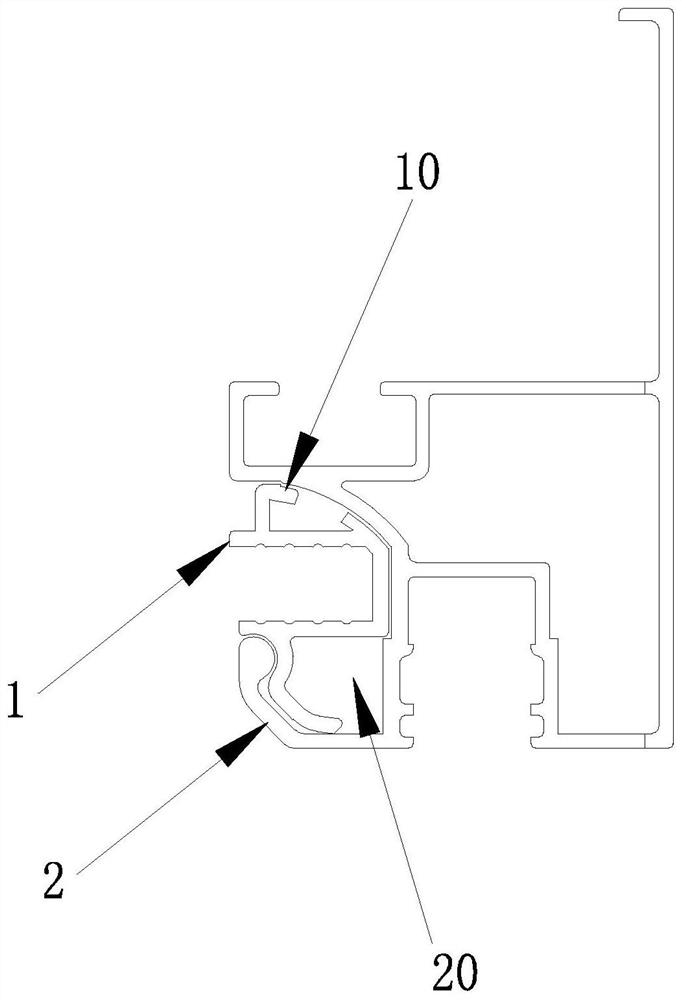

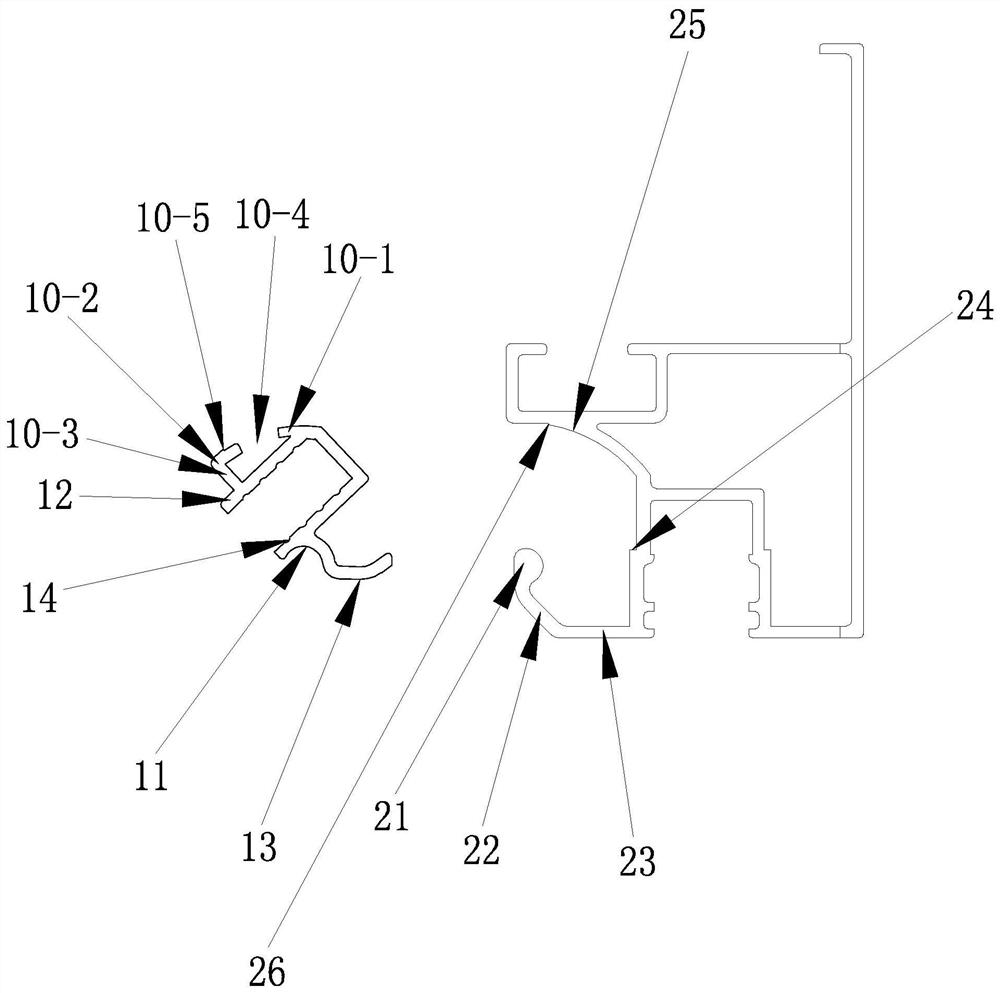

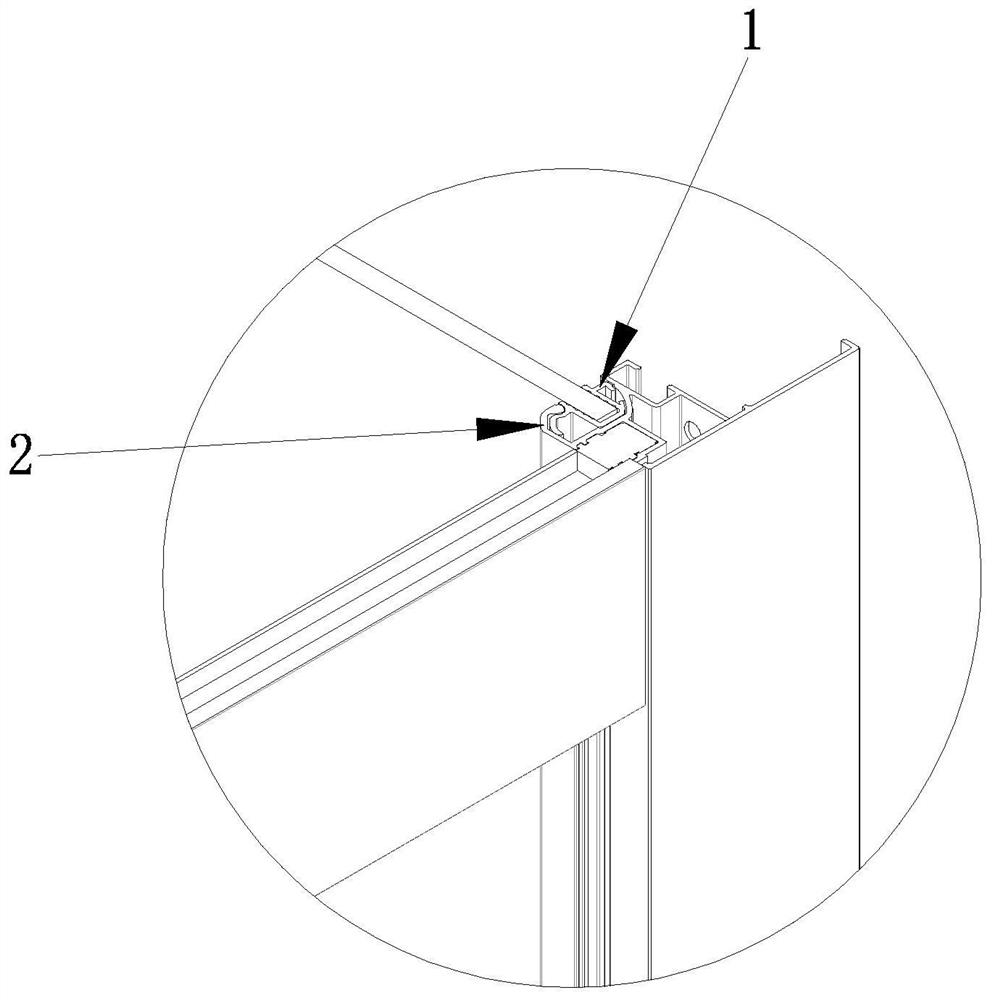

A rotating locking mechanism

ActiveCN110735482BQuick fit lockQuick disassemblySpecial buildingBuilding constructionsMechanical engineeringPhysics

The invention relates to a rotating mounting locking mechanism, which includes a connecting mechanism and a mounting mechanism formed by aluminum profiles; a mounting groove is formed on the mounting mechanism; Rotate the position-limiting protrusion for position-limiting fit, and the end of the position-limiting protrusion is a circular arc structure; correspondingly, the connecting mechanism is formed with a circular-arc structure that matches the position-limiting assembly protrusion The connecting groove of the connecting mechanism is rotationally connected with the limit protrusion on the mounting mechanism, so that the connecting mechanism is transferred into the mounting groove, and the fast locking of the connecting mechanism and the mounting mechanism is realized; the present invention has a simple structure and is easy to use Convenience, the connecting mechanism is rotatably connected to the installation mechanism, which realizes fast transfer and locking between adjacent profiles; the aluminum profile is quickly disassembled, has good performance, and is safe and reliable.

