Patents

Literature

42results about How to "Save assembly cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

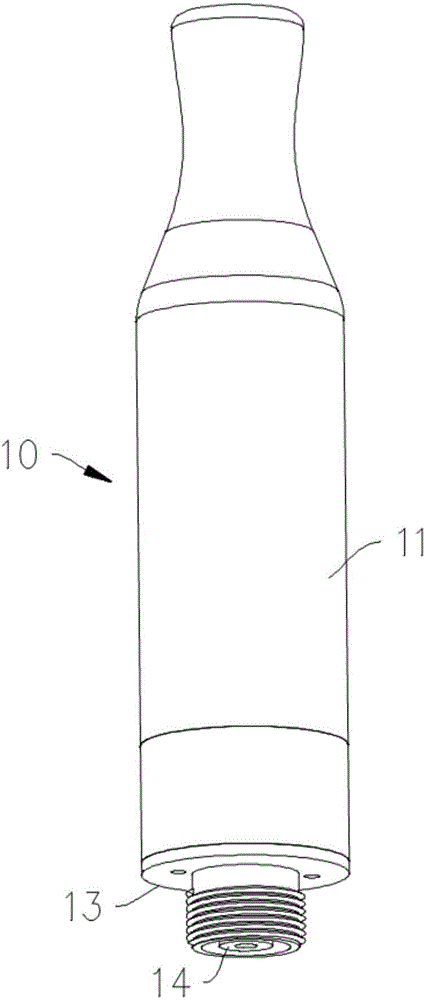

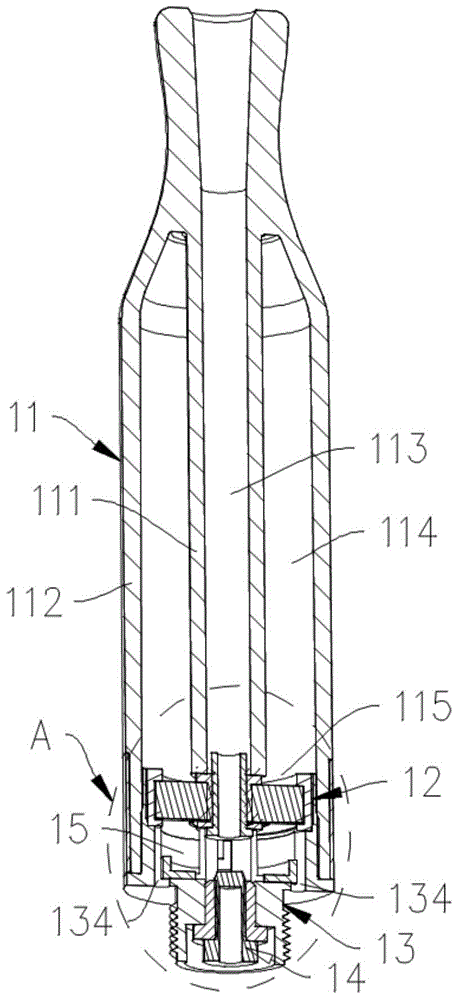

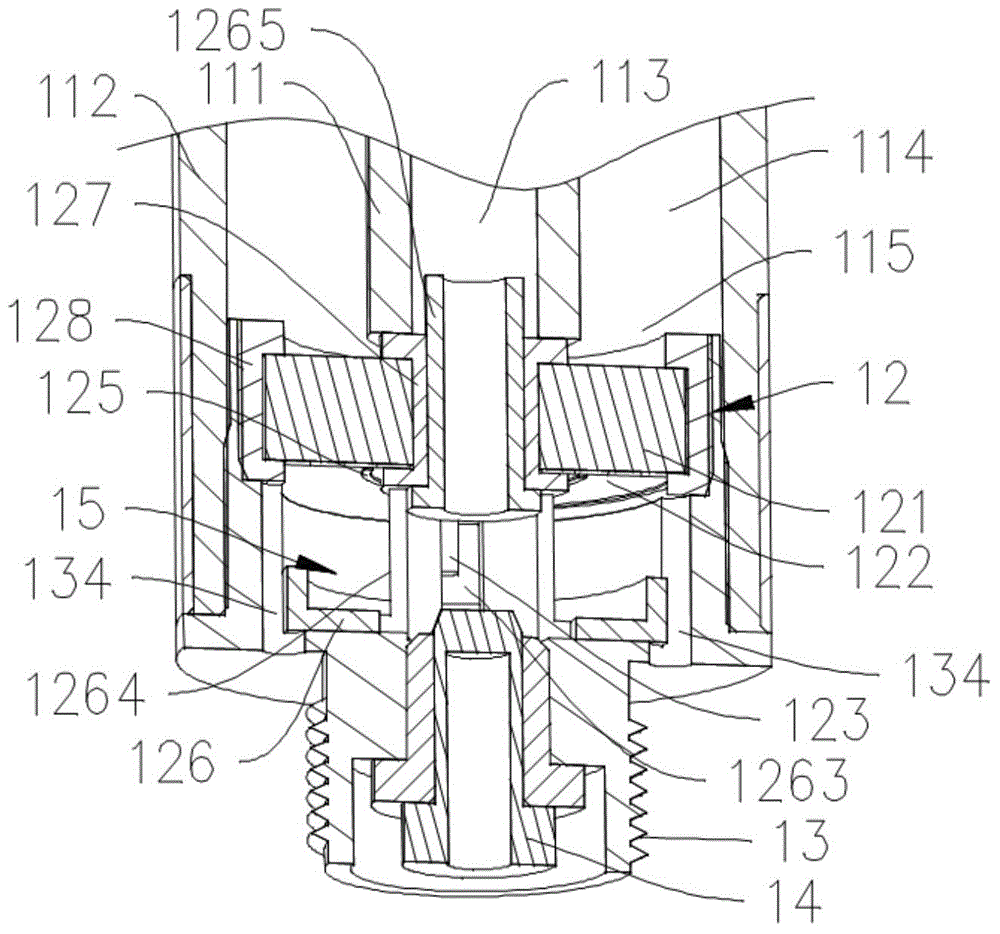

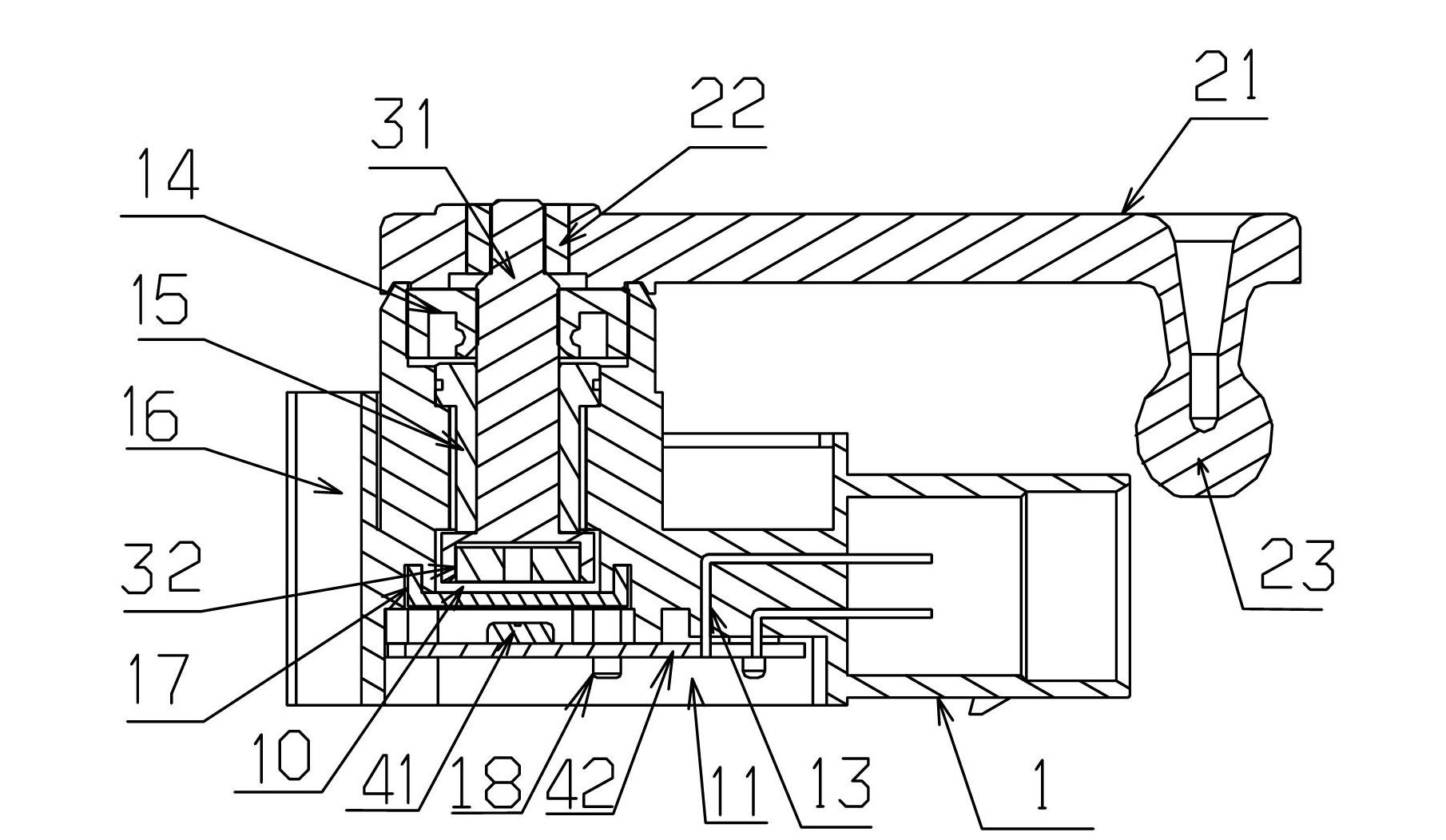

Electronic cigarette and nebulizing device thereof

ActiveCN104872822ADamage to physical healthSimple structureTobacco devicesPhysical healthElectronic cigarette

The invention relates to an electronic cigarette and a nebulizing device thereof. The nebulizing device comprises a smoke cartridge tube and a nebulizing component. The smoke cartridge tube is provided with a smoke passage, a liquid storage cavity and a liquid outlet allowing pass of liquid nicotine. The nebulizing component fits the liquid outlet and comprises a liquid guide body, a polysilicon heating layer and first and second electrodes; the liquid guide body covering the liquid outlet is made of porous material; the polysilicon heating layer is located on one side, far away from the liquid storage cavity, of the liquid guide body; the first electrode and the second electrode are both electrically connected with the polysilicon heating layer so as to connect to a power supply; the side of the polysilicon heating layer is communicated with the smoke passage. The liquid guide body made of porous ceramic is used for guiding liquid; the polysilicon heating layer heats and nebulizes the liquid nicotine leaking out; when the nebulizing component heats the liquid nicotine, no dust is generated and flows to the smoke passage, and the physical health of consumers is protected from impairment; the nebulizing device is simple in structure, convenient to assemble and lower in assembly and labor cost.

Owner:SHENZHEN SMOORE TECH LTD

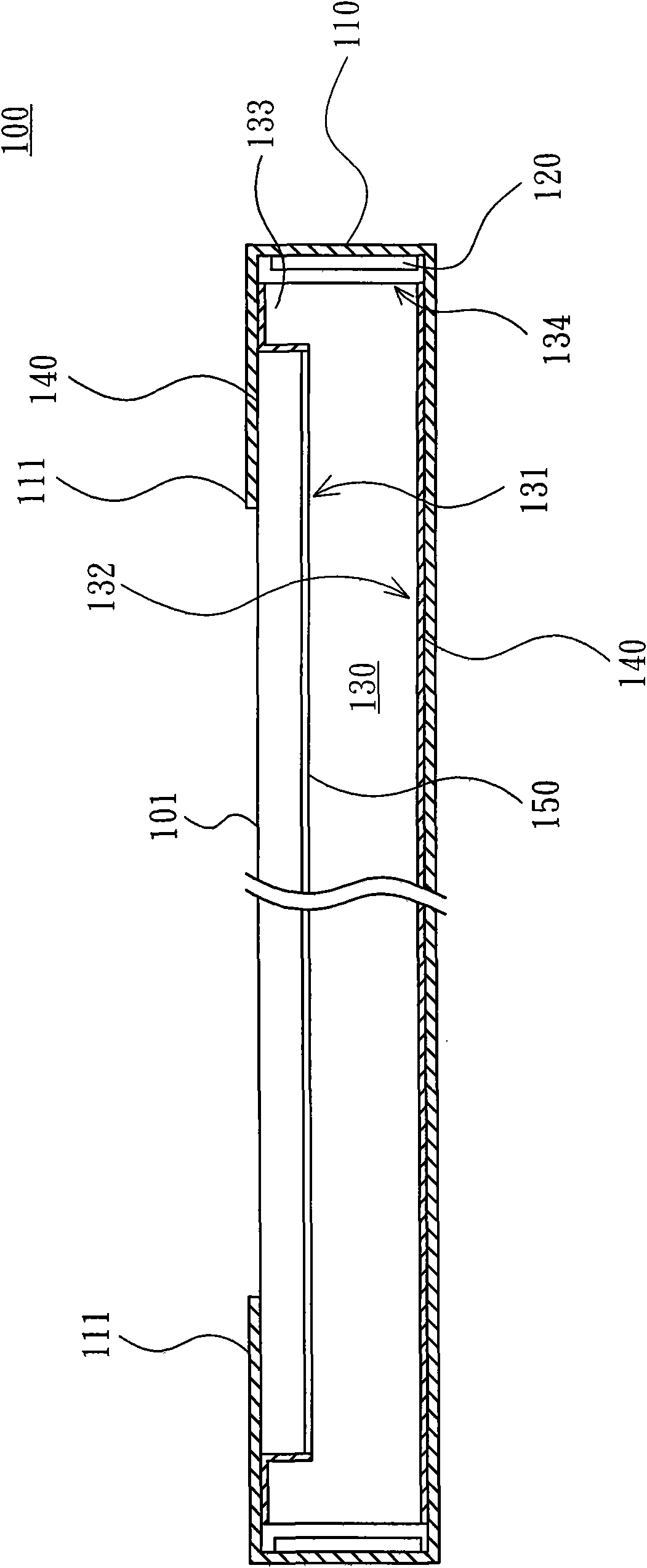

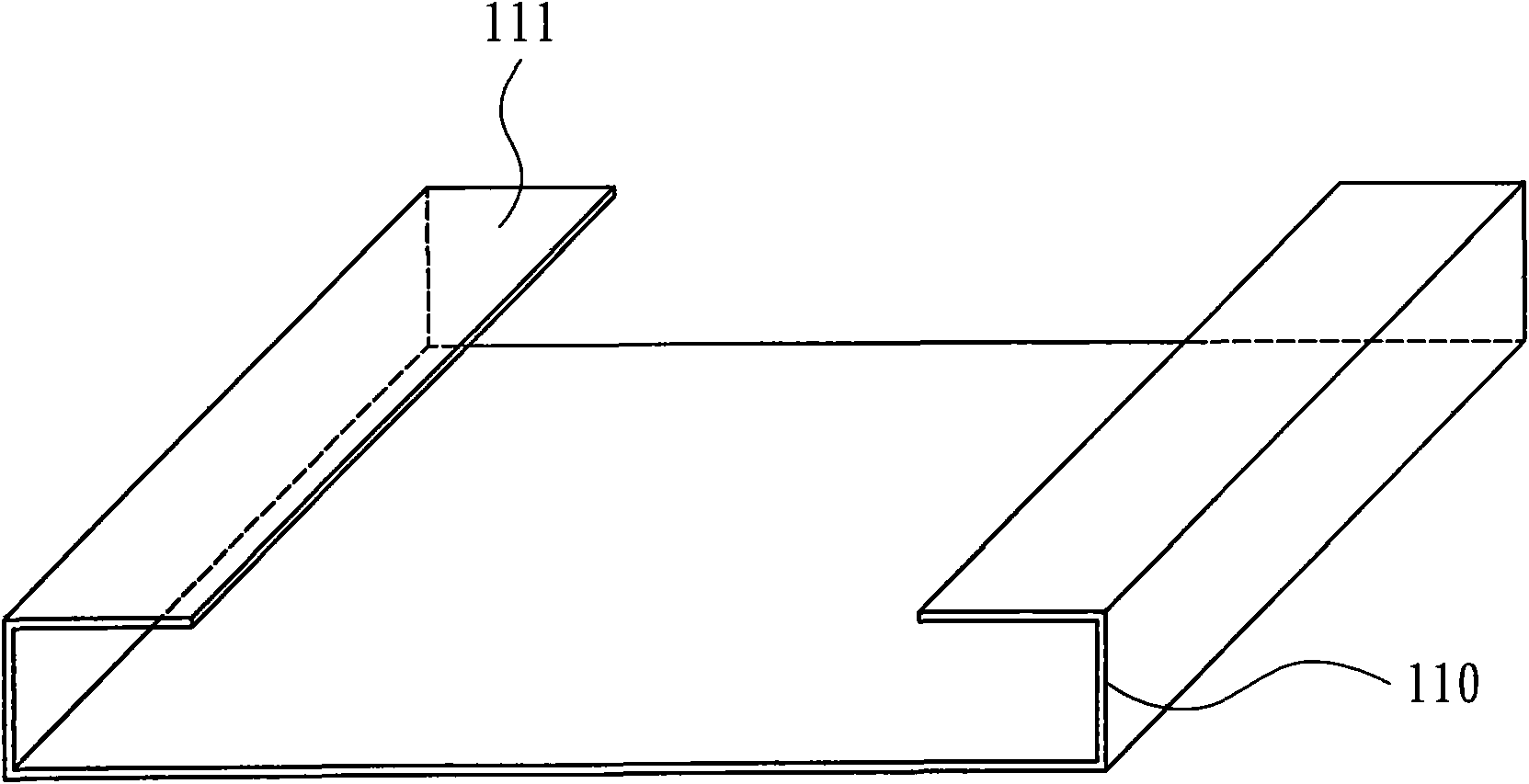

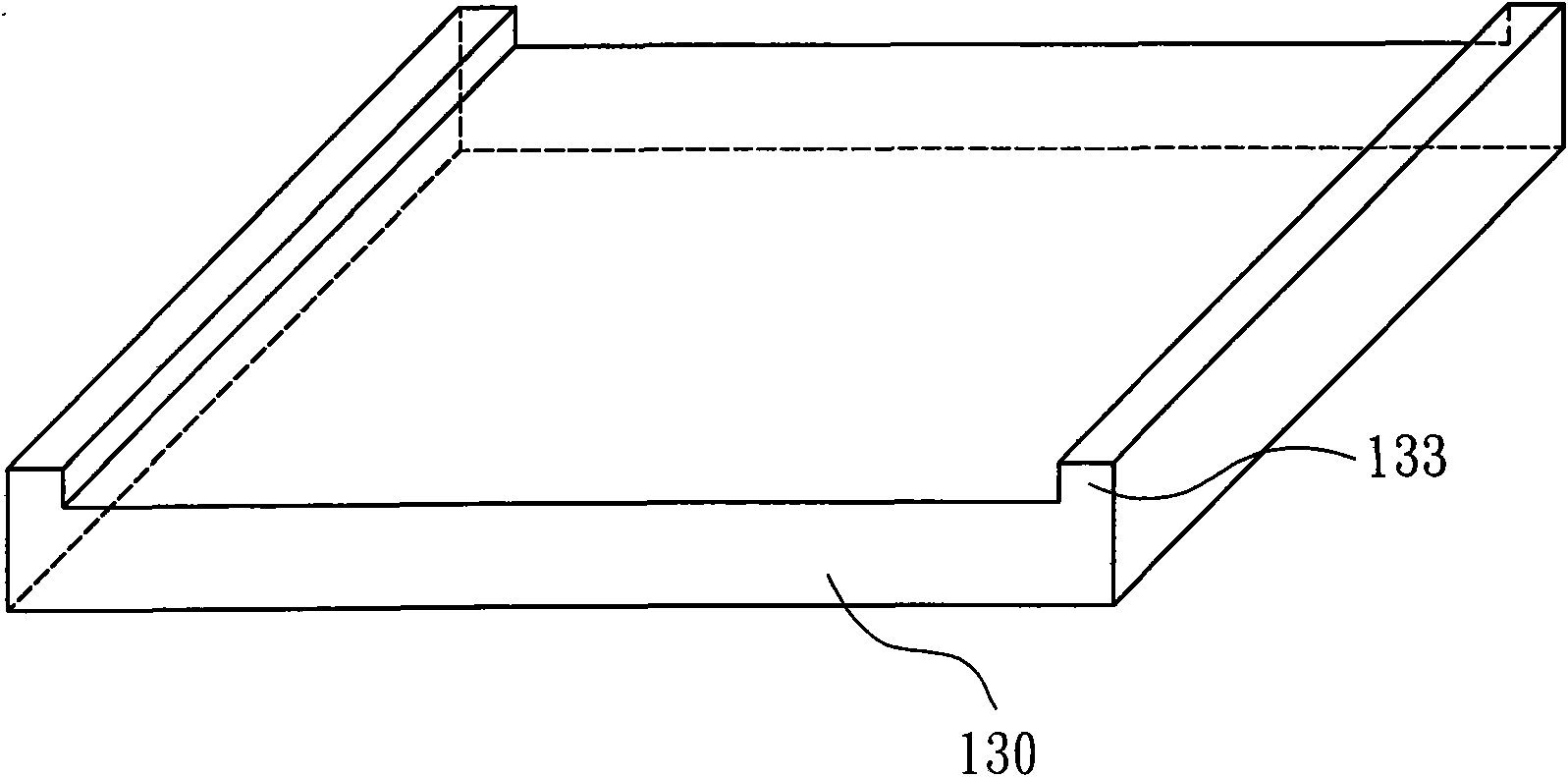

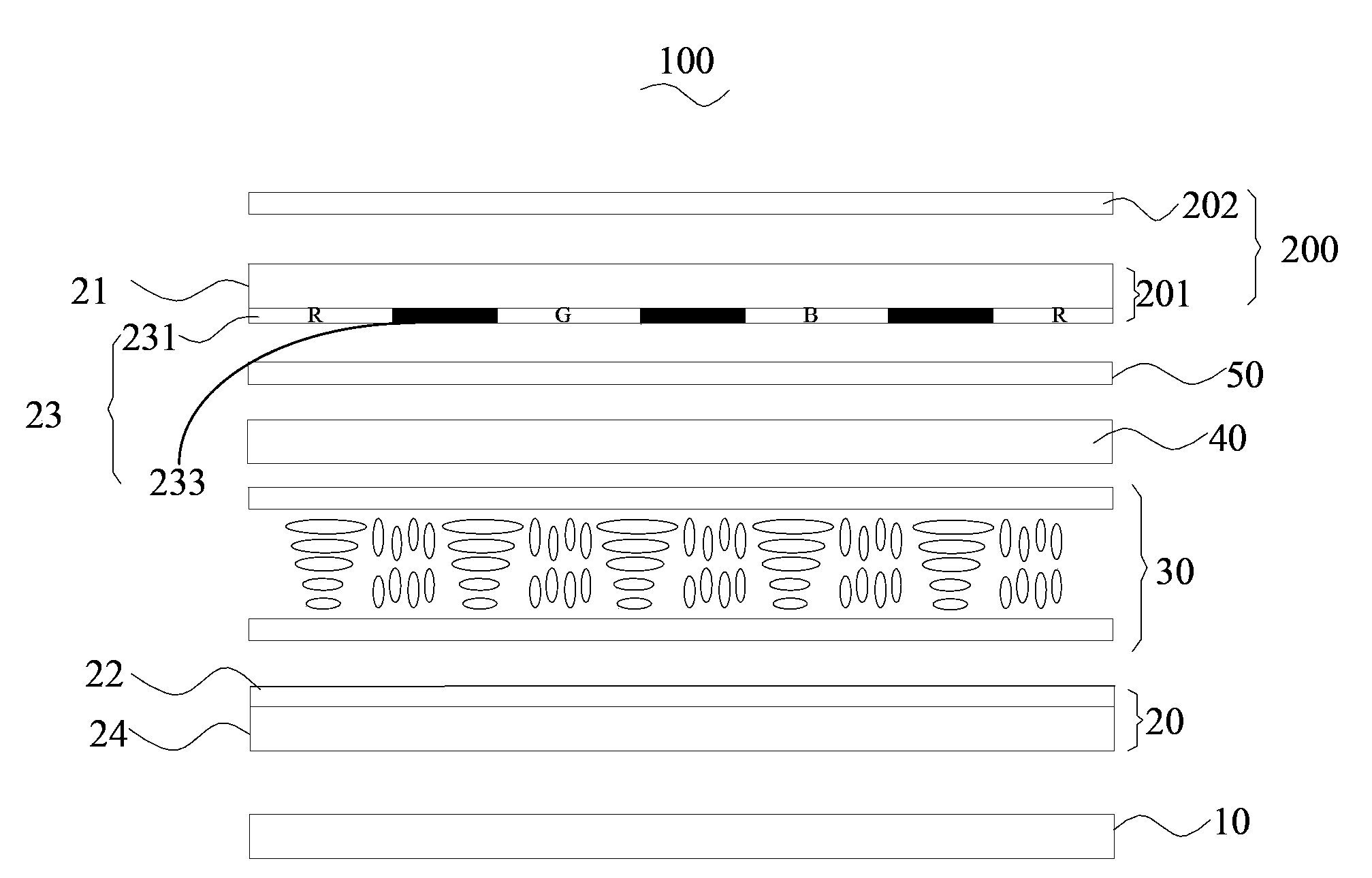

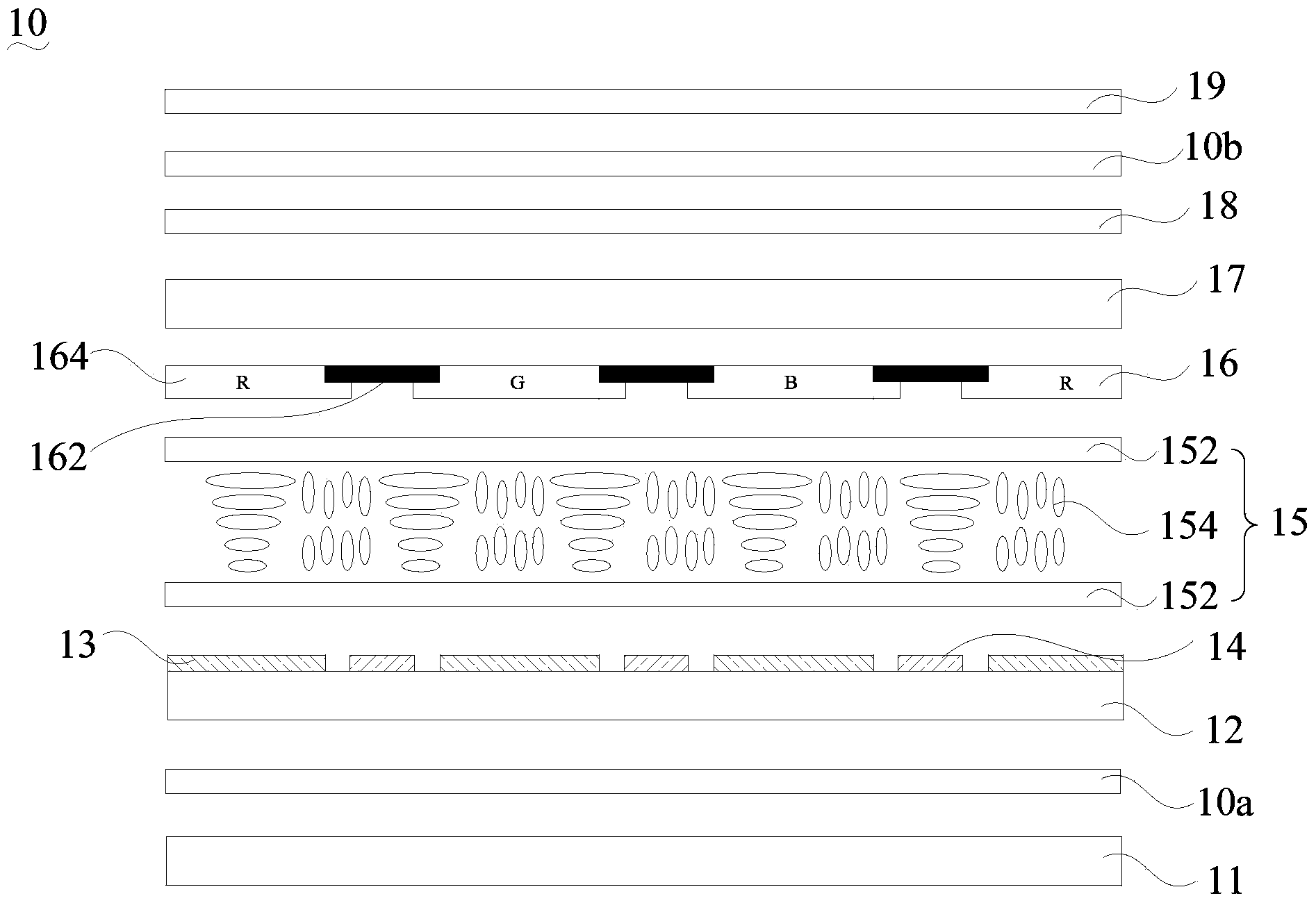

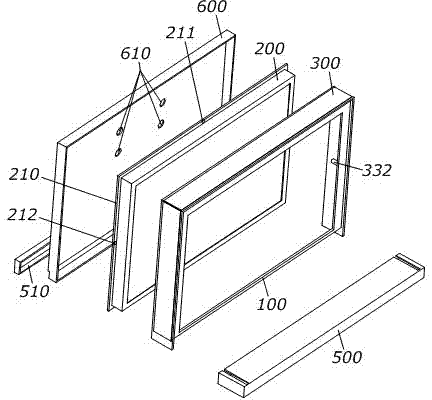

Backlight module and display device

ActiveCN102109131AEasy and fast positioningEasy and fast plug-inMechanical apparatusLight guides for lighting systemsLight guideDisplay device

The invention provides a backlight module and a display device. The display device comprises the backlight module and a display panel. The backlight module comprises a housing, a light guide plate and a light source, wherein the light guide plate is arranged in the housing and is provided with a light-emitting surface and a positioning convex part; the positioning convex part protrudes out of the light-emitting surface; and the light source is arranged on at least one side of the light guide plate. In the invention, the assembly structure and the assembly process of the display device can be simplified through the utilization of the positioning convex part.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

