Syringe needle dismounting device

A technology for dismantling devices and needles, which is applied in the direction of needles, hypodermic injection devices, and devices introduced into the body, etc. It can solve the problems of difficult removal of needles, many types of objects, and large connection force, so as to avoid hurting people, and has a wide range of applications. The effect of easy disassembly operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the drawings and specific embodiments.

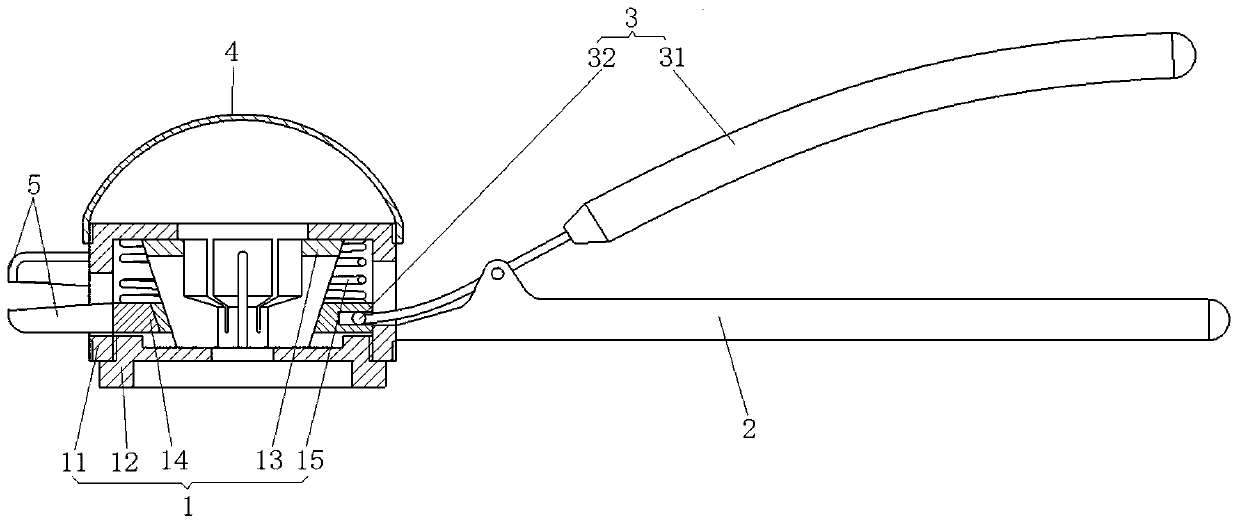

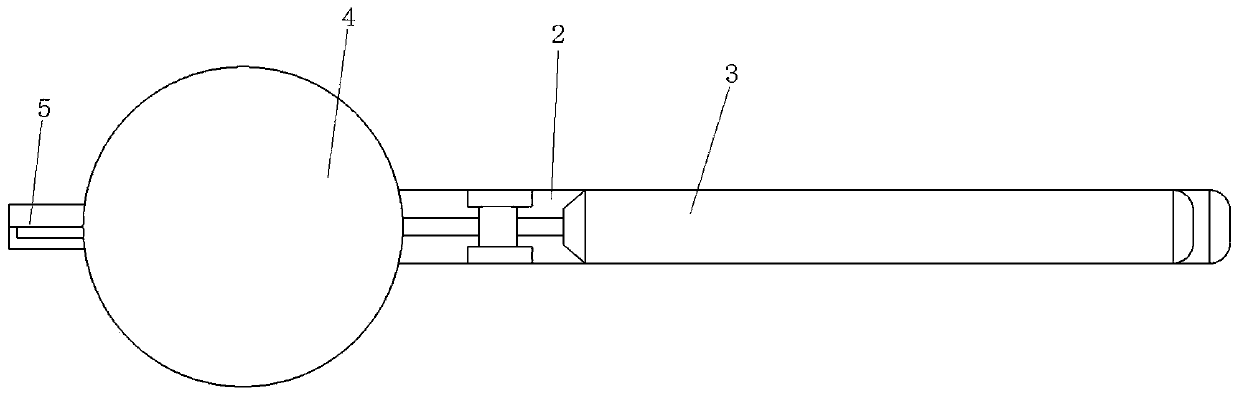

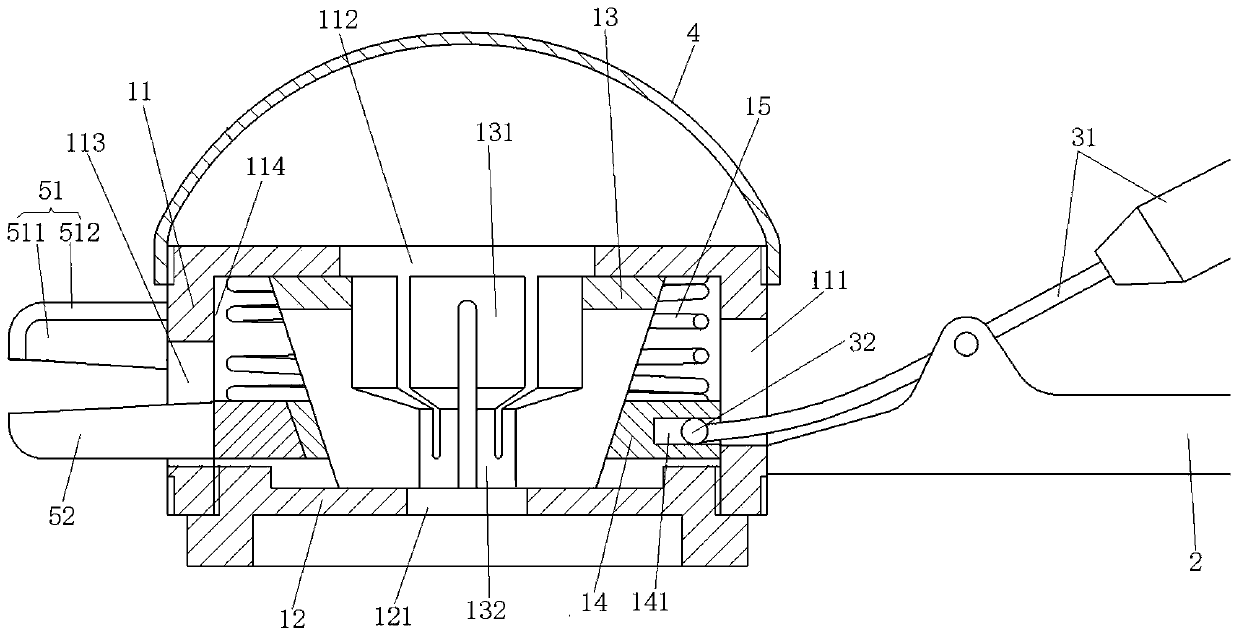

[0033] Such as Figure 1 to Figure 3 As shown: the needle removal device includes a handle 2, an operating rod 3, a clamping head 1 and a shearing structure 5; the clamping head 1 includes an outer sleeve 11, an end cap 12, a telescopic sleeve 13, a moving sleeve 14 and a spring 15; There is a guide hole 114. The side plate of the outer sleeve 11 has a driving groove 111 and a shearing structure groove 113. The end plate at one end of the outer sleeve 11 has a large needle hole 112. The other end of the outer sleeve 11 is connected to the end cap 12 through a screw thread. It has a small needle hole 121; the telescopic sleeve 13, the movable sleeve 14 and the spring 15 are all located in the outer sleeve 11. The telescopic sleeve 13, the movable sleeve 14, the guide hole 114, the large needle hole 112 and the small needle hole 121 are coaxially arranged; the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com