Punching deslagging device of metallurgical furnace

A metallurgical furnace and slag port technology, which is applied in the field of perforation and slag discharge devices, can solve the problems of high risk factor of the furnace, explosion of melt in the furnace, easy water leakage, etc., so as to improve practical safety performance, prolong service life, and avoid easy water leakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

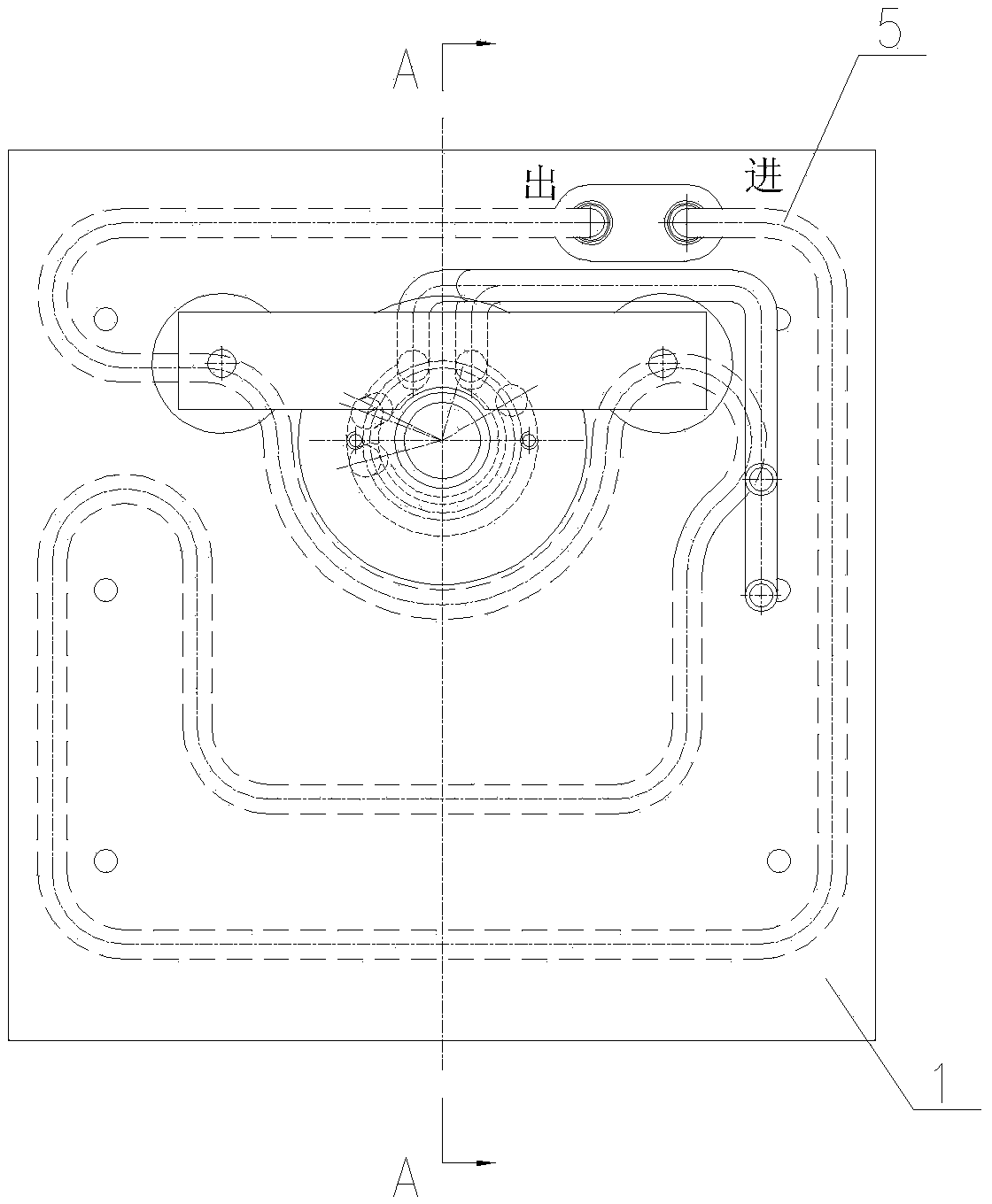

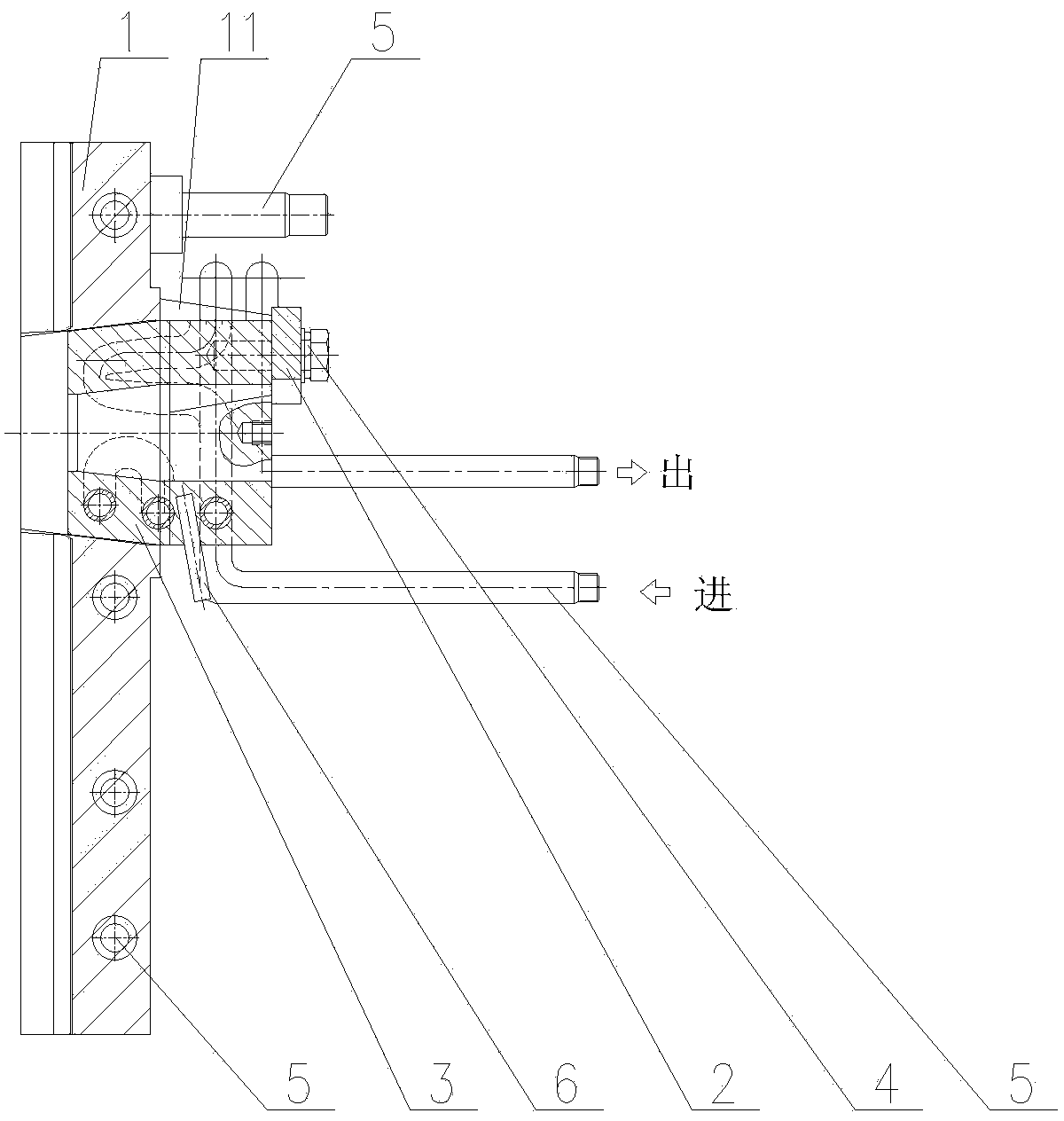

[0011] preferred embodiment, such as figure 1 , figure 2 As shown, this metallurgical furnace punching and slagging device provided by the present invention includes a slag mouth copper water jacket 1 and a copper water jacket plug 3 embedded with pure copper pipes 5, and the slag mouth copper water jacket plug 3 is assembled on Inside the water jacket 1. There is a tapered through hole for installing the copper water jacket plug 3 on the center line of the width direction of the copper water jacket 1 at the slag mouth. There are symmetrical bosses 11 on both sides of the non-heating surface of the tapered through hole. There are axial threaded holes on the top, and the steel plate 2 is connected by bolts 4 between the threaded holes, and the steel plate 2 spans the upper end surface of the copper water jacket plug 3, so that the copper water jacket plug 3 and the slag mouth copper water jacket 1 are fixed and limited . The heating surface of the slag mouth copper water ja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com