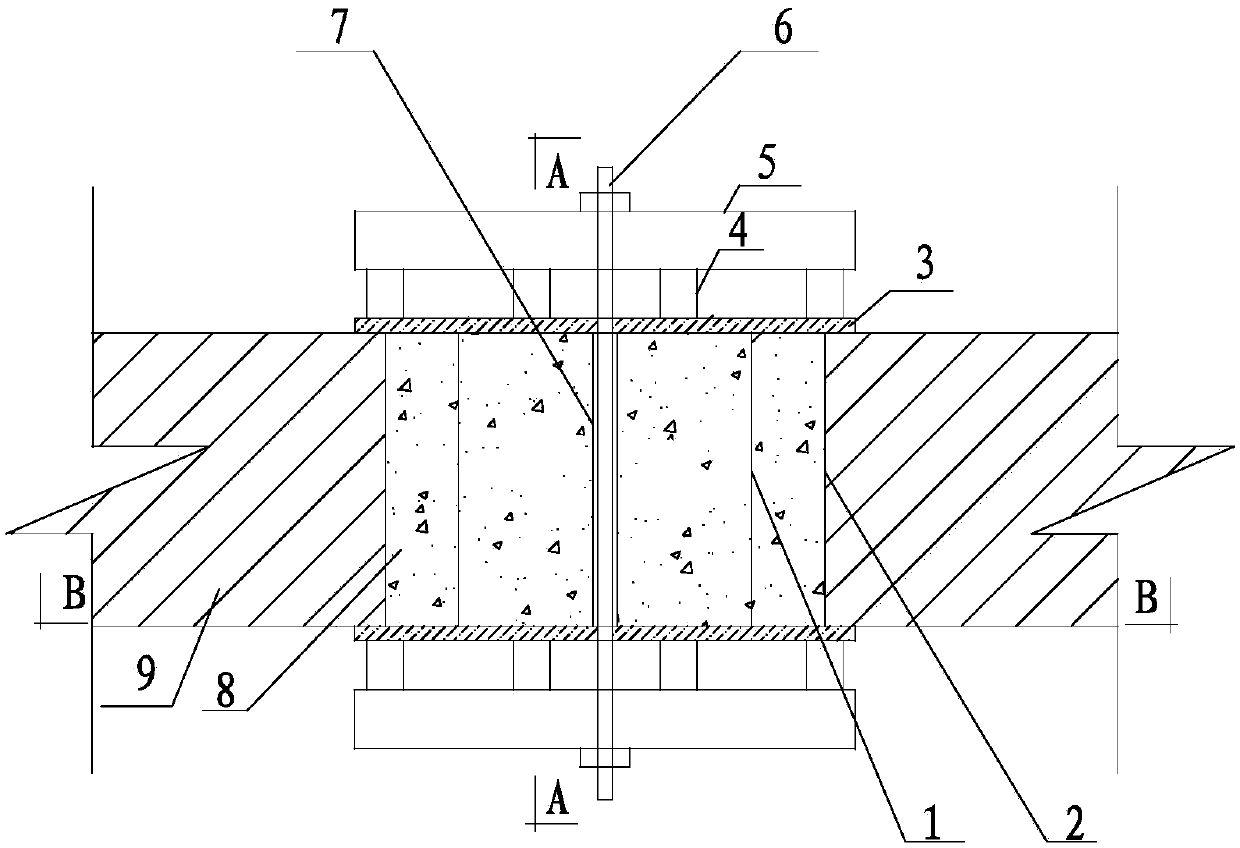

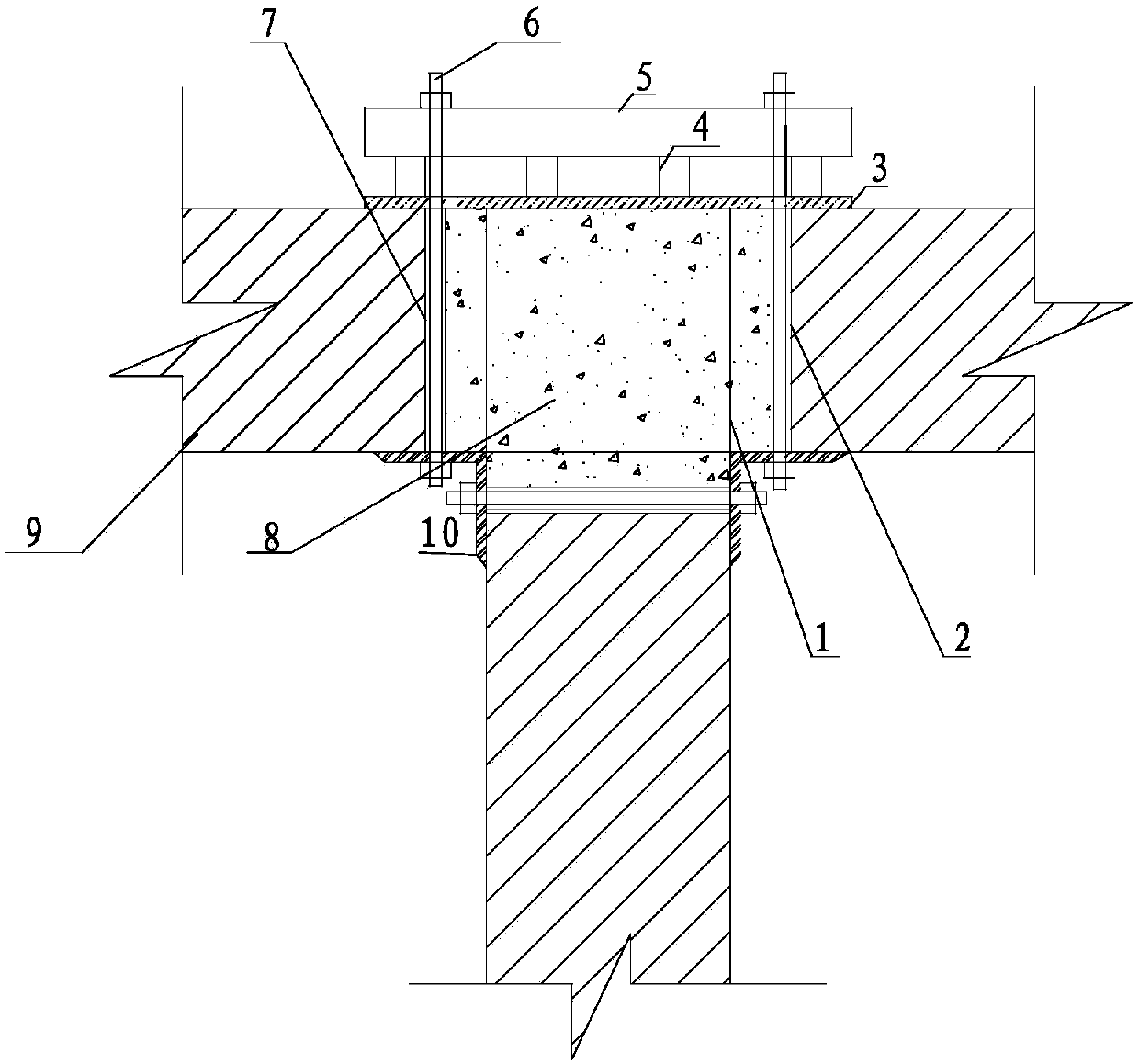

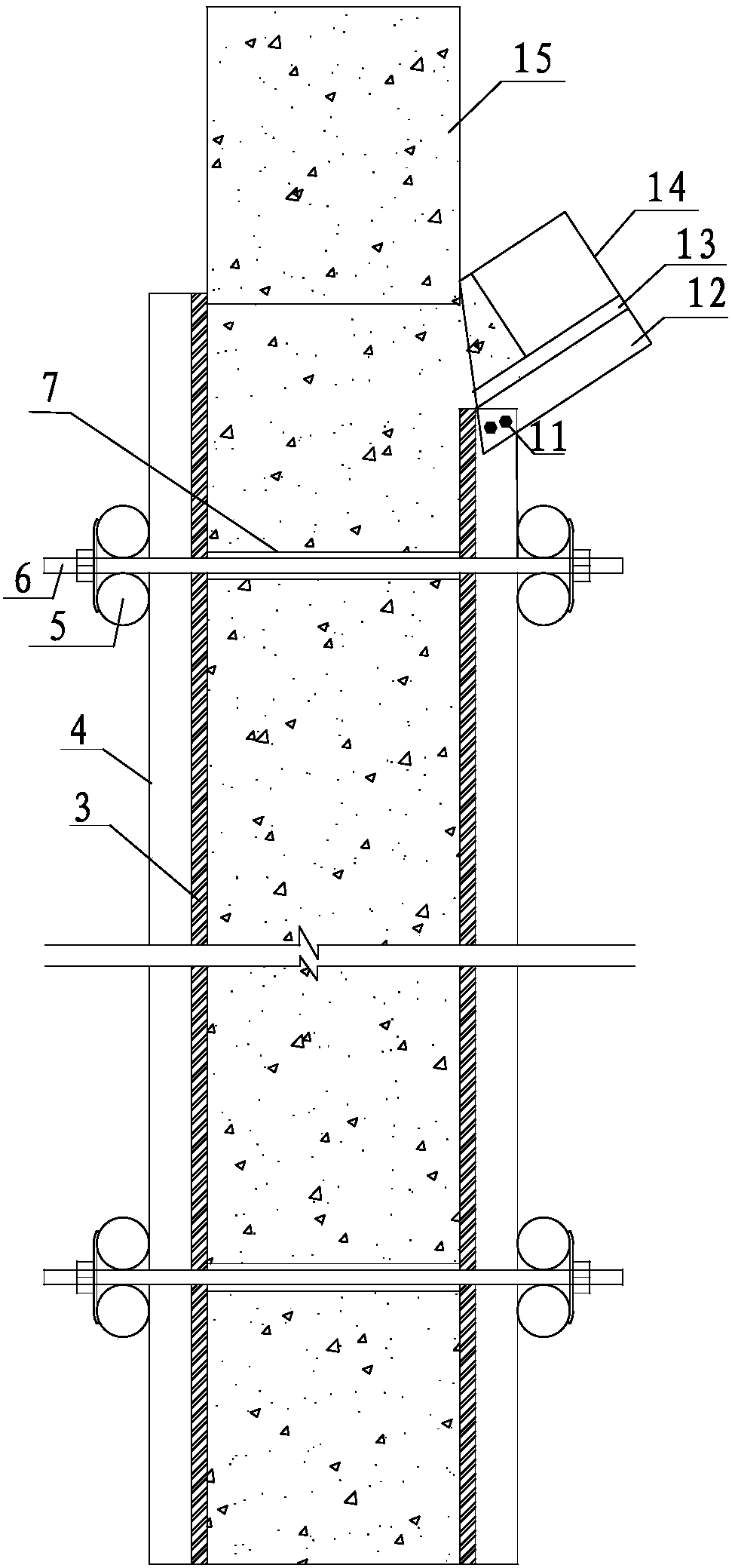

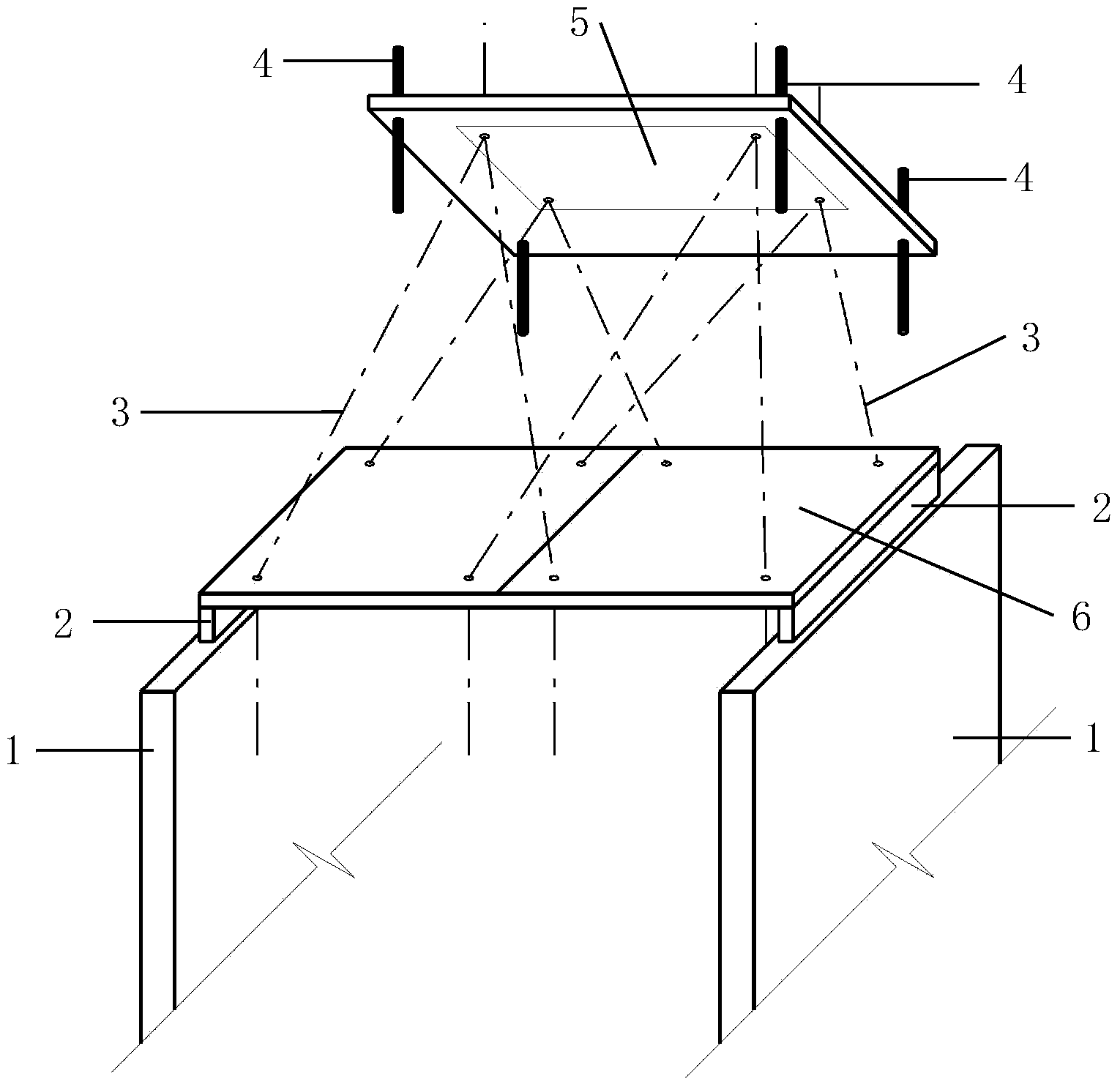

Design checking and construction method for infilled wall structural column formwork

ActiveCN107700710AScientific computing modelReliable knotWallsForms/shuttering/falseworksStructural engineeringEngineering

The invention provides a design checking and construction method for an infilled wall structural column formwork. The design checking and construction method is characterized in that the design checking and construction method takes the following steps that 1, design checking of a T-shaped infilled wall structural column formwork is conducted; 2, design checking of a linear-shaped infilled wall structural column formwork is conducted; 3, a structural column fabricated formwork is made; 4, a T-shaped infilled wall structural column internal corner formwork is made; 5, main edges of the linear-shaped infilled wall structural column formwork and the T-shaped infilled wall structural column formwork are made; 6, split bolts of the linear-shaped infilled wall structural column formwork and theT-shaped infilled wall structural column formwork are made; 7, casing pipes of the split bolts are made; 8, a discharging hopper is made; 9, adhesive tapes are pasted on the outer edge of a stubble; 10, the linear-shaped infilled wall structural column formwork is mounted; 11, the T-shaped infilled wall structural column formwork is mounted; 12; the structural column formworks are corrected and fixed; 13, the discharging hopper is mounted; 14; concrete is poured; 15, protruding concrete on the top of a structural column is removed; and 16, holes of the casing pipes of the split bolts are sealed and plugged.

Owner:SHANDONG WANXIN CONSTR

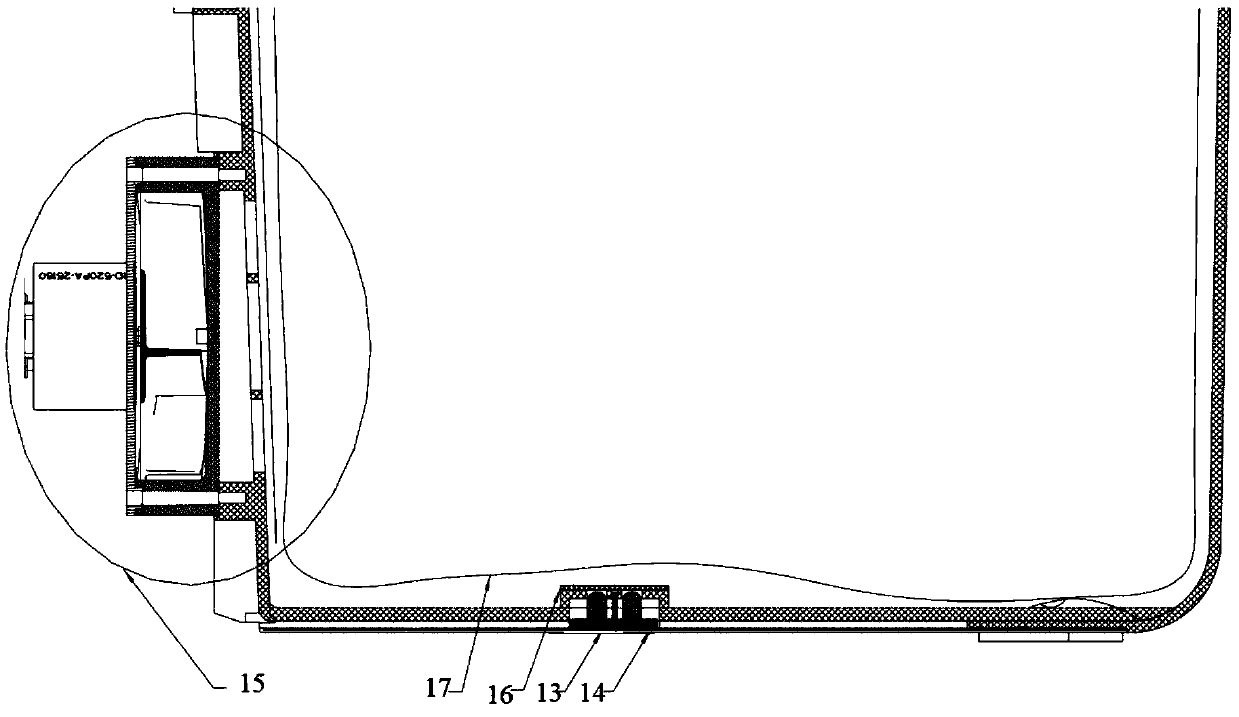

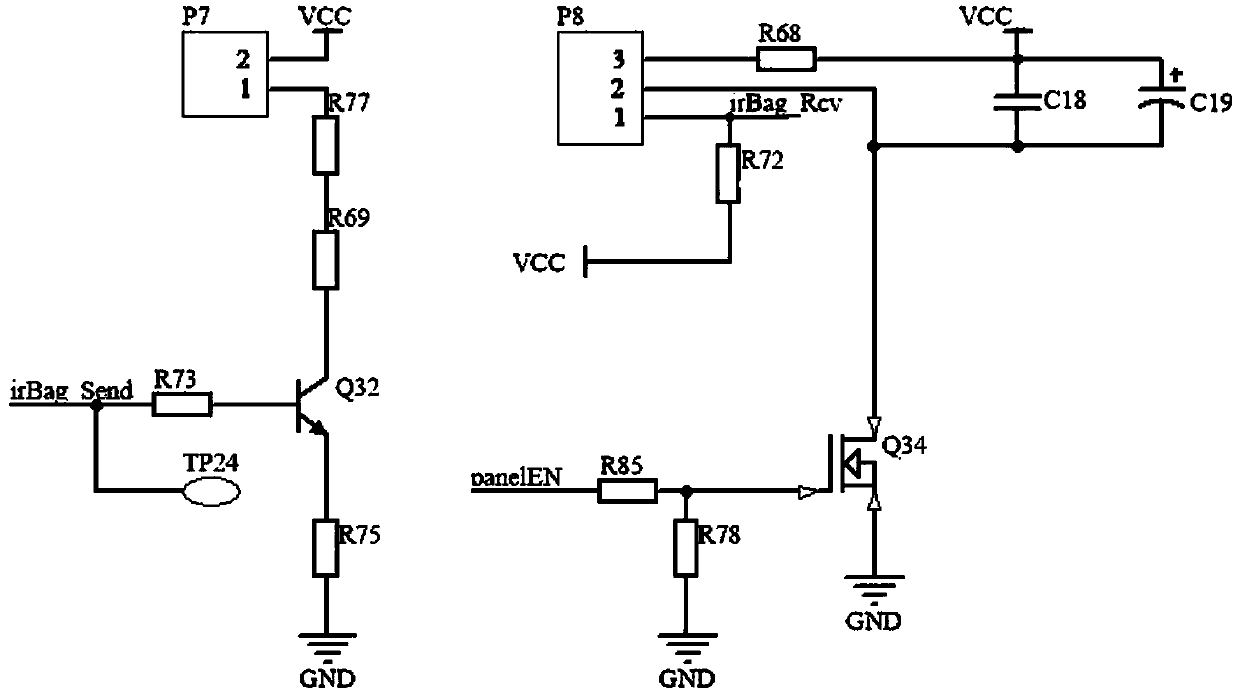

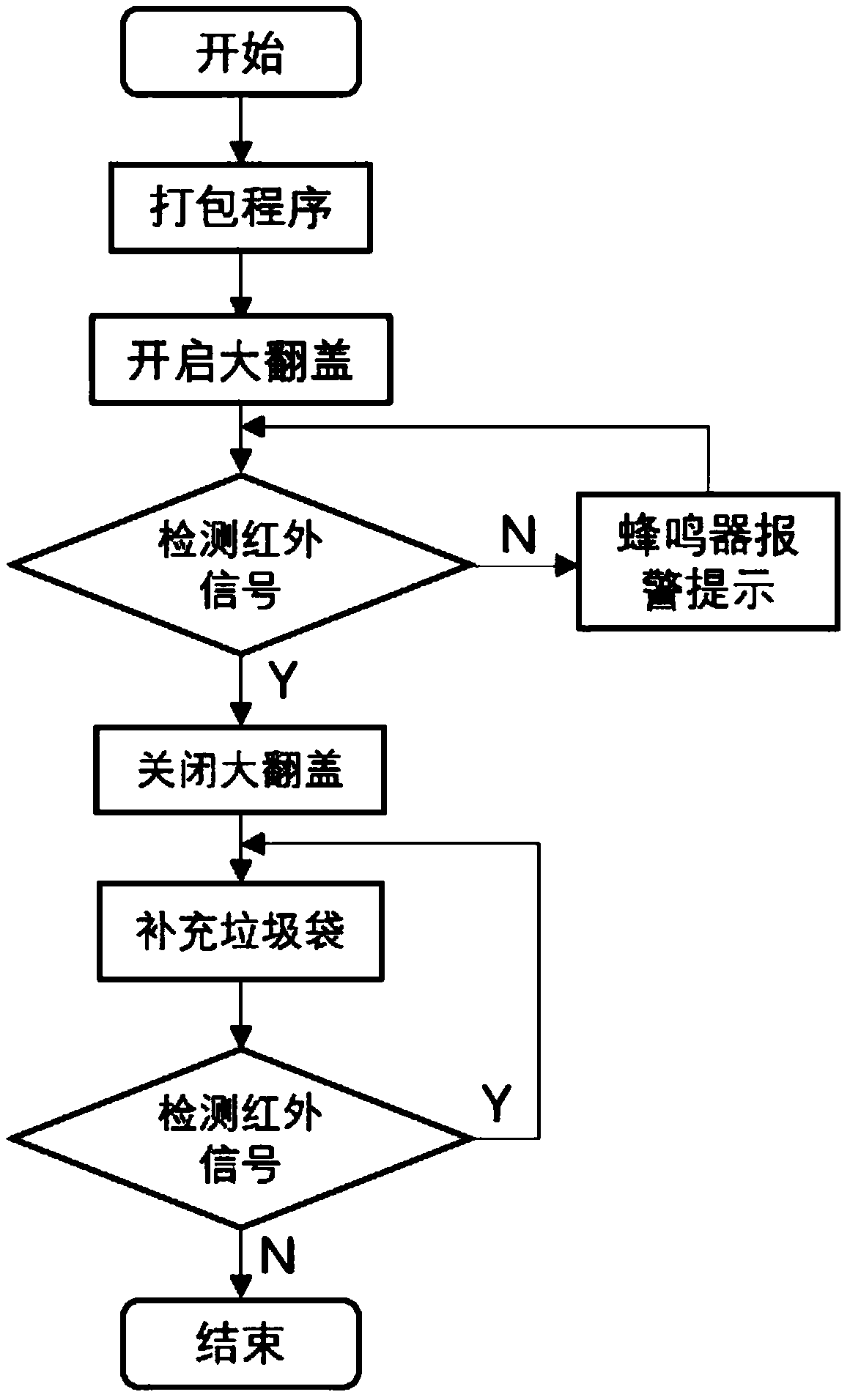

Garbage bag detection device, intelligent garbage can and automatic bag replacing control method

Owner:SHANGHAI TOWNEW INTELLIGENT TECH CO LTD

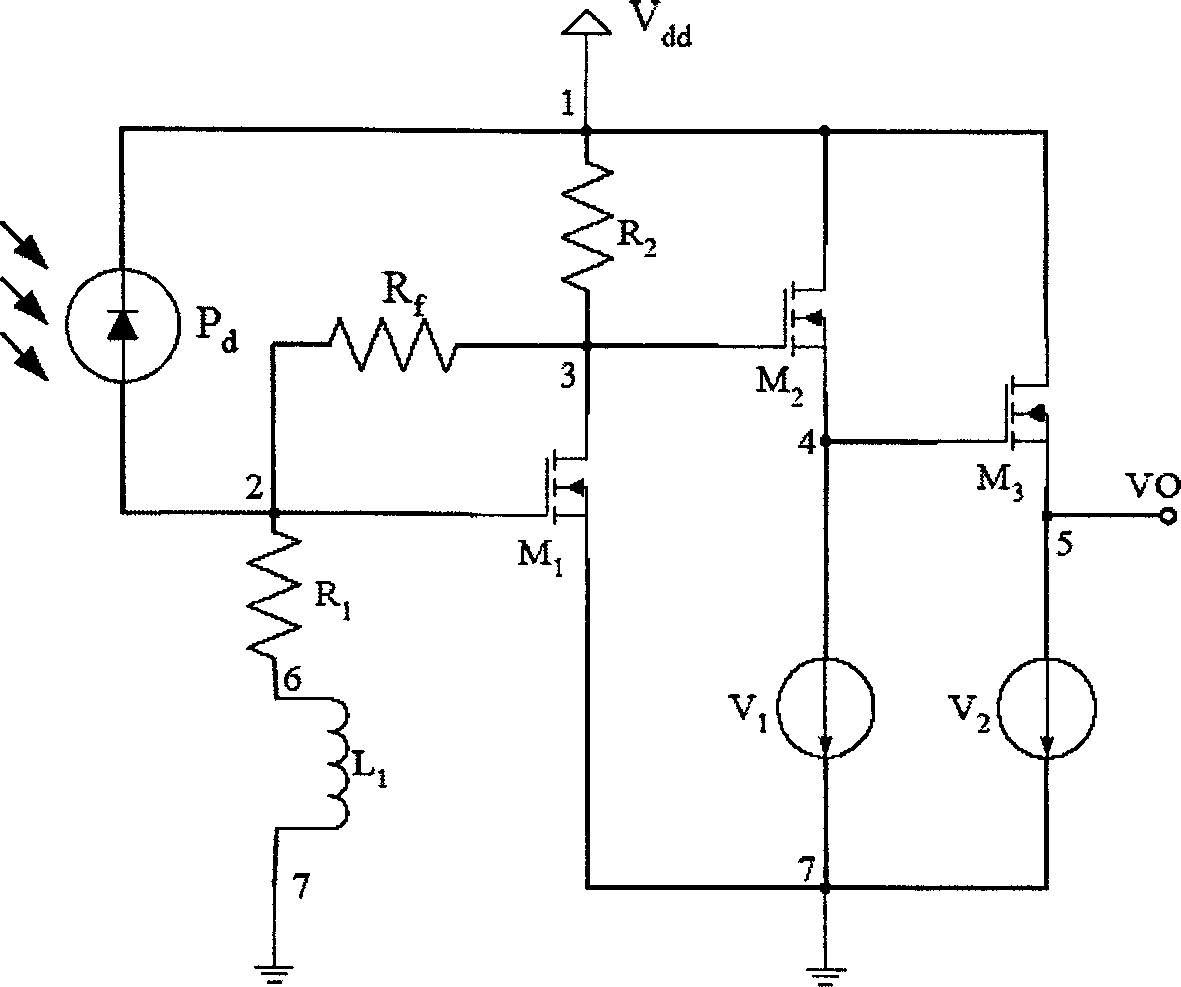

CMOS photoelectric integrated receiver with pre-equalizing circuit

InactiveCN1741278AHigh bandwidthHigh sensitivitySolid-state devicesElectromagnetic receiversCMOSElectrical resistance and conductance

A CMOS photoelectric integrated receiver with front equalizer consists of photo-electric converting component ; front equalizing circuit including buffer resistance , resonant inductance , junction capacity of photoelectric detector and input capacity of preamplifier ; and preamplifier . It is featured as connecting series circuit formed by buffer resistance and resonant inductance to place between input end and earthening end of preamplifier , forming a parallel resonant circuit by connecting said series circuit and junction capacity of silicon photoelectric detector as well as input capacity of preamplifier in parallel.

Owner:TIANJIN UNIV

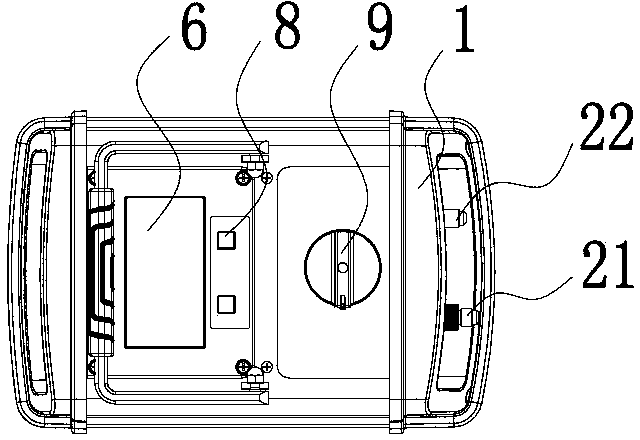

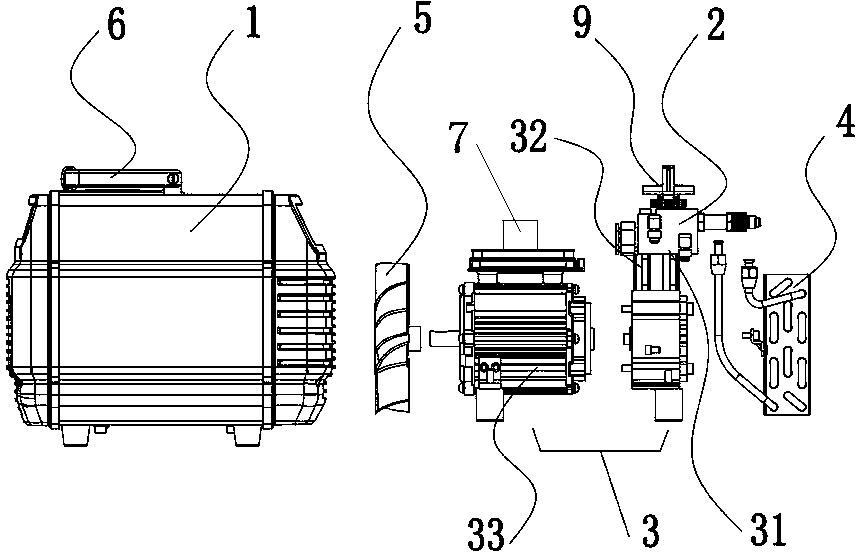

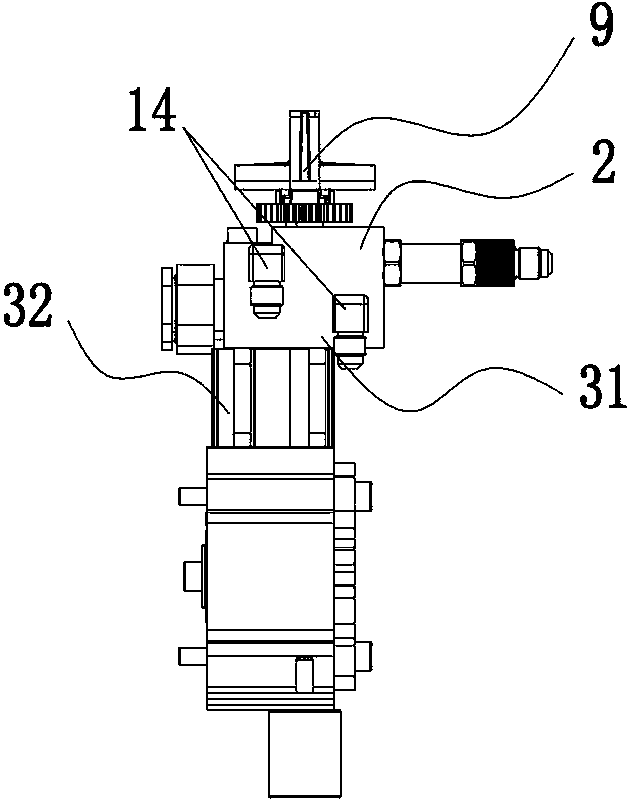

Portable low-leakage refrigerant recycling machine

ActiveCN103983057ACompact spaceReasonable layoutRefrigeration componentsProcess engineeringControl valves

The invention discloses a refrigerant recycling machine, and provides a portable low-leakage refrigerant recycling machine which is compact in structure, fewer in leak points, low in cost and high in quality and performance stability, which solves the technical problems of the prior art that the connection pipeline is easy to leak, the purchase cost and the assembling cost are high, the overall size is large, and the like. The portable low-leakage refrigerant recycling machine comprises a shell and a compressor which is arranged in the shell, wherein one end of the compressor is provided with a fan, the other end of the compressor is provided with a condenser, an air cylinder cover of the compressor extends to be provided with an integrated control valve, the integrated control valve is provided with a condenser pipeline interface which is in butt joint with the condenser as well as an input interface and an output interface extending out of the shell, a plurality of inner pipeline passages are arranged in the integrated control valve, and the input interface and the output interface are communicated with an air cylinder of the compressor and the condenser through the inner pipeline passages.