Owner:PINGHU BELLAVIA SANITARY TECH CO LTD

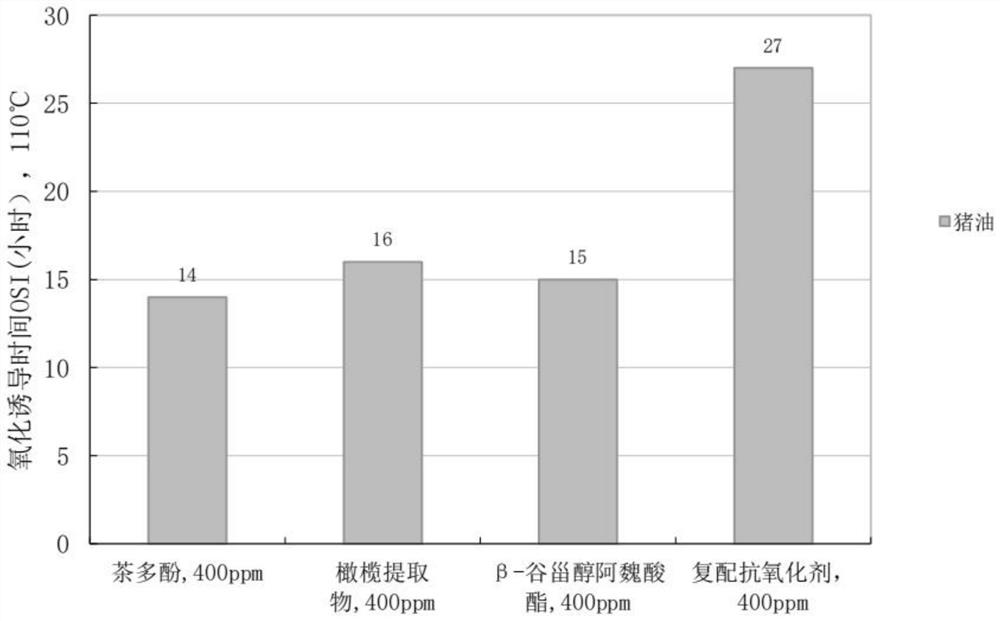

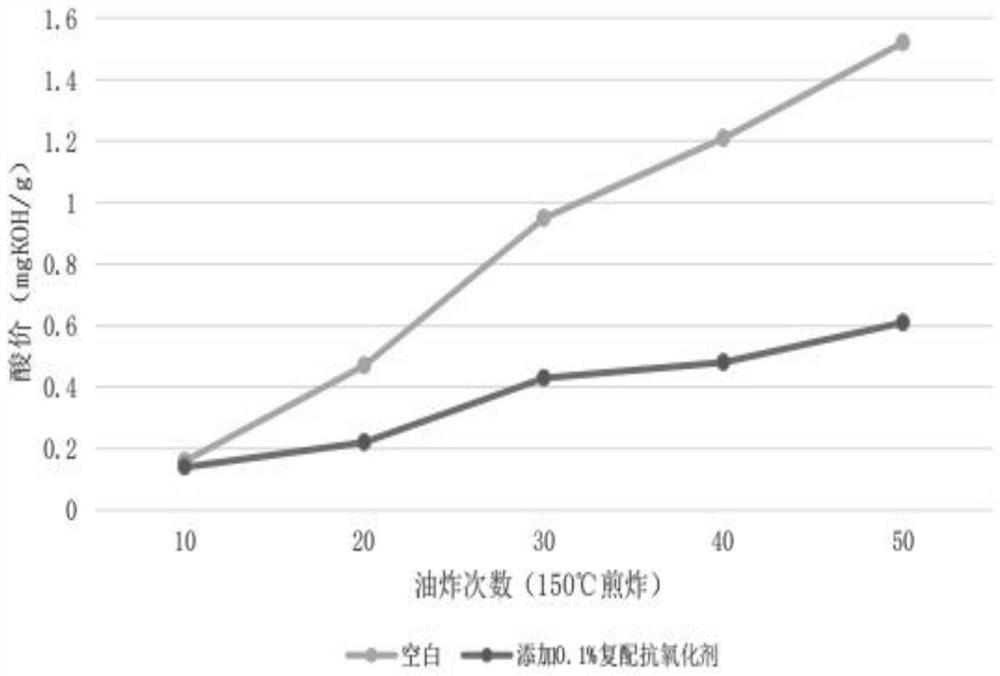

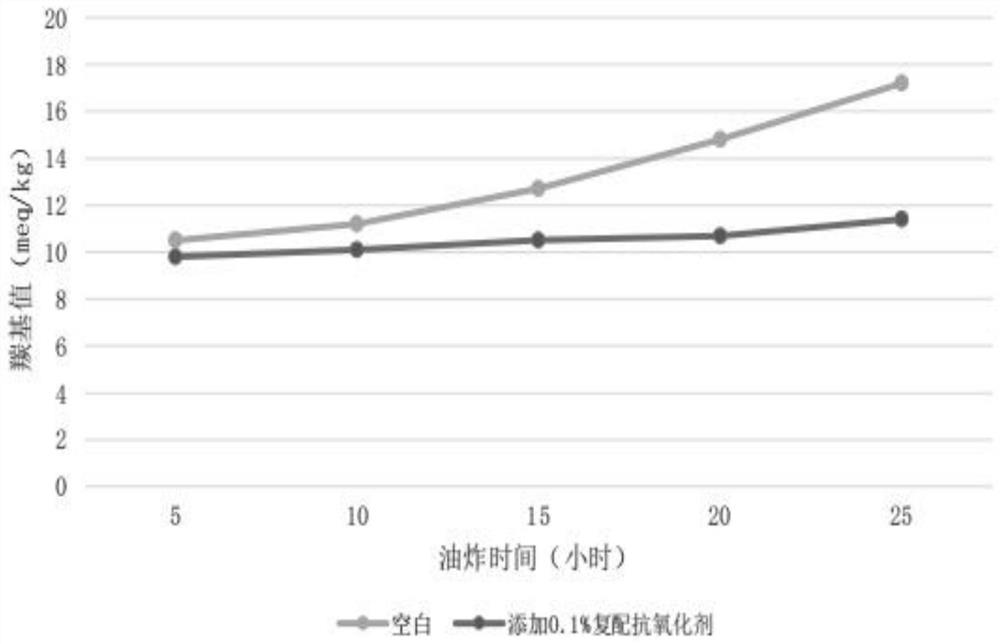

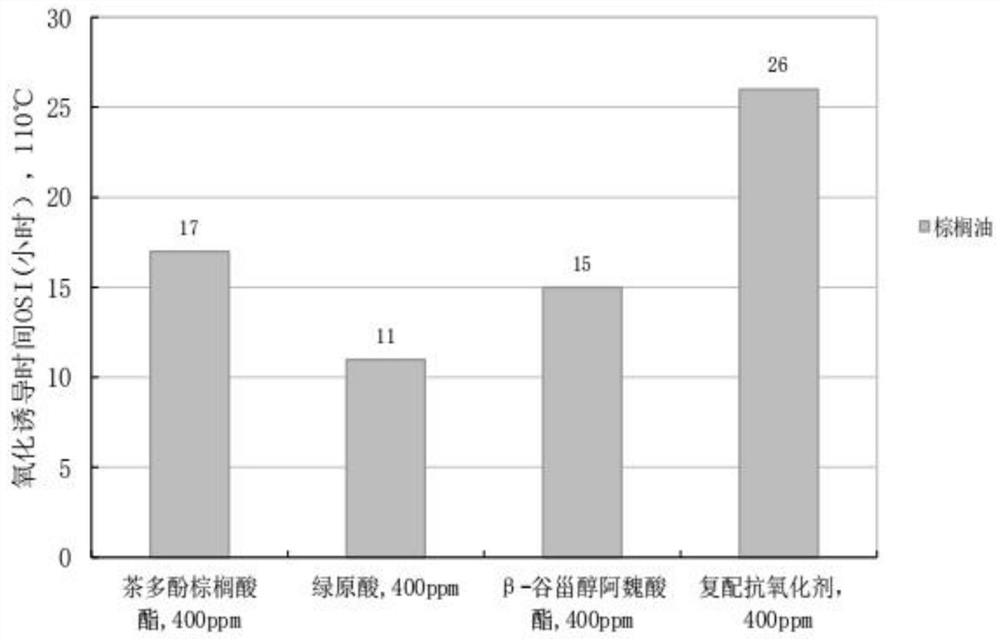

Compound antioxidant suitable for high-temperature frying oil and using method thereof

PendingCN111763567ALow acid valueImprove practical safetyHydrolasesFatty substance preservation using additivesChlorogenic acidMonoglyceride

The invention relates to a compound antioxidant suitable for high-temperature frying oil. The compound antioxidant comprises a compound antioxidant body and immobilized lipase, the compound antioxidant body comprises 60% of monoglyceride and diglyceride fatty acid ester, 20% of tea polyphenol palmitate, 10% of chlorogenic acid and 10% of beta-sitosterol ferulate, and the addition amount of the immobilized lipase is 0.01-0.03% of the content of the compound antioxidant body. The design is scientific and reasonable, and the traditional single-component antioxidant is broken through. Activated carbon immobilized lipase is innovatively added, so that chlorogenic acid is combined with triglyceride of oil, and ester hydrolysis is catalyzed on a water-oil interface. On one hand, the oxidation stability of edible oil is enhanced, meanwhile, in the reaction process, chlorogenic acid can react with free fatty acid in the oil to form a phenolic compound-fatty polymer, the original acid value of the oil is reduced while oil oxidation is enhanced, oil polymerization reaction is effectively prevented, generation of a thermal polymer is effectively slowed down at the moment of high-temperature frying, and fresh color and flavor of the oil are kept.

Owner:天津融信蓝海生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com