Owner:ZHEJIANG VALUE MECHANICAL & ELECTRICAL PROD CO LTD

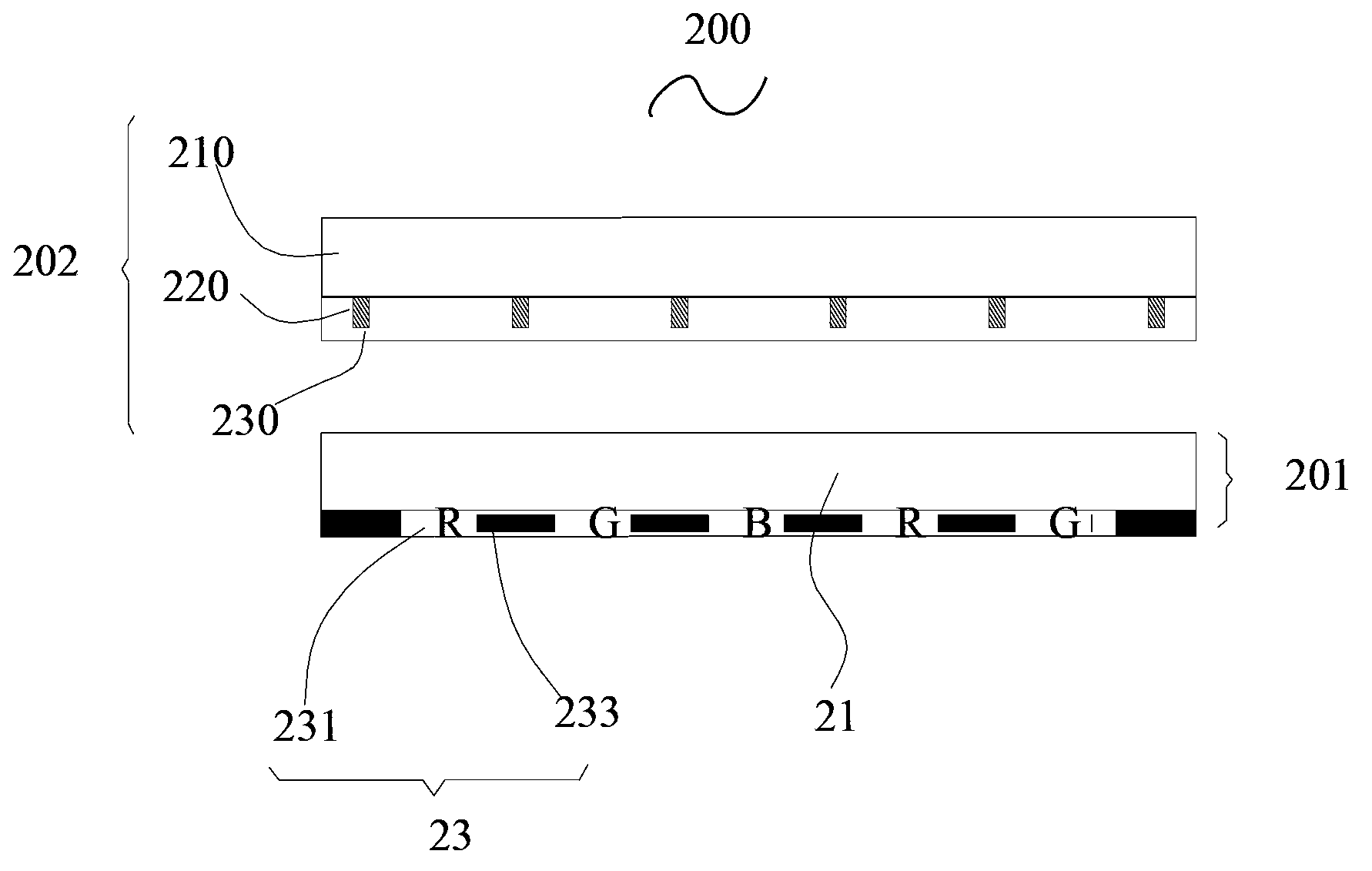

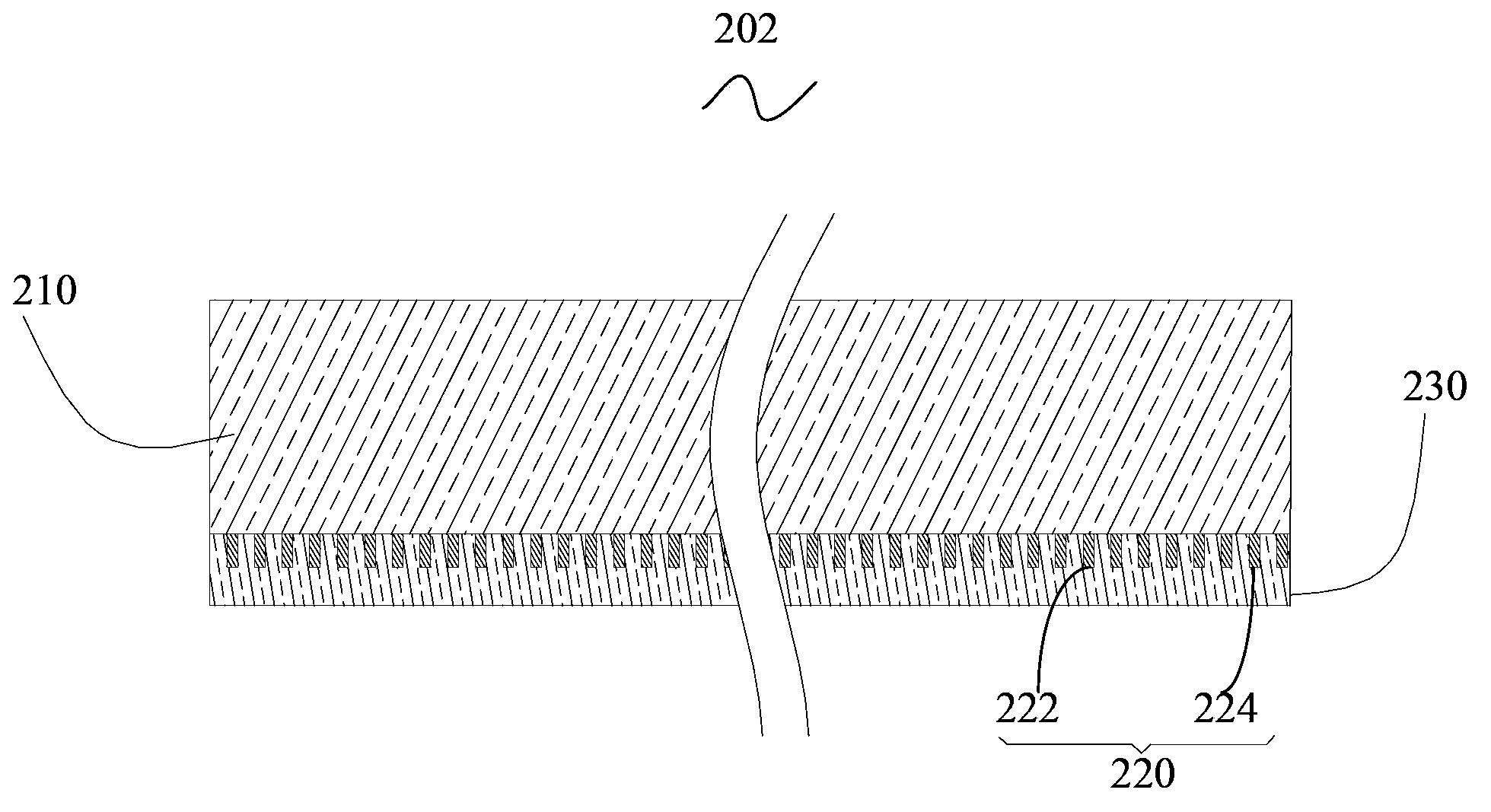

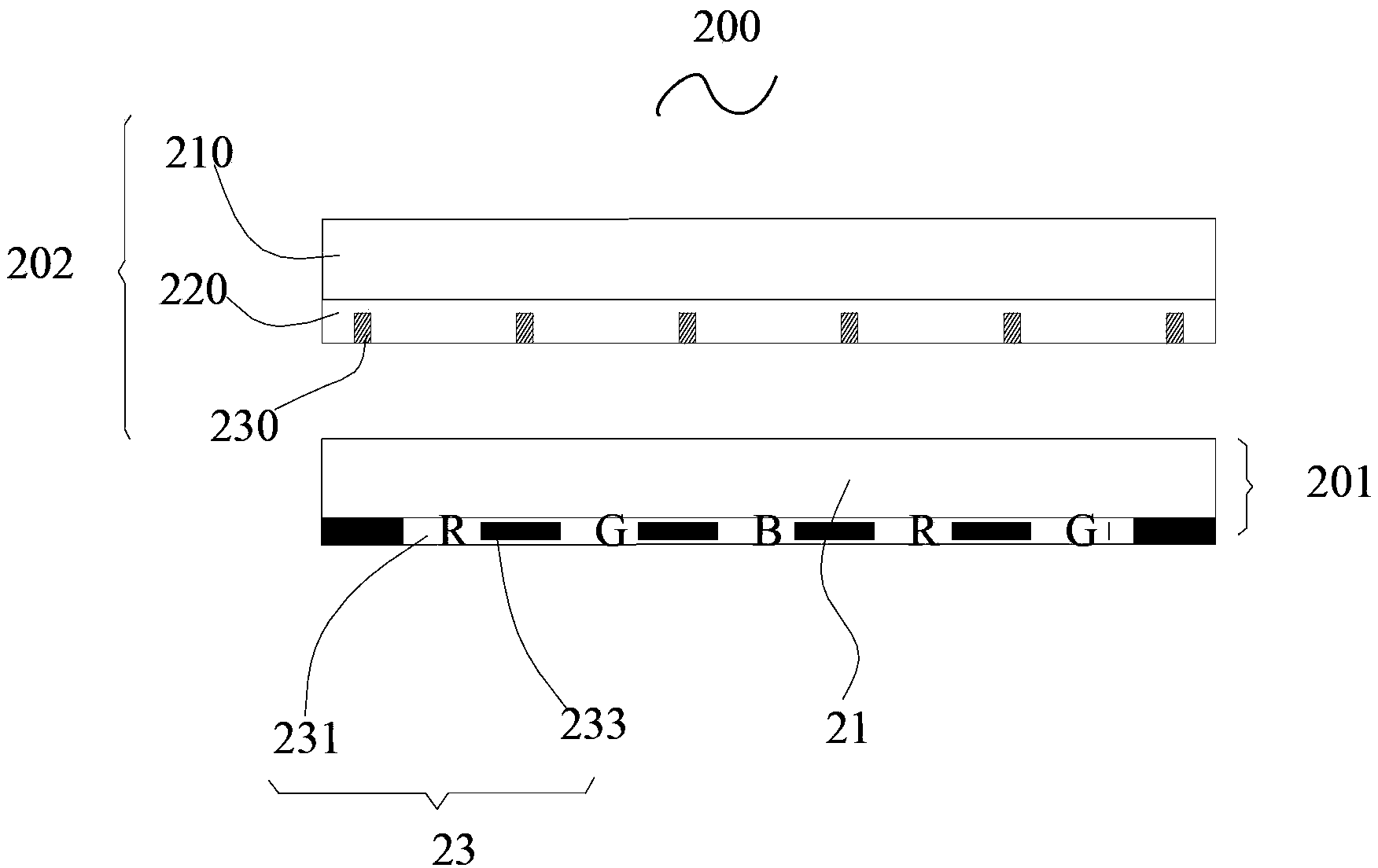

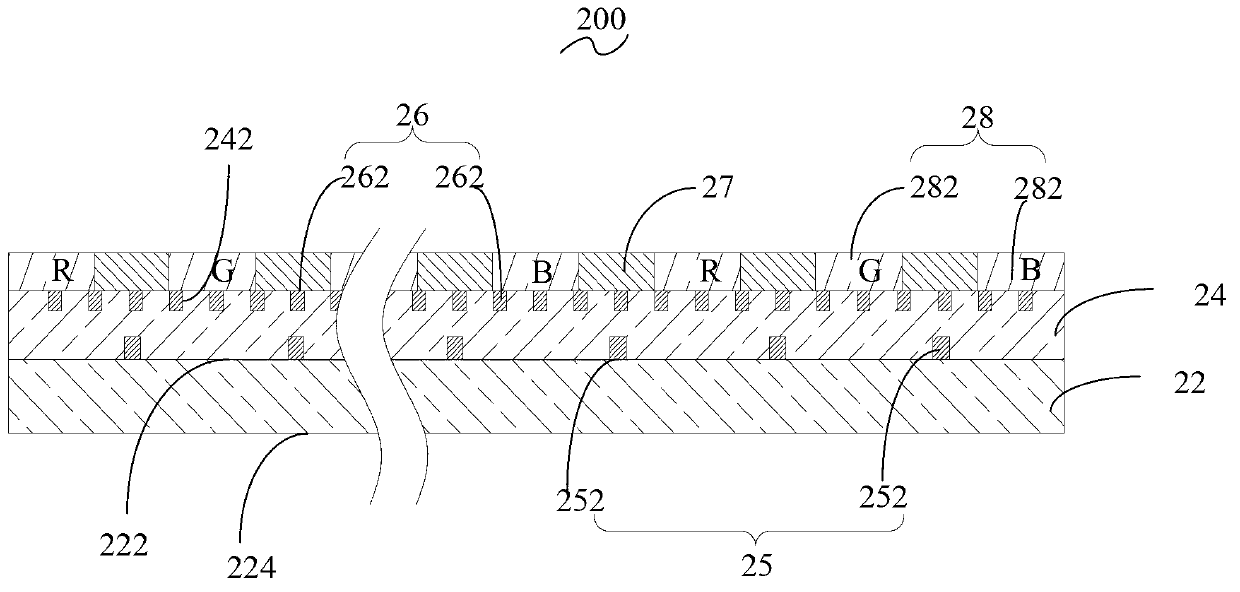

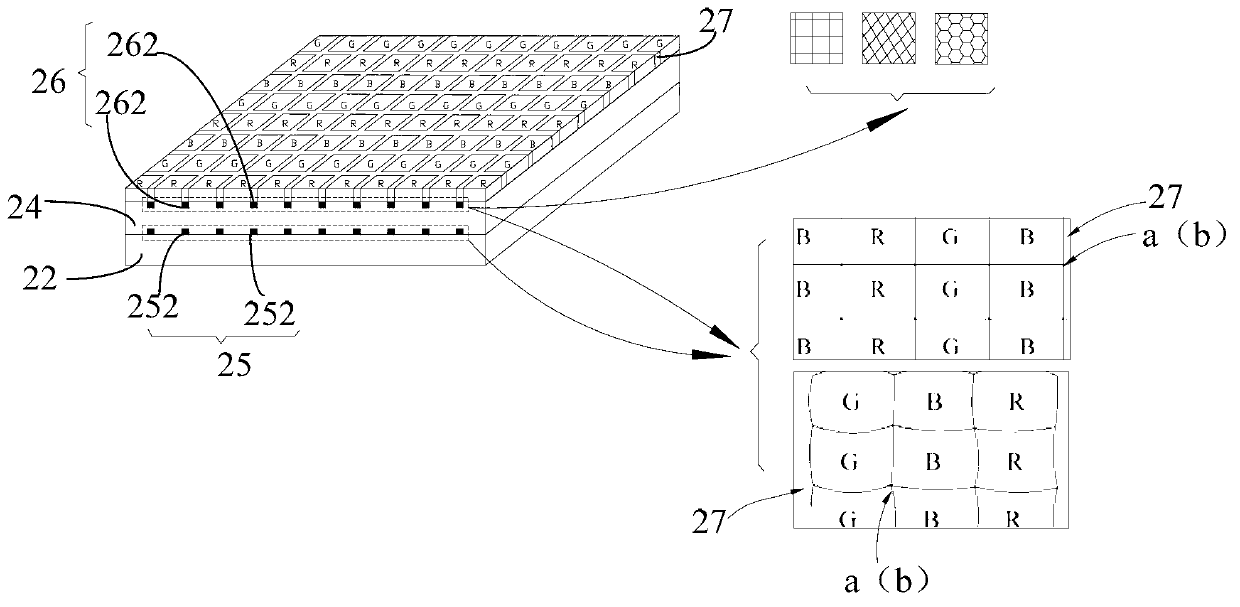

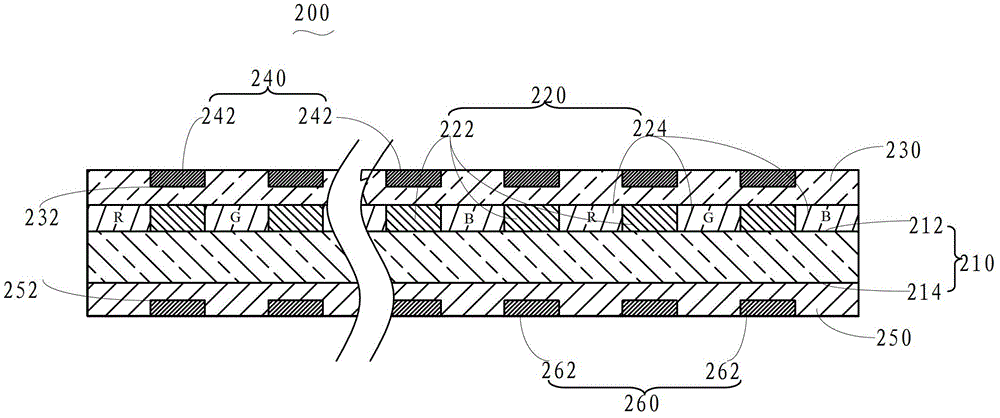

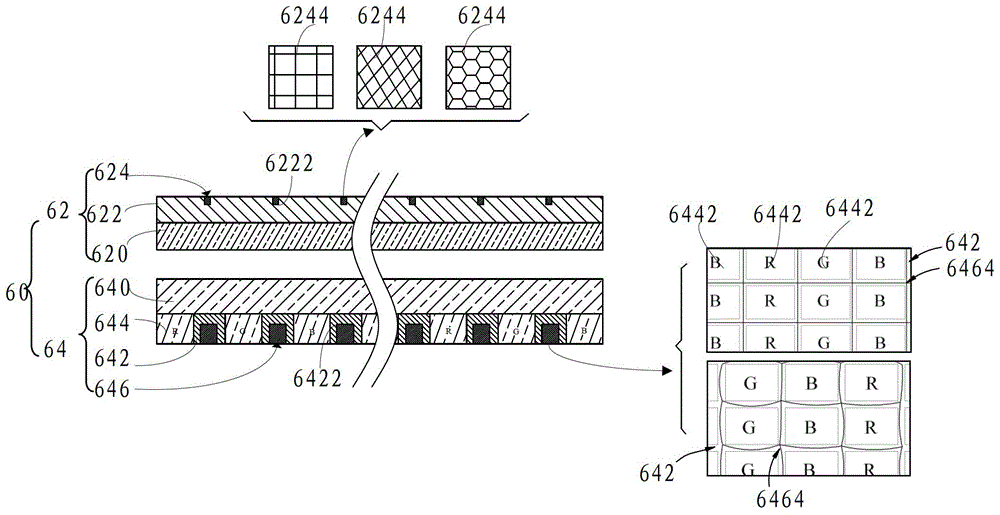

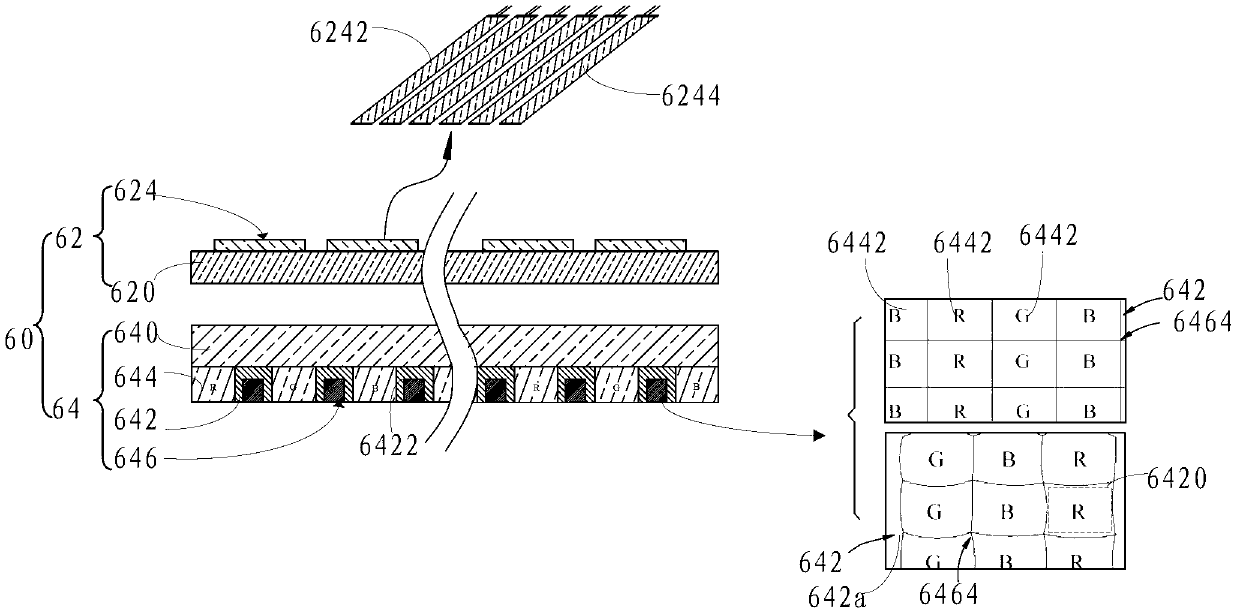

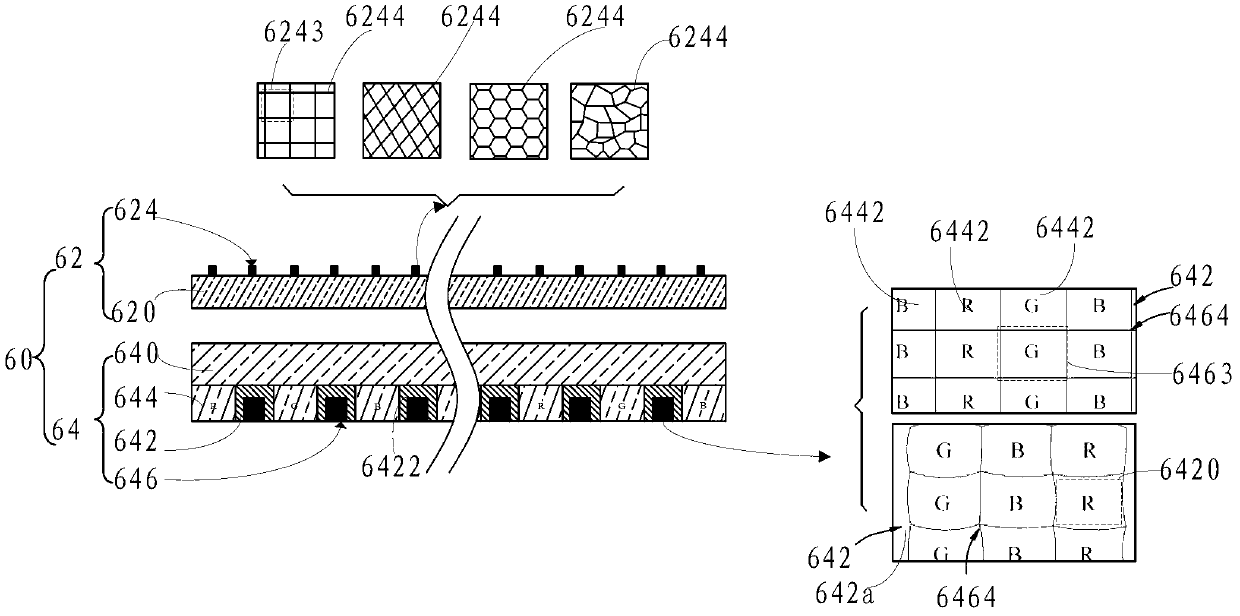

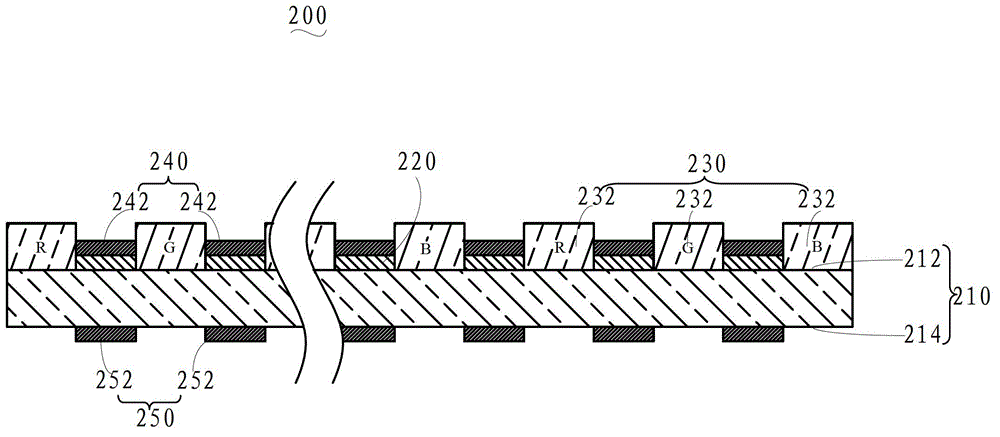

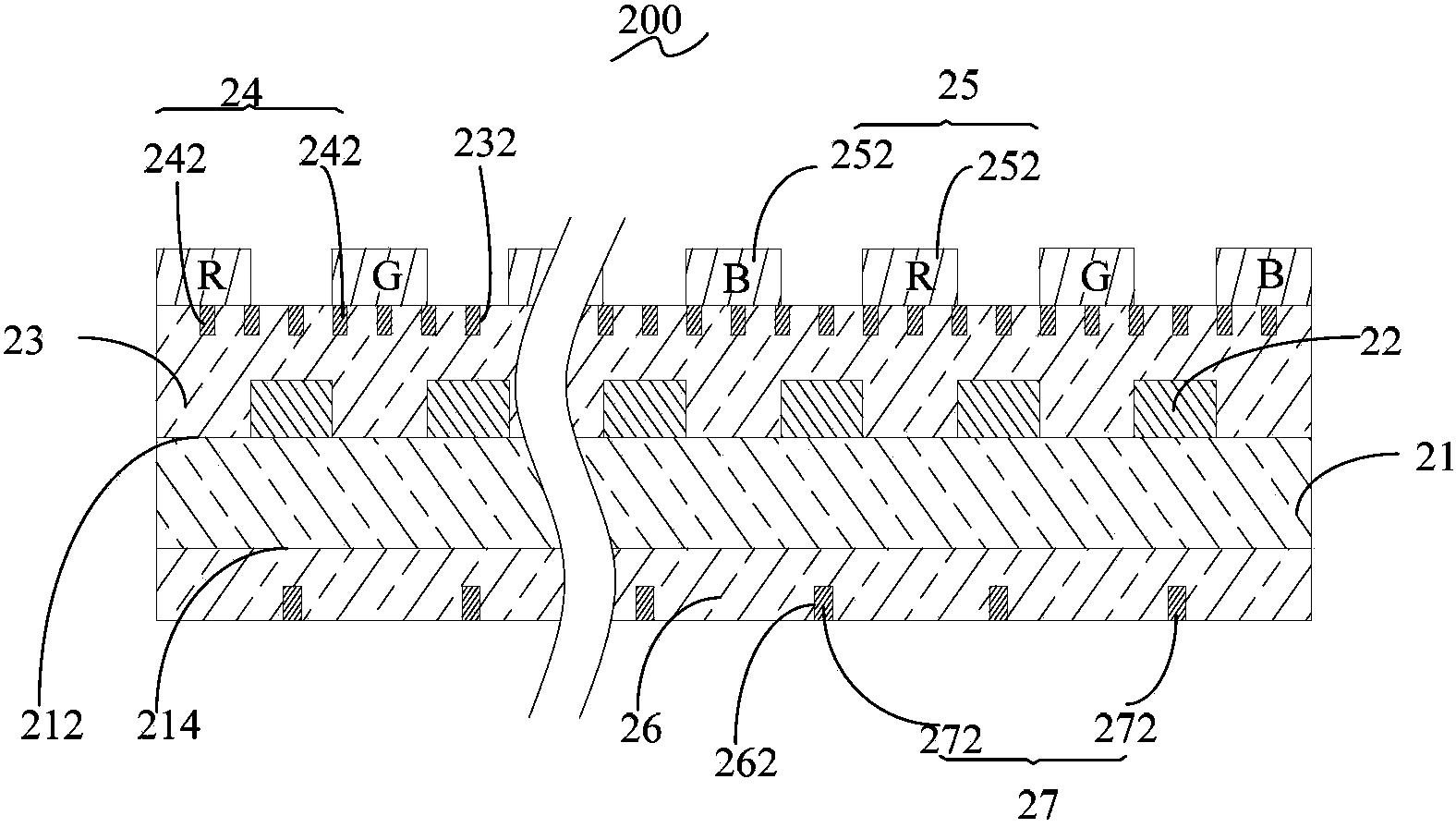

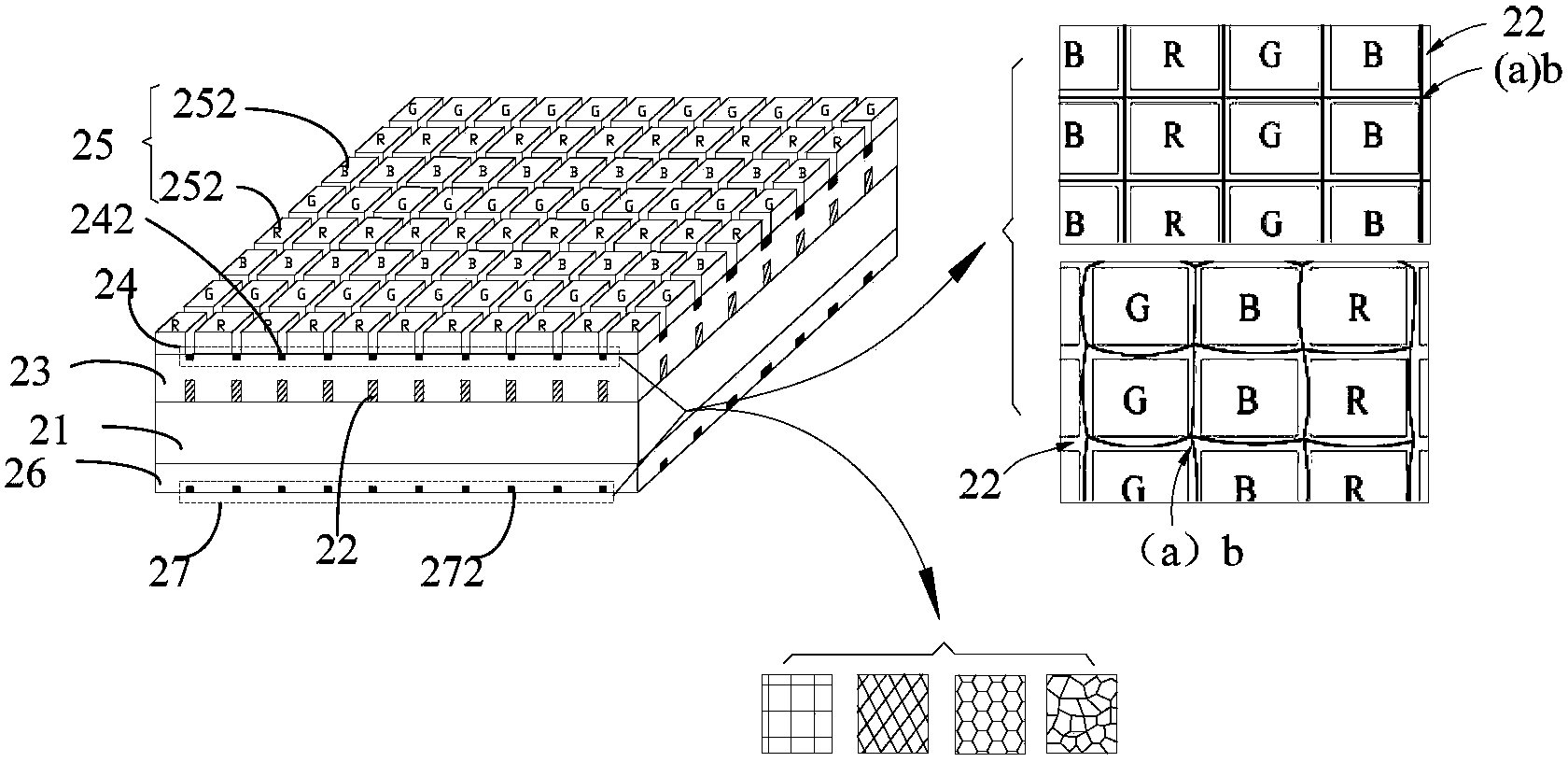

Light polarization and filtration module and touch display screen

InactiveCN103425324AEasy to operateRealize functionOptical filtersPolarising elementsResistCross connection

A light polarization and filtration module comprises a light filter module, a polarizing sheet module, a conducting layer and a protective adhesive layer. The light filter module comprises a bearing substrate, a shading matrix and color light resists scattered in the shading matrix, and the shading matrix comprises grid lines formed by shading materials; the polarizing sheet module comprises a polarizing sheet substrate; the conducting layer is arranged on the polarizing sheet substrate and comprises first conducting patterns and second conducting patterns, the first conducting patterns and the second conducting patterns are arranged at intervals in the extension direction of the polarizing sheet substrate and comprise conducting grids formed by cross connection of conducting silk threads, and projection shadows of the conducting silk threads on the shading matrix drop on the grid lines of the shading matrix; the protective adhesive layer is coated on the conducting layer. According to the light polarization and filtration module, the touch operation and the polarized light emergency function can be achieved simultaneously, the module has a touch function when used in a display screen, a touch screen is not required to be assembled, the electronic product thickness is reduced, and costs are saved. The invention further provides a touch display screen.

Owner:NANCHANG O FILM TECH CO LTD

Light polarization and filtration module and touch display screen

ActiveCN103425322AEasy to operateRealize functionOptical filtersPolarising elementsResistCross connection

A light polarization and filtration module comprises a light filter module, a polarizing sheet module, a protective adhesive layer and a conducting layer. The light filter module comprises a bearing substrate, a shading matrix and color light resists scattered in the shading matrix, and the shading matrix comprises grid lines formed by shading materials; the polarizing sheet module comprises a polarizing sheet substrate; the protective adhesive layer is arranged on the polarizing sheet substrate; the conducting layer is embedded on the protective adhesive layer and comprises first conducting patterns and second conducting patterns, the first conducting patterns and the second conducting patterns are arranged at intervals in the extension direction of the protective adhesive layer and comprise conducting grids formed by cross connection of conducting silk threads, and projection shadows of the conducting silk threads on the shading matrix drop on the grid lines of the shading matrix. According to the light polarization and filtration module, the touch operation and the polarized light emergency function can be achieved simultaneously, a touch screen is not required to be assembled when the module is used in a display screen, the electronic product thickness is reduced, and costs are saved.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

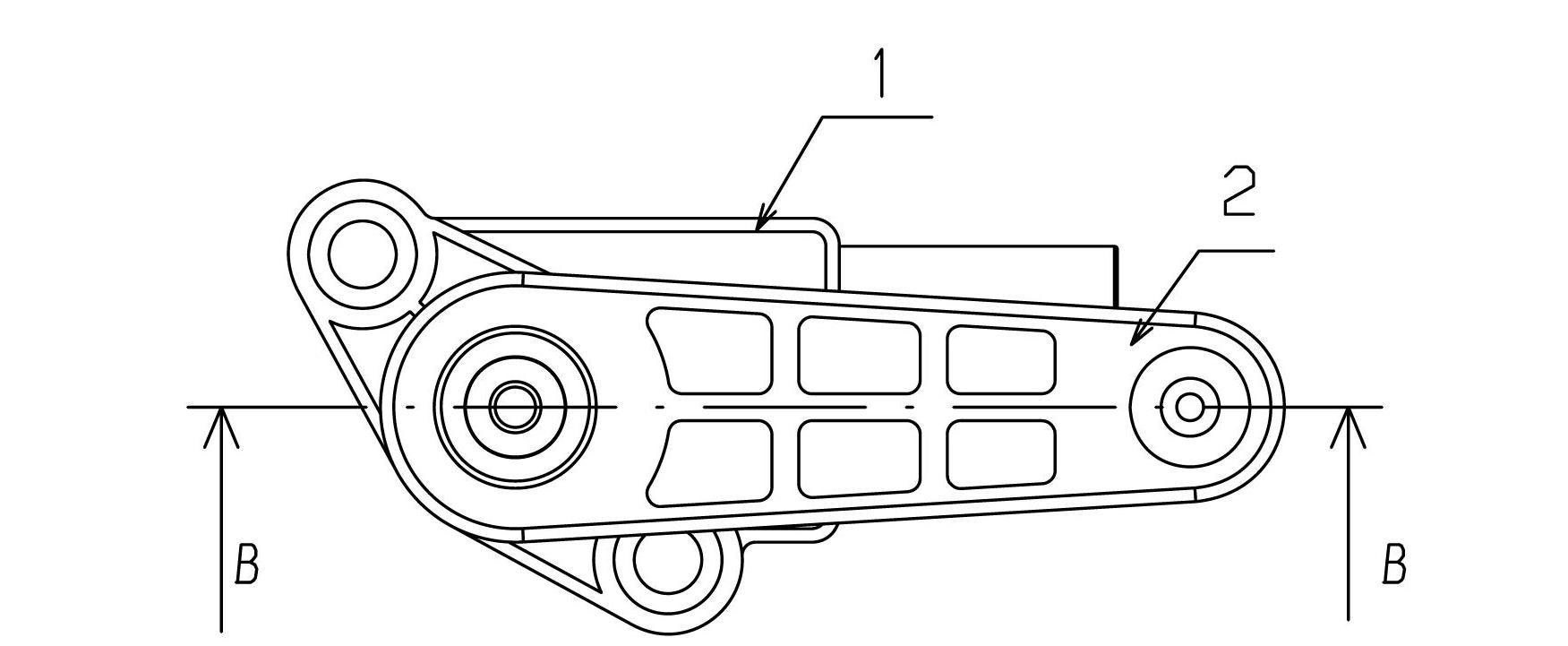

Vehicle chassis height sensor

InactiveCN102645153AReduce production processSimplify the assembly processUsing electrical meansElectricityInjection moulding

A vehicle chassis height sensor relates to a vehicle chassis height detecting device which is characterized by utilizing an electric or magnetic method, and particularly relates to a hall type vehicle chassis height sensor used for vehicle light control. The vehicle chassis height sensor comprises a shell, a rotation unit, a swing arm unit and a hall sensing unit, wherein the rotation unit includes a rotary shaft and a magnetic steel, a first cavity and a second cavity are arranged on the lower portion of the shell, the magnetic steel is placed in the first cavity, a hall chip is flatly posted on a circuit board, close to and aligned to the magnetic steel, the circuit board is fixed in the second cavity through sealing fillers, and the swing arm unit is in an integrated structure by an entire injection molding. A stator portion is omitted, under the condition that the detecting function and accuracy of the sensor are maintained, the manufacturing cost of the sensor is reduced, by means of a swing arm ball stud structure which utilizes curable fillers to perform a sealing perfusion and an entire injection molding, disturbances of an application environment can be reduced, and influences of assembly errors to the accuracy can be reduced, so that the assembly process of the sensor is simple and rapid.

Owner:HASCO VISION TECHNOLOGY CO LTD

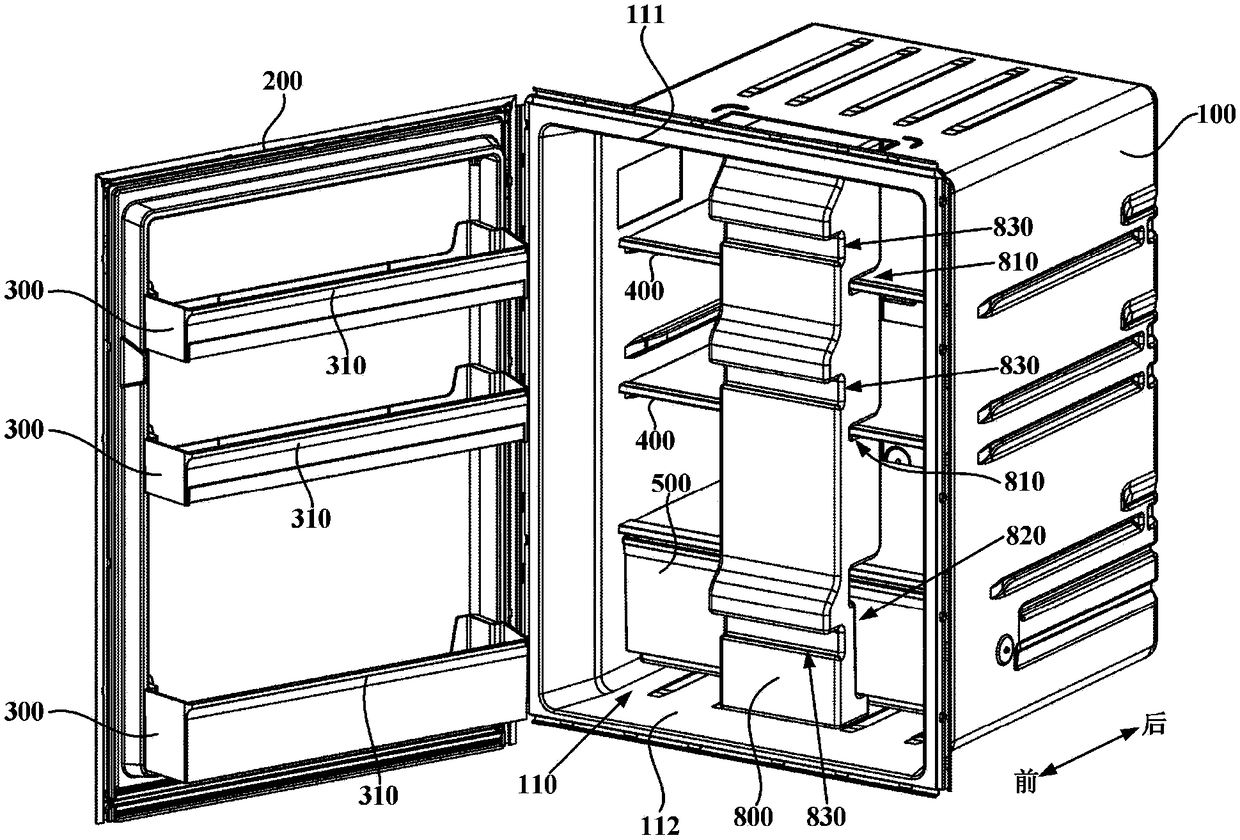

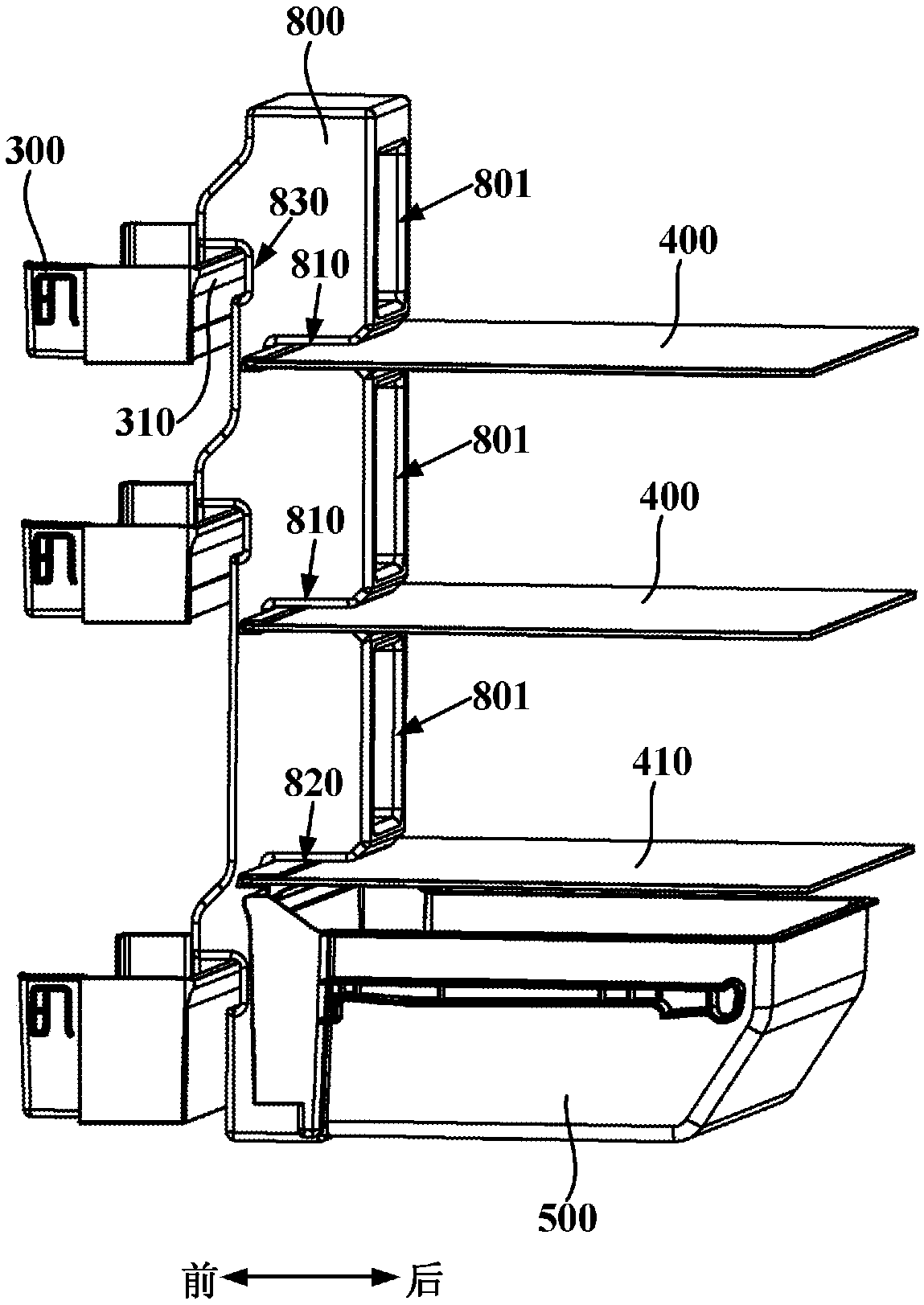

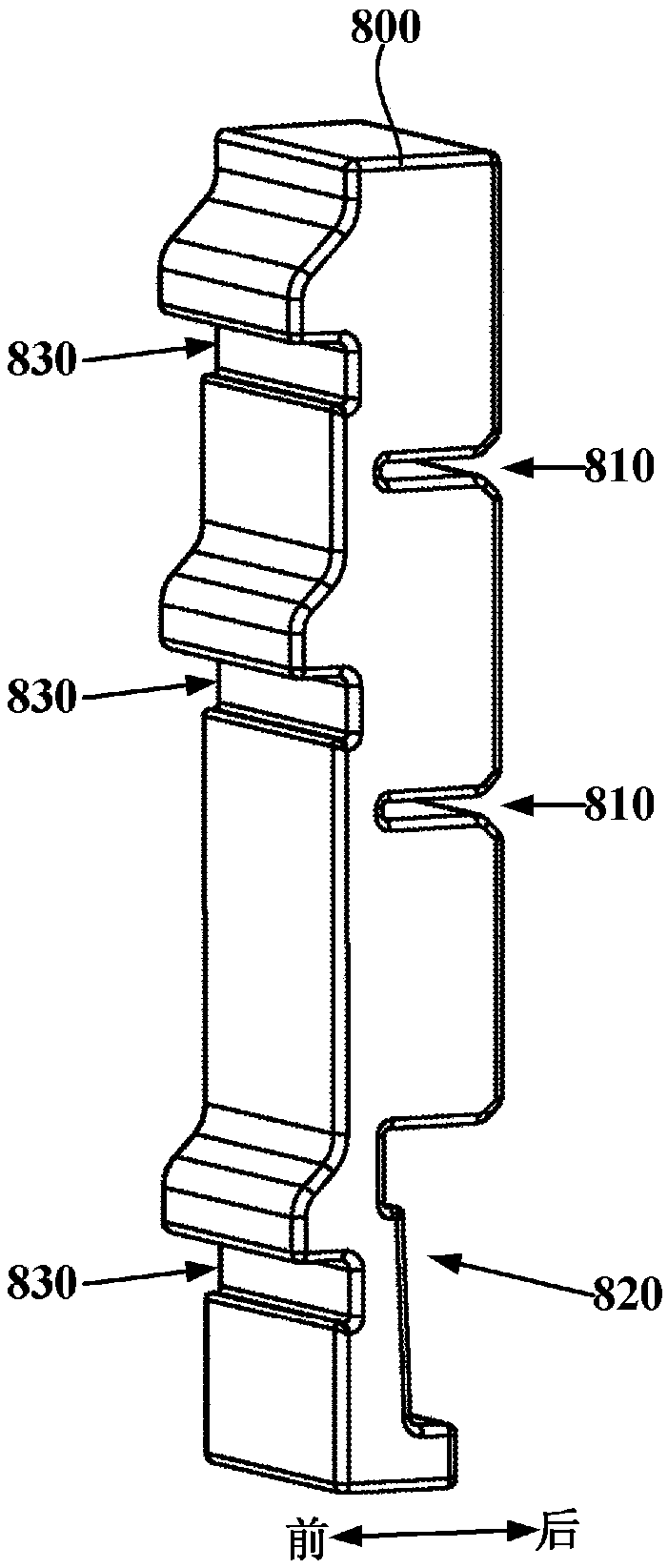

Fixing Frame for Refrigerator and the Interior Thereof

PendingCN108120220AEasy to operateRealize integrated fixationLighting and heating apparatusDomestic refrigeratorsFixed frameEngineering

Owner:HAIER SMART HOME CO LTD

Optical filter box and touch display screen

InactiveCN103345326AEasy to operateRealize functionOptical filtersNon-linear opticsWire widthEngineering

The invention relates to an optical filter box which comprises a glass substrate, a first conducting layer, an imprinting glue layer, a second conducting layer, a shading matrix layer and a color photoresist layer. The first conducting layer comprises first conducting patterns. The imprinting glue layer is arranged on the glass substrate. The second conducting layer comprises second conducting patterns, the second conducting patterns comprise continuous conducting grids, and the first conducting layer and the second conducting layer are arranged at intervals in the thickness direction of the imprinting glue layer to form a sensing structure. The wire width of one of a first conducting wire of the first conducting layer and a second conducting wire of the second conducting layer is 0.2-5micrometers, and projection of the other one on the shading matrix layer falls into the grids. The optical filter box can achieve touch operation and filtering, is beneficial to reducing the thickness of electronic equipment, and saves materials and assembly cost. The invention further provides a touch display screen.

Owner:NANCHANG O FILM TECH CO LTD

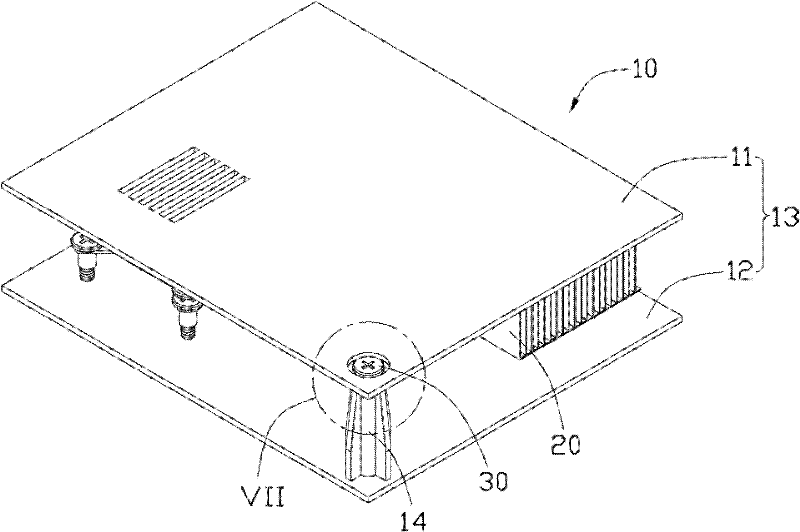

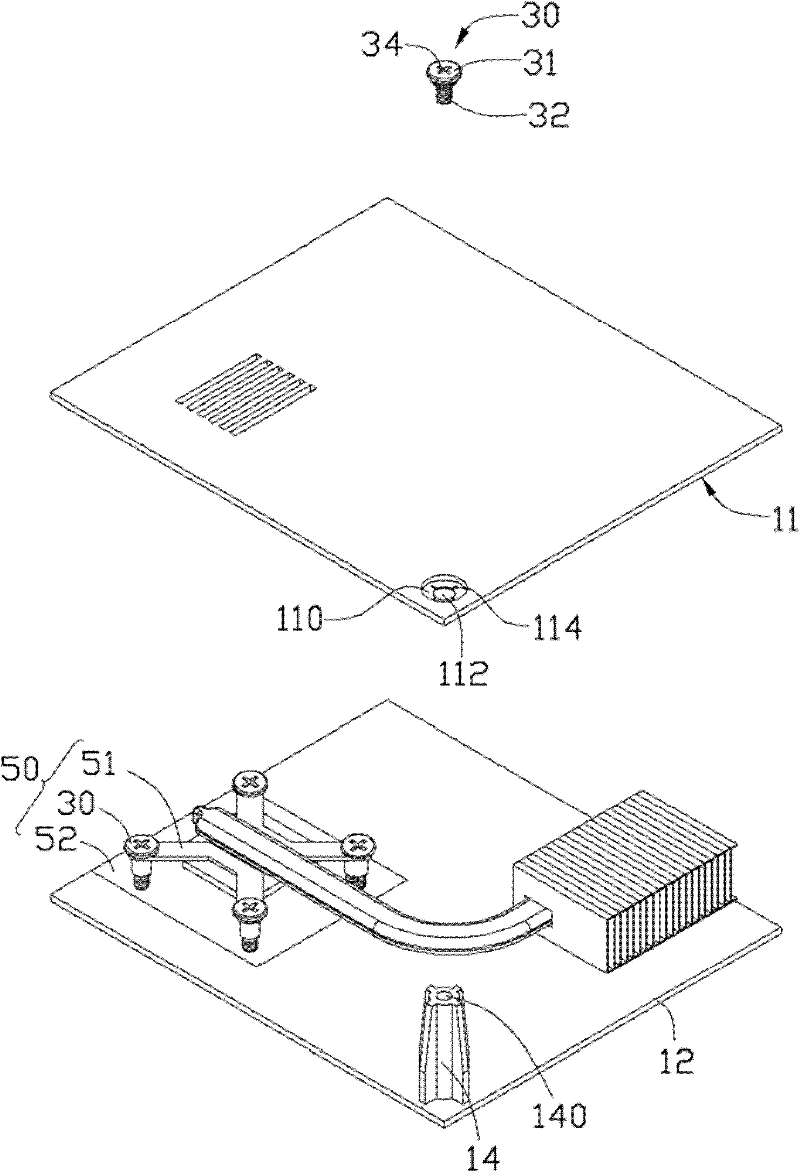

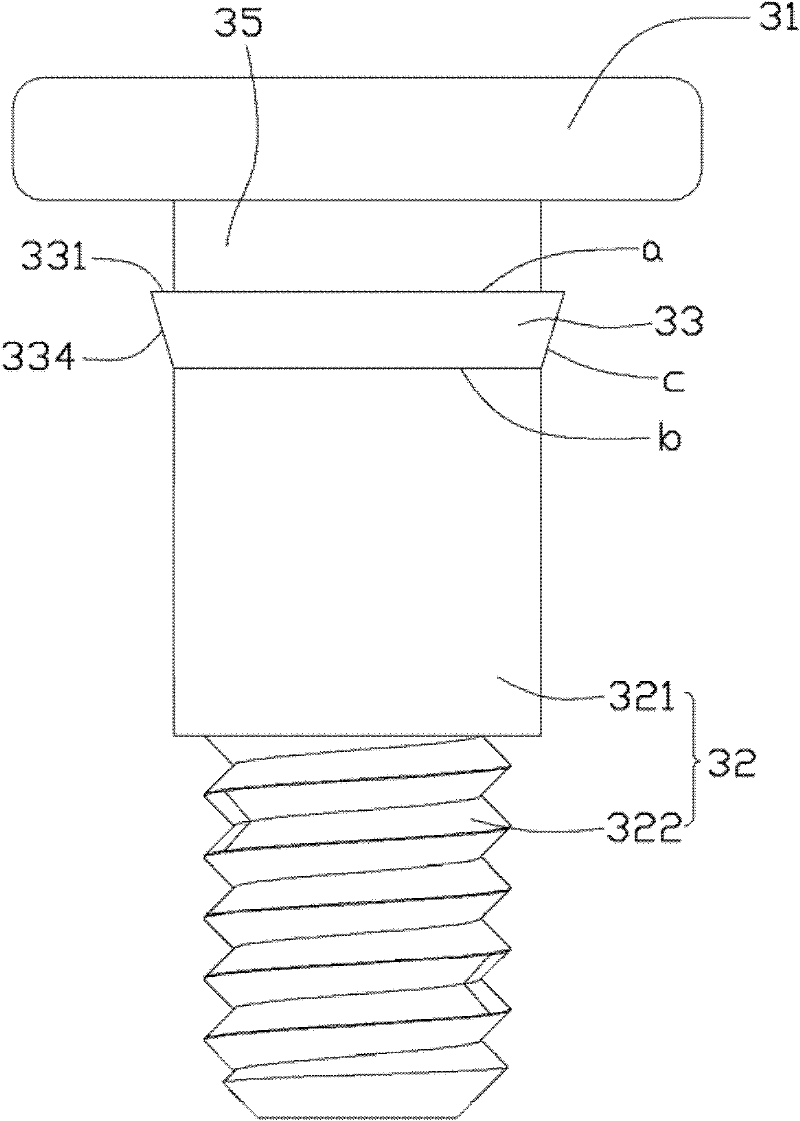

Fixed element and fixed device and electric device using fixed element

InactiveCN102192228ASave costsSave assembly costScrewsElectrical apparatus contructional detailsEngineeringNeck parts

The invention relates to a fixed element, which comprises a head part and a screw rod extending from the head part. A flange extending towards an external radial direction from an outer surface is formed at one end close to the head part of the screw rod; a neck part is arranged between the flange and the head part; and the external diameter of the flange is changed along the extending direction of the screw rod. Due to the arrangement of the flange, the fixed element is pre-assembled on an object without a gasket and other extra elements when the object is connected to another object by the fixed element, and the fixed element can be screwed with the another object during assembly. Therefore, the fixed element is convenient to install, and the material cost and the assembly cost are saved. The invention also provides a fixed device and an electric device applying the fixed element.

Owner:FURUI PRECISE COMPONENT (KUNSHAN) CO LTD +1

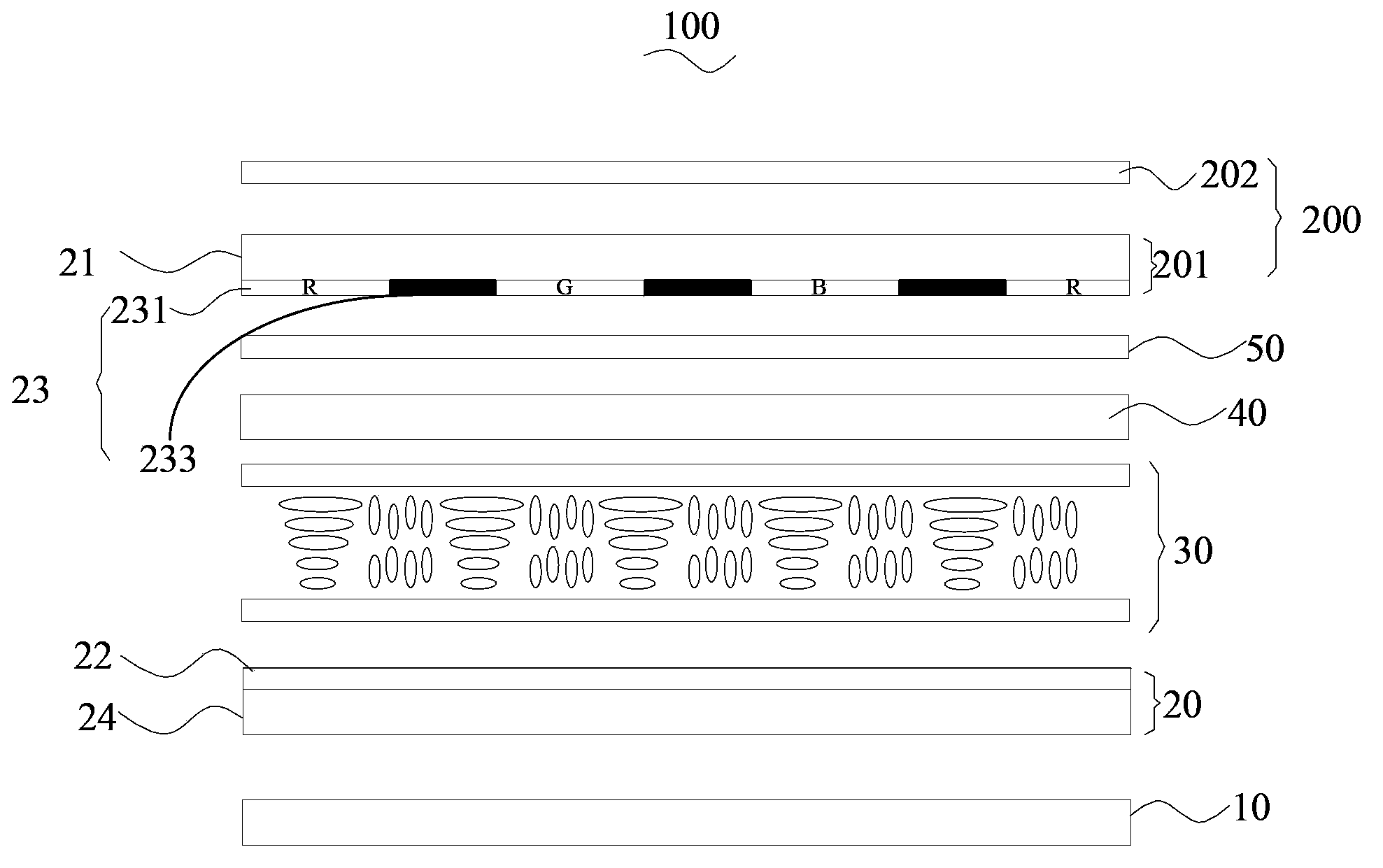

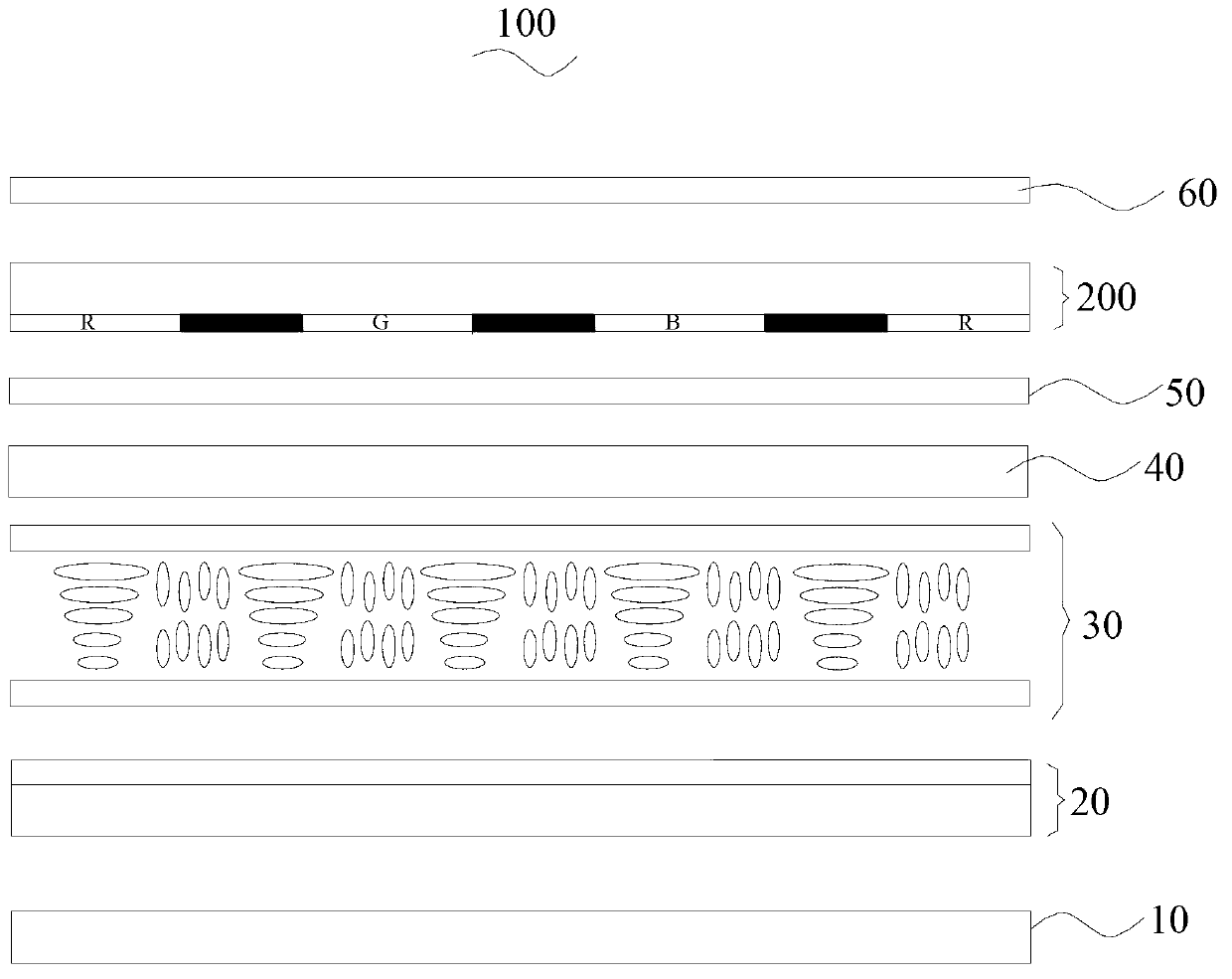

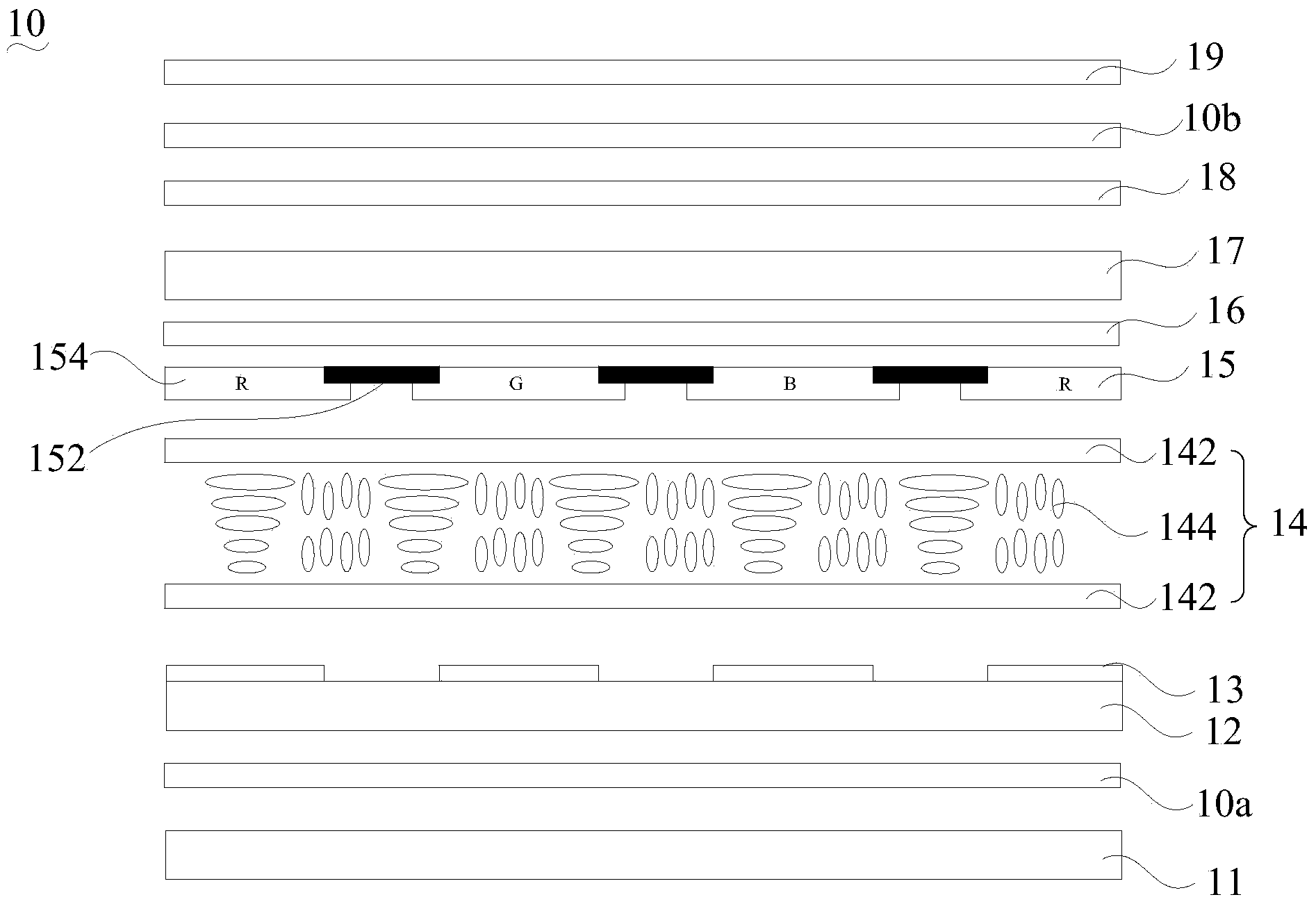

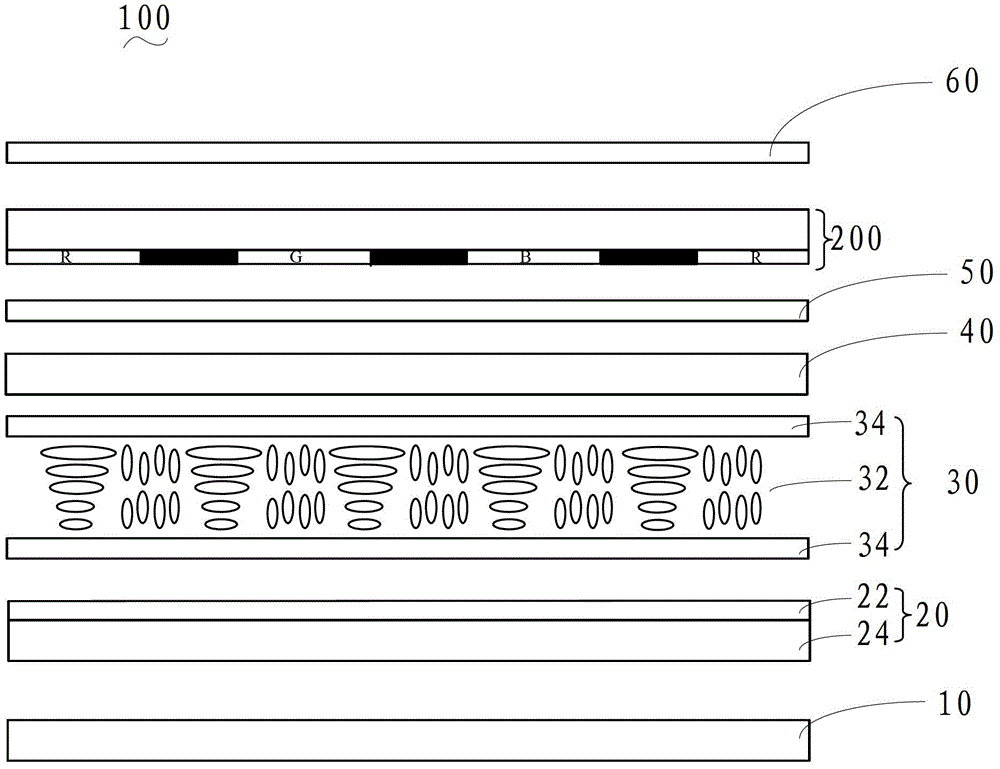

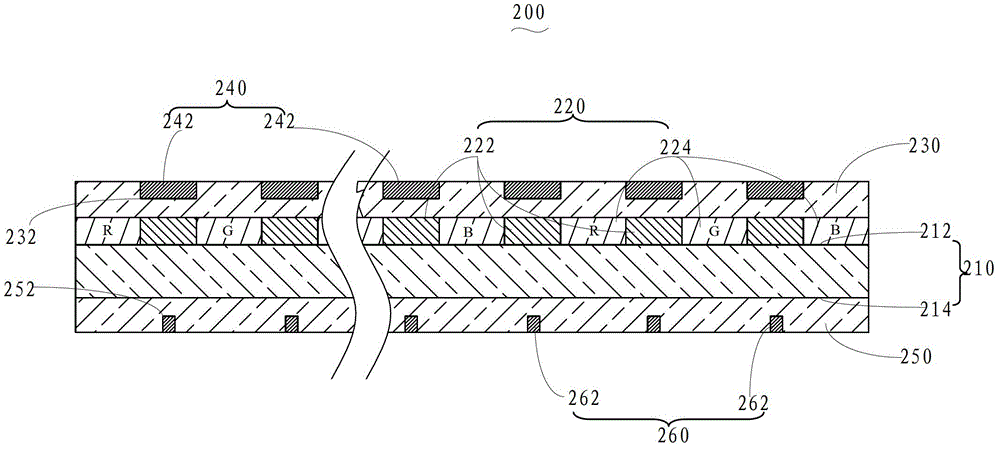

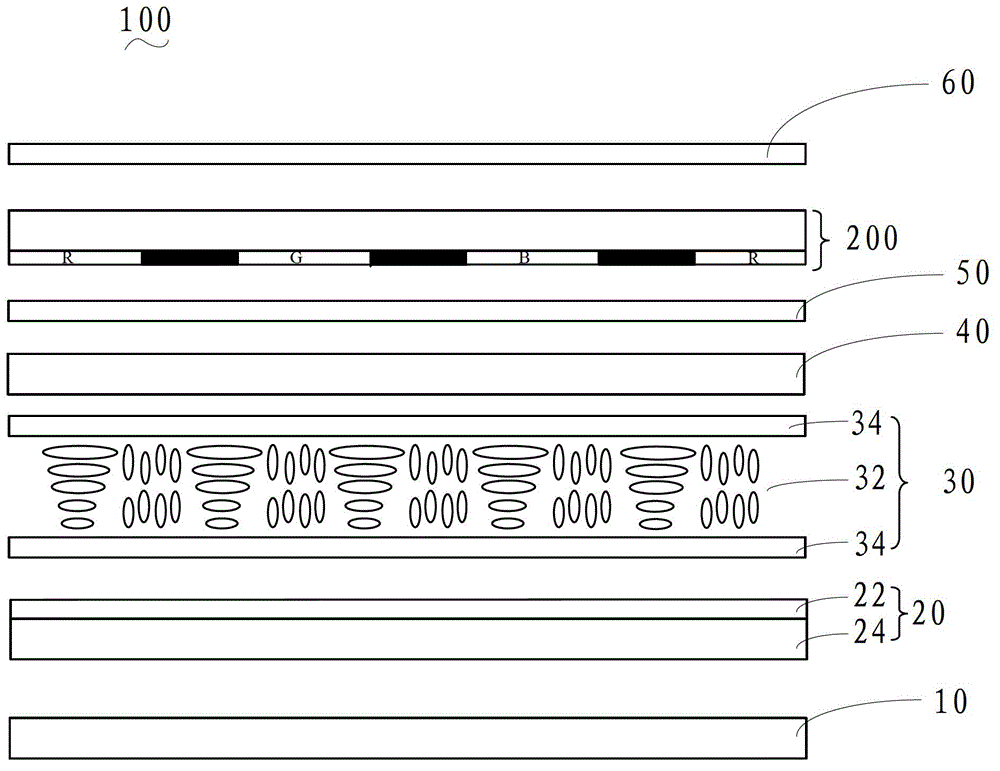

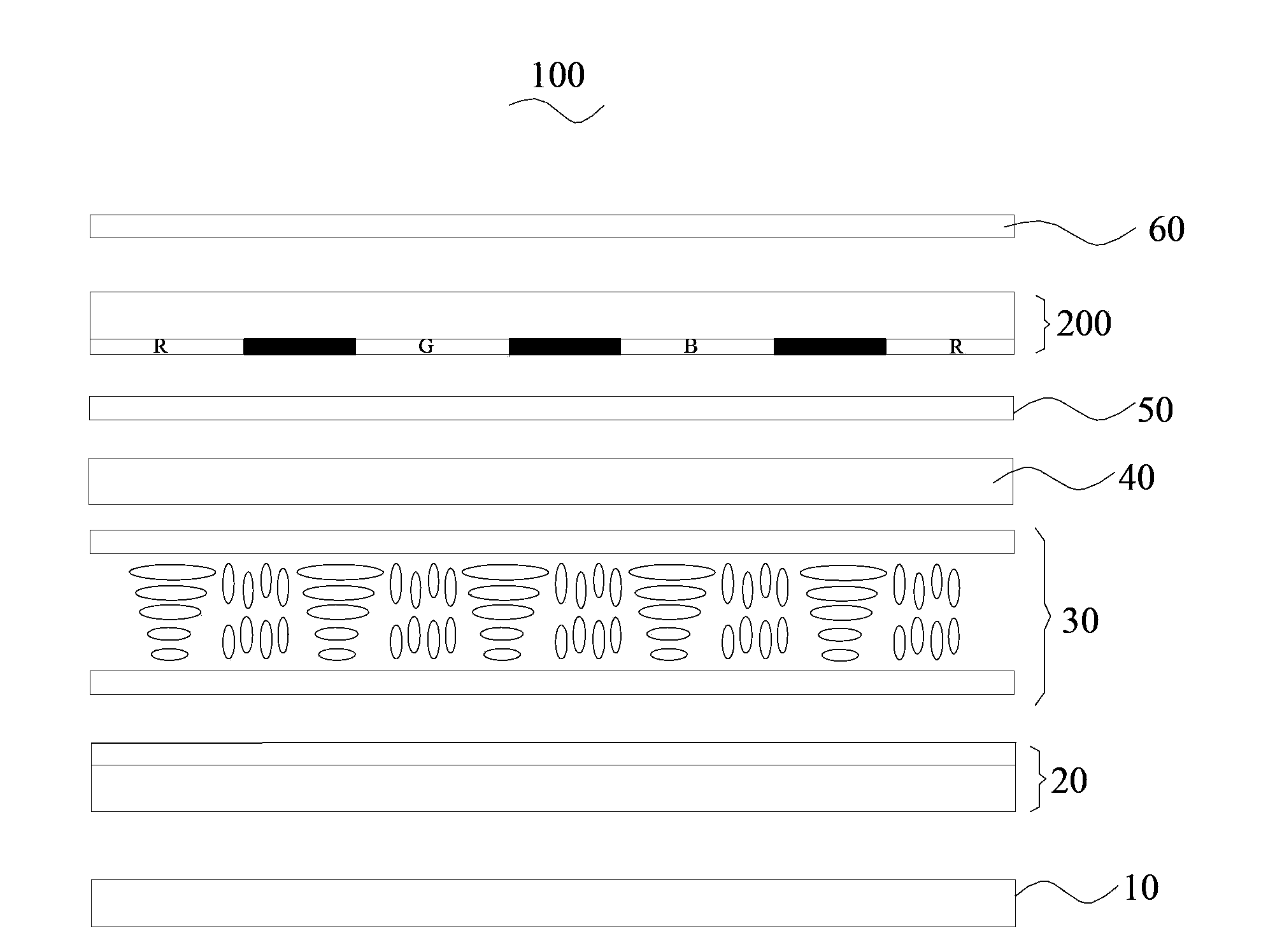

Touch display screen

ActiveCN104238855AWith display functionWith touch functionNon-linear opticsInput/output processes for data processingEngineeringElectrical and Electronics engineering

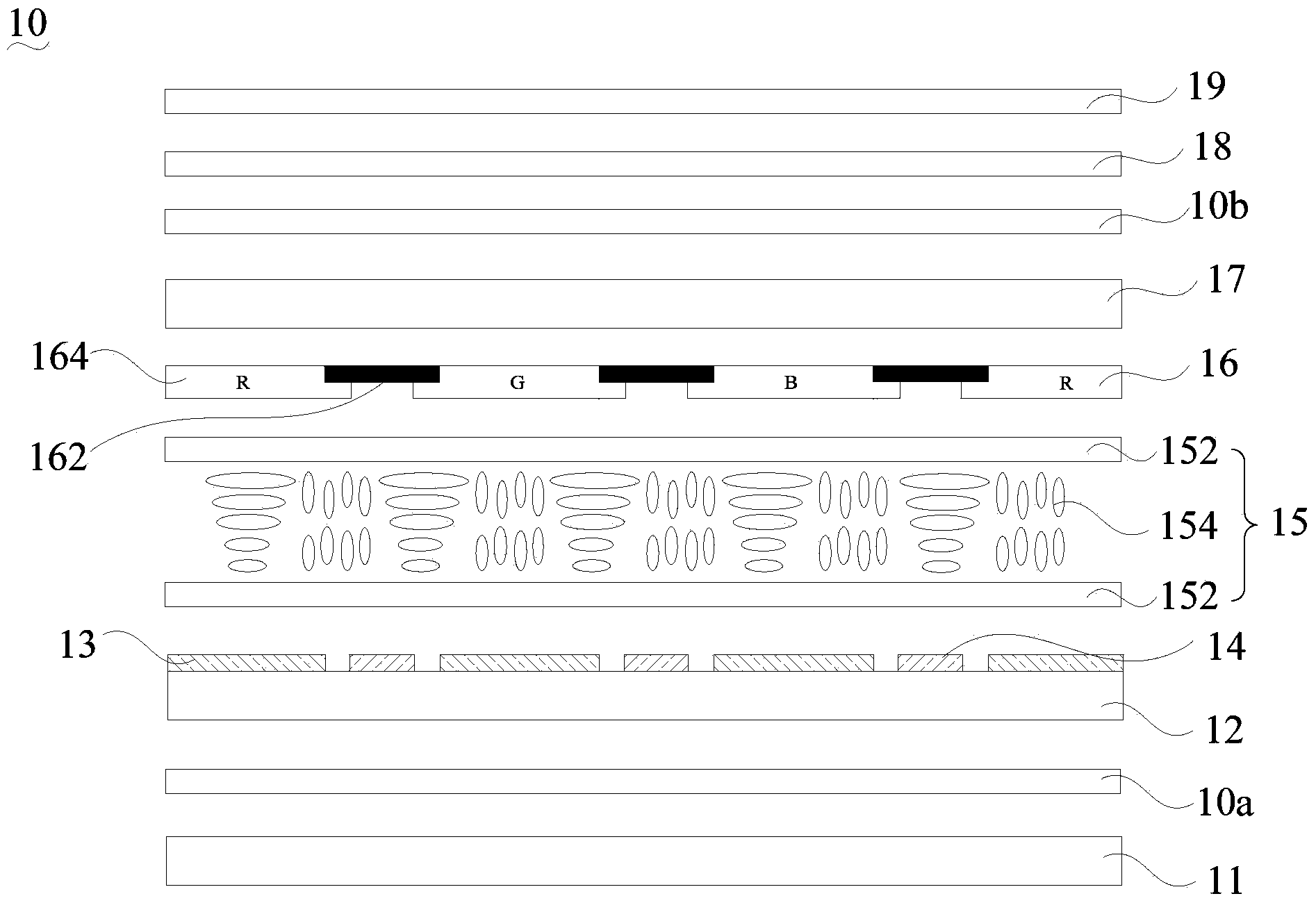

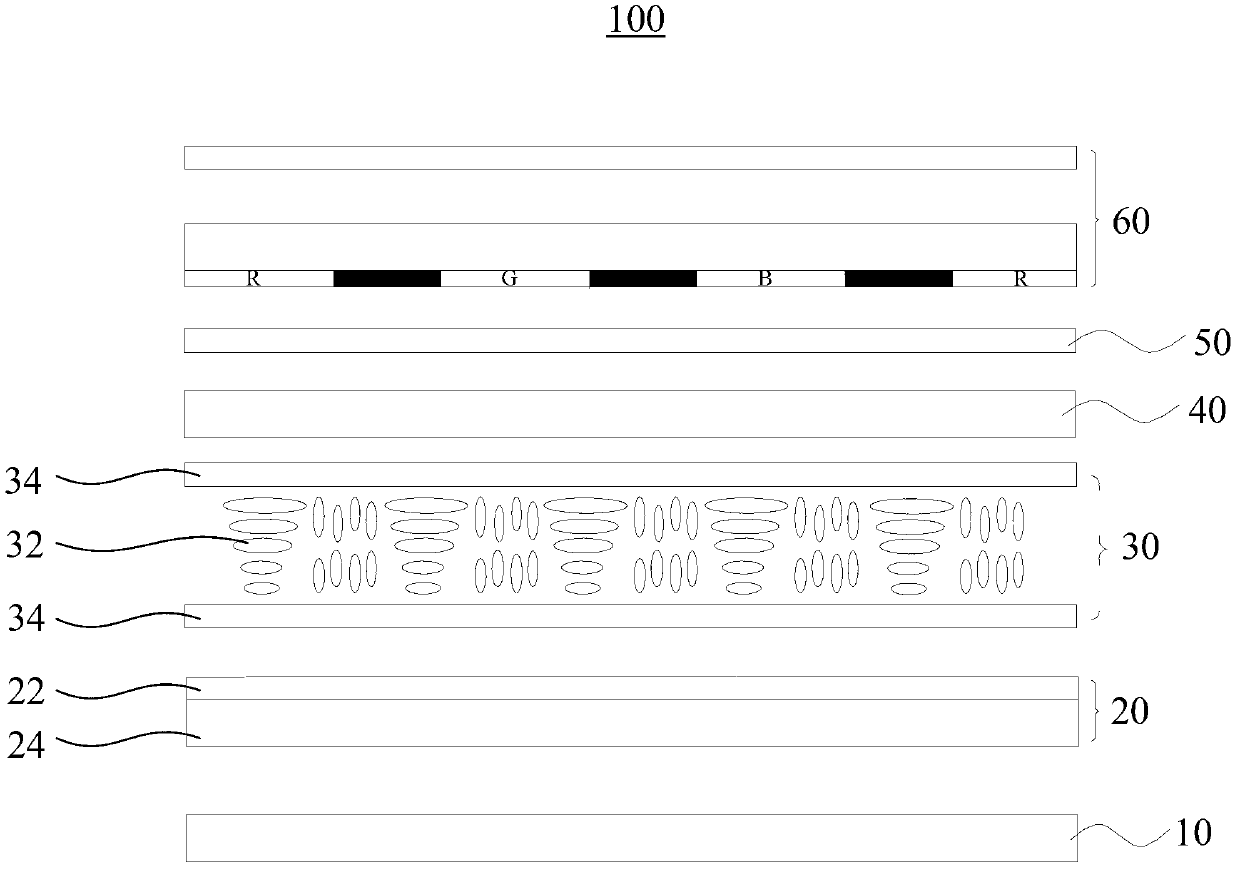

The invention provides a touch display screen, which comprises a first substrate, a liquid crystal module, a filter layer, a second substrate and a first polaroid, wherein the first substrate, the liquid crystal module, the filter layer, the second substrate and the first polaroid are stacked in sequence; the surface, near one side of the liquid crystal module, of the first substrate is provided with a plurality of mutually insulated TFT (thin film transistor) electrodes and a plurality of mutually insulated common electrodes; the common electrodes and the TFT electrodes are alternately arranged in an insulation manner; the TFT electrodes and the common electrodes are matched to control the arrangement state of liquid crystal molecules in the liquid crystal module; the touch display screen also comprises a transparent conducting layer arranged on the surface, backing on to one side of the liquid crystal module, of the second substrate or the surface of the first polaroid; the transparent conducting layer comprises a matrix and conducting nanometer wires filled in the matrix; the matrix is solidified transparent photosensitive resin; the transparent conducting layer is patterned to form a plurality of mutually insulated touch electrodes; the touch electrodes are matched with the common electrodes to form a double-layer touch induction structure, and the double-layer touch induction structure is used for determining coordinates of a touch point. The touch display screen has the characteristics of being thin and low in production cost.

Owner:NANCHANG VIRTUAL REALITY RES INST CO LTD

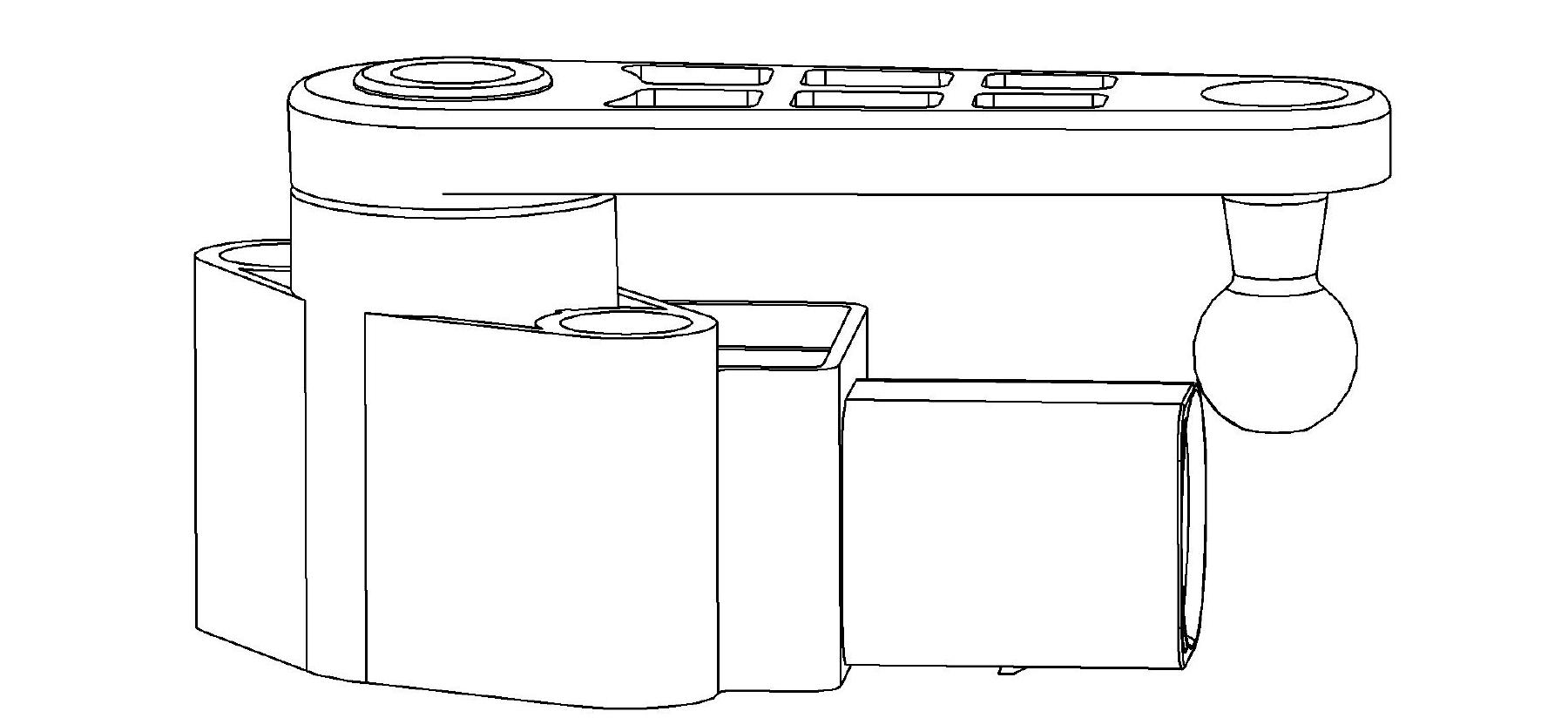

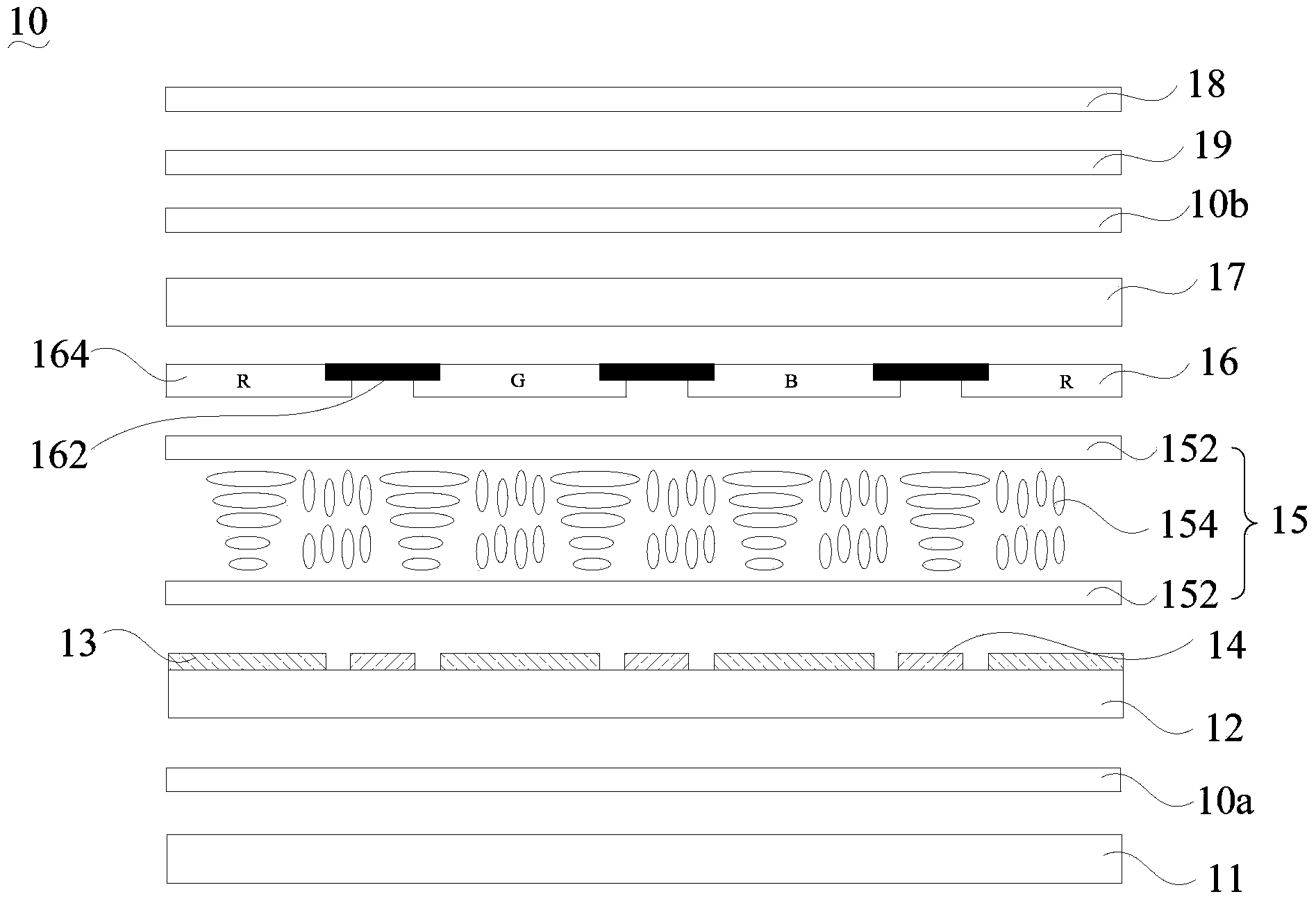

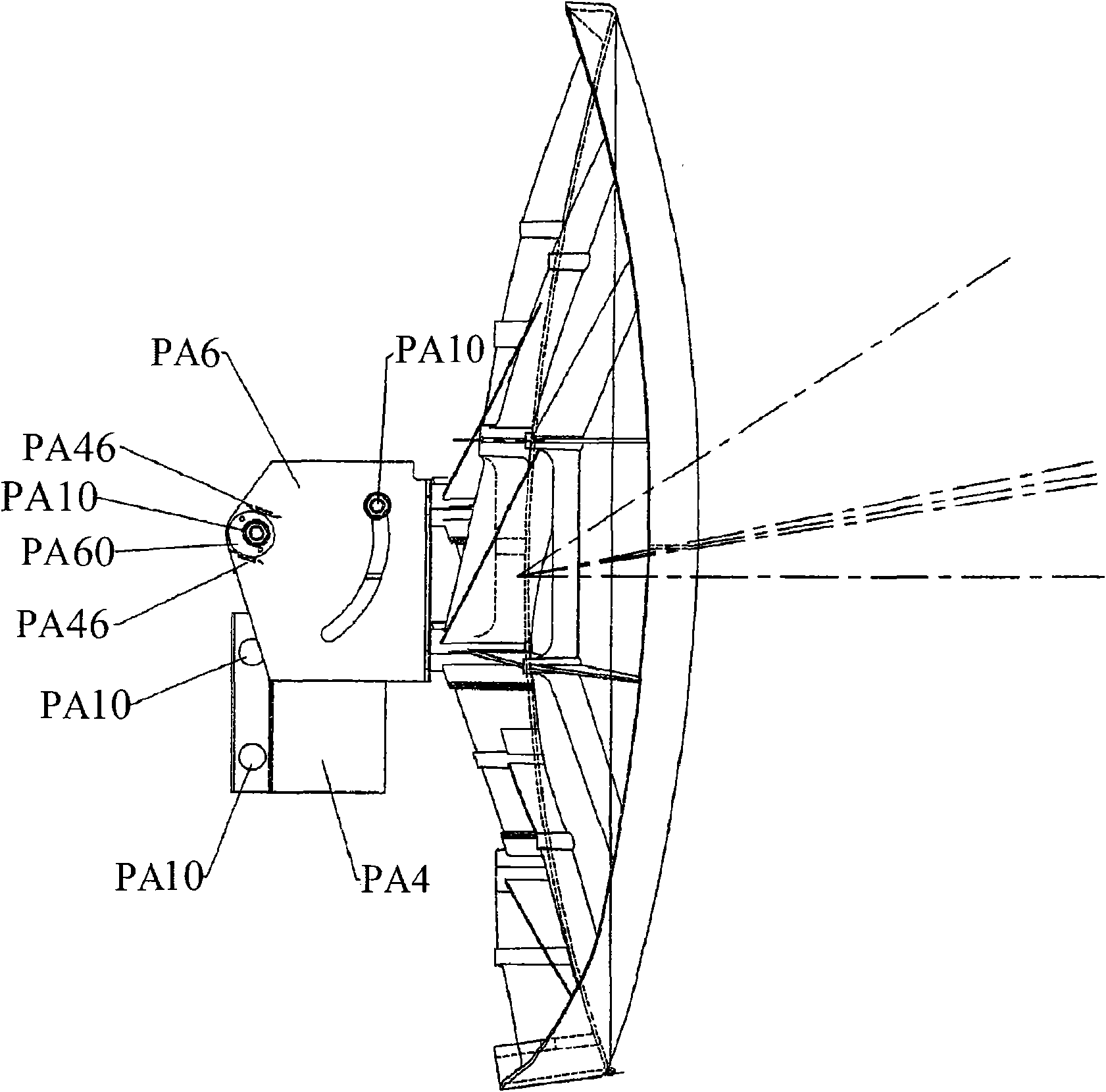

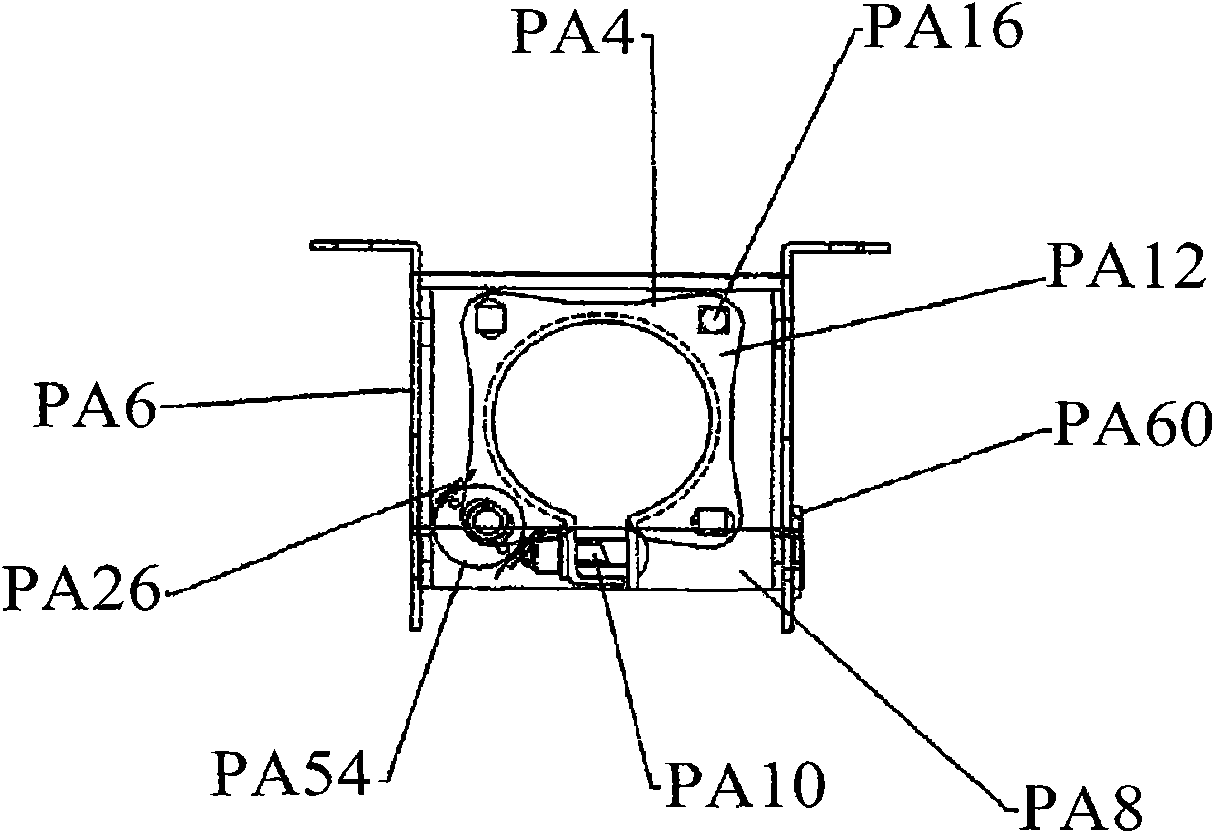

Antenna direction regulating mechanism

InactiveCN101783437ASave assembly costSave material costAntennasCamElectrical and Electronics engineering

The invention discloses an antenna direction regulating mechanism, which is connected to an antenna assembly so as to erect the antenna assembly on a fixed seat and regulate a direction of the antenna assembly. The antenna direction regulating mechanism comprises an antenna assembly combination structure and a pitch angle regulating structure, wherein the pitch angle regulating structure comprises a pitch angle regulating assembly, a bracket and a first cam structure; the pitch angle regulating assembly is provided with a first regulating type assembly groove; the first cam structure is accommodated and limited between the first regulating assembly groove and the bracket, so locking assemblies are not needed at all when the first cam structure is combined with the bracket; and when the first cam structure is driven to rotate, a first cam can drive the pitch angle regulating assembly, the bracket and the antenna assembly combination structure to rotate in turn so as to regulate the direction of the antenna assembly.

Owner:AZURE SHINE INT

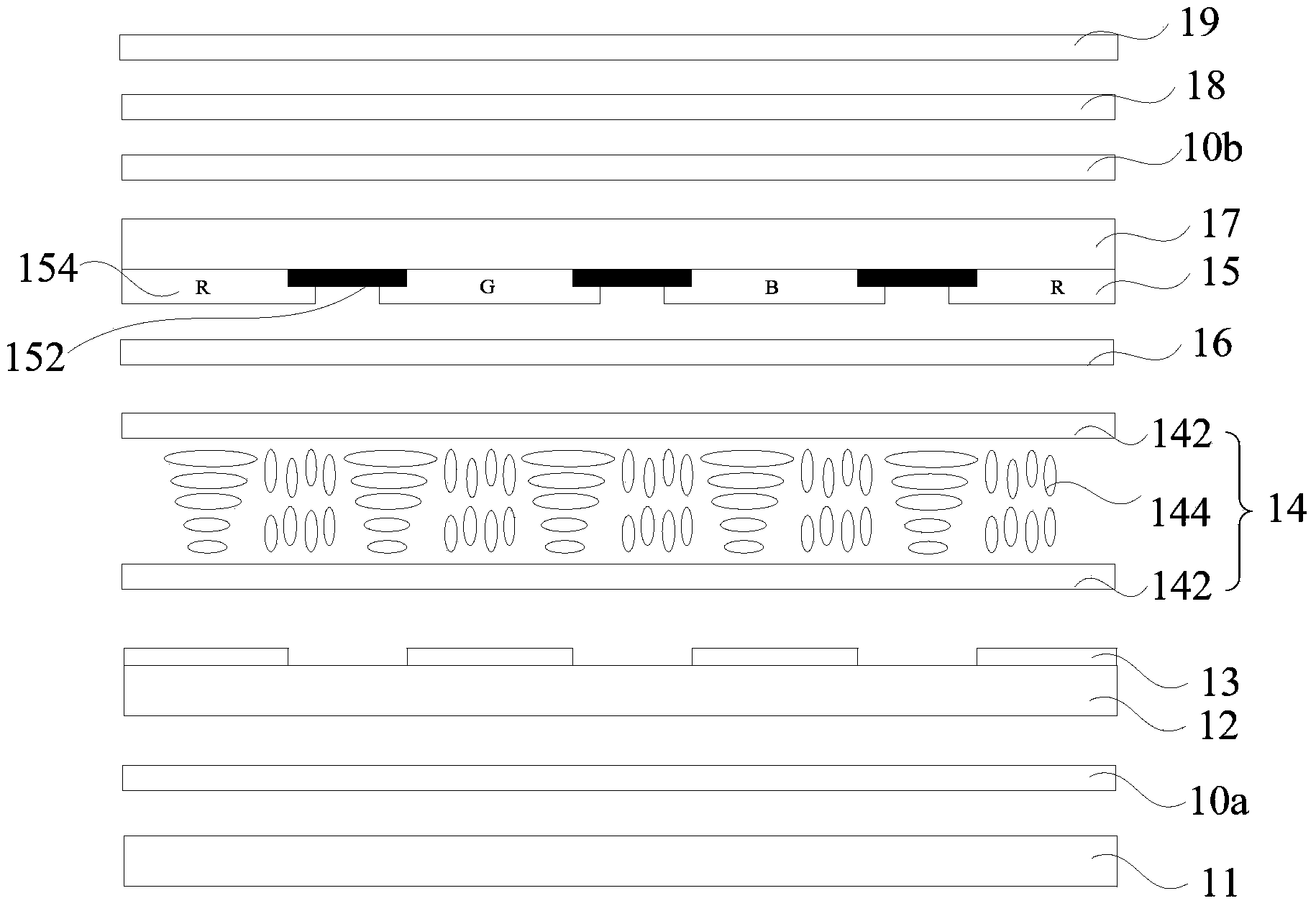

Touch display screen

InactiveCN104238859AWith display functionWith touch functionNon-linear opticsInput/output processes for data processingEngineeringLiquid crystal molecule

The invention provides a touch display screen. The touch display screen comprises a first substrate, a liquid crystal module, a filter layer, a second substrate and a first polaroid, wherein the first substrate, the liquid crystal module, the filter layer, the second substrate and the first polaroid are stacked in sequence; the surface, facing one side of the liquid crystal module, of the first substrate is provided with TFT (thin film transistor) electrodes; one side, facing the liquid crystal module, of the second substrate is provided with common electrodes; the TFT electrodes and the common electrodes are used for jointly controlling the arrangement state of liquid crystal molecules in the liquid crystal module; the touch display screen also comprises a transparent conducting layer arranged on the surface, backing on to one side of the liquid crystal module, of the second substrate or the surface of the first polaroid; the transparent conducting layer comprises a matrix and conducting nanometer wires filled in the matrix; the matrix is solidified transparent photosensitive resin; the transparent conducting layer is patterned to form touch electrodes; the touch electrodes are matched with the common electrodes to form a double-layer touch induction structure, and the double-layer touch induction structure is used for determining coordinates of a touch point. The touch display screen has the characteristics of being thin and low in production cost.

Owner:NANCHANG O FILM TECH CO LTD +2

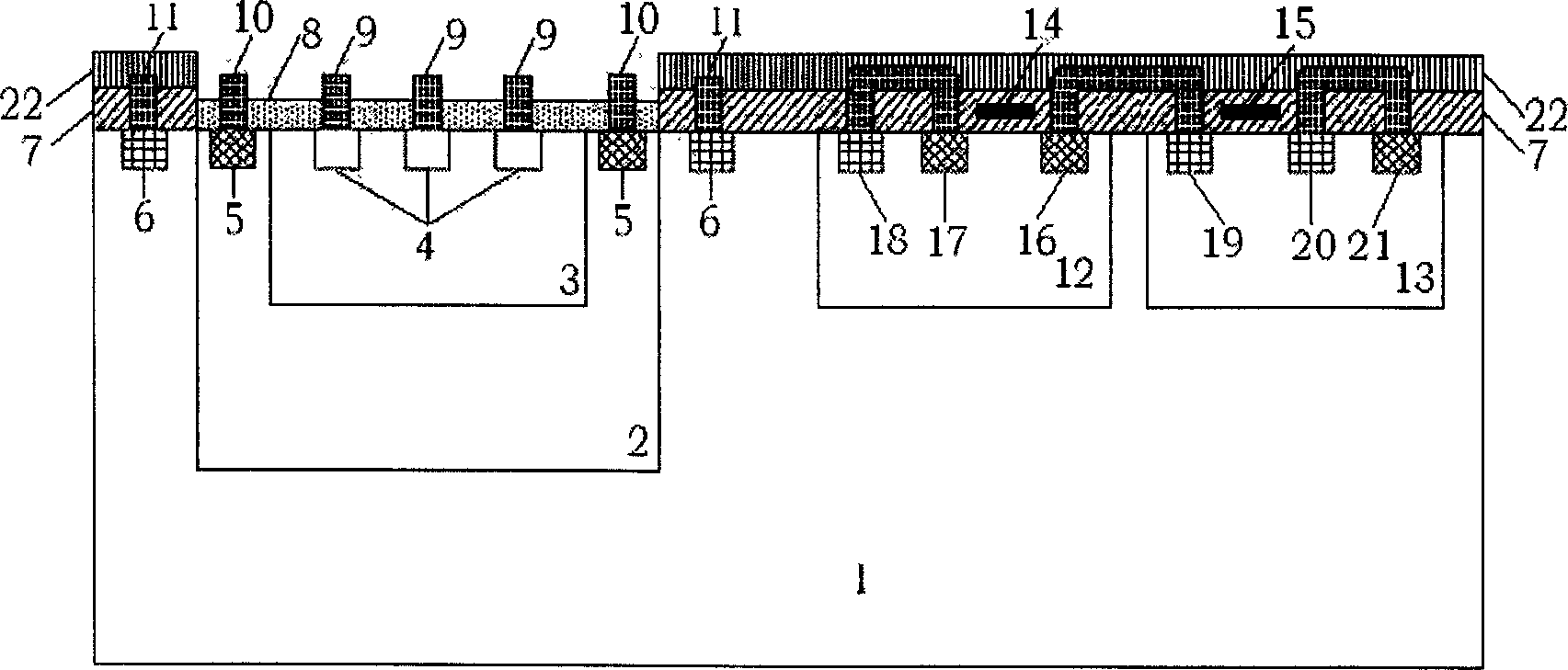

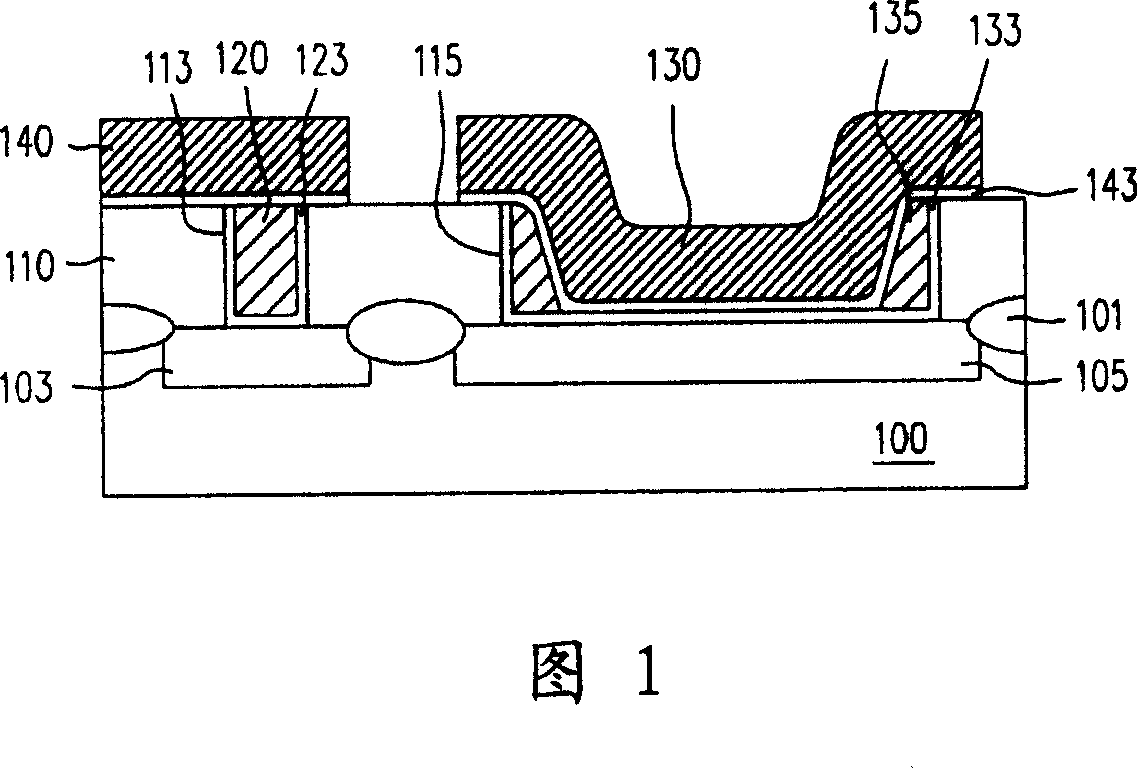

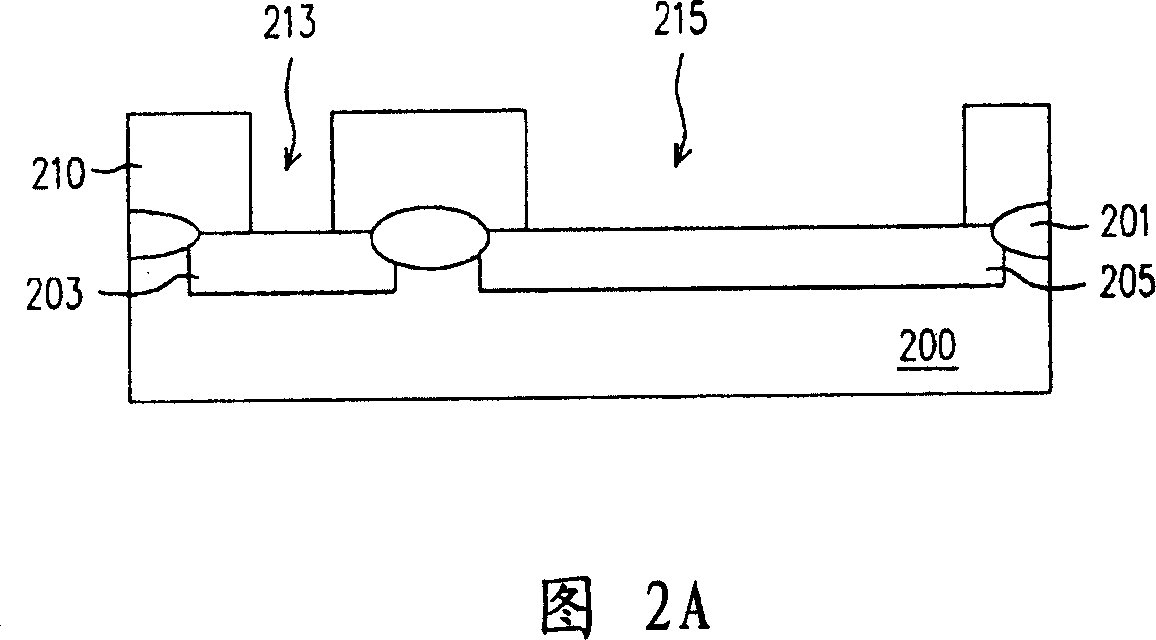

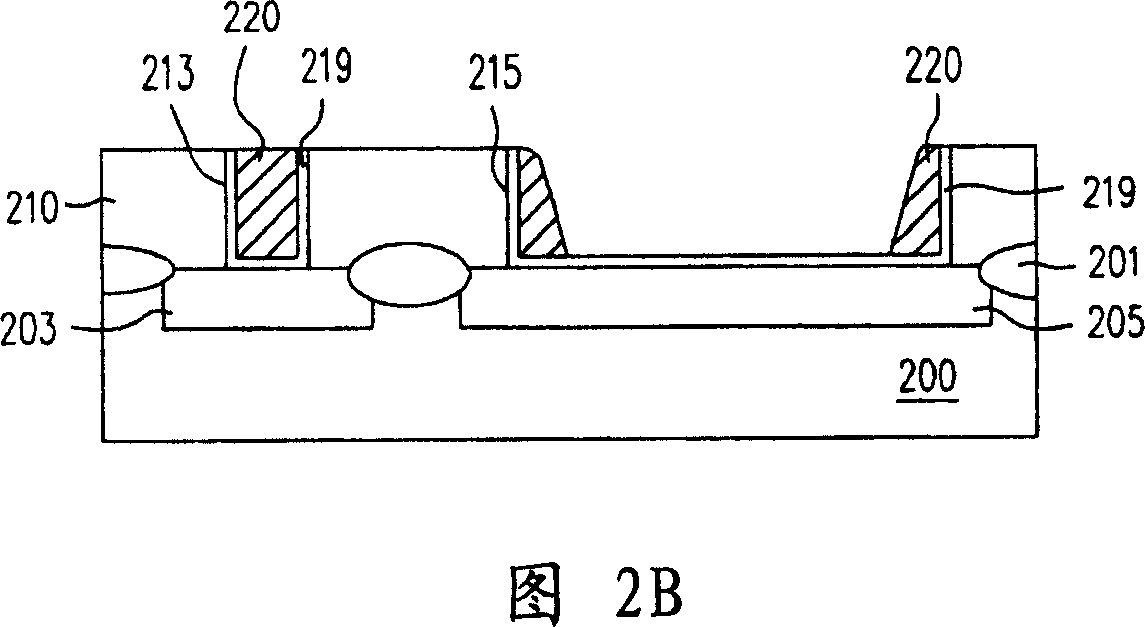

An integral circuit structure and its manufacture method

ActiveCN101060119AQuality improvementHighly integratedSemiconductor/solid-state device detailsSolid-state devicesSchottky diodeMaterials science

The IC structure comprises: a substrate formed a heavy-and light-doped area, a contact window on the heavy-doped area, and a Schottky contact metal layer on light-doped area to form a Schottky diode with the substrate, wherein the material of contact window is different from the Schottky contact metal layer.

Owner:UNITED MICROELECTRONICS CORP

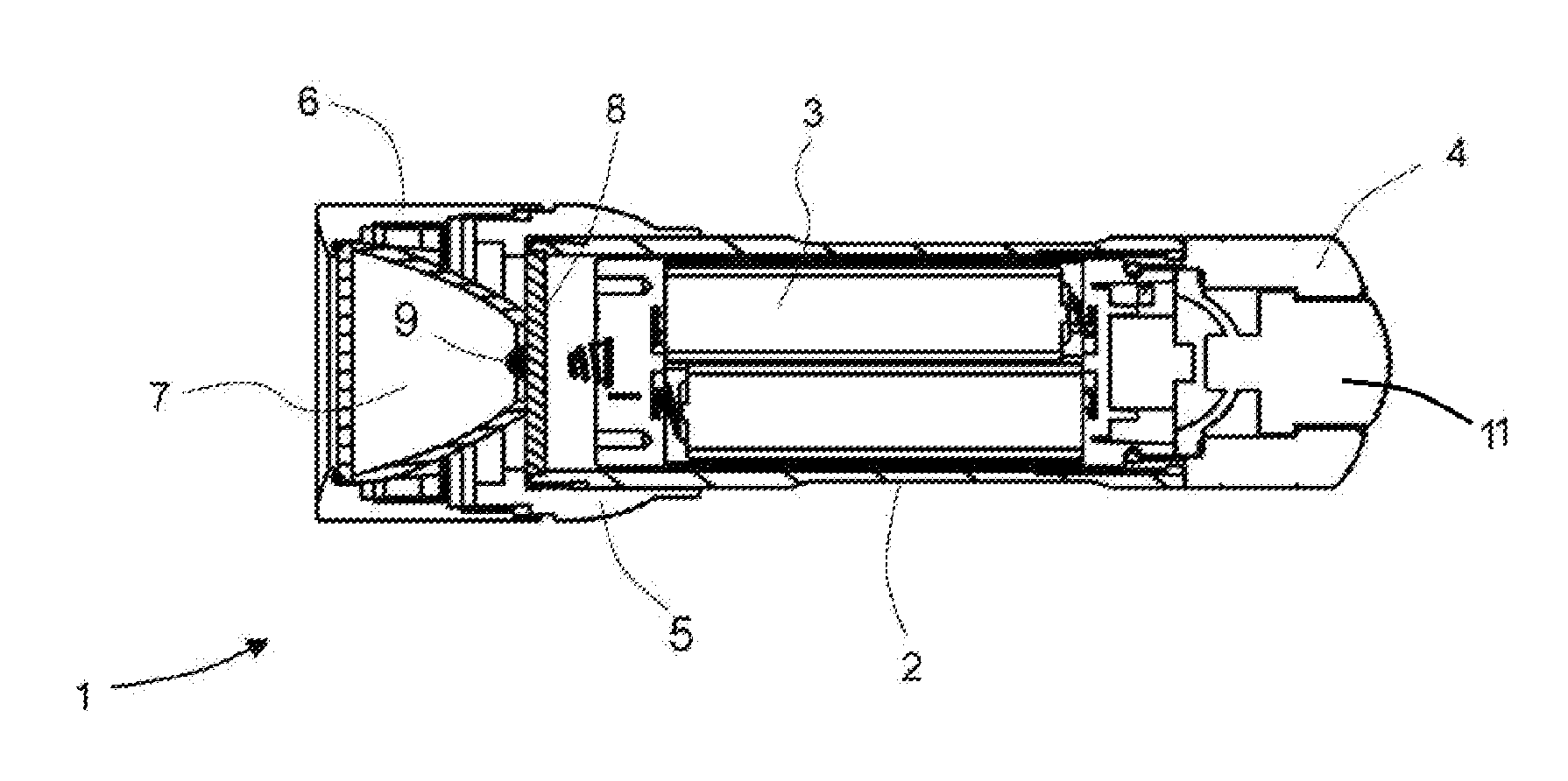

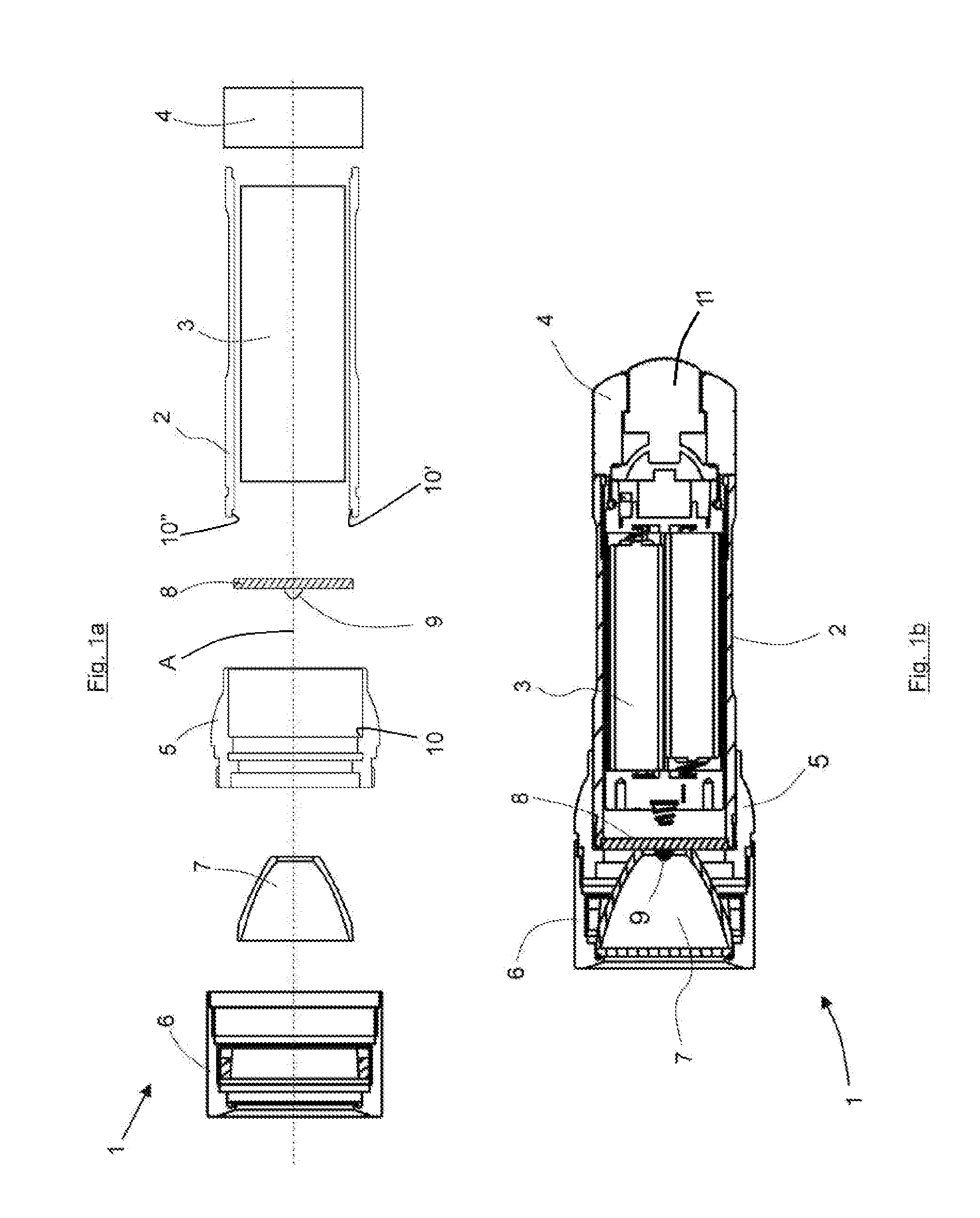

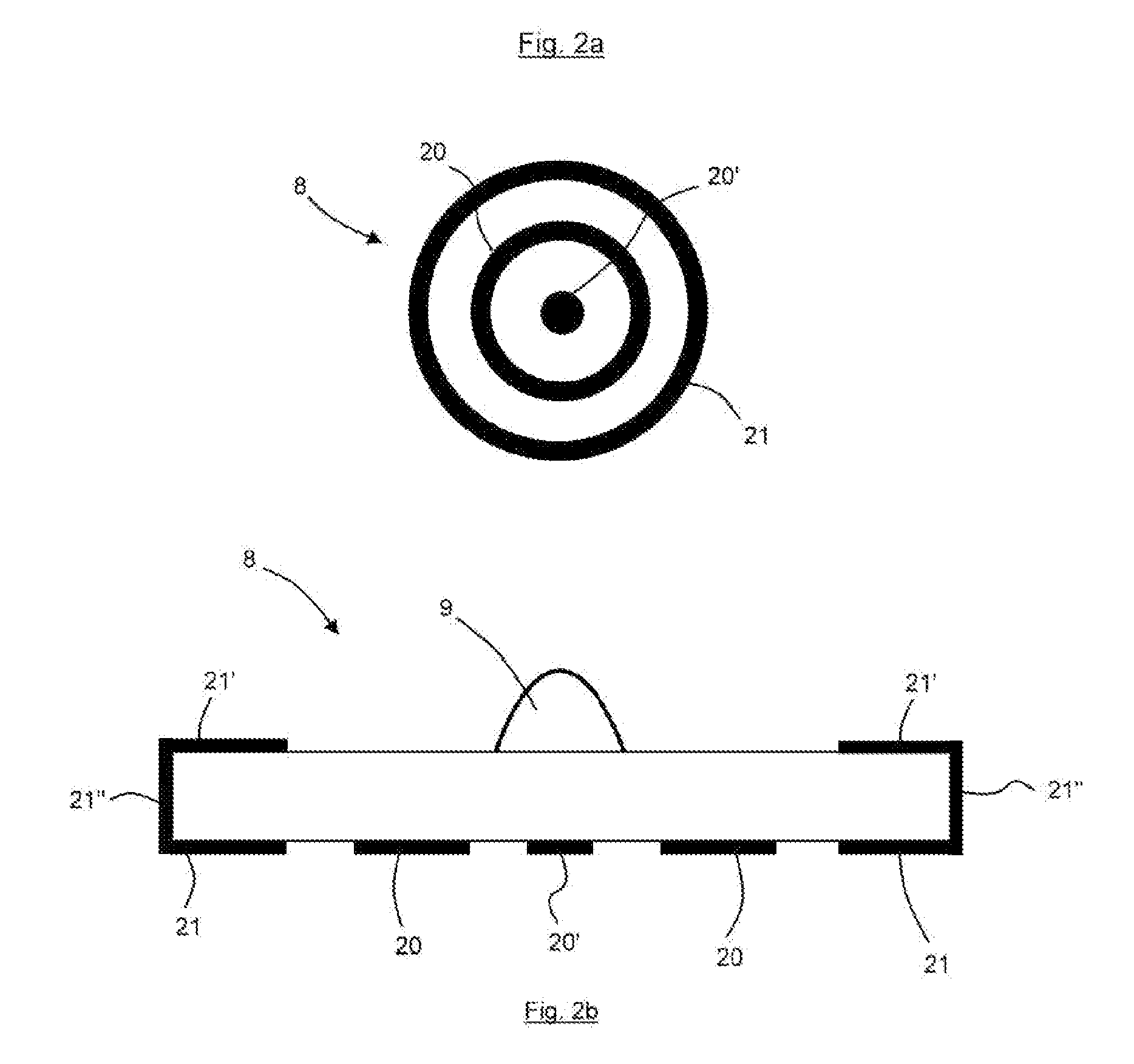

Flashlight

ActiveUS20120020065A1Securely holdSave assembly costPoint-like light sourceElectric circuit arrangementsEngineeringFlashlight

A flashlight has a casing extending along an axis and having axially opposite front and rear ends, a collar fittable on the front end, a support disk engaged and gripped axially between the collar and the front end, a light source on a front face of the disk, thermally conductive regions on the disk, and a lamp head secured to the collar.

Owner:ZWEIBRUDER OPTOELECTRONICS BGMH & CO KG

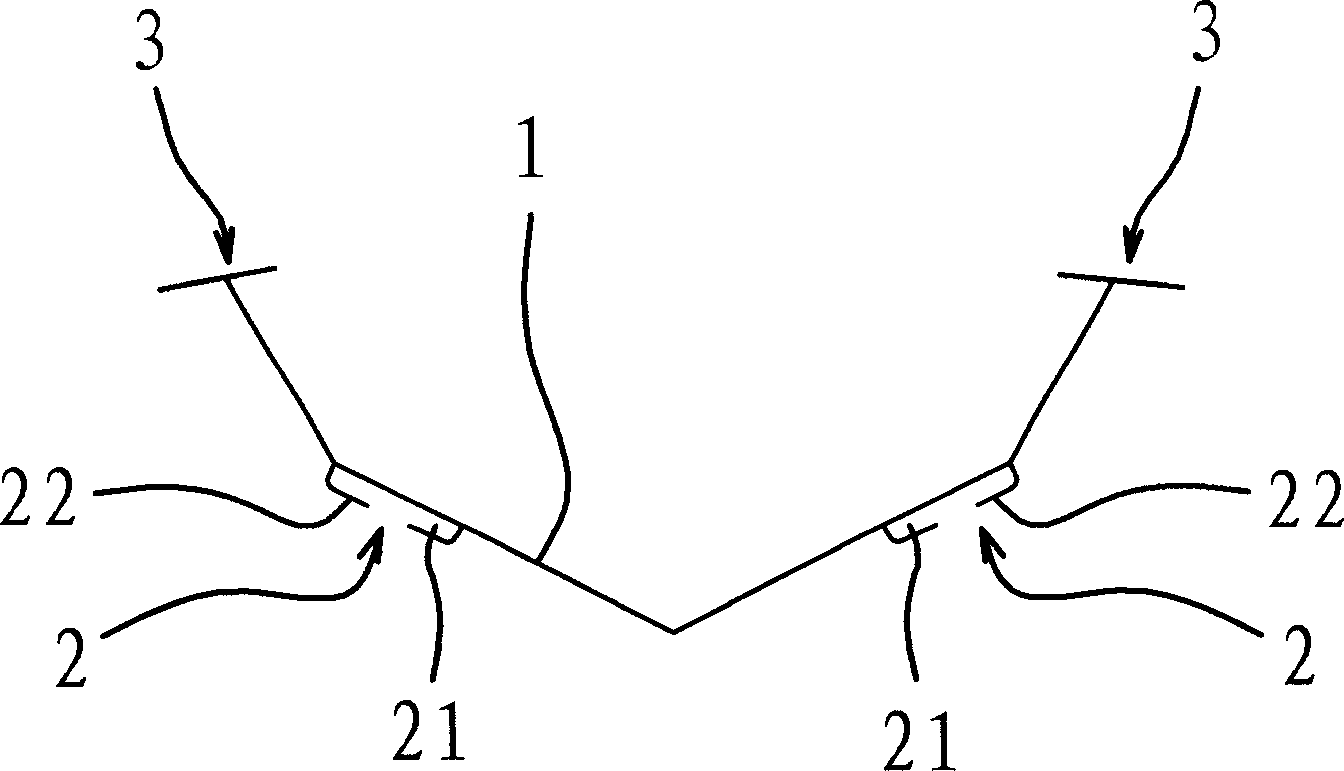

Harness cord device for prolonging service life of electronic jacquard machine

The invention discloses a harness cord device for prolonging the service life of an electronic jacquard machine, relates to the field of textile machinery and particularly relates to an electronic jacquard machine in the textile machinery. The harness cord device comprises a comber board and a seabed board, wherein the comber board is mounted on a wallboard; the seabed board is positioned above the comber board; a harness cord passes through the part between the comber board and the seabed board; and the upper end of the harness cord is connected with the electronic jacquard machine, and the lower end of the harness cord is connected with a steel heald spring. The key technology is that cushion blocks are arranged at the contact parts between the two edges of the comber board and the wallboard, and screws are arranged at the four corners of the seabed board and used for fixing the seabed board. The harness cord device disclosed by the invention has the beneficial effects that when the harness cord is worn, the positions of the seabed board and comber board are changed to leave the original friction point and avoid the worn harness cord section, and the original structure continues working, thus the service life of the jacquard machine can be prolonged by 5-6 years, and the manufacturing cost is saved by over 50%; and compared with the prior art, unexpected technical effects are obtained in spite of the simple structure.

Owner:CHENGDU QILI SILK

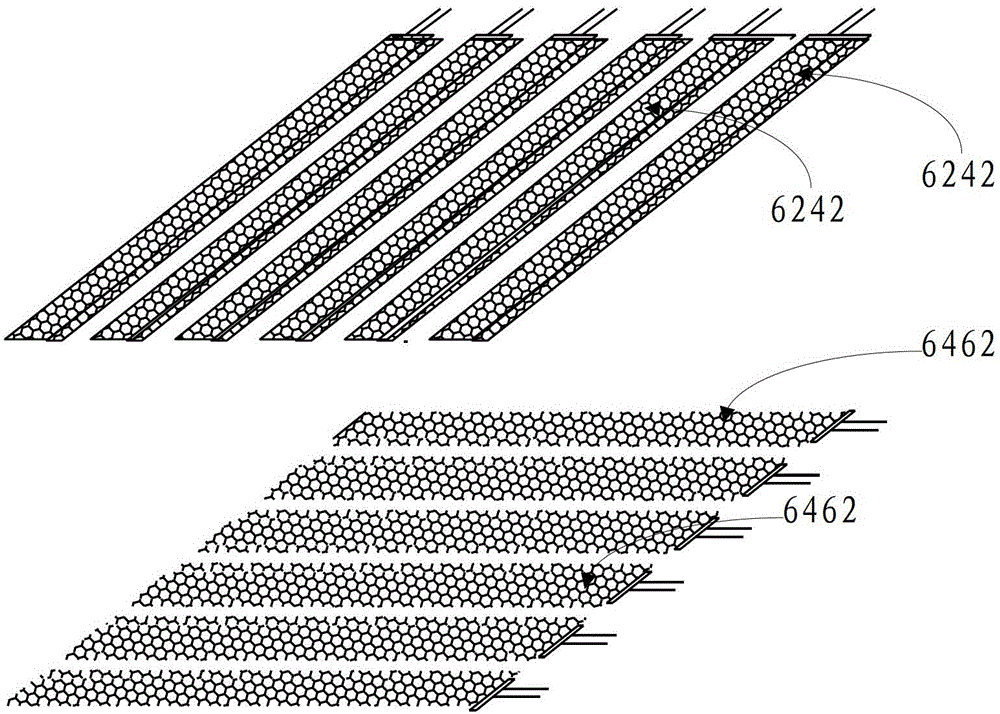

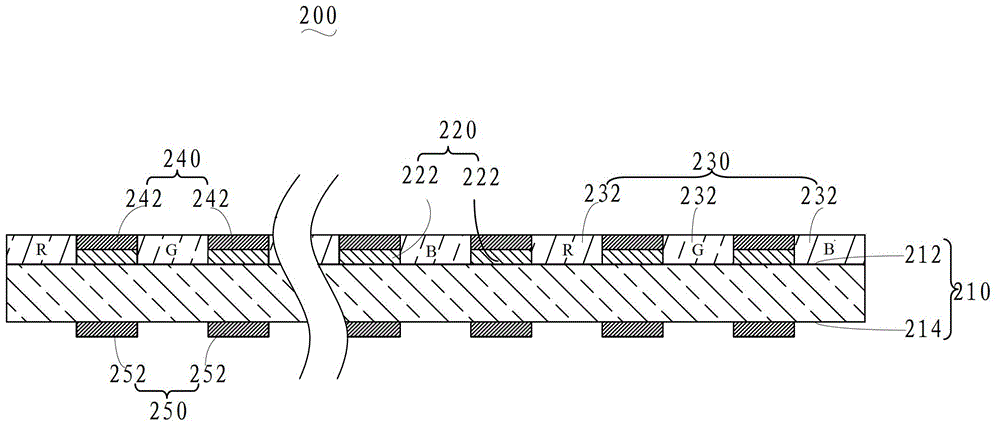

Optical filter assembly and touch display screen using same

InactiveCN103336623AEasy to operateRealize functionOptical filtersNon-linear opticsFlexible circuitsLight filter

An optical filter assembly comprises a substrate, a light-filtering layer, a first conducting layer and a second conducting layer. The light-filtering layer is directly formed on the first surface of the substrate, and first electric conduction patterns and second electric conduction patterns are exposed. All projections, on the light-filtering layer, of electric conduction silk-covered wires of the first conducting layer and the second conducting layer fall on grid wires. The width of the electric conduction silk-covered wires is equal to or smaller than that of the grid wires. According to the optical filter assembly, an induction structure is formed by the first conducting layer and the second conducting layer, so that the optical filter assembly is operated in a touching mode and beside has the function of light filtering. Reduction of the thickness of an electronic product is facilitated, and material and assembly cost are further saved. The first electric conduction patterns and the second electric conduction patterns are exposed, and therefore, subsequent manufacturing of electrode leading wires and binding among a flexible printed circuit board and the electrode leading wires are facilitated. Meanwhile, the width of the electric conduction silk-covered wires can be increased, and the electric conduction capacity of the conducting layers is improved. Meanwhile, the invention provides a touch display screen.

Owner:NANCHANG O FILM TECH CO LTD

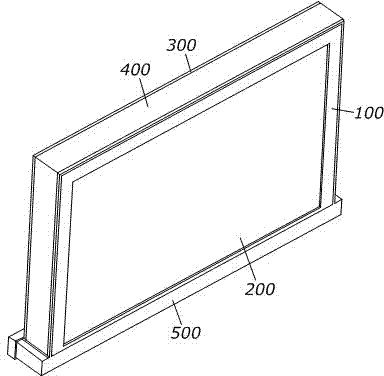

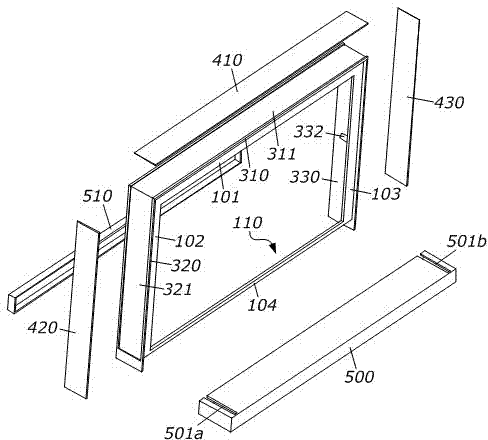

LCD (liquid crystal display) TV structure

InactiveCN104333723AExpand the marketNovel structural designTelevision system detailsColor television detailsEngineeringLCD television

The invention discloses a LCD (liquid crystal display) TV structure, which comprises a surrounding frame and a LCD group. The outer side of the surrounding frame is provided with a surrounding edge to which a decorative strip is attached; the inner side of the surrounding frame forms a covering area for covering the LCD group; and the LCD group is covered in the covering area and fixedly arranged on the surrounding frame. On one hand, through freely exchanging the decorative strips, the appearance of the LCD TV can be varied, thereby facilitating expanding the market and guiding consumption; and on the other hand, the structure is novelly designed and the assembly technology is simple, thereby saving the development cost and greatly saving the manufacturing cost and the assembly cost.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

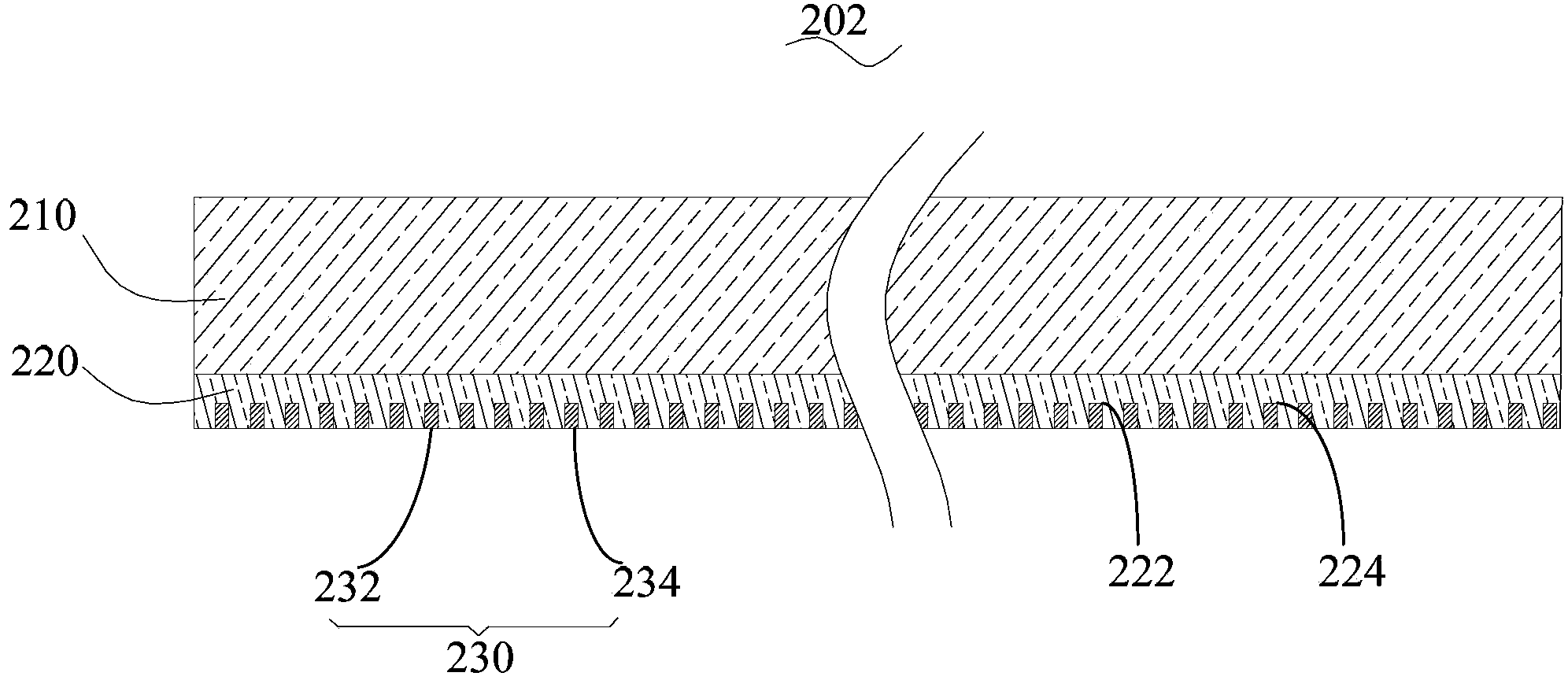

Light polarizing-filtering module and touch display screen

ActiveCN103336383AReduce thicknessRealize touch operationNon-linear opticsInput/output processes for data processingComputer moduleOptoelectronics

A light polarizing-filtering module comprises a light polarizing assembly and a light filtering assembly. The light polarizing assembly comprises a light polarizing plate and a first conducting layer. The first conducting layer comprises a plurality of first electric conduction units which extend in the first direction and are arranged in a mutually-spacing mode. The first electric conduction units comprise first electric conduction grids formed by first electric conduction silk-covered wires in a mutually-crossing mode. The light filtering assembly comprises a transparent substrate, a light-tight layer, a light filtering layer and a second conducting layer. The second conducting layer comprises a plurality of second electric conduction units which extend in the second direction and are arranged in a mutually-spacing mode. The second electric conduction units comprise second electric conduction grids formed by second electric conduction silk-covered wires in a mutually-crossing mode. The first direction is not parallel to the second direction, and all projections of the first electric conduction silk-covered wires fall on grid wires. According to the light polarizing-filtering module, touch control operation, a light polarizing function and a light filtering function can be achieved at the same time. When used in a display screen, the light polarizing-filtering module can directly enable the display screen to have the function of touch control. Therefore, reduction of the thickness of an electronic product is facilitated, and meanwhile, material and assembly cost are greatly saved.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

Light polarization-light filtering module and touch display screen

ActiveCN103345336AWith touch functionReduce thicknessNon-linear opticsInput/output processes for data processingLight filterTouch function

A light polarization-light filtering module comprises a light polarization assembly and a light filtering assembly, wherein the light polarization assembly comprises a light polarization sheet and a first conductive layer, the first conductive layer comprises a plurality of first conductive units which extend in the first direction and are arranged at intervals, the light filtering assembly comprises a transparent substrate, a light-shielding layer, a light filtering layer and a second conductive layer, the second conductive layer comprises a plurality of second conductive units which extend in the second direction and are arranged at intervals, each second conductive unit comprises a second conductive network formed by intersecting second conductive wires, the first direction is not parallel with the second direction. The light polarization-light filtering module can simultaneously realize a touch-control operation, a light-polarization function and a light-filtering function. When the light-polarization light-filtering module is applied to the display screen, the light-polarization light-filtering module directly enables the display screen to have a touch-control function, the thickness of an electronic product is reduced, and materials and assembly cost are largely saved at the same time.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

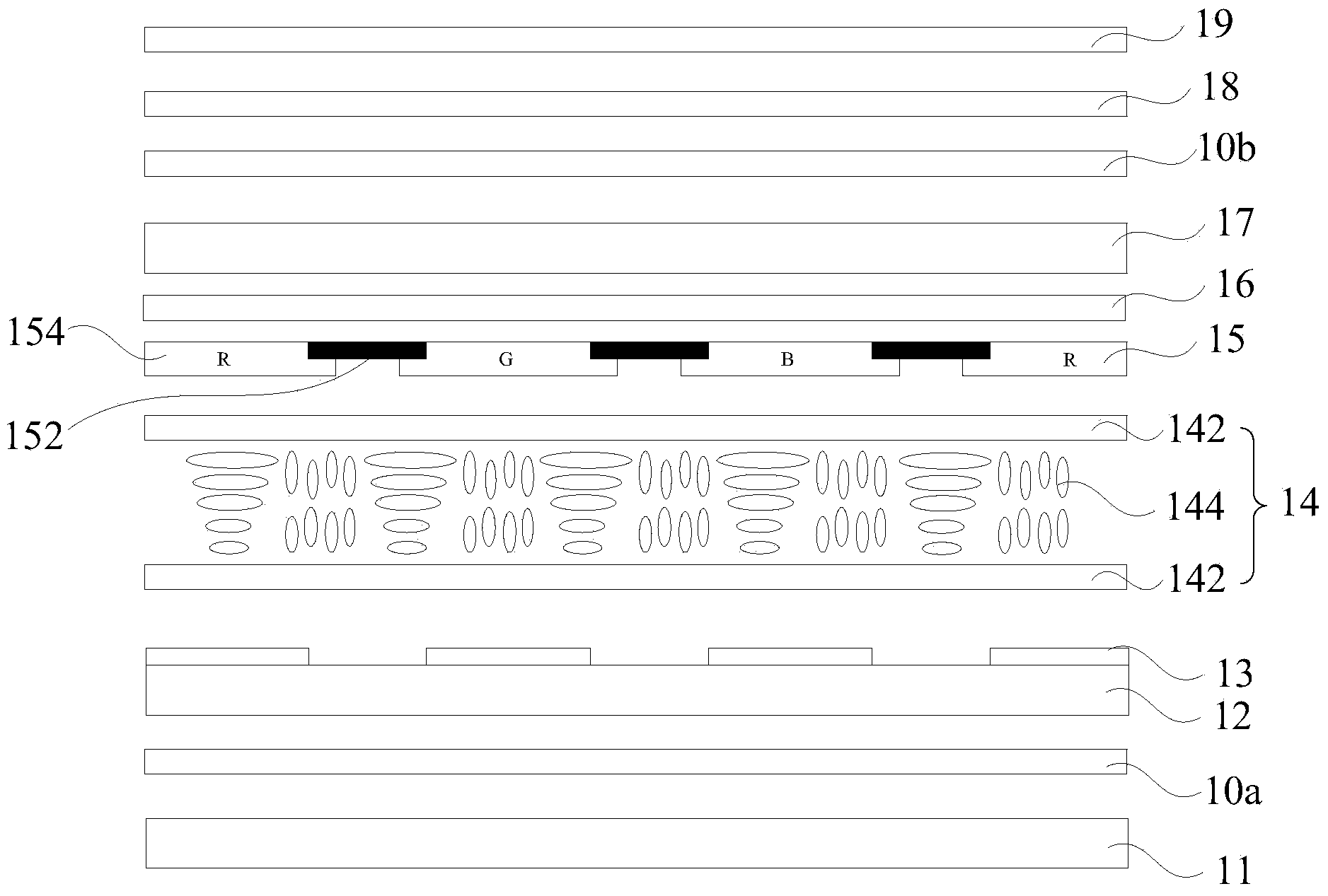

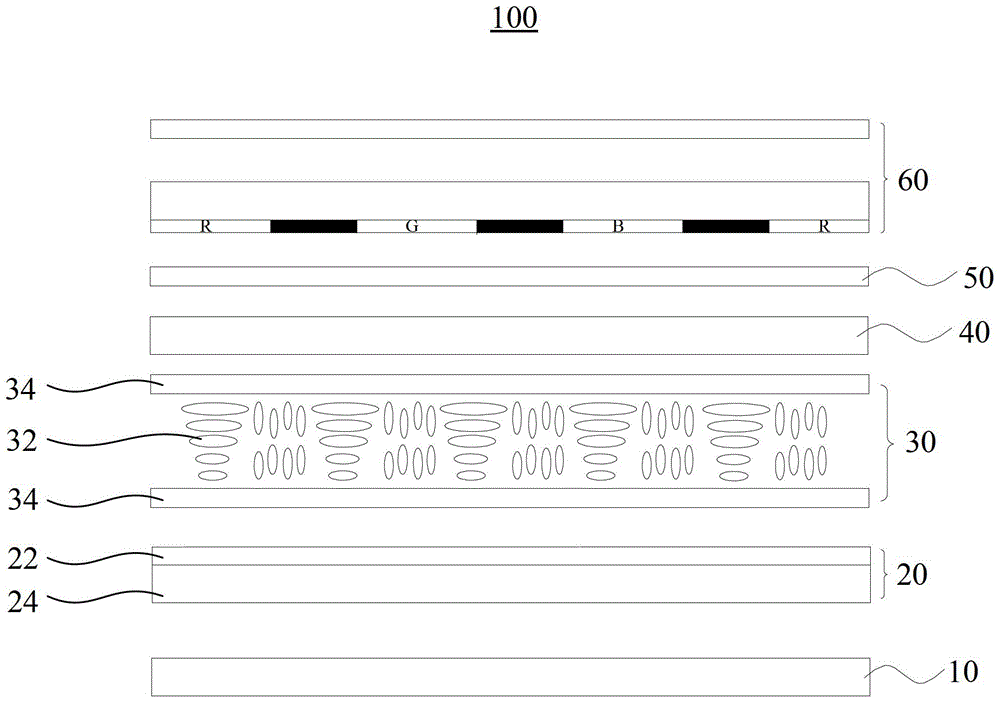

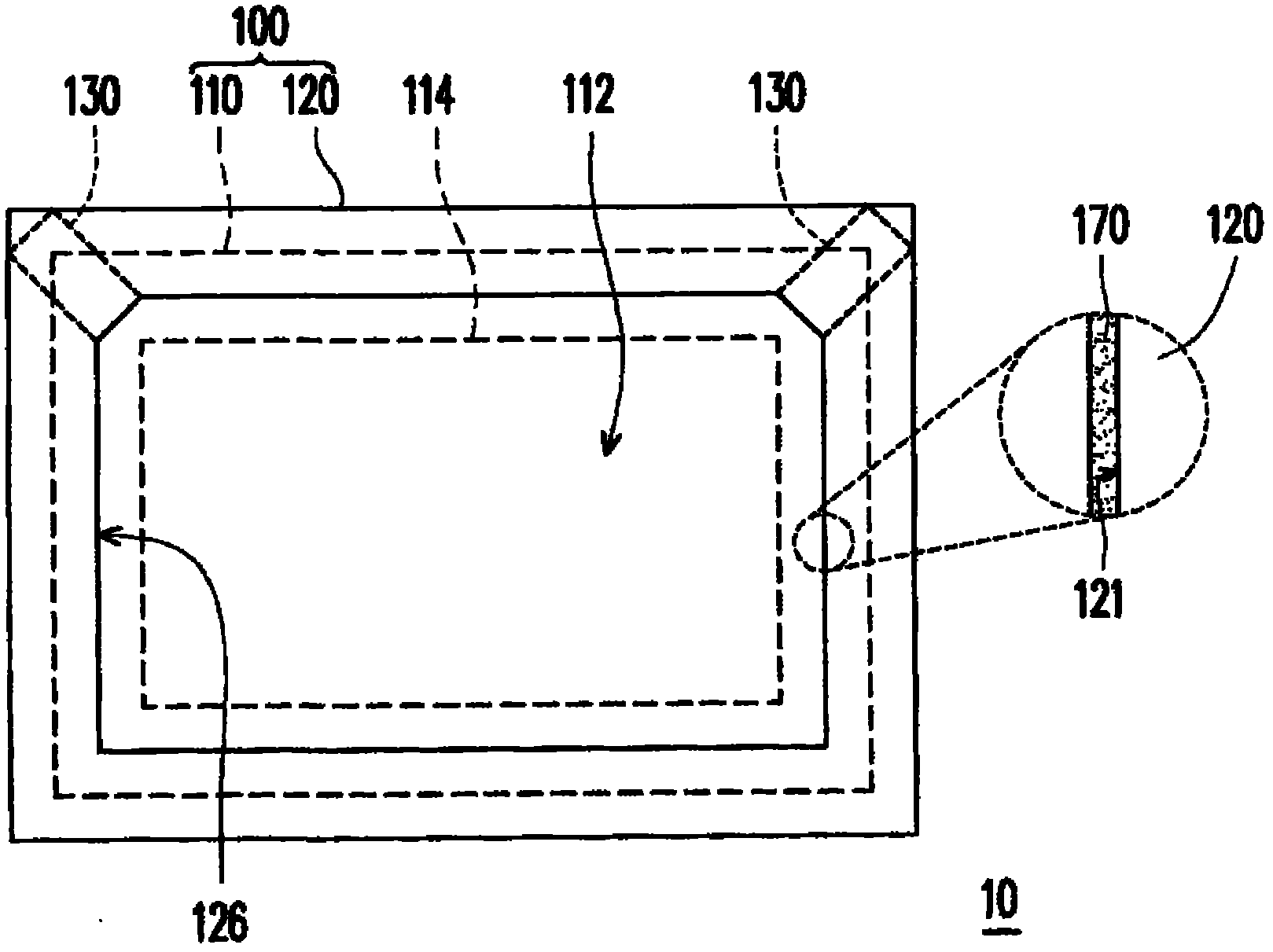

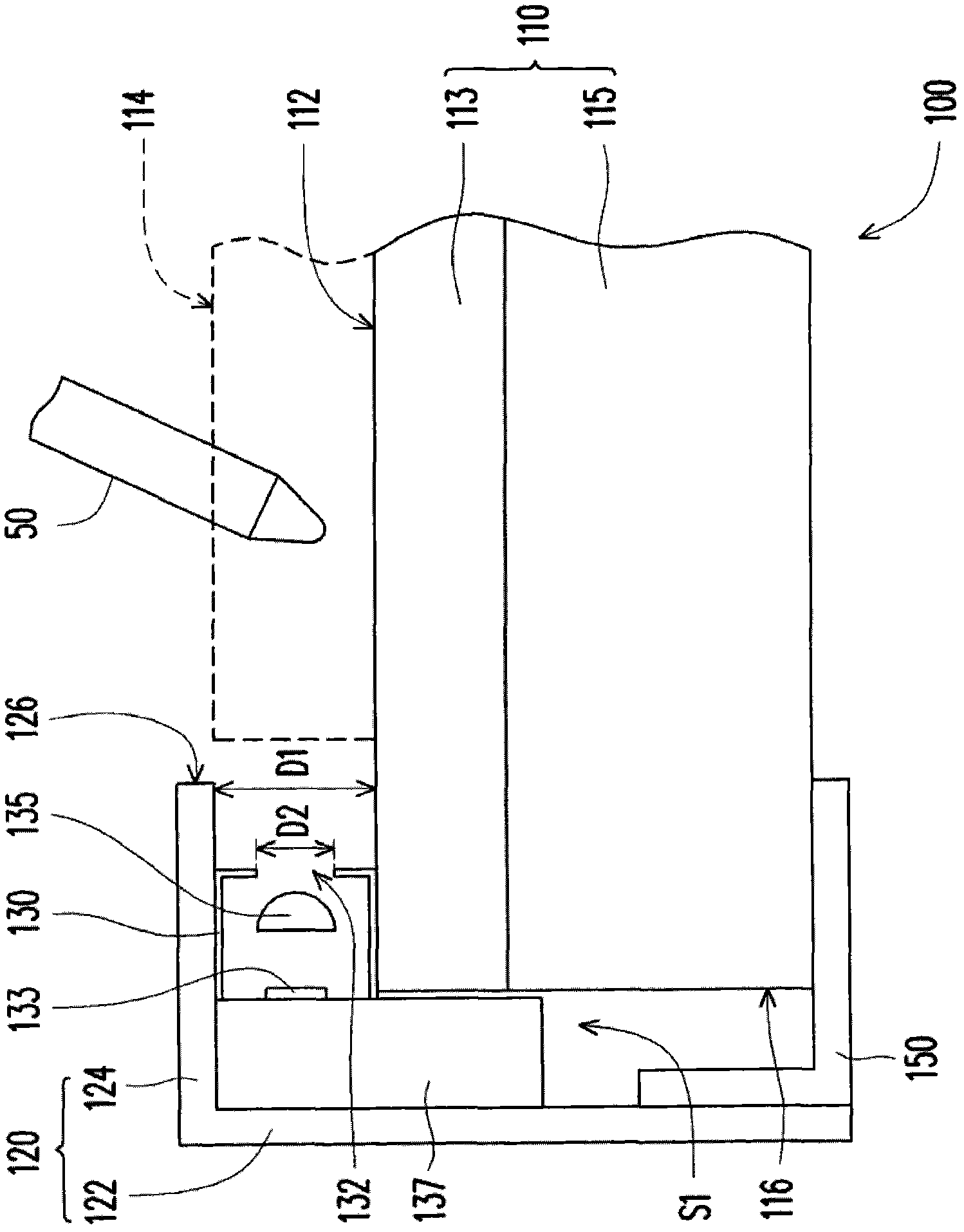

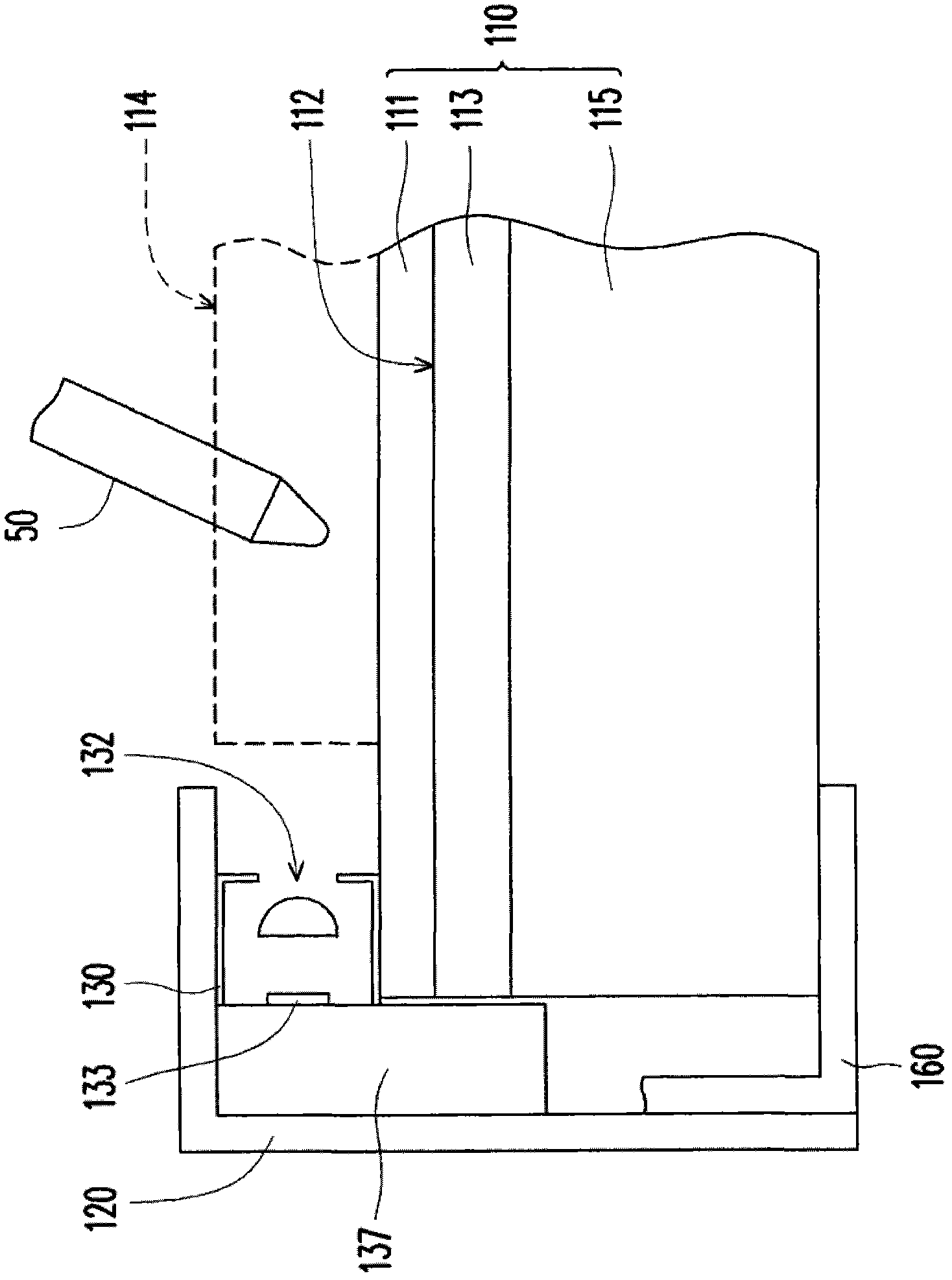

Optical touch liquid crystal display module

InactiveCN101968583AEliminates assembly processSave assembly costStatic indicating devicesNon-linear opticsLiquid-crystal displayComputer science

The invention discloses an optical touch liquid crystal display module which comprises a liquid crystal display module and at least two optical touch units, wherein the liquid crystal display module is provided with a display surface and a side surface arranged at the circumference of the display surface, and comprises a frame arranged at the circumferences of the display surface and the side surface; the frame is provided with an opening for exposing the display surface; each optical touch unit is arranged among the frame, the display surface and the side surface, and defines a sensing space in the front of the display surface; and each optical touch unit is provided with a sensing window towards the sensing space so as to sense touch objects in the sensing space through the sensing window.

Owner:SONIX TECH

Optical filter component, optical filter component manufacturing method and touch display screen

InactiveCN103336631AEasy to operateRealize functionOptical filtersNon-linear opticsLine widthEngineering

The invention provides an optical filter component, and further provides the touch display screen using the optical filter component and an optical filter component manufacturing method. The optical filter component comprises a substrate, a shading layer, a first conducting layer and a second conducting layer. The first conducting layer is attached to the shading layer; the second conducting layer is attached to a second surface of the substrate, first conducting patterns and second conducting patterns cross in projections of the second conducting patterns; the line width of a first conducting wire is smaller than or equal to that of a grid wire; the projection of a second conducting wire in the shading layer completely falls on the grid wire; the line width of the second conducting wire is smaller than or equal to that of the grid wire. The optical filter component achieves touch operation and filtering functions, and can directly ensure that the a display screen has a touch control function when used for the display screen, facilitates reducing the thickness of an electronic product, and also greatly saves materials and assembly cost.

Owner:NANCHANG O FILM OPTICAL DISPLAY TECHNOLOGY CO LTD +2

Optical filter box and touch display screen

ActiveCN103365473AEasy to operateRealize functionOptical filtersNon-linear opticsEngineeringLight filter

The invention relates to an optical filter box, which includes a glass substrate, a first embossing glue layer, a shading matrix layer, a first conducting layer, a color light resistance layer, a second embossing glue layer and a second conducting layer, wherein the glass substrate comprises a first surface and a second surface that are arranged oppositely; the first embossing glue layer is arranged on the first surface, and a first groove is formed in one side of the first embossing glue layer, far from the first surface; the shading matrix layer is arranged on the first surface; the first conducting layer is accommodated in the first groove, and includes first conducting patterns; the color light resistance layer is arranged on the surface of the first embossing glue layer, far from the glass substrate, and the projection of each color light resistance unit is in a grid unit on the shading matrix layer; the second embossing glue layer is arranged on the second surface, and a second groove is formed in the second embossing glue layer; the second conducting layer is accommodated in the second groove and includes second conducting patterns. The optical filter box realizes the touch operation and has the light filtering function, facilitates reduction of thickness and cost of electronic products. The invention further provides a touch display screen.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

Method for tying jacquard multicolor warps

InactiveCN101538768BIncrease productivitySave assembly costLoomsAuxillary apparatusYarnPulp and paper industry

The invention relates to a method for tying jacquard multicolour warps, including the following steps: (1) carrying out early-stage preparation; (2) drawing and loading dermatoglyphic pattern files into an electronic jacquard machine; (3) installing a tying machine; (4) dividing warps with different colors into an upper layer and a lower layer to form an opening, and separating the warps layer bylayer by a lease rod; (5) lifting nylon wires on the lease rod, leading out the warps arranged on the upper layer, and replacing the lease rod with special lease wires on the tying machine; (6) operating the tying machine to tie the warps; and (7) starting the machine to resume the production after the warps are rolled onto a cloth roller. The method solves the unsolved problem of three mixings, i.e. flower mixing, color mixing and warp mixing during the operation of tying the warps on the machine, and shortens the common existing warp tying time of each warp beam into 1 hour from 5 hours, thereby greatly improving the production efficiency and playing a vital role in saving the production cost and developing the weaving of yarn-dyed jacquard products on a jacquard shuttleless loom.

Owner:NINGBO RENFENG HOME TEXTILE

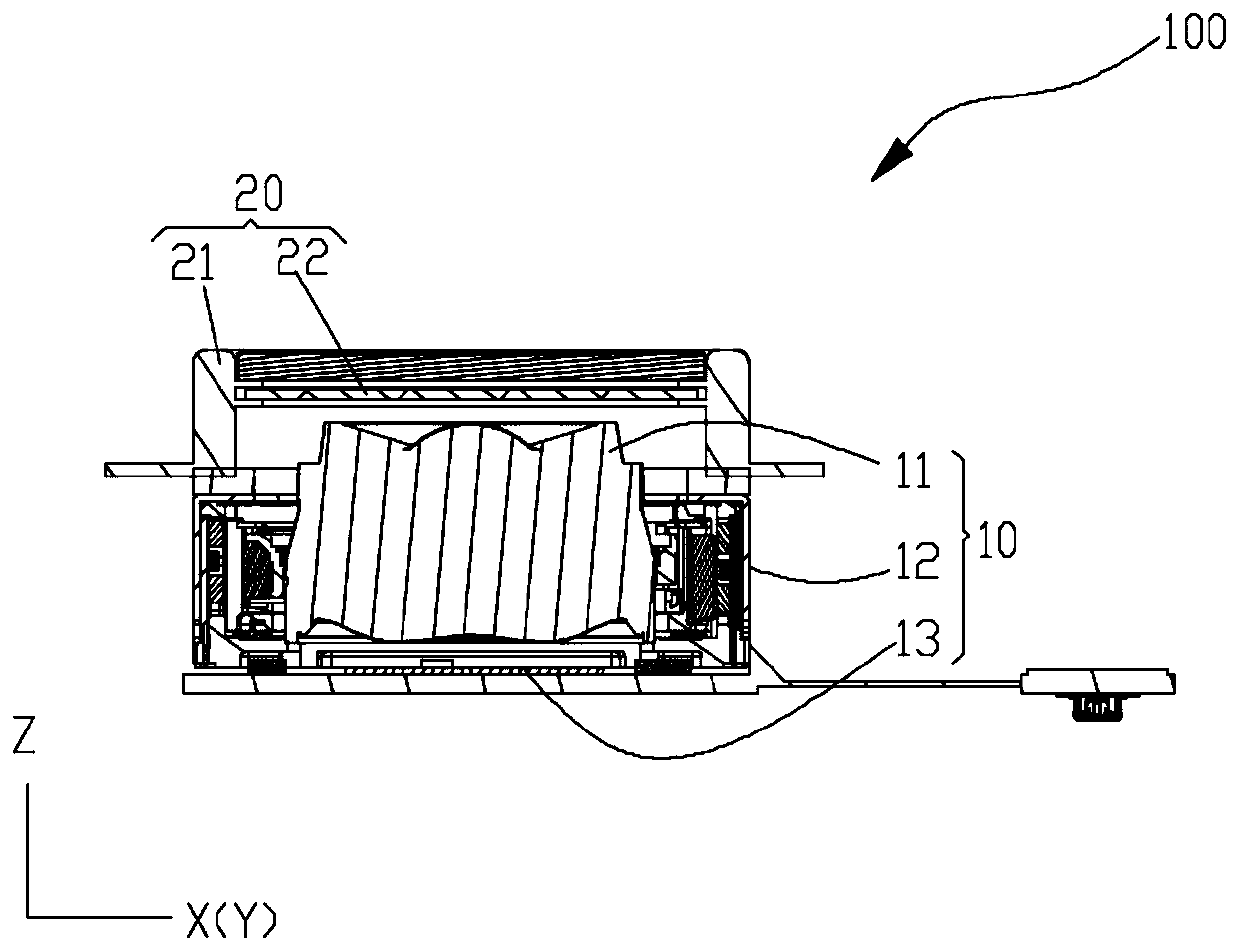

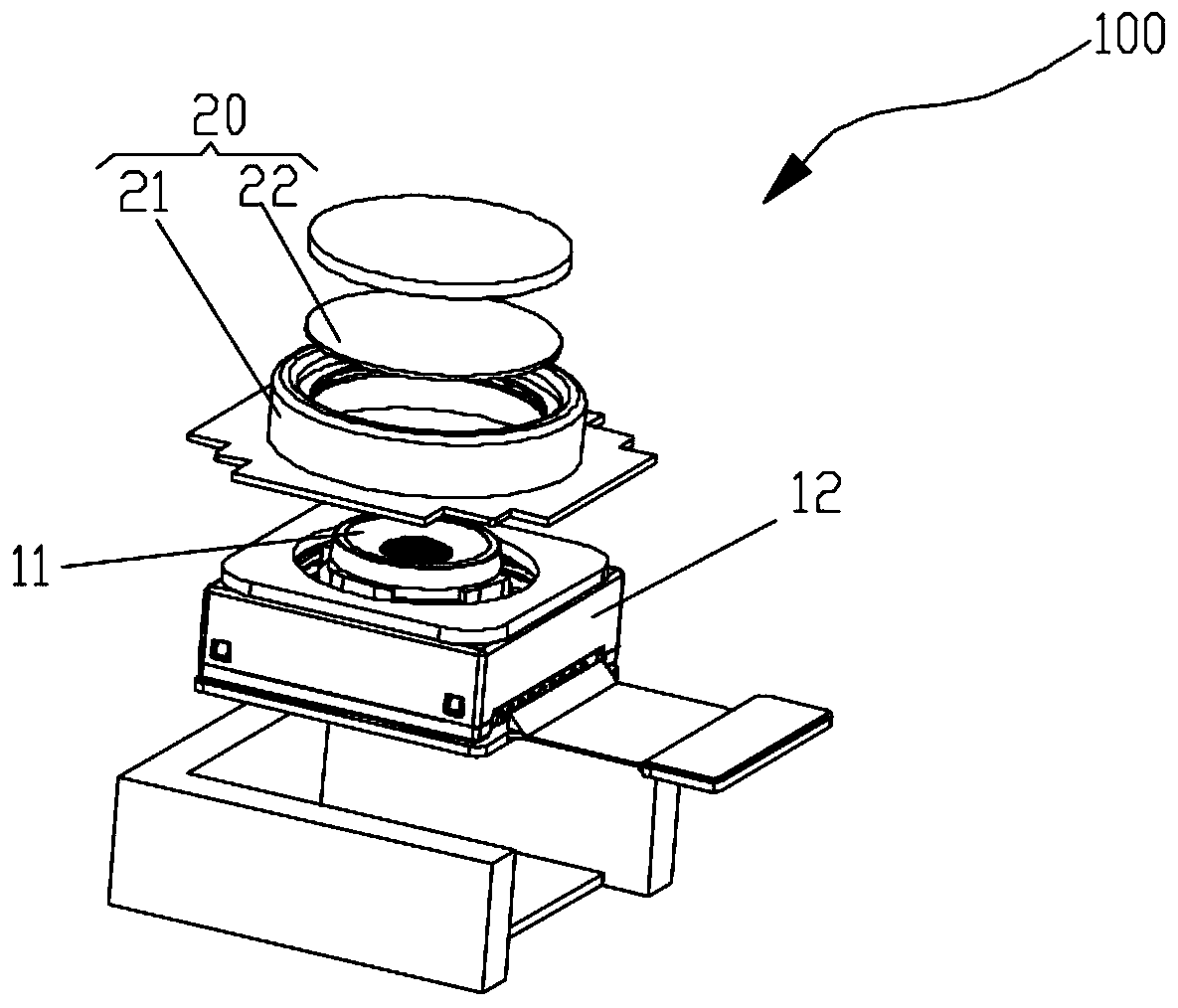

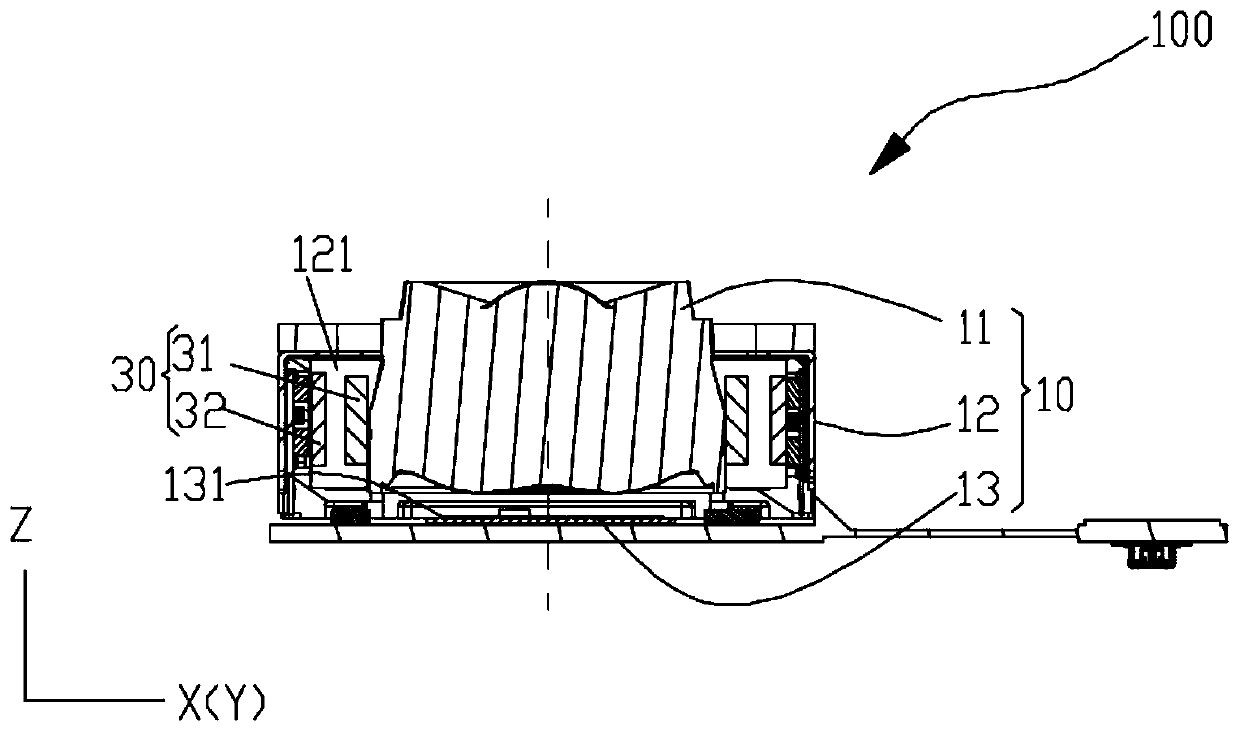

Camera assembly and electronic equipment

ActiveCN110418041ASimple structureSave layout spaceTelevision system detailsColor television detailsCamera lensEngineering

The embodiment of the invention provides a camera assembly and electronic equipment. The camera assembly comprises a camera and a decoration assembly. The camera is provided with a lens and a base connected with the lens. The signal sensing chip is fixed in the base; the lens is right opposite to the signal induction chip. The decoration assembly comprises a decoration part and an optical filter fixedly connected with the decoration part, the decoration part is fixed to the base, the optical filter is located on the side, away from the signal induction chip, of the lens, and the signal induction chip can obtain shooting light through the lens and the optical filter. According to the camera assembly, the installation of the optical filter and the optical filter support frame in the base canbe canceled, the structure of the camera is simplified, the size is reduced, and the arrangement space of the camera in the electronic equipment is saved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

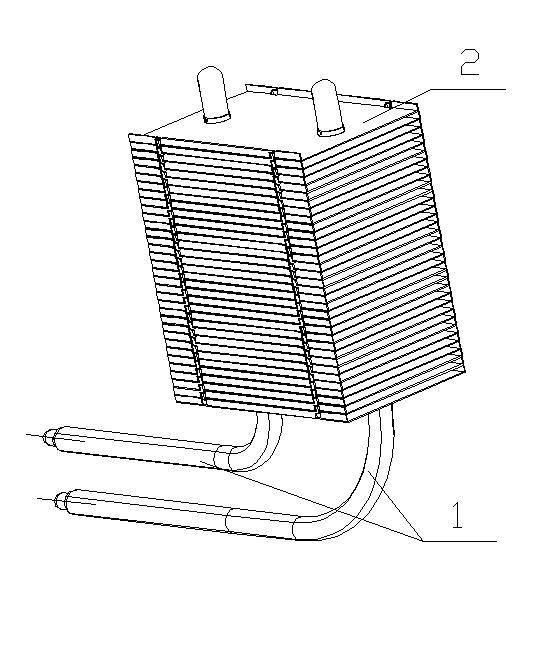

Radiating module with heat conducting pipe and buckling type radiating fin in close fit with each other

InactiveCN102147206ACapable of mass productionOmit thermal conductivityTubular elementsHeat conductingEngineering

The invention discloses a radiating module with a heat conducting pipe and a buckling type radiating fin in close fit with each other. The radiating module comprises a radiating fin component and the heat conducting pipe, wherein the radiating fin component is formed by laminating a plurality of pieces of single fins; two sides of each piece of the single fin are bent upwards to form bend sides with equal height, while the body of the each piece of the single fin is provided with a fin turning hole turned over towards a bending direction of the bend side, wherein the fin turning hole is lower than the bend side; and except for the uppermost single fin, bend sides on two sides of other single fins are provided with a buckling point respectively; the single fins are connected with each other via the buckling points, and are laminated together to form the radiating fin component; and the heat conducting pipe passes through the fin turning hole of each single fin to be fixedly connected with the radiating fin component. The radiating module is simple in structure, few in production processes and environment-friendly; moreover, the working efficiency is greatly improved, the accidents of putting less fins than supposed to or missing the fins when laminating the fins are effectively prevented, and the quality and the performance of a product are guaranteed.

Owner:LEMTECH PRECISION MATERIAL (CHINA) CO LTD

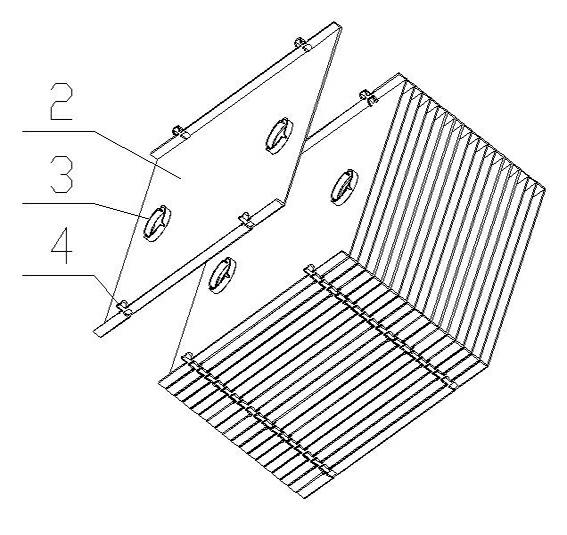

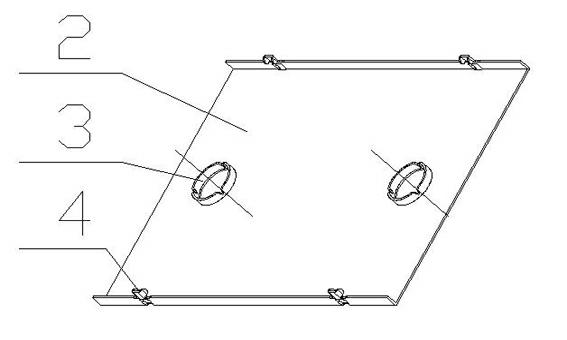

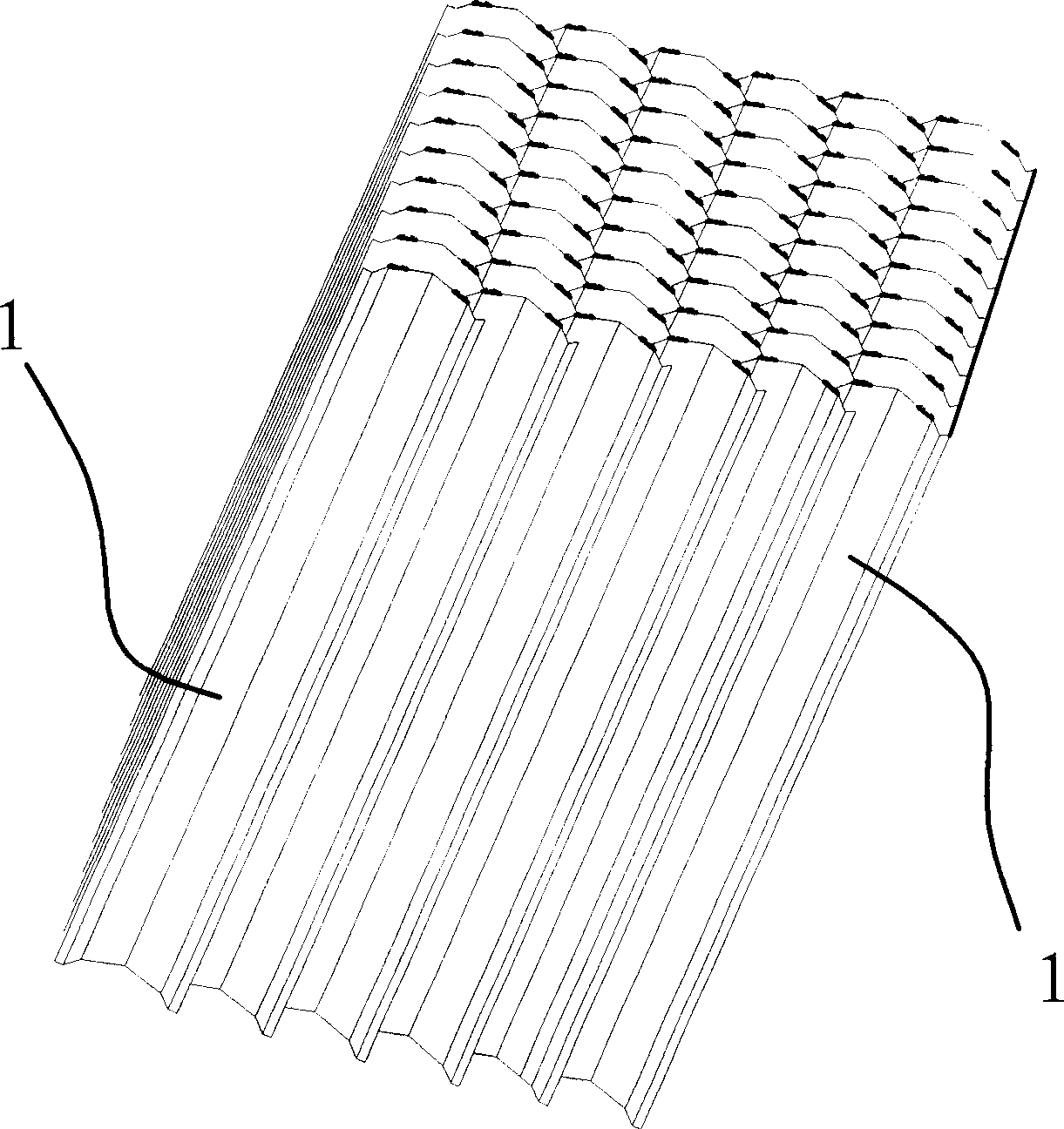

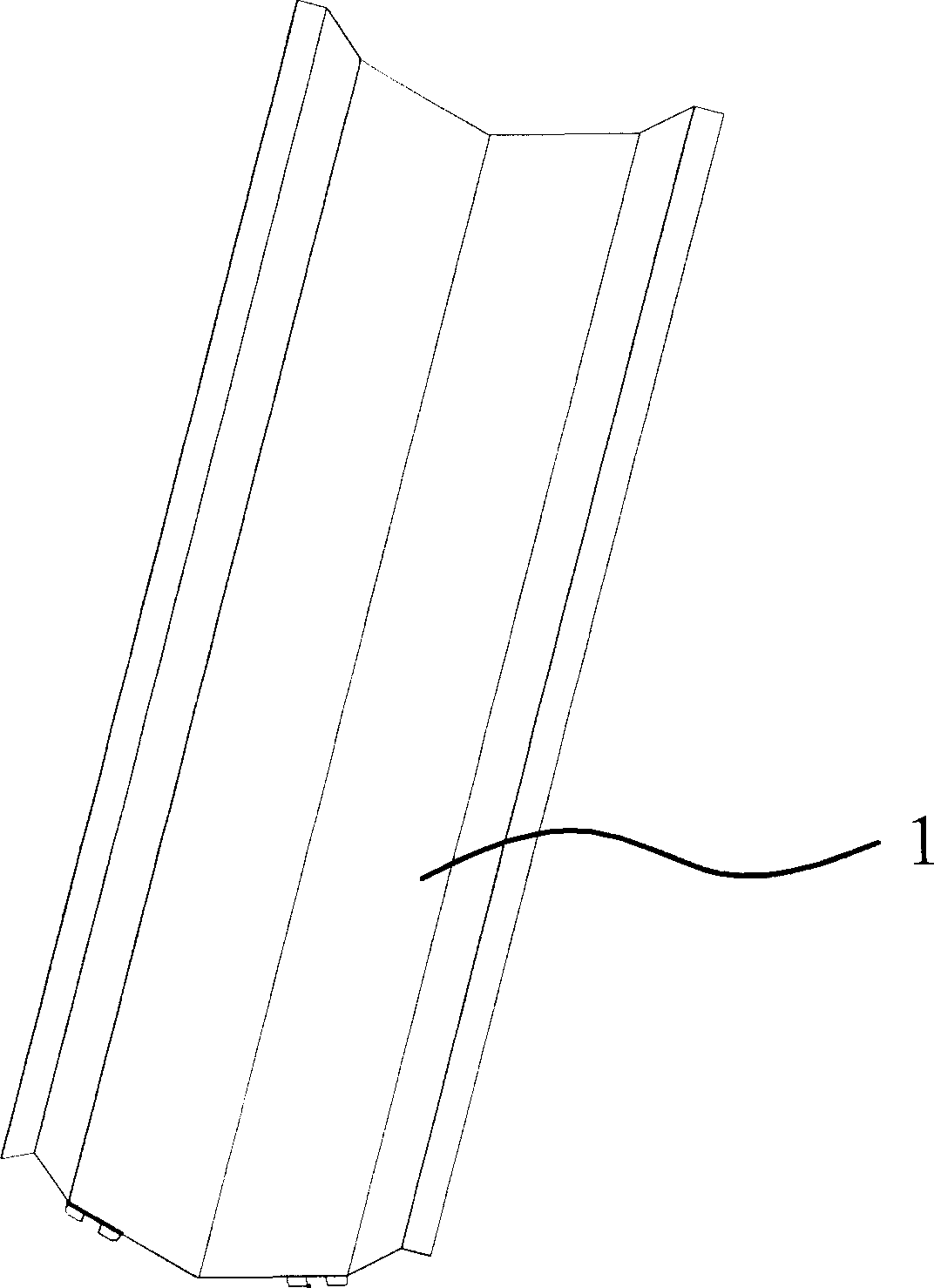

Pipe-chute sheet material for water treatment

InactiveCN1850648AEasy to assembleEasy to install and maintainWater/sewage treatment by flocculation/precipitationSedimentation settling tanksVertical edgeEngineering

The invention provides a water-processing inclined pipe sheet, being a straight stripe in shape, and invaginating to form the outside and inside of a sheet, where the outside of the sheet are provided with two vertically parallel connection parts 1 and the two vertical edges of the sheet are provided with the other two connection parts 2; the connection parts 1 have connection mechanisms to connect with the connection parts2 of another sheet of the same shape; the connection parts 1 of a sheet are connected with the connection parts 2 of another sheet and the connection parts2 of the sheet are connected with the connection parts 1 of a third sheet, and on the analogy of this, connecting several sheets together to compose an inclined pipe. And it has characters of simple structure, convenient to transport and assemble, high use stability and high purifying efficiency.

Owner:池万清 +2

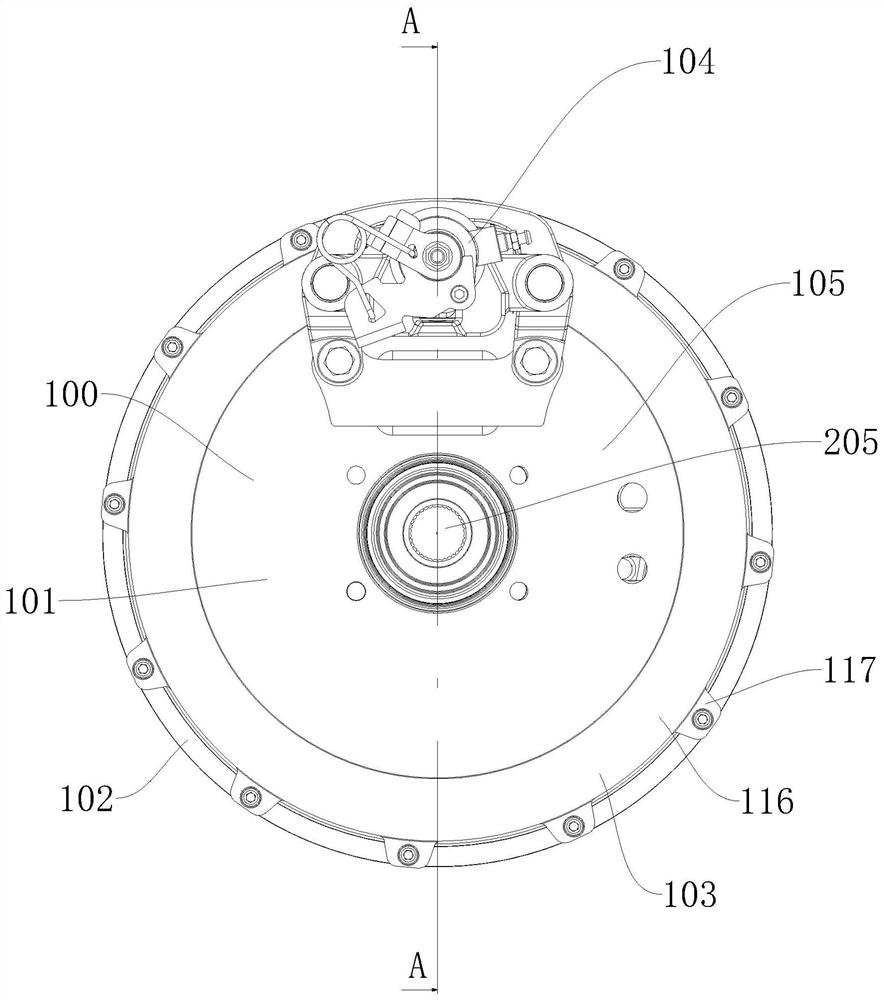

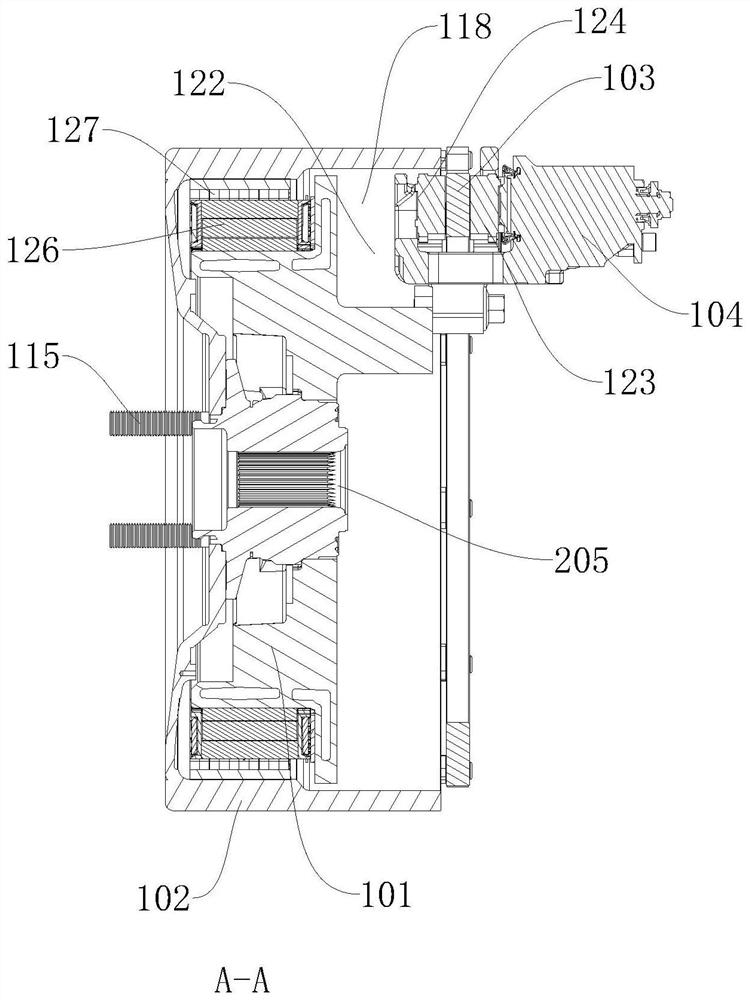

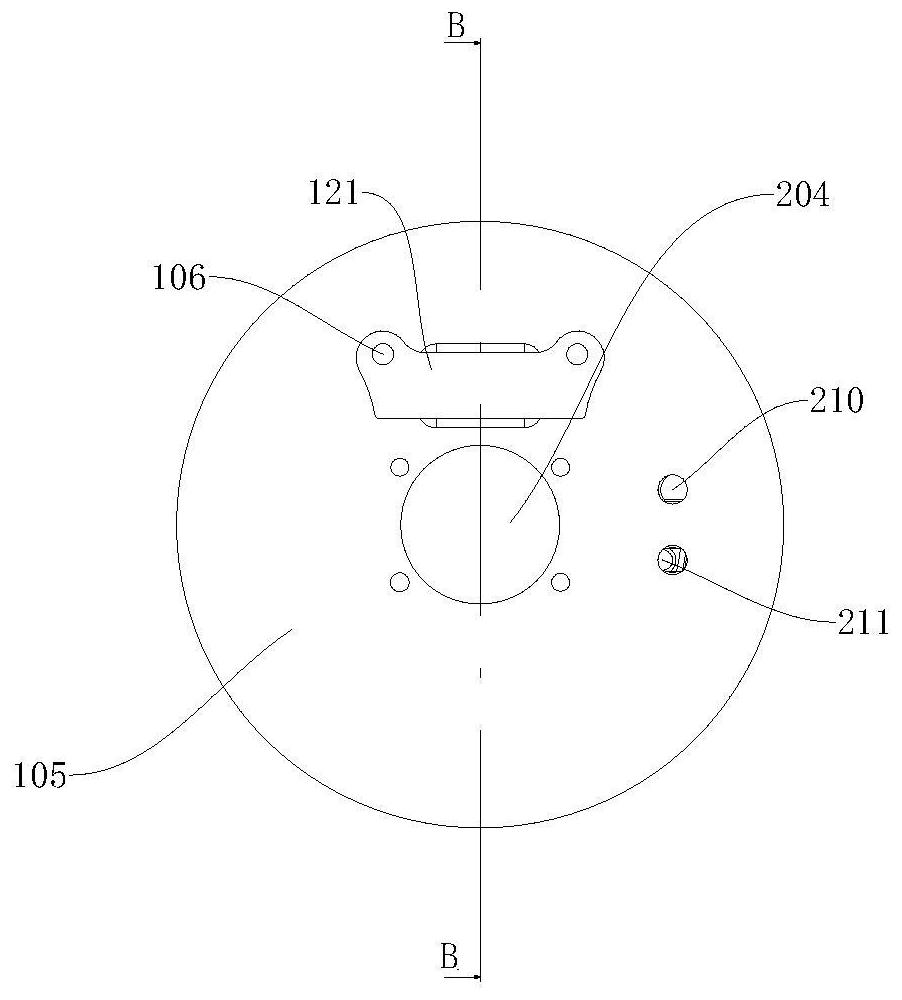

Integrated structure of brake and hub motor

PendingCN113085537ASave process costSave assembly costBraking element arrangementsMotor depositionBrakeElectric machinery

The invention relates to the field of power wheels, and discloses an integrated structure of a brake and a hub motor, which comprises a hub motor and a brake, the hub motor comprises a stator and a rotor for driving a wheel to rotate, a brake disc is mounted on the rotor, the brake is mounted on the stator, and the brake can act on the brake disc to realize a braking action. The hub motor is an outer rotor motor, the brake disc is annular and installed on the outer end face of the stator, the stator is arranged on the inner side of the rotor, and the brake is installed on the outer end face of the stator and located on the inner side of the brake disc. The integrated design of the hub motor and the brake is creatively adopted, the assembling procedures and the assembling cost of the electric wheel are greatly reduced, and the braking action can be stably and reliably performed through the integrated design. And meanwhile, the brake and the hub motor are integrally designed, so that the space in the electric wheel and the rim is greatly saved, and the integrated action of starting and braking can be realized without structural design of the rim.

Owner:ZHEJIANG VIE SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com